Abstract

A Novel approach to remove metals from aqueous solutions has been developed. The method is based on a resin free, solid, non-toxic, microcrystalline bisphosphonate material, which has very low solubility in water (59 mg/l to ion free Milli-Q water and 13 mg/l to 3.5% NaCl solution). The material has been produced almost quantitatively on a 1 kg scale (it has been prepared also on a pilot scale, ca. 7 kg) and tested successfully for its ability to collect metal cations from different sources, such as ground water and mining process waters. Not only was this material highly efficient at collecting several metal ions out of solution it also proved to be regenerable and reusable over a number of adsorption/desorption, which is crucial for environmental friendliness. This material has several advantages compared to the currently used approaches, such as no need for any precipitation step.

Similar content being viewed by others

Introduction

Disposal of industrial waste water is a major environmental issue since these contaminants can ultimately gain access to surface and ground water which may be used for drinking water purposes. Heavy metals are of special concern because of their persistence. Unlike organic contaminants, heavy metals are not biodegradable and tend to accumulate in living organisms. Furthermore many heavy metal ions are known to be toxic or carcinogenic. Thus removal of these toxic heavy metals from wastewater is of crucial importance to protect the human population and the environment. Several heavy metals are particularly important in the treatment of industrial wastewaters i.e. zinc, copper, nickel, mercury, cadmium, lead and chromium1,2,3,4. Various methods exist for the removal of harmful metal ions, particularly heavy metals, from liquids and fluids e.g. waste waters2. Chemical precipitation and coagulation-flocculation are the most widely used methods for removing pollutants1,5. Often metals are removed from solutions by increasing the pH of the effluent, converting the soluble metal into an insoluble form (i.e. its hydroxide)6. Flotation7,8, electrolytic reduction9, ion exchange1,10 and membrane technologies1,6 are also widely used methods. Recently adsorption has been proposed as representing an alternative treatment procedure1,4,5. Naturally occurring low cost adsorbent materials have been studied: e.g. agricultural waste4,11,12,13, industrial by-products12,14, clays15,16,17,18, zeolites19,20 and chemically modified cellulose materials21,22. In recent years, many alternative solid-phase sorbents (e.g. carbon nanotubes, fullerens, ion imprinted polymers, biosorbents, nanoparticles) have been investigated. These new materials are claimed to be better than the traditional agents having enrichment performance in the extraction of their target analytes23,24,25,26,27,28. While each of these methods has some benefits, there are also disadvantages e.g. high capital, maintenance or operation costs, laborious procedures, limited capacity or slow speed1,5,6,12,22. In general, the collection procedure should be simple, relatively rapid, quantitative and not very expensive. The procedure should also require minimum sample treatment. One of the fundamental requirements of any metal collector or adsorbent is its ability to be regenerated and reused over a number of adsorption/desorption cycles since this is both economical and environmentally friendly4,22.

Bisphosphonates (BPs) with a P-C-P backbone are enzymatically and chemically stable analogues of naturally occurring pyrophosphates. During their 60 years lifetime, BPs have been used for several purposes based on their effective metal chelation properties initially as water softeners29 but more recently as bone drugs30,31,32. We have developed a novel, straightforward and rapid method for chromiumIII ion collection from aqueous solutions and tannery effluents using solid bisphosphonates (BPs) which needs no precipitation step33. There do not appear to be any reports in the literature of BPs being utilized in metal ion collection without the presence of some additional resin. In addition, as far as we are aware, no other insoluble chemical compounds have been used in this manner. However, commercially available BP ion exchange resins (Diphonix®) have been used for collecting actinides34 and transition metals35,36. Nevertheless, their production costs are at least 10-fold higher than to the newly-synthetized, insoluble BP described here. Another obvious benefit of our method is that there is no requirement for any precipitation step, which is typically needed if soluble complexation agents are used. This novel microcrystalline “green” BP material called here N10O is non-toxic, recyclable, almost insoluble in water but is still an excellent collector of a wide variety of metal cations. Here we describe the effectiveness of N10O to collect several other metal ions in addition of chromiumIII from aqueous solutions and the suitability of the developed method to remove metal ions from real drinking water and mining process water samples in comparison with the commercially available Diphonix® resin.

Results and Discussion

Properties of N10O

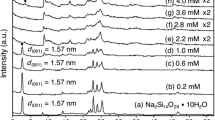

Synthesis of 11-amino-1-hydroxyundecylidene-1,1-bisphosphonic acid37 (N10O, Figure 1) was straightforward at the laboratory scale and also large scale production was successfully demonstrated. The starting materials for the synthesis are economical, which is of crucial importance in commercial terms. The product N10O was a fine white porous microcrystalline powder (Figure 1) consisting flake-like crystals (typical dimensions 2 × 30 × 50 μm). Nitrogen BET specific surface area of N10O was 11.4 m2/g. N10O was determined to be insoluble in organic solvents, like chloroform, acetone and dimethyl sulfoxide, since no 1H or 31P NMR signals were observed in the spectra. In our earlier study38 the water solubility of aminobisphospnonates was highly dependent on the carbon chain length in the middle carbon such that with longer carbon chains (n > 7) poor solubilities were obtained. N10O is also very sparingly soluble in Milli-Q water (only 59 mg/l at pH 4) and even less soluble in 0.8% and 3.5% NaCl solutions (15 and 13 mg/l, respectively) at pH 6.07.

BPs are known to be good metal chelators due to the superior complexing ability of the O = P-C-P = O moiety and they have a recognized ability to form metal complexes with relatively high stabilities39,40. N10O also proved to be an efficient metal chelator and the complexation of CuII to N10O was readily evident, since the light blue colour of CuII in Figure 1, previously present in the solution, was now visible in the solid material leaving behind an almost colourless solution. N10O contains a hydroxyl group and two geminally bound phosphonic acid groups (Figure 1), each providing 1–3 donor oxygen atoms to be used as hooks and bridging sites for metal cations. Thus, stable six membered chelate rings could be formed. It is thought unlikely that the amino group participates in the chelation due to its location and zwitterion character. Although N10O is sparingly soluble in water and also was almost insoluble during the metal chelation process, it was able to collect effectively metal ions from the solution and they could then be subsequently filtered out of the solution without any additional precipitation step. Moreover, in the case where there was only a single metal in the solution, the chelation process was very rapid (ca. 1 min vortexing and centrifugation), probably due to the large surface area of N10O. In addition, the rapid complexation ability was confirmed in a sintered glass crucible experiment (see Experimental section).

In addition, according to the toxicity report (see Supporting info) the material has not exerted any acute toxic effects when this has been examined in rats, Ames-test or in ecotoxicological assays. One of the fundamental requirements of any metal collector or adsorbent is its ability to be regenerated and re-used over a number of adsorption/desorption cycles i.e. it should be both economical in use and environmentally friendly1. Based on our simple test on glass crucibles, N10O was observed to be regeneratable and reusable at least 20 times (see Experimental section). In fact, the loss of N10O in the regeneration steps was even less than expected according to its aqueous solubility determination. This is probably due to the formation of extremely insoluble metal-N10O complexes.

The effect of pH onto the collection of metal ions

The degree of deprotonation of the phosphonic acid groups plays a significant role in complex formation and therefore the pH of the solution is a critical factor in metal collection. The pKa-values of the N10O could not be determined by a conventional titration method due to the very low solubility of the compound. Previously, we have measured the pKa-values for amino-BPs with shorter alkyl chains (pK1: 0.60–1.08, pK2: 1.70–2.58, pK3: 10.04–10.86, pK4: 11.65–12.86)38 and the pKa-values for N10O are assumed to be around the same order of magnitude. The OH group bound to the middle carbon is very weakly acidic and does not deprotonate below pH 1341. In addition, many metal ions can exist in different forms in solution depending on the pH and this can influence their complex formation with N10O.

The efficacy of collection of several transition metals by N10O (Table 1) was studied via recovery studies as a function of the pH value of the solution (pH 0.5–11) by the batch method with an excess of complexing agent. Alkali and alkaline earth elements and AlIII were also included since they are usually present in sample matrices. The pH graphs of these metal ions were observed to fall into four different classes (Figure 2). For the alkali metal ions, N10O proved to be an inefficient collector, since less than 5% of LiI, NaI, KI and CsI ions were bound at the mg/l level (see Figure 2 Na(I)). Instead, most of the metal ions (alkaline earth elements, CrIII, FeIII, CoII, NiII, ZnII and CdII) behaved similarly to the CuII ion: At highly acidic conditions they were not collected, probably because the binding sites on N10O are thought to be protonated, resulting in poor metal collection levels. At the optimum pH range, the binding sites are left partially unprotonated and maximal metal binding is possible over a wide range of pH values (Figure 2, Table 1). However, the lower pH limit of efficient collection differs from one metal ion to the next as can be seen from the pH1/2 values (pH1/2 is the pH value at which 50% of metal ions are collected) in Table 1. This feature could be useful in the separation of metal ions from each other (e.g. FeIII and CuII could be efficiently collected at lower pH's than the other metals) and the collected metal ions could probably be individually removed from N10O by washing it with acid solutions of varying strengths.

MnII and FeII ions behave very similarly as the metal ions mentioned above, except that their recovery decreased at pH above 10 (see Figure 2 FeII). Instead, the behaviour of AlIII ion differed substantially from the other metal ions studied. AlIII ion reveals two high maxima in the pH graph (Figure 2), probably due to its tendency to form an amphoteric hydroxide and thus it could be collected both at low and elevated pH values. On the whole, further by optimizing the collection procedures (e.g. amount of N10O, contact time, stirring) it is anticipated that even more efficient collection of these metal ions could be achieved.

Metal capacities

One of the most important variables required in the design of adsorption processes for the separation and purification of liquid mixtures is the capacity of the adsorbent for any given component42. The ability of N10O to collect different metal ions was clarified in these capacity studies. The recoveries of the metal ions were determined by the batch method with an excess of complexing agent at constant pH 4.0 (except AlIII at pH 1.0). The N10O uptakes of metal ions (Table 2) varied extensively; from 0.05 mol/mol for FeIII to 0.45 mol/mol for CaII. As a comparison, the corresponding capacities (mg/g dry weight, Table 2) for the commercially available Diphonix® resin were determined under the same conditions. Diphonix® resin (2, see Experimental section) has a BP moiety (pK1 = 1.5, pK2 = 2.5, pK3 = 7.2 and pK4 = 10.5) as a part of the resin material, but it contains also some other functionalities (strongly acidic sulfonic and weakly acidic carboxylic acid groups)36. The moisture content of Diphonix® resin is 70%.

The uptakes of FeII and AlIII ions were at the same level for both N10O and Diphonix® resin (Table 2). N10O exhibited higher uptakes of MnII, CoII, CuII, ZnII and CdII, whereas the uptakes of FeIII, CrIII, NiII and SrII were greater with Diphonix® resin. However, in some cases the lower FeIII uptake with N10O can even be beneficial e.g. when the other metal ion collection is desired in a sample containing a high concentration of FeIII in the matrix31. N10O displayed higher uptakes of MgII, CaII and BaII than to Diphonix® resin which can be disadvantageous in some instances, since MgII and CaII are commonly present in different sample matrices. However, in competition situations, these estimates are not so straightforward, since also the stabilities of the complexes need to be taken account. In general, the levels of uptake with N10O were comparable with both naturally occurring adsorbent and modified cellulose materials as well as with commercial ion exchange resins1.

Interaction of metal ions

The solutions emitted by industrial processes and wastewaters usually contain more than one metallic species. Therefore, it is essential to investigate the sorption behaviour under competitive conditions i.e., when several metallic species are present. In such multicomponent liquids, the metal complexing capacities alone do not provide an adequate perspective. In fact, the metal ions are competing with each other for complex formation with N10O and thus stability constants provide more information for the prediction of multicomponent liquid adsorption equilibria. Unfortunately, the stability constants of the N10O metal ion complexes could not be determined by conventional methods due to the very low solubility of N10O itself and also of the formed complexes in water and organic solvents. Generally, BPs are known to be good metal ion chelators, forming stable complexes with several metal ions. The stability constants for complex formation (log β) have usually been measured for etidronate36,43,44,45,46,47, pamidronate and alendronate48,49,50 (e.g. CuII log β 20.146, 29.5348 and 30.2048, respectively).

In the evaluation of metal ion competition for complex formation with N10O in binary systems, batch adsorption tests were conducted employing equal molarities (0.137 mmol) of the two metal ions at a constant pH value. These divalent metal cations which had the highest N10O uptakes were selected in the experiments. MnII ion had to be omitted because it precipitated out at the selected concentration level and pH value (pH = 4.0). Then the solid complexing agent N10O (2:1 mol/mol) was added to the binary metal ion solution. Afterwards, the unbounded metal ion concentrations were determined by AAS and the bound metal ion amounts (mol) and bounding ratios (mol/mol) were calculated (Table 3). On the basis of the results the order of bounding was estimated as follows: CuII > ZnII > FeII > CdII > CoII > MgII > CaII > NiII. Thus, if the N10O amount is limited, CuII ions would be expected to be most effectively collected in preference over the other ions and even the presence of high CaII and MgII concentrations in a sample may not necessarily prevent the ability of N10O to bind CuII.

Ground water samples

There are many studies demonstrating that the natural surface water and groundwater can became contaminated by heavy metals either due to anthropogenic sources or natural geological origin51. Conventional treatment systems are not always capable of removing completely the harmful metals in the water especially when they are present at low concentrations2, thus alternative purification methods are needed to improve the current treatment process. Well waters from the Finnish countryside were used for testing the ability of function of N10O as a metal remover. The ground waters in Finland are mainly soft calcium bicarbonate-containing waters10 and the quality of ground waters for household consumption may differ widely from location to location52. The high concentrations of iron and manganese, which often appear in the same ground waters, are problematic since they can cause technical problems in water supplies, staining of water and water fixtures10,53. Recent studies have also suggested, that exposure to manganese from drinking water can pose health concerns, especially in children54. In water systems, corrosion of piping and fittings in water delivery systems can release metals (e.g. iron, copper and zinc) in water and also metal-containing sediments occasionally released from pipe surfaces can elevate the concentrations of these metals. Aluminum is generally present at low concentrations in both ground and surface waters, but higher concentrations are likely to exist in more acidic waters because pH has a major impact on its mobility53,54. In some cases, water hardness can also cause problems (mainly CaII and MgII)10.

Several ground water samples were used for testing with four representative examples being shown in Table 4; three dug wells (WW1–3) and one drilled well (WW4). The measured initial metal concentrations were mostly below the technical guidelines also shown in Table 4, but some values did exceed them (e.g. Al and Fe in WW1 and WW2, Mn in WW1 and WW4). The removal percentages demonstrate that N10O effectively collected copper, zinc, manganese and alkaline earth elements from all of the water samples. Aluminum was also effectively removed from WW1, but slightly poorer results were achieved with WW2. It is thought that in this sample, the metals were not completely in the free, ionic form favorable for complexation. Unexpectedly, sodium and potassium were also partially removed, possibly due to co-precipitation. Treatment of water samples with commercial Diphonix® resin achieved similar removal results (results are not shown here), except for zinc (about 10% poorer values). However, when compared to Diphonix® resin, N10O is a much less costly material due to its inexpensive starting materials and straightforward production, which makes its use especially attractive. Moreover N10O is also easier to handle since it is entirely solid and contains no moisture unlike Diphonix® resin (70% moisture).

The results clearly indicate that N10O is capable of removing harmful metals from water even if they are present at low concentrations and it can also reduce water hardness. However, although N10O is nontoxic and its solubility in water is very low, even a small amount of N10O remaining in water (on average 35 mg/l in these ground water samples) might restrict its usefulness for drinking water applications, but it still could be efficiently used in certain industrial purposes, e.g. treatment of raw water.

Mining process water samples

Industrial waste constituents are a major source of several kinds of metal pollution in natural waters. For example, the rapid and often unregulated industrialization in developing countries has led to increase disposal of heavy metal into the environment. In the developed world, there are more and more stringent regulations, which require that the concentrations of heavy metals need to be reduced to safe levels before they can be released into the environment, a serious challenge to many industrial concerns2. The ability of N10O to remove metal ions from solutions containing higher metal ion concentrations was tested by using process water samples from a mining company. At first, the efficacy of removal of metal ions from two samples MPW1 and MPW2 (Table 5) with different metal ion concentrations was tested with N10O and also Diphonix® resin as a comparison.

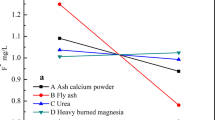

In the case of sample MPW1, the results indicate clearly that the amount of adsorbent used (10 g/l N10O and 30 g/l Diphonix® resin) were too low for this sample and would need to be increased. Only aluminum and copper ions were effectively removed with both adsorbents (also iron ions in the case of Diphonix® resin), whereas MnII, CoII, NiII, ZnII and CdII ions were poorly collected (Table 5, Figure 3). The high removal per cent of CuII was not surprising since CuII ion had been previously observed to compete successfully in complex formation with other metals ions (Table 3). The percent removals of MnII, ZnII and CdII were higher with N10O whereas Diphonix® resin collected FeII/III and NiII ions more effectively, as expected on the basis of the capacity experiments. Instead, N10O collected less calcium and magnesium ions than Diphonix® resin which was somewhat surprising because N10O had higher Ca(II) and Mg(II) capacities (Table 2), but then again calcium and magnesium ions were almost last ones in bounding order (Table 3) and probably they lost the competition for coordination sites. On the whole, both adsorbents removed mainly magnesium, calcium and iron ions (Figure 3) from MPW1.

The contact time can have a major impact on the removal of metals ions: the structure of the ligand material (N10O) is porous material probably containing different sizes of pores whereas in Diphonix® the resin complexing groups are present on the surface of the resin particles) and sample composition (metal ions and their concentrations) may affect the time needed to reach a state of equilibrium. The effect of contact time on the collection of metal ions was studied with MPW1 sample. With N10O (10 g/l) a longer contact time was advantageous, since the removal efficacies systematically increased with increasing contact time regardless of metal ion (Figure 4). This may be due to the porous structure of N10O as diffusion of metal ions inside the material requires more time. Instead, with Diphonix® resin, the increase of contact time improved the removal of MgII, CaII, Fe, Al and CuII ions from sample solution, but meanwhile reduced the removal of CdII, CoII, MnII, NiII and ZnII ions. This behaviour may be a result of competition of metal ions for complexation sites on the surface of resin particles and long contact time may be disadvantageous if the removal of latter ions is desired.

Metal ion concentrations were significantly lower in sample MPW2 and considerably higher removal per cents were achieved (Table 5) thus adsorbent amounts used (10 g/l N10O and 30 g/l Diphonix® resin) were more satisfactory for this specimen. The third sample MPW3 contained also very high metal ion concentrations, but increasing amount of N10O to 50 g/l achieved excellent removal per cents for metal ions (Table 5), evidence that N10O can be used for this kind of samples after optimizing the collection conditions. As before, Na and K ions were only partially removed probably due to co-precipitation. The results above indicate that N10O could be utilized for several purposes e.g. removal of harmful metal ions from waste waters or recovery of useful metal ions from mining tailings. In summary, the process must be optimized carefully for the type of sample in order to ensure the removal of the desired metal ions.

Conclusions

The novel method using solid BP called N10O as a metal collector is readily feasible for use in the purification of ground waters and industrial waste waters. This method has many advantages over currently used methods. Firstly, the process is very simple: a solid BP is directly dispersed into a solution containing metal ions which need to be removed. The only sample pretreatment step required is pH adjusting if the pH of sample solution is not appropriate for N10O metal collection. Interestingly, metal cations can be effectively collect from real waste water samples into this solid material with good binding capacities only within a few hours without any precipitation step. In addition, to being reusable and non-toxic, N10O possesses several other advantages over to similar approaches: ability to capture of many metals simultaneously, the need for minimum sample treatment, high capacity, feasible for use over a wide pH range, possibility for pH selective metal collection, ease of the separation process, inexpensive capital cost, suitable for a wide variety of target pollutants and good recyclable properties. Furthermore, N10O has a low affinity for FeIII, thus it could be utilized in the removal of other metals from solutions containing high concentrations of FeIII. N10O has also proven to be effective collector of solutions with high Mg and Ca contents.

Finally, based on initial screening with our commercial partners, N10O can be considered as a extremely potential next generation complexation agent suitable for a variety of industrial applications. Typically, unwanted metal cations are not only contaminating process and waste waters, but also occur in waters draining through dump sites, ash from waste burning and in well waters. Metal ions may also be present in the chemicals which are to be used as water purification agents or in paper mills1. Another possible application is recovery of valuable metals (e.g. noble metals and rare earth elements) from different kinds of solutions and extracts55. Furthermore the development of new solid-phase materials as sorbents and their application in preconcentration methods for the determination of trace elements is also an interesting scientific topic. It is often difficult to make a direct determination of extremely low concentrations of certain elements by routine analytical techniques. The limitations can be associated with matrix interference or insufficient sensitivity of analytical techniques. In such situations, a preliminary separation and a preconcentration step of the trace elements from the matrix are frequently required24. With N10O, it would be possible to preconcentrate metal ions from the solution onto a compact light solid matrix (e.g. a kind of disc), to be analyzed by either by direct analytical methods (e.g X-ray fluorescence spectrometry), or after subsequent desorption into small volume and detection by other techniques, handling liquid samples.

The material (1, N10O) is available for research purposes i.e. quatities from 1 g up to 1 kg on request. For commercial purposes (trade name: CH Collector), please contact Oy Chemec Ab (http://www.chemec.fi/en). This material has already been proposed to be as a part of water purification system in recent review article56.

Methods

All tests were performed in three replicates.

Chemicals, standard solutions and general information

11-Aminoundecanoic acid was purchaced from Acros; phosphorus trichloride, phosphorous acid and methanesulfonic acid were purchased from Sigma-Aldrich. Suprapur® hydrochloric acid 30% was purchased from Merck. Metal stock solutions were all Titrisol standards purchased from Merck, except FeII solution, which was prepared from FeCl2·4H2O salt (Merck). All standard solutions were prepared in Milli-Q water. All stock and standard solutions were stored at 4°C until use. Diphonix® resin was purchased from Eichrom.

1H, 31P and 13C NMR spectra were recorded on a Bruker Avance 500 spectrometer operating at 500.1, 202.5 and 125.8 MHz, respectively. TSP was used as an internal standard for 1H and 13C measurements and 85% H3PO4 was used as an external standard for 31P measurements. The nJCP couplings were calculated from carbon spectra with the coupling constants given in parenthesis as hertz. Particle size of N10O was determined by JEOL JEM-2100F Transmission Electron Microscope and surface area by BET method57. Metal concentrations were analyzed either by a Perkin Elmer 5100 atomic absorption spectrometer (AAS) by using air-acetylene flame or by an inductively coupled plasma optical emission spectrometer (ICP-OES). A Thermo Electron iCAP 6600 Duo View equipped with Cetac ASX-520Hs and an autosampler were used. Solubility of N10O in water and phosphorus content of N10O were determined at 880 nm by Jasco V-530 spectrophotometer using the molybdenum blue method58. Liquid samples were filtered (0.2 μm membrane filter) and solid samples were decomposed with nitric acid by the microwave digestion technique using CEM MDS-81D Microwave System prior to determination. Elemental analysis (C, H, N) was accomplished with a ThermoQuest CE Instruments EA 1110-CHNS-O elemental analyzer (CE Instruments, Milan, Italy).

Synthesis, isolation and purification of solid chelation material, 11-Amino-1-hydroxyundecylidene-1,1-bisphosphonic acid (N10O) (see Figure 5) and its characterization data

N10O was synthesized using the method previously reported59. The isolation and purification procedures are somewhat different and will be reported here in detail. A mixture of 11-aminoundecanoic acid (157 g), phosphorous acid (64 g) and methanesulfonic acid (375 ml) was heated to 65°C followed by addition of PC13 (140 ml) for over 1–2 hours. The mixture was maintained at 65°C for 48 h and cold distilled water (1 L) was added to a cooled solution with vigorous stirring. After refluxing overnight, the reaction mixture was allowed to cool to room temperature (r.t.) (usually overnight) and the solid product was collected by filtration. Filtered crude product was added to a 2 L flask and distilled water (1 L) was added and the mixture was heated to approx. 70–80°C with vigorous stirring. After the mixture was cooled to ca. 50°C, white solid was filtered, washed with 1 M HCl (approx. 700 ml), distilled water (ca. 1.5 L) and finally with acetone (0.5 L). Final product (1) was allowed to dry in r.t. approx. 48 h before it was obtained as white powder (271 g, 95% yield) When prepared in approx. 1 kg scale (four times of all amounts reported above) yield was 90%. N10O has also been prepared successfully in pilot scale (approx. 7 kg batch, but the procedure is not reported here). 1H NMR (D2O + 1 drop of 6 M NaOD, 500 MHz) δ 2.60 (t, 2H, 3JHH = 7.5), 1.93–1.82 (m, 2H), 1.60–1.51 (m, 2H), 1.47–1.39 (m, 2H), 1.36–1.23 (m, 12H). 13C NMR (D2O + 1 drop of 6 M NaOD, 500 MHz) δ 79.6 (t, 1JCP = 134.2), 43.4, 39.0, 34.5, 33.3, 31.95, 31.94, 31.6, 31.4, 28.9, 27.2 (t, 2JCP = 5.3). 31P NMR (D2O + 1 drop of 6 M NaOD, 202 MHz) 20.4. Anal. Calcd. for C11H27O7P2N·H2O: C, 36.17; H, 8.00; N, 3.83; P, 16.96. Found: C, 36.20; H, 8.03; N, 3.73; P, 16.94.

Solubility determination

Solubility of N10O in aqueous solution was determined at constant room temperature (21.0°C) by preparing a saturated solution in Milli-Q water without buffering. The mixture containing an excess of N10O was first agitated for 30 min with a magnetic stirrer and then the sample mixture was allowed to stand for 24 h without stirring. A sample (ca. 5 ml) was drawn from the liquid above the solids, pH was measured and the sample was filtered through a 0.2 μm membrane filter to prevent the presence of possible insoluble particles. The phosphorus concentration in the filtered sample solution was determined with a spectrophotometer as described above and it was used to calculate the solubility of the compound. Solubility experiments of N10O in 0.8% and 3.5% NaCl solutions at pH 6.07 were performed similarly as described above. Instead, the solubility of N10O in tap waters (in Chapter 2.5) was calculated on the basis of the difference of the phosphorus concentrations in untreated and N10O treated samples.

Test tube experiment

White solid N10O (1.3 g) was vortexed with 0.1 M CuCl2 solution (7 ml) in a glass tube for 1 min. before centrifugation. The solution lying above the solids was removed to another glass tube and observed to be almost colourless and the solids (pale blue) were washed with water, vortexed for 1 min. and centrifugated (repeated twice). Solids were observed to maintain its pale blue colour.

Sintered glass crucible experiment

White solid N10O (3.0 g) was placed in a sintered glass crucible (G4) and 0.1 M CuCl2 solution (35 ml) was poured on top of it which the passed slowly through the N10O with vacuum suction. The N10O layer in the sintered glass had turned from white to pale blue and the colour remained even when washed with a large amount of distilled water indicating the formation of insoluble N10O CuII complex. CuII was liberated from the complex by addition of 1.0 M HCl through the complex in the sintered glass and after this the colour of N10O changed from pale blue to white again and the HCl solution which had been in contact with N10O changed from being colourless to blue.

Regeneration experiment

Regeneration experiments were conducted by sucking alternatively 20 ml 0.1 M CuCl2 solution and 25 ml 0.5 M, 1.0 M or 2.0 M HCl solutions through N10O (0.700 g) in glass crucibles (G4). Regeneration could be achieved on twenty successive occasions without any significant loss of CuII uptake efficacies. HCl effectively removed CuII from N10O, even in 0.5 and 1 M concentrations and no notable loss of N10O due to increased solubility was observed. Instead, with 2.0 M HCl approx. 10% of N10O was lost over the 20 regeneration procedures.

pH vs Recovery experiment

The recoveries of metal ions were determined as a function of pH by the batch method in the presence of an excess of N10O. The sample pH was adjusted with HCl or NaOH solutions of appropriate concentrations and initial metal ion concentration was measured by atomic absorption spectrometry (AAS) after filtration (0.2 μm membrane filter). N10O (m = 100 mg) was added to the sample (V = 100 ml) and mixture was agitated 24 h with a magnetic stirrer. After filtration, the final metal ion concentration was measured again. The recovery per cent of metal ions was calculated from the initial and final metal ion concentrations.

Capacity experiment

The metal complexing capacities for N10O and Diphonix® (see chemical structure in Figure 6) were determined by batch method in the excess of metal ion (C(Mn+) = 100 mg/l) at pH 4.0, (except AlIII and FeIII pH 1.0 and 3.0, respectively). The amount of N10O used was 100 mg and Diphonix® resin 300 mg, because moisture content of Diphonix® resin is 70%. Experiments were accomplished otherwise as described above. Uptake of metal ion per unit mass of N10O or Diphonix® resin (mg/g) was calculated as q = (C0-C) ·V/W where C0 and C (mg/l) corresponded to liquid-phase concentration of metal ion initial and final sampling times, respectively, V is the volume of solution (l) and W is the mass of dry N10O or Diphonix® resin used (g).

Interaction experiments

In interaction experiments to the synthetic binary solution (V = 0.100 l) of metal ions of equal molarities (C(Mn+) = 1.37 mM) complexing agent N10O (m = 0.100 g, n = 0.274 mmol) was added. Otherwise samples were treated in a similar way as in the recovery experiments described above. Metal concentrations were measured by AAS and metal amounts (mol) bounded were calculated on the basis of the difference of initial and final metal concentrations and bounding ratio (mol/mol) was calculated for binary system.

Experiment with ground water samples

Ground water samples (WW1–4) were taken from the tap after water was led into the building. Before the sampling, the water was allowed to run for several minutes. The pH values of samples were measured (waters 1–4 pH 7.11, 7.37, 8.06 and 8.50, respectively) but not readjusted prior to the addition of either N10O or Diphonix® and the initial metal concentrations (see Table 2) were measured with an inductively coupled atomic emission spectrometer (ICP-OES). N10O or Diphonix® (0.100 g or 0.300 g, respectively) was added to the water sample (100 ml) and the mixture was agitated with a magnetic stirrer 24 h. After filtration (0.2 μm membrane filter) metal ion concentration was measured again. Removal per cents of metal ions from well waters were calculated by determining as the final metal ion concentrations divided by their initial pretreatment concentrations.

Experiment with mining process water samples

Mining process water samples (MPW 1 and 2) were taken directly from two different process locations. The pH values of samples were 4.55 and 5.12, respectively. Otherwise samples (100 ml) were treated and the results calculated in a similar way as in the case of well waters, except that the amounts of N10O or Diphonix® were greater (1.000 g or 3.000 g, respectively). For sample, MPW 3 an even greater amount of N10O was used (5.000 g). The contact time experiments for sample MWP1were conducted with N10O (10 g/l) in the same way as above except that the contact times were 0.5 h, 6 h or 24 h.

References

Fu, F. & Wang, Q. Removal of heavy metal ions from wastewaters: A review. J. Environ. Manage. 92, 407–418 (2011).

Sharma, S. K., Sanghi, R. & Mudhoo, A. in Advances in Water and Pollution Prevention, Sharma, S. K. & Sanghi, R. (Eds.), Springer, 1–36 (2012).

Li, X.-G., Ma, X.-L., Sun, J. & Huang, M.-R. Powerful reactive sorption of silver(I) and mercury(II) onto poly(o-phenylenediamine) microparticles. Langmuir 25, 1675–1684 (2009).

Huang, M.-R., Li, S. & Li, X.-G. Longan Shell as Novel Biomacromolecular Sorbent for Highly Selective Removal of Lead and Mercury Ions. J. Phys. Chem. B. 114, 3534–3542 (2010).

Lim, A. P. & Aris, A. Z. A review on economically adsorbents on heavy metals removal in water and wastewater. Rev. Environ. Sci. Biotechnol. 13, 163–181 (2014).

Kurniawan, T. A., Chan, G. Y. S., Lo, W.-H. & Babel, S. Physico-chemical treatment techniques for wastewater laden with heavy metals. Chem. Eng. J. 118, 83–98 (2006).

Rubio, J., Souza, M. L. & Smith, R. W. Overview of flotation as a wastewater treatment technique. Min. Eng. 15, 139–155 (2002).

Puget, F. P., Melo, M. V. & Massarani, G. Comparative study of flotation techniques for the treatment of liquid effluents. Environ. Technol. 25, 79–87 (2008).

Dermentzis, K., Christoforidis, A. & Valsamidou, E. Removal of nickel, copper, zinc and chromium from synthetic and industrial wastewater by electrocoagulation. Int. J. Environ. Sci. 1, 697–710 (2011).

Vaaramaa, K. & Lehto, J. Removal of metals and anions from drinking water by ion exchange. Desalination 155, 157–170 (2003).

Shukla, A., Zhang, Y.-H., Dubey, P., Margrave, J. L. & Shukla, S. S. The role of sawdust in the removal of unwanted materials from water. J. Hazard. Mater. 95, 137–152 (2002).

Kurniawan, T. A., Chan, G. Y. S., Lo, W.-H. & Babel, S. Comparisons of low-cost adsorbents for treating wastewaters laden with heavy metals. Sci. Total Environ. 366, 409–426 (2006).

Chiban, M., Soudani, A., Sinan, F., Tahrouch, S. & Persin, M. Characterization and application of dried plants to remove heavy metals, nitrate and phosphate ions from industrial wastewaters. Clean – Soil, Air, Water 39, 376–383 (2011).

Abdel-Aal, E. E., Gad, Y. H. & Dessouki, A. M. The use of wood pulp and radiation-modified starch in wastewater treatment. J. Appl. Polym. Sci. 99, 2460–2469 (2006).

Abollino, O., Aceto, M., Malandrino, M., Sarzanini, C. & Mentasti, E. Adsorption of heavy metals on Na-montmorillonite. Effect of pH and organic substances. Water Res. 37, 1619–1627 (2003).

Inglezakis, V. J., Loizidou, M. D. & Grigoropoulou, H. P. Ion exchange of Pb2+, Cu2+, Fe3+ and Cr3+ on natural clinoptilolite: selectivity determination and influence of acidity on metal uptake. J. Coll. Interf. Sci. 261, 49–54 (2003).

Dal Bosco, S. M., Jiminez, R. S. & Carvalho, W. A. Removal of toxic metals from wastewater by Brazilian natural scolecite. J. Coll. Interf. Sci. 281, 424–431 (2005).

Stylianou, M. A., Hadjiconstatinou, M. P., Inglezakis, V. J., Muostakas, K. G. & Loizidou, M. D. Use of natural clinoptilite for the removal of lead, copper and zinc in fixed bed column. J. Hazard. Mater. 143, 575–581 (2007).

Álvarez-Ayuso, E., Garcia-Sánchez, A. & Querol, X. Purification of metal electroplating waste waters using zeolites. Water Res. 37, 4855–4862 (2003).

Peric, J., Trgo, M. & Medidovic, N. V. Removal of zinc, copper and lead by natural zeolite - a comparison of adsorption isotherms. Water Res. 38, 1893–1899 (2004).

Miretzky, P. & Cirelli, A. F. Cr(VI) and Cr(III) removal from aqueous solution by raw and modified lignocellulosic materials: A review. J. Hazard. Mater. 180, 1–19 (2010).

O'Connel, D. W., Birkinshaw, C. & O'Dwyer, T. F. Heavy metal adsorbents prepared from the modificationof cellulose: A review. Bioresource Technology 99, 6709–6724 (2008).

Crini, G. Recent developments in polysaccharide-based materials used as adsorbents in wastewater treatment. Prog. Polym. Sci. 30, 38–70 (2005).

Lemos, V. A. et al. New materials for solid-phase extraction of trace elements. Appl. Spectros. Rev. 43, 303–334 (2008).

Abdel-Halim, E. S. & Al-Deyab, S. S. Removal of heavy metals from their aqueous solutions through adsorption onto natural polymers. Carbohydr. Polym. 84, 454–458 (2011).

Li, X.-G., Feng, H. & Huang, M.-R. Strong Adsorbability of Mercury Ions on Aniline/Sulfoanisidine Copolymer Nanosorbents. Chem. Eur. J. 15, 4573–4581 (2009).

Lü, Q.-F., Huang, M.-R. & Li, X.-G. Synthesis and heavy-metal-ion sorption of pure sulfophenylenediamine copolymer nanoparticles with intrinsic conductivity and stability. Chem. Eur. J. 13, 6009–6018 (2007).

Huang, M.-R., Lu, H.-J. & Li, X.-G. Synthesis and Strong Heavy-Metal Ion Sorption of Copolymer Microparticles from Phenylenediamine and Its Sulfonate. Journal of Materials Chemistry 22, 17685–17699 (2012).

Abdou, W. M. & Shaddy, A. A. The development of bisphosphonates for therapeutic uses and bisphosphonate structure-activity consideration. ARKIVOC ix, 143–182 (2009).

Wolfgang, J. & Chrystèle, H. An in vitro assay to measure targeted drug delivery to bone mineral. ChemMedChem. 5, 770–776 (2010).

Miller, K., Erez, R., Segal, E., Shabat, D. & Satchi-Fainaro, R. Targeting bone metastases with a bispecific anticancer and antiangiogenic polymer–alendronate–taxane conjugate. Angew. Chem. Int. Ed. 48, 2949–2954 (2009).

Houghton, T. J. et al. Linking bisphosphonates to the free amino groups in fluoroquinolones: Preparation of osteotropic prodrugs for the prevention of osteomyelitis. J. Med. Chem. 51, 6955–6969 (2008).

Alanne, A.-L. et al. A novel bisphosphonate-based solid phase method for effective removal of chromium(III) from aqueous solutions and tannery effluents. RSC. Adv. 3, 14132–14138 (2013).

Horowitz, E. P. et al. Uptake of metal ions by a new chelating ion-exchange resin. Part 1: Acid dependencies of actinide ions. Solvent Extr. Ion Exch. 11, 943–966 (1993).

Chiarizia, R. et al. Uptake of metal ions by a new chelating ion-exchange resin: Part 2: Acid dependencies of transition and post-transition metal ions. Solvent Extr. Ion Exch. 11, 967–985 (1993).

Chiarizia, R., Horwitz, E. P., Alexandratos, S. D. & Gula, M. J. Diphonix® resin: A review of its properties and applications. Sep. Sci. Technol. 32, 1–35 (1997).

Roth, A. G. et al. Potent and selective inhibition of acid Sphingomyelinase by bisphosphonates. Angew. Chem. Int. Ed. 48, 7560–7563 (2009).

Alanne, A.-L. et al. Systematic study of the physicochemical properties of a homologous series of aminobisphosphonates. Molecules 17, 10928–10945 (2012).

Matczak-Jon, E. & Videnova-Adrabinska, V. Supramolecular chemistry and complexation abilities of diphosphonic acids. Coord. Chem. Rev. 249, 2458–2488 (2005).

Matveev, S. V. et al. N-Substituted 2-aminoethylidenediphosphonic acids as complexones. Russ. Chem. Bull. 47, 1736–1740 (1998).

Gumienna-Kontecka, E. et al. Bisphosphonate chelating agents: complexation of Fe(III) and Al(III) by 1-phenyl-1-hydroxymethylene bisphosphonate and its analogues. Inorg. Chim. Acta 339, 111–118 (2002).

Georgantas, V. et al. Synthetic, structural and solution speciation studies on binary Al(III)-(carboxy)-phosphonate systems. Relevance to the neurotoxic potential of Al(III). J. Inorg. Biochem. 256, 1530–1541 (2009).

Bouhsina, S., Buglyó, P., Abi Aad, E., Aboukais, A. & Kiss, T. Formation of oligonuclear complexes between copper(II) and 1-hydroxyethane-1,1-diphosphonic acid. Inorg. Chim. Acta 357, 305–310 (2004).

Cukrowski, I., Zeevaart, J. R. & Jarvis, N. V. A potentiometric and differential pulse polarographic study of CdII with 1-hydroxyethylenediphosphonic acid. Anal. Chim. Acta 379, 217–226 (1999).

Lacour, S., Deluchat, V., Bollinger, J. & Serpaud, B. Complexation of trivalent cations (Al(III), Cr(III), Fe(III)) with two phosphonic acids in the pH range of fresh waters. Talanta 46, 999–1009 (1998).

Deluchat, V., Bollinger, J., Serpaud, B. & Caulet, C. Divalent cations speciation with three phosphonate ligands in the pH-range of natural waters. Talanta 44, 897–907 (1997).

Nash, K. L. f-Element complexation by diphosphonate ligands. J. Alloys Compd. 249, 33–40 (1997).

Kubiček, V., Kotek, J., Herman, P. & Lukeš, I. Aminoalkylbis(phosphonates): their complexation properties in solution and in the solid state. Eur. J. Inorg. Chem. 2, 333–344 (2007).

Zeevaart, J. R. et al. Metal-ion speciation in blood plasma incorporating the bisphosphonate, 1-hydroxy-4-aminopropilydene-diphosphonate (APD), in therapeutic radiopharmaceuticals. J. Inorg. Biochem. 73, 265–272 (1999).

Dyba, M. et al. 1-Hydroxyalkane-1,1-diyldiphosphonates as potent chelating agents for metal ions. Potentiometric and spectroscopic studies of copper(II) co-ordination. J. Chem. Soc, Dalton Trans. 6, 1119–1123 (1996).

Fawell, J. & Nieuwenhuisen, M. J. Contaminants in drinking water. Br. Med. Bull. 68, 199–208 (2003).

Bouchard, M. F. et al. Intellectual Impairment in School-Age Children Exposed to Manganese from Drinking Water. Environ. Health Perspect. 119, 138–143 (2011).

Lahermo, P. et al. One thousand wells – the physical-chemical quality of Finnish well Waters in 1999, Report of Investigation. 155, 1-92 (Geological Survey of Finland, 2002) (htpp://www.ymparisto.fi/download/noname/%D511CB71-0A6E.../57054) (Date of access: 26/01/2015) (in finnish).

Zacheus, O. M. & Martikainen, P. J. Physicochemical quality of drinking and hot waters in Finnish buildings originated from groundwater or surface water plants. Sci. Total Environ. 204, 1–10 (1997).

Hurst, C. China's rare earth elements industry: what can the west learn? Institute for Analysis of Global Security (IAGS).(2010) (http://fmso.leavenworth.army.mil/documents/rareearth.pdf) (Date of access: 25/11/2014)

Simate, G. S. & Ndlovu, S. Acid mine drainage: Challenges and opportunities. J. Environ. Chem. Eng. 2, 1785–1803 (2014).

Brunner, S., Emmett, P. H. & Teller, E. Adsorption of Gases in Multimolecular Layers. J. Am. Chem. Soc. 60, 309–319 (1938).

4500-P Phosphorus in Standard methods for the examination of water and wastewater 20th edn, (APHA, 1999) (www.mwa.co.th/download/file_upload/SMWW_4000-6000.pdf) (Date of access: 26/01/2015).

Kieczykowski, G. R. et al. Preparation of (4-amino-1-hydroxybutylidene)bisphosphonic acid sodium salt, MK-217 (alendronate sodium). An improved procedure for the preparation of 1-hydroxy-1,1-bisphosphonic acids. J. Org. Chem. 60, 8310–8312 (1995).

Acknowledgements

We thank Mrs. Maritta Salminkoski and Mrs. Helena Vepsäläinen for their skilfull technical assistance, Mrs. Mari Ruuskanen for Fig. 1 layout and Mr. Janne Kankkunen for providing mine water samples. European PhoSciNet is also acknowledged. This work was supported by the strategic funding of the University of Eastern Finland and a grant from Academy of Finland(132070).

Author information

Authors and Affiliations

Contributions

P.T. has synthesized the N10O material and was the first one to observed its potential. S.P. performed most of the experiments. S.P. and J.V. planned the most of the performed experiments. The manuscript was written by S.P. and P.T. All authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Supporting Info

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Turhanen, P., Vepsäläinen, J. & Peräniemi, S. Advanced material and approach for metal ions removal from aqueous solutions. Sci Rep 5, 8992 (2015). https://doi.org/10.1038/srep08992

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep08992

- Springer Nature Limited

This article is cited by

-

Dolomite as a potential adsorbent in water treatment: pH, turbidity and Pb (II) removal studies

International Journal of Environmental Science and Technology (2024)

-

A review on the industrial wastewater with the efficient treatment techniques

Chemical Papers (2023)

-

Sensitive ratiometric sensor for Al(III) detection in water samples using luminescence or eye-vision

Analytical Sciences (2023)

-

Removal of nickel from aqueous solution using synthesized IL/ZnO NPs

Environmental Science and Pollution Research (2020)

-

Hydrogels derived from 2-hydroxyethyl-methacrylate and 2-acrylamido-2-methyl-1-propanesulfonic acid, with ability to remove metal cations from wastewater

Polymer Bulletin (2019)