Abstract

GeS2-Ga2S3-Li2S electroconductive glasses were prepared by the conventional melt-quenching method through carefully controlling the heating rate. Comparing with the reference of glass-forming region, our investigated GeS2-Ga2S3-Li2S system was extended to the cation ratio of 0–20% Li with around 40% Ga. GeS2-Ga2S3-Li2S glass-ceramics containing IR Li2Ga2GeS6 nonlinear nanocrystals were obtained by the more carefully controlled heating rate. Its optical nonlinearity was investigated by the Maker fringe measurements, the maximum second harmonic intensity was observed to be 0.35 of the reference Z-cut quartz. IR Li2Ga2GeS6 nonlinear crystals were directly obtained at the composition of 40GeS2-30GaS1.5-30LiS0.5.

Similar content being viewed by others

Introduction

Second harmonic generation (SHG) is not allowed in either isotropic or centro-symmetrical materials like glasses, but active crystals inside glass matrix can break its homogeneity and permanent SHG can be observed1,2. Recently, chalcogenide glass-ceramics containing well-known nonlinear crystals (β-GeS23,4, AgGeGaS45, CdGa2S46), which represented a promising avenue for future nonlinear optical technologies in the mid-IR region. In this case, the isotropic structure of glass was broken by the precipitated nonlinear crystals induced by heat treatment, which induced SHG in glass-ceramics, also induced declination of transmittance1,2. One kind of new Li2Ga2GeS6 sulfide compound was firstly synthesized by Kim et al.7, which was an isomer of AgGaGeS4. Li2Ga2GeS6 was phase-matched with SHG efficiency of approximately 200 times of α-SiO2 and also showed a high laser damage threshold (3.65 eV) which made it be served as one kind of potential nonlinear optical (NLO) materials in the IR frequency converters. However, the size of Li2Ga2GeS6 crystal (around 0.20 × 0.15 × 0.15 mm3 from Kim's data) limited its practical applications and as far as we know, no larger Li2Ga2GaS6 crystal was synthesized up to now. On the other hand, the glass-forming ability of GeS2-Ga2S3-Li2S system has been studied in detail as amorphous fast ion conductor8,9,10. In this paper, to our knowledge, we firstly fabricated GeS2-Ga2S3-Li2S glass-ceramics containing IR nonlinear Li2Ga2GaS6 crystals (see Table 1) by the conventional melt-quenching method11 through carefully controlling the heating rate.

Results

It was seen from Table 1 that ΔT (ΔT = Tx-Tg, Tg is the glass transition temperature, Tx is the crystallization temperature and Tpis the crystallization peak temperature) of GGL6 and GGL19 glasses was about 90°C, indicating their good thermal stability, so their crystallized processes could be easily controlled. The glass-forming ability was primarily reported on the region of higher Li2S content, from 40% to 60% of 1/2 Li2S, because glasses with higher electroconductivity would be expected in the region with maximum Li2S concentration8,9,10. However, our present studies indicated that the glass-forming region of this system could extend to the 0–20% range of Li content with around 40% 1/2 Ga2S3, which is shown in Fig. 1. Glass was not obtained with more than 28% Li-cation ratio, but nonuniform Li2Ga2GeS6 crystal was directly obtained in the composition containing 30% of 1/2 Li2S (GGL30).

When the glasses were annealed at lower temperature (<420°C) for long time, well-distributed crystals were obtained but no SHG appeared, so 420°C was chosen as THT of GGL19. Figure 2 illustrates the UV–vis–NIR transmittance spectra of GGL19 glass matrix and glass-ceramics. Its transmittance remarkably decreased under the heat-treatment of THT = 420°C. The glass became closed to opaque when it was annealed for 6 hours at THT = 420°C (labeled as sample 420-6 h). With further annealing time, the glass-ceramic samples became opaque because more crystals were precipitated in the glasses to make transmittance declined.

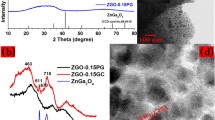

To check the crystalline phases, XRD patterns of some representative samples were done and shown in Fig. 3. After 6 hours of heat treatment at THT = 420°C, more strong diffraction peaks appeared and intensities became stronger after longer durations of heat treatment, but only one crystalline phase appeared in the samples which was in good agreement with the experimental data of Li2Ga2GeS6 crystal from Kim et al7.

XRD patterns of nanocrystallized GGL19 glass-ceramics at THT = 420°C under different annealing time and the experimental data of Li2Ga2GeS6 crystals (from Kim)7.

Figure 4 shows the Maker fringe patterns of annealed GGL19 glass-ceramics. They are lobe shapes even second harmonic (SH) intensity is as small as 0.05 of Z-cut quartz, which can be considered as a consequence of bulk crystallization4,5,6. Broad Maker fringe pattern from surface crystallized samples4,6 did not appear as the precipitation of crystals in glasses. Relatively remarkable SHG signals emerged when the heat-treating durations was more than 6 hours. There exited a trend that SH intensity increased with longer annealing time or higher annealing temperature. The maximum value could reach as high as 0.35 of Z-cut quartz (reference sample) from samples 420-10 h and 430-3 h. But for longer duration (13 hours) at THT = 420°C, the intensity declined to 0.3 of the reference (not shown here).

We succeeded in fabricating IR transmitting GeS2-Ga2S3-Li2S electroconductive glasses containing large amount of IR optical nonlinear Li2Ga2GeS6 crystals and studying its second-order optical nonlinearity. With higher concentration of Li2S and Ga2S3, GGL19 glass-ceramics showed good SH intensity. The maximum SH intensity of GGL19 is about 0.35 times of the Z-cut quartz under the optimized condition of crystallization process (THT = 420°C for 10 h).

IR nonlinear Li2Ga2GeS6 crystals with non-uniform yellowish transparent grains, were also directly obtained from 5 g batch of the raw materials in the composition GGL30 (see Table 1). The size of obtained Li2Ga2GeS6 crystals was about 0.3 × 0.25 × 0.3 mm3, which was bigger than that of Kim (0.2 × 0.15 × 0.15 mm3)7, it was verified to be so susceptive to H2O, this character was further validated by XRD and Maker fringe measurements.

Discussion

We assume that the nonlinear optical behavior of the obtained glass-ceramics is analogous to that of polycrystalline powder with randomly oriented non-centro-symmetric particles dispersed in glasses. In this case, it was demonstrated that the crystallized volume fraction favored the enhancement of the second-order nonlinearity in glass-ceramics3. Bysides, as described by Kurtz and Perry12, the SH intensity in polycrystalline powder could be analyzed according to r/lc ratio where r is the particle size and lcis the coherent length of the particle. Consequently, the small SH intensity for samples which was annealed less than 6 hours was probably due to the small amounts of precipitated Li2Ga2GeS6 crystals and the size of the more precipitated Li2Ga2GeS6 crystals was too small compared to lc (about 5 µm). It is well known that the crystallization process becomes completed well with the increase of the number and the particle size of precipitated Li2Ga2GeS6 through longer annealing time or higher temperature and also SH intensity increases, but which also causes an enhanced scattering loss and effectively diminishes the NLO effects. We speculated that the higher concentrations of Li2S and Ga2S3 resulted in an increase in the number of precipitated Li2Ga2GeS6 crystals which enhanced SH intensity of GGL19 samples. Similar trend was also observed in (100–x) Li2B4O7-x SrBi2Ta2O9 glass–ceramic composites, where SH intensity was also enhanced with higher concentrations of SrBi2Ta2O92. Finally, it is seen from Fig. 5 that an optimized condition of crystallization process (THT = 420°C for 10 h) was obtained and the maximum SH intensity was about 0.35 times that of Z-cut quartz. However, the characterization of the crystal size and the crystallized volume fraction was difficult as a result of its deliquescence.

IR nonlinear Li2Ga2GeS6 crystals was verified to be so susceptive to H2O that it could be dissolved into water in a few minutes and left only floccus. This phenomenon was further confirmed by the XRD and Maker fringe tests of GGL19 glass-ceramics. After keeping sample 420-10 h in a silicagel desiccator for 3 months (labeled as Sample 420-10 h, 3 m), the XRD peaks approximately disappeared (Fig. 3) and the SH intensity declined to only 1.5% of Z-cut quartz. The details of this phenomenom are still unclear.

Methods

We studied the second-order optical nonlinearity of the glass-ceramics under different heat-treatment conditions. GeS2-Ga2S3-Li2S bulk glasses were prepared by the conventional melt-quenching method in a vacuum sealed SiO2 tube from commercial Li2S, GeS2 and Ga2S38,9. According to Yamashita et al.10, however, synthesized Li2S was used for preparing glasses to eliminate oxygen presented in commercial reagent-grade Li2S, which was synthesized from sulfur vapor and lithium metal in a Y-shaped silica tube (2Li + S(g)→Li2S) and then was mixed with GeS2 and Ga2S3 to prepare GeS2-Ga2S3-Li2S glasses10. Lithium reacts with liquid sulfur (at 120°C when sulfur melts) is very complicated, which can be described as:

The by-product of this reaction, Li2Sn (2 ≤ n ≤ 4), is unstable and explosive. We experimentally succeed in preparing GeS2-Ga2S3-Li2S glasses with elements Li, Ge, Ga and S as raw materials by the conventional melt-quenching method. Explosion from Lithium reacting with liquid sulfur was avoided by carefully controlling the heating rate. Firstly, we increased the temperature very slowly and started to rock the sample in our designed rocking stoven at 120°C and kept this temperature for 1 hour. Continually, the temperature was increased at the rate of 1°C/min from 120°C to 750°C and at a rate of 0.5°C/min from 750°C to 950°C and finally was kept 10 hours to make the raw materials react fully in the oven at 950°C.

Glass plates (Φ8 mm × 0.75 mm) were obtained from bulk and polished to optical quality and then were sealed for annealing in a fused quartz tubes. The Tg, Tx and Tp of glasses were determined by the differential scanning calorimetry (DSC, NETZSCH STA 449C). The annealing temperature THT and period depended on Tgand the crystallizing process. The UV–vis–NIR transmissive spectra were recorded using a Shimadzu UV-1601 spectroscopy system between 200 and 1100 nm wavelength. SH intensity of glass-ceramics was measured by a fundamental wavelength of a Q-switched neodymium doped YAG laser (1064 nm) via the Maker fringe method13. Z-cut quartz with the thickness of 1.11 mm was used as a reference. The crystallization of heat-treated samples was studied by the X-ray diffraction (XRD, PANalytical X'Pert PRO) using Cu Ka radiation at room temperature. The particle size of Li2Ga2GeS6 crystals was determined by Dark-field optical digit microscope (VHX-600 Japanese KEYENCE). The morphology of glass-ceramics was characterized by SEM (JSM-5610LV, JEOL Ltd., Japan).

References

Liu, Q. et al. Thermally induced nanocrystallization in SrO-TiO2-SiO2 glasses tracking by Maker fringe patterns analysis. J.Optoelectronic and Advanced Materials 14, 905–908 (2012).

Murugan, G., Varma, K., Takahashi, Y. & Komatsu, T. Nonlinear-optic and ferroelectric behavior of lithium borate–strontium bismuth tantalate glass–ceramic composite. Appl. Phys. Lett. 78, 4019–4021 (2001).

Guignard, M. et al. Crystalline phase responsible for the permanent second-harmonic generation in chalcogenide glass-ceramics. Opt. Mater. 30, 338–345 (2007).

Popović, Z. V. et al. High-pressure Raman Scattering and Optical Absorption Study of β-GeS2 . Physica Status Solidi 198, 533–537 (1996).

Ni, Y. et al. Synthesis and growth of nonlinear infrared crystal material AgGeGaS4 via a new reaction route. J. Cryst. Growth 311, 1404–1406 (2009).

Bodnar, I. V., Rud, V. & Rud, Y. Growth and Properties of CdGa2S4 Single Crystals, Inorgan. Mater. 40, 102–106 (2004).

Kim, Y. et al.Characterization of new infrared nonlinear optical material with high laser damage threshold Li2Ga2GeS6 . Chem. Mater. 20, 6048–6052 (2008).

Kanno, R., Hata, T., Kawamoto, Y. & Irie, M. Synthesis of a new lithium ionic conductor, thio-LISICON–lithium germanium sulfide system. Solid State Ionics 130, 97–104 (2000).

Saienga, J., Kim, Y., Campbell, B. & Martin, S. Preparation and characterization of glasses in the LiI-Li2S-GeS2-Ga2S3 system. Solid State Ionics 176, 1229–1236 (2005).

Yamashita, M. & Yamanaka, H. Formation and ionic conductivity of Li2S-GeS2-Ga2S3 glasses and thin films. Solid State Ionics 158, 151–156 (2003).

Liu, Q. et al. Second Harmonic Generation in Ge20As25S55 glass by an electron beam. Opt. Lett. 26, 1347–1349 (2001).

Kurtz, S. & Perry, T. A powder technique for the evaluation of nonlinear optical materials. J. Appl. Phys. 39, 3798–3813 (1968).

Maker, P., Terhune, R., Nisenoff, M. & Savage, C. Effects of dispersion and focusing on the production of optical harmonics. Phys. Rev. Lett. 8, 21–22 (1962).

Acknowledgements

This research work was financially supported by the National Natural Science Foundation of China (51272183).

Author information

Authors and Affiliations

Contributions

P.Z. fabricated samples. Q.L. and P.Z. wrote the main manuscript text and P.Z. prepared figures. All authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 4.0 International License. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/4.0/

About this article

Cite this article

Liu, Q., Zhang, P. IR Li2Ga2GeS6 nanocrystallized GeS2-Ga2S3-Li2S electroconductive chalcogenide glass with good nonlinearity. Sci Rep 4, 5719 (2014). https://doi.org/10.1038/srep05719

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep05719

- Springer Nature Limited

This article is cited by

-

Tl2S–Ga2S3–GeS2 glasses for optically operated laser third harmonic generation

Journal of Materials Science: Materials in Electronics (2017)