Abstract

American white (Quercus alba L.) oak casks have been used for liquid storage for centuries. Their use in aged spirits is critical to imparting flavor and mouthfeel to the final product. The reason that barrels retain liquid has been hypothesized to be the result of abundant physiological structures called tyloses in parenchyma tissues and medullary rays in white oak. Using non-destructive X-ray computed tomography (XRCT) imaging, we reveal an unprecedented view of tylose structure and quantify the pore-filling capacity of tyloses in white oak that underscores the liquid retention we observe in casks. We show that pores of white oaks are filled with sevenfold higher tylose volume compared to northern red oak (Q. rubra), consistent with prior literature that casks made from white oak retain liquid while red oak fails to do so. We propose that XRCT represents a methodological standard for observing these complex structures and should be employed to understand the many questions related to liquid losses from casks, cultural treatment of casks, and the influence of climate change on oak tyloses in the future.

Similar content being viewed by others

Introduction

Tyloses, also referred to as thyloses, are anatomical features described as ingrowths of parenchyma cells into the embolized lumen of xylem vessels1,2,3,4,5,6. They are visualized by microscopy as balloon-like features4,7. These structures have been described in specific angiosperm taxa: Populus, Rhus, Robinia, Morus, Sassafras, Catalpa, Juglans, and Quercus8. In most cases, their formation has been correlated with a response to wounding or a result of pathogen ingress4,9,10,11,12. In specific cases, however, such as in Q. petraea (French oak), the formation of tyloses appears constitutively and is part of the transition from sapwood to hardwood; the same is hypothesized in white oak13,14. Tylose formation is thought to occur partly due to turgor pressure changes that reposition the sac-like structure from the occupancy parenchyma cell into the lumen of vascular cells4,15,16.

Q. alba L. (American white oak) is an important species for the cooperage of whisky, whiskey, and wine barrels7,17. The ability for white oak casks to hold liquid is thought to arise due to a combination of how wood is cut as well as the abundant tyloses that block the transport of liquids through xylem vessels18. New charred white oak casks are a standard of identification for bourbon production and are then used in secondary maturations to produce scotch whisky and other aged spirits7. Despite their importance to retaining liquid and the costs of losing liquid from barrels over decades, methods for non-destructively visualizing and quantifying the volume of tyloses per pore are lacking. Coopers have a keen interest in tyloses content, and whiskey and wine producers do as well, as it is thought that lacking tyloses will result in unacceptable losses from the end of the staves producing leaky barrels7,19,20. The main varieties used for cooperage are Q. alba from the United States, Q. robur (pendunculus), Q. petrea (sessile) from Europe, and Q. crispula (mizunara) in Japan7,21. Northern red oak (Q. rubra) is a species of oak that is not known to exhibit tylose formation and is described as ‘open’ and ‘porous’ but can form a limited amount of tyloses under specific condions3,7,15,20,22.

Herein, we aimed to develop a methodology to study and quantify tylose volume within a pore. Traditionally, the method used to study tyloses has been via destructive fixation, sectioning, and microscopic imaging of the wood sample via compound microscopy3. By applying X-ray computed tomography (XRCT)23, we aim to extract information in three dimensions and provide quantitative information. XRCT is a robust, non-destructive imaging technique to reconstruct the three-dimensional structure of a material. It is a technique widely used to study materials with complex architectures ranging from materials used in energy storage24,25, heat shields used on space capsules26,27,28, and analysis of biological tissues29. XRCT has also been extensively used to analyze the broad characteristics of wood samples23,30,31,32,33 including species like poplar34,35. A summary of the studies can be found in a review by Wei et al23. However, none of the studies have focused on oak variants. Moreover, very limited studies have focused on tyloses. A study by Ingel et al.33 used XRCT to identify the presence or absence of tyloses to investigate the mechanism of xylem disruption during Ralstonia wilt of tomato but did not attempt to quantify the volume of tyloses inside the elements. Here, we leverage XRCT imaging to reveal an unprecedented view of oak wood structures with a focus on vascular tissues as the tylose content directly influences liquid bearing capacity of different oak materials. Herein, we document the challenges and opportunities of using XRCT on oak xylem in Q. alba, Q. robur, and Q. rubra.

Methods

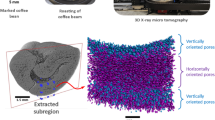

Three-dimensional imaging of wood structures

XRCT imaging of oak wood is carried out by the HeliScan Mk2 instrument supplied by Thermo Fisher Scientific (herein referred to as HeliScan) in the electron microscopy center at the University of Kentucky. The Plant material Q. alba and Q. robur was sourced from commercial sources. The Q. rubra sample was sourced from the Wood Utilization Center of the University of Kentucky Forestry Department. The samples came in shape of a brick or stave in dry condition that were cut into smaller pieces and were sanded to yield cylindrical shape. The diameter and height of the cylindrical samples were approximately 10 and 20 mm, respectively. Imaging was performed on dry oak samples, and no drift was observed during image acquisition. A white oak sample loaded into HeliScan is illustrated in Fig. 1a. The sample is mounted on a 360° rotatable stage. As the sample is rotated, it is illuminated by polychromatic X-ray beams (tungsten target). These beams travel through the sample and reach the detector behind the sample. HeliScan employs a large area amorphous silicon flat panel detector, and a 2 mm aluminum plate is attached to the detector to limit beam hardening artefacts. During the imaging process, projections, which contain both the radiograph and the rotational information that can be used to reconstruct the 3D structure, were acquired. These projections were used by the internal HeliScan software to generate the 3D structure, a process called tomographic reconstruction. For the analysis described in this article, reconstruction was performed using the propagation-based phase-contrast method36. Specifically, the phase retrieval method using a single defocus distance from Paganin and co-workers, available in the Heliscan software, was employed37. For phase retrieval, a parameter value of 13, obtained through trial-and-error, yielded sharp contrast between tyloses and the base wood structures enabling clean extraction of three-dimensional tylose structures. A reconstructed slice using a phase retrieval parameter of 13 and a slice without phase reconstruction is shown in Fig. S1 (supplementary information). The corresponding binary images are shown in Fig. S2 (supplementary information). A microfocus source was used in the HeliScan software using the medium focal spot option. The exact focal spot size is not known as it is internally controlled through HeliScan proprietary software. The reconstruction converts the raw 2D projections to reconstructed axial slices. The pixel set is reduced during the 3D reconstruction because the HeliScan software crops out any image distortion in the projections. A schematic of the XRCT process is shown in Fig. 1b. The HeliScan machine can perform both circular and helical rotations of the sample through the path of the X-ray beam27. This study employed a circular trajectory because it was sufficient to obtain the desired image resolution. The detector is located sufficiently farther away from the beam source to reduce the inherent image distortion associated with circular rotations. The images for each sample was acquired using a single scan.

Input parameters used to perform the scans for each oak samples in the HeliScan machine were determined by trial and error until satisfactory quality of the data was achieved. The distances between the source, detector, and samples were adjusted to ensure that the voxel resolution of the images was less than 3 µm for all scans. The acceleration voltage and tube current were set between 87–140 kV and 60–198 µA, respectively. The range for the target current of the X-ray source, the distance between the source and the sample, and the distance of the detector from the source were 45–60 µA, 6–15 mm, and 400–800 mm, respectively. The sample was larger than the detector field of view. These settings yielded voxel size of 2.1–2.8 µm for all samples. Based on the specific HeliScan instrument, approximately five voxels are needed to distinguish the smallest feature in an image. Therefore, the spatial resolution of the 3D volumes ranges from 10 to 14 µm. The position of rotation stage was also corrected to keep the center of sample to be placed at the center of rotation. As the sample completed one revolution, 1800 projections were acquired. The voxel size and the total number of voxels for all scanned samples are shown in Table 1. The X-ray exposure time was adjusted to ensure that the max \({2}^{16}\) bit grayscale value would be under 40,000 to prevent the projections from having excessive white spots. Each acquired projection was set to 3040 × 3040 pixels. For white oak, the complete set of projections, originally at 3040 × 3040 × 3040 pixels, was reduced to 2800 × 2800 × 1800 pixels during reconstruction. This set of reconstructed slices was imported into the visualization software for all analyses. The set of reconstructed slices results in a reconstructed 3D volume.

To ensure consistency and ease of analysis, all samples were loaded such that the z-axis aligned to root-to-shoot direction. As a result, the projections of the pores in the wood will appear circular in the xy plane, while in the other two planes, the pores will appear rectangular. Two-dimensional views of the reconstructed 3D volumes in the yz and xy planes are shown in Fig. 2. The alignment of the root-to-shoot and pith-to-bark directions are also shown in Fig. 2.

Data processing, visualization, and analysis

The reconstructed data sets from the HeliScan software were assembled into a stack of a single master tiff file using the ImageJ image processing software38. The reconstructed images had a low dynamic range. Therefore, the grayscale histogram was scaled from 0 to 65,535. This volume was imported into the Avizo material characterization software supplied by Thermo Fisher Scientific. The volume was first filtered with an unsharp masking method to sharpen the image. The resulting image was filtered again with a non-local means algorithm for denoising. This filtered data was segmented by specifying the upper and lower boundary of the grayscale value to mask wood tissue and tylose. Masking selects all the solid material (wood and tylose) and does not include any of the void spaces within the sample. After masking, the region is finally binarized to separate solid and empty regions. At this point, 3D volumes can be generated for visualization, and the pores can be analyzed individually.

To analyze individual pores, each pore was isolated using Avizo’s segmentation tools. This pore solely contains the vessel elements and tylose volumes, and this individual pore is cleanly separated from the base wood sample. Since the only solid material in the pore is tylose, the tylose structure within this single pore is separated from the vessel elements’ space through a simple threshold. After separation, both the tylose and vessel element space volumes were assigned as separate materials, and material statistics tools in Avizo were used to measure the volume of vessel elements space and tylose. The binarized data of the two unique material volumes (vessel element space and tylose) were also used to render the surface of the two volumes for visualization. The pore’s diameter can also be measured using the measurement tool. It is noted here that the diameter is a rough estimate based on the longest distance across the pores. However, the volume is true data because it is extracted directly from the 3D structure, and no assumptions are made. This analysis is repeated for all the pores to generate the volume statistics.

Results

Visualization of oak wood

Volumes extracted for Q. alba, Q. robur, and Q. rubra samples are shown in Fig. 3a–c. The volumes shown in Fig. 3a–c are 1.33, 1.03, and 1.13 mm3, respectively. However, the total volumes of Q. alba, Q. robur, and Q. rubra illuminated by the X-ray beam that were eventually reconstructed are 181.0, 107.3, and 132.4 mm3, respectively. The differences in volume sizes arise because of variations in the voxel size of the XRCT scans of individual oak materials, as reported in Table 1. It was verified that the volumes analyzed were the representative elementary volume (REV) by comparing the tylose proportions for different slice lengths in the z-direction. The individual pores and the tylose inside the pores can be observed for all three variants of oak samples (Fig. 3). Q. alba exhibited the greatest volume of tylose within a pore (Fig. 3a), Q. robur (Fig. 3b) exhibited a lower tylose volume per pore in comparison to Q. alba but contains greater tylose volume than Q. rubra (Fig. 3c). Q. rubra contains the least tylose volume among the three wood variants examined (Fig. 3c) and is not used to construct barrels to hold spirits7.

White Oak’s high tylose content is visually apparent. Volumes of different species of Oak (Quercus): (a) white (alba), (b) French (robur), and (c) red (rubra). The volumes shown in a–c are 5003 voxels, and the viewing direction is along the z-axis, i.e., the viewing plane is the xy plane. The z-axis aligns with the root-to-shoot direction. The structure of vessel elements space (left) and tylose (right) in the perspective of the xz plane for white, French, and red oak is shown in d–i, respectively. A scale bar of 0.3 mm is added to provide a perspective on all dimensions. The volume of a–c is 1.33, 1.03, and 1.13 mm3, respectively, and the height of d–i is 4.2, 3.3, and 3.7 mm, respectively.

The strength of XRCT lies not just in overall 3D reconstruction but utilizing the 3D volumes to obtain individual qualitative and quantitative metrics. Each pore in the wood sample can be isolated and analyzed. This isolation is demonstrated in Fig. 3d–i, where a pore from the 3D volume is extracted, the ‘tylose’ and ‘non-tylose’ space has been spatially resolved, and the structure of the tylose and the vessel elements space was generated. The volumes on the left and right in Fig. 3d–i represent the vessel elements’ non-tylose space’ and ‘tylose’, respectively. The vessel elements space is the region remaining behind after the tylose has been separated from the individual pores. These individual volumes provide an avenue to analyze the tylose structure and shed light on the structure. Consistent with current knowledge, it is observed that tylose are balloon-like structures comprised of cell walls and a detailed structure of a region containing tylose volume is shown in Fig. 4.

Segmented volume view of a region of Quercus alba. 3D visualization of Quercus alba data obtained from the XRCT scans. This volume is a cube with an edge length of 0.936 mm. The red material in the pores represents tylose, while the blue material depicts the base wood material. The cross-section cut of the rightmost pore provides an informative cross-sectional view of the tylose structure.

Image analysis and relative quantification of vessel elements and tyloses volume

In addition to a deeper qualitative understanding of the tylose structure, relative quantitative metrics can be extracted from the 3D volumes generated from the XRCT scans. The process to isolate a pore and separate the tylose structure from that pore has been described in the Methods section. Figure 5 shows the average values of various quantities for different species of oak wood material. The average volumes of vessel elements space and tylose in each oak sample are shown in Fig. 5a and b, respectively. The averages are obtained across 35 Q. alba and 33 Q. robur and Q. rubra pores. For completeness, the sum of vessel elements and tylose volumes (pore volume) is shown in Fig. 5c. Although individual pores can be quantified through high resolution, one limitation of utilizing the XRCT technique is the small sample sizes used to generate the volumes. Pores in oak samples can be longer than the size of the scanned samples. In addition, the reconstruction process results in variations within the slices along a given Cartesian axis. Although great care has been taken to minimize these effects, the slice lengths do vary between the three oak species sampled. This variation in slice length occurred along the z-axis (root-to-shoot direction). The slice length of Q. alba, Q. robur and Q. rubra is 4.2, 3.7, and 3.3 mm, respectively. The pore volumes presented in Fig. 5a–c have been divided by the slice length to allow a one-to-one comparison between the three species of oak.

Average value of the vascular tissue element parameter reveals the variability across white (alba), french(robur), and red oak (rubra). The vessel elements are space volume per slice (a), Tylose volume per slice (b), pore volume per slice (c), Tylose percent of a pore (d), and pore diameter (e). Pore volume is the summation of vessel elements space and Tylose volume, and Tylose percent of a pore is the division of Tylose volume by pore volume. All volume measurements are divided by the slice length (height of the pore) because of the differences in the slice length across the species. The average values are obtained across 35 pores for white oak and 33 pores for French and red oak. The pore diameter is approximated using the measurement tool in the analysis software Avizo. A Tukey–Kramer multiple comparison test was used to determine statistical significance (n = 33 pores; different letters denote statistically significant differences at P < 0.05; error bars indicate a standard error).

Vessel elements space volume shown in Fig. 5a shows the average deficiency of tylose in pores of the oak by species. Q. rubra has the highest vessel elements space volume, indicating that it contains the least amount of tylose. In contrast, Q. alba having the least vessel elements space volume (P = 0.0003, one-way ANOVA) suggests a high content of its tylose volume, as shown in Fig. 5b. An interesting observation is that Q. rubra has a higher tylose volume than Q. robur on average (P < 0.0001, one-way ANOVA). Still, it has a higher pore volume (P = 0.0210, one-way ANOVA), as apparent in Fig. 5c, which decreases the tylose volume percent (P < 0.0001, one-way ANOVA). (Fig. 5d). The comparison of pore diameter also shows interesting features. Both Q. alba, and Q. robur oak are similar in pore volume and pore diameter, while red oak has the largest diameter (P = 0.0402, one-way ANOVA) and pore volume (Fig. 5e). Based on the comparison, red oak holds a similar pore volume compared to the Q. alba, but it exceeds the vessel elements space and lacks in tylose volume, supporting the previous visual absence of tylose. Q. robur displays a lower quantity of tylose than Q. rubra, but it has higher tylose proportions within the pore because its pore is smaller.

The variation across each pore is shown in Fig. 6. Even though there are variations in individual pore quantities, the data appears to cluster into the three variants of white, French, and red oak wood material. The small positive linear association shows that the pore size and volume do not affect the percentage of tylose in the pore (R2 = 0.00002, 0.0022 for tylose percent by diameter and pore volume, respectively). However, vascular element parameters across oak species had significant differences (R2 = 0.2922, 0.0002, and 0.0009 for tylose percent by diameter for Q. alba, Q. robur, and Q. rubra, respectively, and R2 = 0.2729, 0.0121, and 0.0118 for tylose percent by pore volume).

Pore size affects the amount of tylose present in white (alba) Oak Data distribution of the Tylose percentage of a pore for different pore volumes per slice and diameter. Each data point here represents a pore that was analyzed. The dashed line represents the fit of each species. The data point of white (alba) oak is symbolized as a green circle, French (robur) as a blue triangle, and red (rubra) as a red diamond. Thirty-five pores of white oak and 33 pores of French and red oak are quantified in this figure.

The 3D images are also used to tease out relative qualitative differences in the densities of tylose within pores. Each pixel in the 3D image has a grayscale value that ranges from 0 to 65,535. The grayscale value is a measure of X-ray attenuation during XRCT scanning. In a porous material such as oak wood, the vessel element lumen space has lower grayscale values than the solid material (tylose and base oak wood). A grayscale range was chosen for the analysis discussed to separate the vessel element lumen space and the solid material (tyloses and base wood). This grayscale range is now further adjusted to select only the base wood or only the tylose. The grayscale ranges for tyloses and base wood of Q. alba, Q. robur, and Q. rubra are shown in Table 2. There is an overlap between the grayscale range for tylose and the base wood structure. The percentage of tylose volume that overlaps with the grayscale range of the base wood structure is also shown in Table 2. Based on the relative comparison, tyloses have a lower grayscale range compared to the base wood for all three oak variants, which indicates that the tyloses are less dense than the base wood for all three variants. The overlap in grayscale values for red oak was only 2%, while the overlap for white and French oak samples was 13% and 8%, respectively. Therefore, the difference in density between tyloses and base wood for red oak is likely to be higher than the other two oak variants. We note here that this comparison and the subsequent inferences about the densities are qualitative. Raw grayscale values cannot be compared across samples without comparison to a standard. The grayscale values of tyloses of a given wood can only be compared to its base structure, i.e., the grayscale values of tyloses for a given white oak sample can only be compared to the grayscale values of that sample. Additionally, grayscale values for the individual oak structure can only be quantitatively compared if the non-tylose structure and the corresponding tyloses have similar chemical composition. Finally, the grayscale values depend on various parameters such as voltage, current, geometry, size of the sample, etc., and are specific to the settings used in this work. Since the Mk2 HeliScan instrument is a common XRCT machine, comparative grayscale values are presented here for potential replication for future efforts.

Discussion

The Quercus genus encompasses approximately 600 diverse species distributed worldwide39. Oaks are classified as angiosperms with a well-developed vascular system comprising xylem and phloem. Within the xylem are vessel elements and tracheids, crucial for water transport in the tree. Each year, as an oak tree grows, it forms an annual growth ring composed of two distinct layers: “earlywood” and “latewood,” both of which are part of the xylem40,41. In French and American white oak, it is thought that during the transformation of sapwood into heartwood, vessel elements become filled with tyloses42,43. Heartwood is characterized by its tylose density and blocked vessels no longer conduct water4,8. Here, we examined tyloses using XRC, also referred to as microCT. The use of microCT is not new to plant tissues44 or in the use of analyzing specialized anatomical features45. Our data showed that Q. alba and then Q. robur displayed an abundance of tyloses within xylem tissue pores. Heartwood is almost exclusively used in the production of barrel staves, as sapwood is undesirable due to incomplete tylose formation and propensity of staves to display increased diffusion7,17.

In the United States several wood species, including Acacia, Ash, Chestnut, and Mulberry, can be used to make barrels, most casks are crafted from white oak46,47. Coopers have historically asserted differences in tylose content among these woods, leading to distinct methods for crafting leak-proof casks7. Our findings confirm species-specific variations in tylose content. Q. alba exhibited the highest tylose volume per pore, followed by Q. robur. By contrast, Q. rubra lacked or exhibited a low volume of tylose within xylem pores Fig. 5d. Q. robur displayed an intermediate volume of tyloses between white oak and red oak. It is unclear if these data are an artifact of sampling protocol or a standard across the species. Regardless, future work may explore whether the intermediate pore tylose content is correlated with the French cooperage tradition of splitting logs to utilize ray cells, preventing stave leakage, whereas American white oak (Q. alba) is generally quarter-sawn7,17,18.

Selecting stave-quality lumber considers several wood characteristics. These include ring density, grain angle, absence of wood imperfections, and tylose content7. The tyloses membrane is not measured and sparsely studied, but it has been hypothesized to impact the water-proofing nature of tyloses. For instance, Q. alba has a membrane that is ten times thicker than Q. robur 18,48. Our data could not measure the membrane; however, the abundance of tyloses was correlated with stave quality for cooperage. We hope to employ future studies to attempt to distinguish the membrane. Tylose are thought not to be a factor for radial diffusion through a staves7,49,50. However, tylose content will impact the stave end where it meets the barrel head to prevent end joint leaks, which occur at the chime7,49,50.

One benefit of XRCT is that it may be possible to establish a qualitative relative density value for the material in question (Table 2)51,52. Wood density values are generally reported as specific gravity, and published values indicate variation in the Q. alba and Q. rubra samples over the years53,54. A comparison between samples would not be appropriate with this experimental setup. Our results indicate that Q. alba and Q. robur likely have a reduced density in the tylose compared to the non-tylose structures in oak. In contrast, Q. rubra tylose density was similar to its base wood, which was overall lower. While these values should not be extrapolated out of context, we do believe that they may be helpful for replication of the study in the future and application of the method and may indicate a difference of density between tyloses and other elements of oak. The difference may indicate a compositional variation between the base wood and tyloses3.

Other factors, such as responses to pathogens or drought conditions, can influence the growth of tyloses8,9,10,55. This phenomenon is observed in Q. rubra, which is unsuitable for barrel production due to its lack of tyloses but accumulates tyloses after pathogen association linked to red oak wilt3,20. Tylose content is generally considered a property based on the species and the geographical location of where the tree was harvested8. The formation of tyloses is attributed to weather conditions as the sapwood becomes heartwood, as evidence indicates that drought is the signal to start formation from a decrease in turgor pressure8,15,16. These are areas for further investigation with this non-destructive method to attempt to understand tylose formation related to environmental conditions. Considering the regionality of stave quality white oak’s harvest range, one can envision a circumstance where a warming climate could impact stave quality white oak supply in the future17.

In the samples measured herein, vessel elements displayed a range of values between 190 and 420 µm Fig. 5e (n = 35). The average diameter of all vessel element was 280 µm Fig. 5e. In reviewing other works, these data are similar to prior publications19,56. It is important that we are careful in drawing conclusions from these observations. Vessel diameter in oaks have been shown to be influenced by when and where the samples are taken as well as the environmental conditions that the tree is growing in4,22,55,57,58,59,60,61,62. Results displayed herein are therefore presented as ranges and trends with more emphasis on this technique and its future use in studying various cellular structures.

Our results indicate that Q. rubra not only has fewer tyloses but also has larger vessel elements56. The result found an average of 1.7% Q. rubra vessel elements are filled with tyloses. In Q. alba, we found a vessel element filled by approximately seven-fold more tyloses (14%) than Q. rubra on a by-volume bias. Our result indicated that Q. robur had a two-fold increase in tylose (3.5%) than Q. rubra. We found in our samples that Q. alba shows the broader trend that larger vessel elements had greater tyloses fill while Q. rubra & Q. robur did show the same results Fig. 6b. This finding with Q. alba agrees with other work that has noted the phenomenon, but it should be noted that Q. alba tyloses will enlarge to fill a vessel, limiting the growth4,11. We did not see similar results in the Q. rubra & Q. robur; this finding should be replicated with the greater sample in future studies.

Using XRCT, we can visualize the tylose shape within a pore at high resolution, understand the relationship with the vessel elements, and surmise the volume of tylose fill (Fig. 3). Traditional methods of understanding tyloses and vessel elements are done by taking physical cross-sections followed by visualization or, in some studies, stains through the wood vascular tissues15,63. Using the method outlined above of XRCT, sample preparation is minimal and does not require disturbing the vessel elements56,64. Using this approach, we show in Fig. 4d that data indicates a profound difference in the tylose content between various species. XRCT increases our ability to understand tylose in oak as these structures are of economic value to the barrel industry and allow for future studies of how various processes impact oak tylose.

Data availability

All data generated during this study are included in this published article. The corresponding author can provide the reconstructed tomographic scans upon reasonable request.

References

Leśniewska, J. et al. Defense responses in aspen with altered pectin methylesterase activity reveal the hormonal inducers of tyloses. Plant Physiol. 173, 1409–1419. https://doi.org/10.1104/pp.16.01443 (2017).

Kirsch, S. The Origin and Development of Resin Canals in the Coniferae with Special Reference to the Development of Thyloses and their Correlation with the Thylosal Strands of the Pteridophytes (McGill University, 1910).

Sachs, I., Kuntz, J., Ward, J., Nair, G. & Schultz, N. Tyloses structure. Wood Fiber Sci., 259–268 (1970).

De Micco, V., Balzano, A., Wheeler, E. A. & Baas, P. Tyloses and gums: A review of structure, function and occurrence of vessel occlusions. IAWA J. 37, 186–205. https://doi.org/10.1163/22941932-20160130 (2016).

HAMPSHIRE, N. & DAKOTA, S. The Discovery of Tylose Formation by a Viennese Lady in 1845 MH Zimmerman, Harvard Forest Petersham, Massachusetts 01366 USA.

Winckler, E. Geschichte der Botanik (Literarische Anstalt, 1854).

Singleton, V. L. Maturation of wines and spirits: Comparisons, facts, and hypotheses. Am. J. Enol. Vitic. 46, 98–115 (1995).

Kozlowski, T. T. & Pallardy, S. G. (eds) Physiology of Woody Plants 2nd edn, 34–67 (Academic Press, 1997).

Yadeta, K. A. & Thomma, B. P. J. The xylem as battleground for plant hosts and vascular wilt pathogens. Front. Plant Sci. 4, 97. https://doi.org/10.3389/fpls.2013.00097 (2013).

Beckman, C. H. Host responses to vascular infection. Annu. Rev. Phytopathol. 2, 231–252 (1964).

Ellmore, G. S. & Ewers, F. W. Hydraulic conductivity in trunk xylem of elm, Ulmus americana. IAWA J. 6, 303–307 (1985).

Pearce, R. B. & Holloway, P. J. Suberin in the sapwood of oak (Quercus robur L.): Its composition from a compartmentalization barrier and its occurrence in tyloses in undecayed wood. Physiol. Plant Pathol. 24, 71–81. https://doi.org/10.1016/0048-4059(84)90075-4 (1984).

Dufraisse, A., Coubray, S., Girardclos, O., Dupin, A. & Lemoine, M. Contribution of tyloses quantification in earlywood oak vessels to archaeological charcoal analyses: Estimation of a minimum age and influences of physiological and environmental factors. Quat. Int. 463, 250–257. https://doi.org/10.1016/j.quaint.2017.03.070 (2018).

Gerry, E. Tyloses: Their occurrence and practical significance in some American woods. J. Agree. Res. (1914).

Murmanis, L. Formation of tyloses in felled Quercus rubra L.. Wood Sci. Technol. 9, 3–14. https://doi.org/10.1007/BF00351911 (1975).

Koran, Z. Ultrastructure of tyloses and a theory of their growth mechanism. (State University of New York College of Environmental Science and Forestry, 1964).

Gollihue, J., Pook, V. G. & DeBolt, S. Sources of variation in bourbon whiskey barrels: A review. J. Inst. Brew. 127, 210–223. https://doi.org/10.1002/jib.660 (2021).

del Alamo-Sanza, M. & Nevares, I. Oak wine barrel as an active vessel: A critical review of past and current knowledge. Crit. Rev. Food Sci. Nutr. 58, 2711–2726. https://doi.org/10.1080/10408398.2017.1330250 (2018).

Schahinger, G. & Rankine, B. C. Cooperage for Winemakers: A Manual on the Construction, Maintenance and Use of Oak Barrels (Ryan Publications, 1992).

Vansteenkiste, D., De Boever, L. & Van Acker, J. Alternative processing solutions for red oak (Quercus rubra) from converted forests in Flanders, Belgium (Universität für Bodenkultur Wien, 2005).

Mosedale, J. Effects of oak wood on the maturation of alcoholic beverages with particular reference to whisky. Forestry 3, 203. https://doi.org/10.1093/forestry/68.3.203 (1995).

Leal, S., Melvin, T. M., Grabner, M., Wimmer, R. & Briffa, K. R. Tree-ring growth variability in the Austrian Alps: The influence of site, altitude, tree species and climate. Boreas 36, 426–440 (2007).

Wei, Q., Leblon, B. & Larocque, A. On the use of X-ray computed tomography for determining wood properties: A review 1. Can. J. For. Res. 41, 2120–2140. https://doi.org/10.1139/x11-111 (2011).

Maggiolo, D. et al. Particle based method and X-ray computed tomography for pore-scale flow characterization in VRFB electrodes. Energy Storage Mater. 16, 91–96. https://doi.org/10.1016/j.ensm.2018.04.021 (2019).

Withers, P. J. et al. X-ray computed tomography. Nat. Rev. Methods Prim. 1, 18. https://doi.org/10.1038/s43586-021-00015-4 (2021).

Panerai, F. et al. Micro-tomography based analysis of thermal conductivity, diffusivity and oxidation behavior of rigid and flexible fibrous insulators. Int. J. Heat Mass Transf. 108, 801–811. https://doi.org/10.1016/j.ijheatmasstransfer.2016.12.048 (2017).

Mohan Ramu, V. B., Chacon, L., Brewer, C. & Poovathingal, S. J. Development of a supervised learning model to predict permeability of porous carbon composites. AIAA J. 61, 843–858. https://doi.org/10.2514/1.J062265 (2023).

Poovathingal, S., Stern, E. C., Nompelis, I., Schwartzentruber, T. E. & Candler, G. V. Nonequilibrium flow through porous thermal protection materials, Part II: Oxidation and pyrolysis. J. Comput. Phys. 380, 427–441. https://doi.org/10.1016/j.jcp.2018.02.043 (2019).

Rawson, S. D., Maksimcuka, J., Withers, P. J. & Cartmell, S. H. X-ray computed tomography in life sciences. BMC Biol. 18, 21. https://doi.org/10.1186/s12915-020-0753-2 (2020).

Van den Bulcke, J. et al. 3D tree-ring analysis using helical X-ray tomography. Dendrochronologia 32, 39–46. https://doi.org/10.1016/j.dendro.2013.07.001 (2014).

Ligne, L. D. et al. Studying the spatio-temporal dynamics of wood decay with X-ray CT scanning. Holzforschung 76, 408–420. https://doi.org/10.1515/hf-2021-0167 (2022).

Hermanek, P., Zanini, F. & Carmignato, S. Traceable porosity measurements in industrial components using X-Ray computed tomography. J. Manuf. Sci. Eng. https://doi.org/10.1115/1.4043192 (2019).

Ingel, B. et al. Revisiting the source of wilt symptoms: X-Ray microcomputed tomography provides direct evidence that ralstonia biomass clogs xylem vessels. PhytoFrontiers™ 2, 41–51. https://doi.org/10.1094/phytofr-06-21-0041-r (2022).

Arabatti, R. Watching wood dry. Physics 13, 182 (2020).

Ballesteros-Cánovas, J. A., Stoffel, M. & Guardiola-Albert, C. XRCT images and variograms reveal 3D changes in wood density of riparian trees affected by floods. Trees 29, 1115–1126 (2015).

Cloetens, P. et al. Observation of microstructure and damage in materials by phase sensitive radiography and tomography. J. Appl. Phys. 81, 5878–5886. https://doi.org/10.1063/1.364374 (1997).

Paganin, D., Mayo, S. C., Gureyev, T. E., Miller, P. R. & Wilkins, S. W. Simultaneous phase and amplitude extraction from a single defocused image of a homogeneous object. J. Microsc. 206, 33–40. https://doi.org/10.1046/j.1365-2818.2002.01010.x (2002).

Schindelin, J. et al. Fiji: An open-source platform for biological-image analysis. Nat. Methods 9, 676–682. https://doi.org/10.1038/nmeth.2019 (2012).

Denk, T., Grimm, G. W., Manos, P. S., Deng, M. & Hipp, A. An updated infrageneric classification of the oaks: review of previous taxonomic schemes and synthesis of evolutionary patterns. bioRxiv, 168146 (2017). https://doi.org/10.1101/168146

Feuillat, F. & Keller, R. Variability of oak wood (Quercus robur L., Quercus petraea Liebl.) anatomy relating to cask properties. Am. J. Enol. Vitic. 48, 502–508. https://doi.org/10.5344/ajev.1997.48.4.502 (1997).

Evert, R. F. & Eichhorn, S. E. Esau’s Plant Anatomy: Meristems, Cells, and Tissues of the Plant Body: Their Structure, Function, and Development 3rd edn. (Wiley, 2006).

Mosedale, J. R. & Puech, J. L. In Encyclopedia of Food Sciences and Nutrition 2nd edn (ed. Caballero, B.) 393–403 (Academic Press, 2003).

Taylor, A. M., Gartner, B. L. & Morrell, J. J. Heartwood formation and natural durability-a review. Wood. Fiber Sci. (2002).

Steppe, K. et al. Use of X-ray computed microtomography for non-invasive determination of wood anatomical characteristics. J. Struct. Biol. 148, 11–21. https://doi.org/10.1016/j.jsb.2004.05.001 (2004).

Stelzner, J., Million, S., Stelzner, I., Nelle, O. & Banck-Burgess, J. Micro-computed tomography for the identification and characterization of archaeological lime bark. Sci. Rep. 13, 6458. https://doi.org/10.1038/s41598-023-33633-x (2023).

Wolstenholme, A. G. In Distilled Spirits (eds Hill, A. & Jack, F.) 1–36 (Academic Press, 2023).

Tao, Y., García, J. F. & Sun, D.-W. Advances in wine aging technologies for enhancing wine quality and accelerating wine aging process. Crit. Rev. Food Sci. Nutr. 54, 817–835. https://doi.org/10.1080/10408398.2011.609949 (2014).

Chatonnet, P. & Dubourdieu, D. Comparative study of the characteristics of american white oak (Quercus alba) and European oak; Quercus petraea and Q. robur) for production of barrels used in barrel aging of wines. Am. J. Enol. Vitic. 49, 79–85. https://doi.org/10.5344/ajev.1998.49.1.79 (1998).

Conner, J. In Whisky 2nd edn (eds Russell, I. & Stewart, G.) 199–220 (Academic Press, 2014).

Schahinger, G. & Rankine, B. C. Cooperage for Winemakers: A Manual on the Construction, Maintenance and Use of Oak Barrels (Winetitles, 2005).

Burch, S. Measurement of density variations in compacted parts using X-ray computerised tomography. Metal Powder Rep. 57, 24–28. https://doi.org/10.1016/S0026-0657(02)85009-3 (2002).

Babout, L., Marrow, T., Mummery, P. & Withers, P. Mapping the evolution of density in 3D of thermally oxidised graphite for nuclear applications. Scr. Mater. 54, 829–834. https://doi.org/10.1016/j.scriptamat.2005.11.028 (2006).

Carmona, M., Seale, R. & Nistal França, F. J. Physical and mechanical properties of clear wood from red oak and white oak. Bioresources 15, 4960–4971. https://doi.org/10.15376/biores.15.3.4960-4971 (2020).

Rink, G. & McBride, F. D. Variation in 15-year-old Quercus robur L. and Quercus alba L. heartwood luminance and specific gravity. Ann. For. Sci. 50, 430s–434s (1993).

Corcuera, L., Camarero, J. J. & Gil-Pelegrín, E. Effects of a severe drought on growth and wood anatomical properties of Quercus faginea. IAWA J. 25, 185–204. https://doi.org/10.1163/22941932-90000360 (2004).

Cochard, H. & Tyree, M. T. Xylem dysfunction in Quercus: Vessel sizes, tyloses, cavitation and seasonal changes in embolism. Tree Physiol. 6, 393–407. https://doi.org/10.1093/treephys/6.4.393 (1990).

Castagneri, D., Regev, L., Boaretto, E. & Carrer, M. Xylem anatomical traits reveal different strategies of two Mediterranean oaks to cope with drought and warming. Environ. Exp. Bot. 133, 128–138. https://doi.org/10.1016/j.envexpbot.2016.10.009 (2017).

Galle, A., Esper, J., Feller, U., Ribas-Carbo, M. & Fonti, P. Responses of wood anatomy and carbon isotope composition of Quercus pubescens saplings subjected to two consecutive years of summer drought. Ann. For. Sci. 67, 809. https://doi.org/10.1051/forest/2010045 (2010).

Gea-Izquierdo, G. et al. Xylem hydraulic adjustment and growth response of Quercus canariensis Willd. to climatic variability. Tree Physiol. 32, 401–413. https://doi.org/10.1093/treephys/tps026 (2012).

Hacke, U. G., Spicer, R., Schreiber, S. G. & Plavcová, L. An ecophysiological and developmental perspective on variation in vessel diameter. Plant Cell Environ. 40, 831–845. https://doi.org/10.1111/pce.12777 (2017).

Pérez-de-Lis, G., Rozas, V., Vázquez-Ruiz, R. A. & García-González, I. Do ring-porous oaks prioritize earlywood vessel efficiency over safety? Environmental effects on vessel diameter and tyloses formation. Agric. For. Meteorol. 248, 205–214. https://doi.org/10.1016/j.agrformet.2017.09.022 (2018).

Vander Mijnsbrugge, K., Turcsán, A., Erdélyi, É. & Beeckman, H. Drought treated seedlings of Quercus petraea (Matt.) Liebl., Q. robur L. and their morphological intermediates show differential radial growth and wood anatomical traits. Forests 11, 250 (2020).

Feng, Z., Wang, J., Rößler, R., Kerp, H. & Wei, H.-B. Complete tylosis formation in a latest Permian conifer stem. Ann. Bot. 111, 1075–1081. https://doi.org/10.1093/aob/mct060 (2013).

Kim, M., Chang, Y., Kang, J., Lee, J. & Eom, C. Presence of tyloses in 6 Korean oak species for production of liquor barrels and correlation of retention of large vessel lumen. Bioresources 17, 1364–1372. https://doi.org/10.15376/biores.17.1.1364-1372 (2022).

Acknowledgements

We thank Beam Suntory Inc. for supporting this research. We thank the Wood Utilization Center of the University of Kentucky Forestry Department for providing a Northern red oak wood sample for analysis. This work was performed in part at the U.K. Electron Microscopy Center, a member of the National Nanotechnology Coordinated Infrastructure (NNCI), which is supported by the National Science Foundation (NNCI- 2025075). The authors are grateful to Dr. Nicolas Briot for fruitful discussions. We herein confirm that the study was performed in accordance with relevant institutional, national, and international guidelines and legislation relative to the IUCN Policy Statement on Research Involving Species at Risk of Extinction and the Convention on the Trade in Endangered Species of Wild Fauna and Flora.

Author information

Authors and Affiliations

Contributions

SJP, JG, and SD conceived the study. DK performed all the imaging and data generation. DK and JG performed the analysis of the data. DK, JG, and SJP wrote the manuscript. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Kim, D., Gollihue, J., Poovathingal, S.J. et al. Detailed three-dimensional analyses of tyloses in oak used for bourbon and wine barrels through X-ray computed tomography. Sci Rep 14, 17044 (2024). https://doi.org/10.1038/s41598-024-67298-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-67298-x

- Springer Nature Limited