Abstract

Through tests and micro-observations, the static and dynamic mechanical properties and microstructure of rubber concrete samples modified with varying amounts of silica fume and polypropylene fiber content were explored. The results indicate that incorporation of silica fume and polypropylene fiber can effectively enhance the performance of rubber concrete. Moreover, at 10% and 0.1% of silica fume and polypropylene fiber content respectively, rubber concrete’s compressive strength, splitting tensile strength, flexural strength, and dynamic compressive strength reached maxima. Furthermore, microstructure characteristic analysis indicated that inadequate adhesion between rubber particles and the matrix is responsible for compromised bearing capacity in unmodified rubber concrete. However, with the addition of silica fume and polypropylene fiber, the fiber binds the rubber particles closely with the matrix, while the silica fume fills the gaps between the matrix components. This combination results in rubber concrete with a denser internal structure and enhances its bearing capacity significantly.

Similar content being viewed by others

Introduction

Concrete is a critical pillar of civil construction, transportation, and water conservancy projects; however, concrete relies heavily on gravel and sand aggregates typically obtained through environmentally destructive methods including excavations of mountains and dredging of riverbeds1. Mass extraction of these aggregates not only depletes natural resources but also degrades affected parts of the environment2. As a consequence, finding sustainable alternatives to sand and stone aggregates is crucial to the long-term sustainable development of the concrete industry. In a similar but parallel vein, finding environmentally safe methods to handle “black pollution” or waste rubber from end-of-use tires is also a global concern, needing urgent and effective solutions3. One potential solution proposed is the use of rubber particles from waste tires as a replacement for traditional concrete aggregates. Concrete created using this approach, or rubber concrete, not only addresses black pollution from industrial waste residue but also reduces over-exploitation of sandstone resources. Moreover, compared to conventional concrete, rubber concrete offers superior performance in sound absorption4, heat insulation5, impermeability6, frost resistance7, and shock absorption8. However, the addition of rubber particles to concrete does come with a trade-off, it reduces the compressive and flexural strength of concrete9. To mitigate this negative impact, research has focused on finding additives that can enhance the mechanical properties of rubber concrete.

Silica fume has a relatively small particle size, and the potential to reduce the porosity and increase the density and thus compressive strength of concrete matrixes. Silica fume further exhibits strong pozzolanic activity, reacting with Ca(OH)2 generated by cement hydration to form a C–S–H gel. This process effectively repairs surface cracks that can result from the use of coarse aggregates and enhances the interfacial bonding strength (or adhesion) in concrete10. Consequently, numerous scholars have conducted extensive research examining the properties of silica fume-reinforced concrete. Salehi et al.11 examined the relationship between varying silica fume content and concrete failure modes. It was observed that as silica fume content increased from 0 to 5%, the initial fracture energy of the concrete matrix increased by 19%, while fracture toughness increased by 14%. Zhang et al.12 further established that when other conditions are held constant, silica fume introduction can improve both porosity and micro-defects in concrete. Further notable, the strength of the interfacial transition zone is enhanced in silica fume-reinforced concrete.

Polypropylene fiber addition can enhance the bearing capacity and toughness of concrete by effectively inhibiting the formation and expansion of internal cracks. However, it has little effect on concrete’s compressive strength. Therefore, improving the performance of polypropylene fiber-modified concrete to achieve both high strength and high toughness has become a pivotal research focus. Notably, Yoo et al.13 initiated the exploration of polypropylene fiber-reinforced concrete and found that the integration of polypropylene and other synthetic fibers contributed to the enhancement of cement matrix strength, particularly in terms of material impact resistance. Makita et al.14 further established that polypropylene fiber significantly enhances the impact resistance and residual ductility of concrete. But Wang et al.15 study conducted with polypropylene fiber volume content (0%, 0.05%, 0.10%, 0.15%) as the primary variable indicated that polypropylene fiber did not significantly improve the compressive strength of concrete, although it did enhance the final failure state.

Numerous intriguing results have been reported regarding improving the compressive and flexural strength of rubber concrete through various means including the addition of additives. Of note, Agrawal et al.16 found the use of NaOH pretreatment methods with 20 mm long rubber fibers enhanced the tensile strength of rubber concrete by approximately 10%. Youssf et al.17 discovered that 2 h of pre-treatment of the rubber at 200 °C played a crucial role in improving impact resistance of rubber concrete when substituting 40% to 80% of traditional concrete aggregate content with heat-treated rubber. Further, they found the utilization of water magnetized for 24 h increased the compressive strength by 50%. Abdal et al.18 found employing two types of fibers enhanced the mechanical properties of rubber concrete at a fiber dosage of 15 kg/m3. However, these novel methods are associated with high costs and complex processes. Moreover, although Su et al.19 mitigated the strength reduction of rubber concrete under various high temperatures through the addition of basalt and polypropylene fibers, they did not investigate the microstructure of rubber concrete under the influence of fibers to identify the strengthening mechanism.

At present, numerous studies have been conducted in China to investigate the impact of single-doped silica fume or polypropylene fiber on the mechanical properties of rubber concrete. However, research combining the advantages of both dopants and investigating their comprehensive mechanical properties remains limited. To address this gap, this paper aims to systematically investigate rubber concrete and its silica fume and polypropylene fiber modified specimens. In particular, it focuses on studying the static and dynamic mechanical properties of double-doped silica fume and polypropylene fiber modified rubber concrete. Furthermore, it analyzes the strengthening mechanism of silica fume and polypropylene fiber at the micro level. Ultimately, this study aims to provide a theoretical basis for the production of high-strength, high-toughness rubber concrete.

Test

Materials

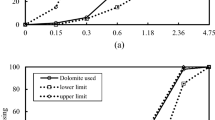

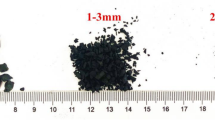

The P.O 42.5 grade normal Portland cement serves as the binder. The coarse aggregate consists of gravel with a particle size ranging from 5 to 15 mm, while the fine aggregate is river sand with an apparent density of 2410 kg/m3 and a fineness modulus of 2.6. The rubber particles have a particle size of 20 mesh and an apparent density of 950 kg/m3. The polypropylene fiber measures 12 mm in length and has a density of 910 kg/m3. The silica fume is a white powder containing approximately 98% silicon with an average particle size of 0.1–0.2 μm, and the specific surface area was approximately 30.6 m2/g. In addition, the silica fume also contains 0.4% Al2O3 and 0.6% CaO. The water reducing agent is a polycarboxylate superplasticizer, and regular tap water is used.

Mix proportion and specimens preparation

Utilizing C40 concrete as a base material, in accordance with JGJ55-2011. Many studies have shown that when the rubber content reaches 20%, the strength of concrete will significantly decrease, but it still falls within an acceptable range20,21. In addition, it is only when there is a notable decrease in the strength of rubber concrete that the use of silica fume and fiber reinforcement becomes more meaningful. Therefore, in this study, 20 mesh rubber particles were used to replace 20% of the fine aggregate in equal volume22.

The study also incorporated silica fume replacing 0% and 10% of the cement in equal volume. Polypropylene fiber was mixed into the concrete with volume fractions of 0%, 0.05%, 0.1%, 0.15%, and 0.2% for mechanical property testing and microscopic examination23. The abbreviations C and SC represent normal concrete and silica fume concrete, respectively, while PRC and SPRC represent polypropylene fiber rubber concrete and silica fume polypropylene fiber rubber concrete, respectively. The test encompassed a total of 12 groups, as shown in Table 1.

To conduct tests on compressive, splitting tensile, flexural, and impact performance, the following specimens were prepared: The cube specimen with a size of 100 mm, cuboid specimens measuring 400 mm in length, 100 mm in width, and 100 mm in height, and a cylindrical specimen with a diameter of 50 mm and a height of 25 mm. Each group consisted of twelve specimens, resulting in a total of 12 groups.

Experimental design

Static test

This experiment utilizes the WAW-1000 electro-hydraulic servo universal testing machine to conduct compression, tension, and flexural strength tests on rubber concrete and its modified specimens. The loading is stopped when the stress–strain curve begins to stabilize, with loading speeds of 1 mm/min, 1 mm/min, and 0.5 mm/min, respectively. The loading method and strength calculation diagram are shown in Fig. 1. Among them, the static compression, tension, and flexural strength tests are conducted to analyze the process of slow deformation in structures such as buildings, tunnels, coal mines, and so on.

Dynamic test

Aiming at the problem of dynamic damage caused by rock burst, earthquake and explosion, the SHPB (Split Hopkinson Pressure Bar) device was used to conduct the dynamic compressive tests on rubber concrete specimens with varying polypropylene fiber contents (0%, 0.05%, 0.1%, 0.15%, 0.2%) and different silica fume contents (0%, 10%), all under a consistent air pressure of 0.3 MPa (The strain rate is 34 s−1). The objective was to analyze the compressive strength and failure mode characteristics of silica fume fiber rubber concrete under impact conditions. The test device and schematic diagram are shown in Fig. 2. The rod is a high alloy steel with an elastic modulus of 210GPa and a wave velocity of 5190 m/s. Prior to testing, precise adjustments were made to ensure the impact bar, incident bar, and transmission bar were aligned on the same horizontal plane. To minimize end face friction, Vaseline was applied to both the specimen's surface and the bars24,25. During the test, high-pressure nitrogen propelled the punch at a specific velocity against the incident bar, converting its kinetic energy into incident energy. This energy, transmitted to the specimen in the form of waves, resulted in partial conversion into reflected energy stored within the reflected wave. Additionally, a portion was stored in the transmitted wave and absorbed by the energy-absorbing device, while the remainder was predominantly absorbed by the specimen, contributing to the formation of new cracks26. Test data was gathered by collecting pulse signals through strain gauges positioned on both the incident and transmission bars. These pulse signals were then converted into strain signals by the strain testing system. From these readings, stress and strain values were calculated using Formula (1).

In the formula, σ and ε represent the stress and strain of the specimen, respectively. E, A and C represent the elastic modulus, cross-sectional area, and wave velocity of the compression bar, respectively. As and Ls stand for the initial cross-sectional area and initial length of the specimen, respectively. εi, εr and εt represent the incident strain, reflection strain, and transmission strain, respectively.

The dynamic compressive strength of the specimen is tested with the Split Hopkinson Pressure Bar (SHPB) device. During the impact test loading process, whether the stress at both ends of the specimen can achieve balance determines the reliability of the test results27, so it is necessary to verify the stress balance. The degree of dispersion between the sum of the incident wave and the reflected wave and the transmitted wave curve can reflect the stress balance state of the combined specimen during the loading process. As can be seen from Fig. 3, the two curves fit well, so the stress balance at both ends of the specimen can be satisfied.

Microstructure

In scanning electron microscopy (SEM) test, scanning electron beam was used to excite physical signals from the sample surface and modulate the imaging, so that the microscopic three-dimensional morphology of the sample can be obtained. The concrete in the core area of compressive test specimen was cut into slices with the size of 6 mm × 6 mm × 4 mm. After drying the slices, the microstructure was studied by using FlexSEM1000 scanning electron microscope produced by Hitachi, Japan.

Test results and analysis

Compressive strength test

Stress–strain curves

Concrete members are primarily subjected to compression, making compressive strength the most fundamental mechanical performance indicator of concrete. Figure 4 depicts the stress–strain curves for normal concrete (C), silica fume concrete (SC), polypropylene fiber rubber concrete (PRC), and silica fume polypropylene fiber-modified rubber concrete (SPRC) in a compressive strength test. It is evident that silica fume and fiber exert distinct effects on the failure process of concrete.

The impact of various fiber contents on the compressive strength of concrete is presented in Fig. 5. The cube compressive strength of normal concrete C, silica fume concrete SC, rubber concrete PRC-1, polypropylene fiber rubber concrete PRC-3 and mixed silica fume, polypropylene fiber modified rubber concrete SPRC-3 are 38.32 MPa, 45.23 MPa, 32.59 MPa, 36.17 MPa and 41.11 MPa, respectively. Notably, the compressive strength of silica fume concrete SC is 18% higher than that of normal concrete after the addition of 10% silica fume. This increase is attributed to the small particle size of silica fume, which effectively fills the gaps within normal concrete and enhances the compactness of its internal structure, thereby elevating the compressive strength of the specimen28,29.

The compressive strength of the specimen decreased significantly with the incorporation of rubber particles, registering a 15% reduction compared to normal concrete. This decrease can be attributed to the inherent characteristics of rubber particles, which possess low strength and high elasticity30. Additionally, the adhesion between the rubber particles and the concrete matrix was poor, when rubber particles are mixed with concrete as fine aggregate, the specimen exhibits reduced compressive strength31,32. However, upon the addition of 0.1% fiber, the compressive strength of specimen PRC-3 increased by 11% compared to PRC-1. This observation indicates that the randomly distributed fiber plays a reinforcing role, effectively hindering the expansion of internal cracks and thereby enhancing the strength of the specimen33,34.

Figure 5 evident that the addition of fiber enhances the compressive strength of concrete. When no fiber is present (0% fiber content), the compressive strength of PRC-1 is 32.59 MPa. However, with increasing fiber content of 0.05%, 0.1%, 0.15%, and 0.2%, the compressive strength of the specimens increases by 7.00%, 10.98%, 9.91%, and 7.58%, respectively. It is noteworthy that the compressive strength initially increases with the fiber content but subsequently decreases, beginning to decline when the fiber content exceeds 0.10%. This trend can be attributed to two primary reasons. Firstly, excessive fibers cannot be evenly distributed within the concrete, resulting in clusters of fibers. These clusters create larger gaps within the concrete structure, leading to stress concentration and damage at these weak points during compression35. Secondly, the larger gaps reduce the overall compactness of the concrete, thus reducing its compressive strength36. Under identical fiber contents, the compressive strength of SPRC concrete is significantly higher than that of PRC after the addition of silica fume. Notably, when the polypropylene fiber content is 0.1%, the compressive strength of the specimen increases by 13.99%. This improvement can be attributed to the Pozzolanic activity of silica fume and the filling effect of fine particles, both of which enhance the compactness of the specimen's structure37.

Failure modes

In the compressive strength test of concrete, a fine crack parallel to the stress direction emerged in the middle of the surface of the normal concrete specimen. As the stress intensified, the specimen expanded towards the unstressed surface, and some of the concrete on the surface began to detach. Examination of the detachment site revealed a significant number of concrete aggregates exposed, indicating more prominent internal cracks. As the load increased, specimen deformation grew, the number of cracks multiplied, and the width expanded. When the load exceeded the ultimate limit, the specimen emitted a violent noise, with serious concrete aggregate detachment in a wedge-shaped pattern. This indicated a clear brittle failure, as exemplified in Fig. 6a. In contrast, when rubber concrete was subject to destruction, the sound generated was much lower than that of normal concrete. Although specimen detachment was not significant, when pressure reached the ultimate load, its bearing capacity plummeted. The number of cracks on the rubber concrete specimen's surface correspondingly increased, as displayed in Fig. 6b.

By introducing fiber into rubber concrete, the deformation and surface cracks of the specimen are significantly improved. The specimen's anti-deformation capacity is noticeably enhanced, with a reduced number of surface cracks and significantly narrower widths. As the load increases, the specimen's surface transitions from the previously described wide crack to multiple fine cracks. When the ultimate load is reached, the surface cracks do not penetrate, reducing the area of concrete block detachment and enhancing specimen integrity, as displayed in Fig. 6c. When silica fume and fiber are mixed, cracks begin to appear in the upper part of the specimen. As the load increases, the number of cracks gradually increases and extends to the lower part of the specimen until the ultimate load is reached. Surface concrete debris detaches to a lesser extent, as shown in Fig. 6d.

The distinct failure modes of the aforementioned concrete specimens are primarily attributed to the introduction of rubber particles which exhibit low strength but high elasticity into the concrete. This enhances the specimens' toughness. The fibers, which are randomly distributed in three dimensions within the concrete, form a network structure that impedes crack expansion and improves both the strength and ductility of the specimens33. Additionally, silica fume contributes its pozzolanic activity and fine particle filling effect, enhancing the structural compactness of the specimen32,37.

Splitting tensile strength test

Test results and analysis

The splitting tensile strength of concrete is presented in Fig. 7. The specimens C, SC, PRC-1, PRC-3, and SPRC-3 exhibit splitting tensile strengths of 2.43 MPa, 3.04 MPa, 2.21 MPa, 2.67 MPa, and 3.38 MPa, respectively. Analysis reveals that the addition of silica fume enhances the splitting tensile strength of the specimen. Notably, the splitting tensile strength of SC is 25.1% higher than that of specimen C. However, incorporating rubber particles into the concrete reduces the splitting tensile strength of PRC-1 by 9.05% compared to specimen C. This decrease is primarily due to the increased presence of weak bonding surfaces and weak points within the concrete, reducing the effective area available for bearing tensile stress within the matrix and thus diminishing the splitting tensile strength of the specimen. The addition of fiber significantly improves the splitting tensile strength of the specimen. On this basis, when silica fume is added to specimens containing fiber, the splitting tensile strength is further enhanced. In particular, the specimens SC, PRC-3, and SPRC-3 exhibit splitting tensile strengths that are 9.88%, 39.09%, and 39.09% higher than those of normal concrete C, respectively. These findings indicate that compared to single-doped fibers, the combination of silica fume and fibers is more effective in enhancing the splitting tensile properties of the specimens.

Figure 8 shows the impact of varying fiber content on the splitting tensile strength of concrete. As the figure reveals, the splitting tensile strength of rubber concrete PRC-1 without fiber is 2.21 MPa. However, when 0.05%, 0.1%, 0.15%, and 0.2% fibers are introduced, the splitting tensile strength of the cube increases by 11.31%, 20.81%, 14.93%, and 8.14% respectively. This suggests that the inclusion of a specific amount of fiber significantly enhances the splitting tensile strength of rubber concrete, among them, when the fiber content is 0.1%, the improvement effect is the most obvious. However, beyond this content, the splitting tensile strength of each group of rubber concrete begins to decrease. This decline may be attributed to excessive fiber content in rubber concrete, where fiber agglomeration fails to provide reinforcement35.

The addition of silica fume to specimen PRC has a significant impact on SPRC's splitting tensile strength. On a macroscopic level, fibers are randomly distributed within the concrete, immediately blocking cracks as they encounter adjacent fibers. This prevents cracks from expanding and extending, thereby enhancing the splitting tensile strength of concrete. On a microscopic scale, the introduction of silica fume into the matrix reacts to form a new gel, improving the weak interface introduced by rubber’s addition. Additionally, the filling effect of fine particles reduces the number of pores in the specimen and enhances the compactness of the rubber concrete specimen, greatly enhancing its splitting tensile strength38.

Failure modes

Figure 9 shows the failure mode of concrete splitting tensile test. After the test commenced, specimen C exhibited cracks on its surface quickly under the applied load. These cracks rapidly propagated vertically, ultimately traversing the entire specimen. At this point, a loud sound of damage was heard, and the load promptly decreased to zero, resulting in a wide crack visible in Fig. 9a. Upon the inclusion of rubber particles, the specimen's damage sound was noticeably reduced compared to normal concrete. The specimen's surface cracks were numerous and smaller, as shown in Fig. 9b. This phenomenon occurred because the rubber particles were evenly distributed within the concrete, mitigating stress concentration at the crack tips. During loading, these particles converted macro cracks in the matrix into numerous micro cracks, thereby reducing stress concentrations within the concrete's pores.

When polypropylene fiber was added, numerous microcracks appeared on the specimen's surface during the loading process. As the load increased, the length and width of these cracks expanded. When peak stress was reached, penetrating cracks formed, yet the specimen retained its integrity, as seen in Fig. 9c. This indicates that adding polypropylene fiber enhances the splitting tensile strength of rubber concrete. When silica fume and fiber were mixed, the specimen exhibited more cracks on its surface with narrower widths. The test duration was longer, and no visible through cracks appeared until failure39, as shown in Fig. 9d.

Tension–compression ratio

The ratio of splitting tensile strength to compressive strength serves as a crucial metric for assessing the brittleness of concrete materials40. A higher tension–compression ratio indicates reduced brittleness and enhanced toughness in the specimen. Figure 10 illustrates the variation curve of the concrete tension–compression ratio as the varying content of polypropylene fiber. Notably, the tension–compression ratio for PRC-1 is 0.0678, while that of C is 0.0634. The incorporation of rubber particles does improve the brittleness of concrete to some extent, albeit with a reduction in strength. Building on PRC-1, the addition of 0.05%, 0.1%, 0.15%, and 0.2% polypropylene fibers results in tension–compression ratios of 0.0705, 0.0738, 0.0709, and 0.0682, respectively. It shows that the introduction of fibers not only bolsters the strength of rubber concrete but also enhances its toughness. When compared to PRC, the tension–compression ratio of SPRC experiences further improvement. This finding suggests that the combination of silica fume and polypropylene fiber is more effective in elevating the tension–compression ratio of rubber concrete than the use of polypropylene fiber alone41,42.

Flexural strength test

Test results and analysis

The flexural strength values for various types of concrete are presented in Fig. 11. Specifically, the flexural strengths for specimens C, SC, PRC-1, PRC-3, and SPRC-3 measure 4.83 MPa, 5.81 MPa, 4.29 MPa, 5.12 MPa, and 5.97 MPa, respectively. Notably, the addition of silica fume alone enhances the flexural strength of normal concrete. In fact, the flexural strength of SC is 20.29% higher than that of C, likely due to silica fume's filling effect, which improves concrete compactness. However, when rubber particles are introduced into normal concrete, as seen in PRC-1, the flexural strength decreases by 11.18%. This decrease is attributed to the physical and mechanical properties of rubber, which create weaker bonding points within the concrete and reduce its effective bending area43.

Fortunately, the addition of fibers to rubber concrete significantly improves flexural strength, as seen in the PRC-3 specimen. Furthermore, the inclusion of silica fume on this basis further elevates the flexural strength. Compared to PRC-1, the flexural strengths of PRC-3 and SPRC-3 specimens increase by 19.34% and 39.16%, respectively. These findings underscore the effectiveness of silica fume in enhancing the flexural strength of concrete44.

Figure 12 demonstrates the impact of various polypropylene fiber contents on the flexural strength of concrete. As the fiber content increases from 0.05 to 0.1%, the flexural strength of PRC specimens initially increases, increased by 12.35% and 19.35% respectively. However, further increases in fiber content to 0.15% and 0.2% result in a reduction of the flexural strength enhancement effect, achieving only 16.08% and 13.29% growth, respectively. This suggests that an excessive fiber content can negate the positive effects on PRC's flexural strength. When compared to PRC, the flexural strengths of SPRC-1, SPRC-2, SPRC-3, SPRC-4, and SPRC-5 exhibit greater improvement under identical fiber content conditions. Their flexural strengths increase by 13.05%, 16.39%, 16.60%, 13.86%, and 13.79%, respectively. This underscores the remarkable enhancing effect of silica fume on the performance of the interfacial transition zone, matrix density, and bonding between aggregate, cement matrix, and fiber45.

Failure modes

The failure mode in the flexural test of concrete is presented in Fig. 13. As the load is gradually applied, specimen C emits a noticeable sound, yet there are no visible changes on its surface. As the load approaches the ultimate load, the sound generated by the specimen's force gradually intensifies. When the ultimate load is reached, the load decreases sharply along with a loud and destructive sound, indicating a brittle fracture, as shown in Fig. 13a. When rubber particles are added to normal concrete, the sound emitted by PRC-1 diminishes, but the number of cracks increases, as displayed in Fig. 13b.

With the addition of fibers, PRC-3 exhibits numerous small cracks at the bottom early in the test, which then expand to the upper part. The specimen maintains ductility until its ultimate failure, as seen in Fig. 13c. Upon incorporating silica fume, the specimen initially shows no cracks. However, as stress increases, cracks appear at the bottom and gradually expand upward. When peak stress is reached, the cracks do not penetrate the specimen, indicating a ductile failure, as shown in Fig. 13d.

Flexural-compression ratio

The ratio of flexural strength to compressive strength serves as a crucial indicator of concrete materials' ductility and crack resistance. A higher flexural-compression ratio signifies lower brittleness and superior toughness46. Figure 14 illustrates the flexural-compression ratio's variation with polypropylene fiber content. As the fiber content rises, the flexural-compression ratio initially increases and then subsequently declines. At 0% fiber volume content, the PRC flexural-compression ratio stands at 0.132, while SPRC's is 0.134. When the fiber volume content reaches 0.1%, the maximum PRC flexural-compression ratio jumps to 0.142, a 7.58% increase from its initial value, and SPRC's maximum flexural-compression ratio surges to 0.145, representing an 8.21% increase from its initial value. These findings suggest that polypropylene fiber enhances concrete's ductility and crack resistance. Moreover, under identical fiber content conditions, SPRC's flexural-compression ratio consistently outperforms PRC's. This advantage can be attributed to polypropylene fiber's ability to minimize internal crack formation and enhance concrete's toughness and tensile strength47. However, excessive fiber incorporation can undermine concrete's strength, emphasizing the importance of optimal fiber content for enhancing the flexural-compression ratio48.

Dynamic mechanical test

Impact test results and analysis

Figure 15 displays the stress–strain curve of each group of specimens under impact loading.

As Fig. 15 shows, the stress–strain curves share a similar shape. As the fiber volume content increases, the initial elastic modulus, peak stress, and peak strain initially rise and then decline. At a fiber volume content of 0.1%, the three factors reach the maximum values. With the same fiber content, the ascending segment of the stress–strain curve's shape of specimens remains consistent, whereas the descending segment exhibits notable different. The addition of silica fume enhances the initial elastic modulus, peak stress, and peak strain of SPRC compared to PRC49. Moreover, the descending section is smoother, indicating that silica fume's modification of PRC results in SPRC achieving superior deformation capacity and ductility performance50.

The dynamic compressive strengths of specimens C, SC, PRC-1, PRC-3, and SPRC-3 are 46.93 MPa, 56.85 MPa, 40.84 MPa, 50.6 MPa, and 58.61 MPa, respectively. Notably, the introduction of rubber particles led to a significant decrease in the dynamic compressive strength of the specimen, registering a 12.98% drop compared to C. Conversely, the addition of silica fume boosted the dynamic compressive strength of SC by 21.24% compared to C. When incorporating polypropylene fiber, the dynamic compressive strength of PRC-3 surged by 23.9% compared to PRC-1. Finally, under the combined influence of silica fume and polypropylene fiber, the dynamic compressive strength of SPRC-3 outperformed PRC-3 by 15.8%.

The impact of varying fiber content on the dynamic compressive strength of concrete is further illustrated in Fig. 16. As the fiber volume content increases, the dynamic compressive strength of PRC and SPRC initially rises and then declines. At a fiber volume content of 0.1%, PRC-3 attains a dynamic compressive strength of 50.6 MPa, representing a 23.9% improvement over PRC-1. Similarly, SPRC-3 reaches a maximum dynamic compressive strength of 58.61 MPa, surpassing SPRC-1 by 25.8%. SPRC consistently exhibits a higher dynamic compressive strength than PRC when the fiber volume content is the same. This is primarily due to silica fume's ability to fill and mend cracks and microcracks in concrete, thereby enhancing the performance of the interfacial transition zone51.

Failure modes

When exposed to impact load, the degree of rupture and debris characteristics (number and size) of rubber concrete vary depending on the silica fume and polypropylene fiber content. These changes can be observed from various perspectives, as illustrated in Fig. 17

During dynamic compression, as impact kinetic energy is continuously released, cracks propagate until they penetrate the specimen, ultimately leading to its complete destruction. In normal concrete, initial microcracks are predominantly found at the interface between the cement mortar and aggregate. Upon impact, these microcracks do not have sufficient time to expand along the path of least resistance, instead, they propagate directly through the aggregate, resulting in macroscopic cracks52. Consequently, normal concrete specimens exhibit crush damage. When rubber particles are added, as seen in Fig. 17b, the excellent elastic deformation characteristics of rubber particles improve the crushing condition of the specimen compared to normal concrete, leading to a more complete failure mode.

When rubber concrete is reinforced with fibers, the fiber's reinforcement capability slows down the crack's propagation speed, allowing it to follow the weakest link within the concrete. Consequently, numerous cracks appear on the specimen's surface, and small amounts of debris detach, as shown in Fig. 17c–e. When the fiber content is low, the load on the crack is reduced, and during the debonding process, the load on the polypropylene fiber is substantial. As the fiber content increases, the tensile capacity of individual fibers gradually diminishes until they can no longer reach their yield limit. When the fiber content exceeds a certain amount, the bonding force between fibers and other factors result in an increase of weak layers within the concrete, leading to a decrease in concrete strength and ultimately leads to the more brittle matrix at the section, as seen in the failure diagram of PRC-5. Therefore, when the polypropylene fiber content is 0.10%, such as in PRC-3, specimen failure is favorable. By adding a certain amount of silica fume, the impact resistance of rubber concrete specimens can be further optimized. This addition significantly reduces the number of fragments resulting from impact damage, as shown in Fig. 17f.

Dynamic increase factor

The dynamic increase factor (DIF) is the ratio of dynamic strength to static strength of concrete, serving as a fundamental parameter that characterizes the dynamic properties of materials53. Figure 18 shows the relationship between DIF and various fiber contents. As the figure suggests, as fiber content increases, DIF initially rises and then subsequently declines. When the fiber volume content is 0.10%, the DIF reaches its maximum value. This observation might be attributed to the impact of fiber content on crack development path and expansion degree. Based on this, when the rubber content is 20%, the optimal dosage of polypropylene fiber is 0.1%. Furthermore, under identical fiber content conditions, the DIF of SPRC specimens surpasses that of PRC. With the increase in fiber content, the DIF value of SPRC specimens increases by 3.20%, 1.47%, 2.14%, 2.21%, and 3.01% respectively compared to PRC, indicating that the integration of silica fume enhances the internal structure of concrete and improves the strain rate sensitivity of concrete materials.

In addition, under similar strain rates, the DIF54 of concrete with a high fiber content (4.55 kg/m3) is similar to the DIF of SPRC with 0.91 kg/m3 (0.1% dosage) of fibers in this study, which suggests that the addition of silica fume and rubber has a significant effect on enhancing the DIF.

Microstructure analysis

Effect of rubber on the microstructure of concrete

Figure 19 shows the SEM images of rubber concrete at a magnification of 1000 times. Through a detailed examination of PRC-1, it is evident that the cracks in the transition zone of rubber concrete are more pronounced. This is primarily due to the hydrophobic nature of rubber, which exhibits inferior water retention compared to sand. When rubber particles are incorporated into concrete, it results in the formation of numerous pores. Consequently, PRC-1 exhibits numerous cracks and experiences a corresponding reduction in strength. Additionally, the inclusion of rubber particles slows down the hydration reaction in concrete, leading to conspicuous cracks in the transition zone55. Because of rubber's poor water retention characteristics, PRC-1 experiences an increase in water loss during the hydration reaction, which limits the water requirement for the hydration process and results in a comparatively loose internal structure of the specimen during testing. The hydrophobicity of rubber also prevents hydration reactions from occurring on its surface. Consequently, stress is often concentrated near cracks close to the specimen, ultimately compromising the bearing capacity of concrete. When compared to normal concrete, PRC-1 exhibits reduced compressive strength, splitting tensile strength, and flexural strength.

Effect of silica fume on the microstructure of concrete

To analyze the microscopic morphology of concrete specimens with silica fume content of 0% and 10%, both were magnified by 1000 times. As displayed in Fig. 20a, there is a significant presence of needle-shaped ettringite crystals in the microstructure, with insufficient C–S–H gel filling between the crystals, leading to notable gaps. Conversely, Fig. 20b reveals an improved microstructure compactness in the specimen. It is noteworthy that there is no substantial accumulation of Ca(OH)2 crystals and the needle-shaped crystals are well-encapsulated by C–S–H gel. The primary reason for these observations lies in the surface effects and small size effects of silica fume. These properties enable it to participate in the hydration reaction of concrete, releasing heat and promoting further reactions56. Additionally, it effectively fills the pores between cement pastes, enhancing matrix compactness. Furthermore, silica fume exhibits strong pozzolanic activity, reacting with Ca(OH)2 produced by cement hydration to form C–S–H gel. This process not only repairs surface cracks in coarse aggregates but also enhances interfacial bonding strength, thereby improving mechanical properties56.

Effect of polypropylene fiber on the microstructure of concrete

From the 1000 times magnification of the interface between the polypropylene fiber and the matrix in Fig. 21, it is evident that the fiber exhibits a flat appearance, uneven surface, and visible friction marks. These characteristics arise due to the fiber's involvement in tensile forces. Prior to concrete solidification, fibers are typically evenly distributed in a network within the concrete. This arrangement supports the settlement of coarse and fine aggregates, effectively mitigating surface cracks. Fibers act as barriers against concrete's post-hardening autogenous shrinkage, diminishing microcrack tensile deformation. Consequently, stress concentration at microcrack tips is reduced. When concrete sustains damage, fibers distributed at microcrack tips dissipate energy physically, preventing microcrack formation and propagation. This leads to an enhancement of concrete's internal structure. However, as fiber content increases, randomly distributed fibers within concrete bear a portion of the stress, leading to tensile deformation. This reduces concrete's autogenous shrinkage and transfers shrinkage-generated energy to individual fiber monofilaments. This transfer weakens the fibers' reinforcing effect. Similarly, large fiber dosages can cause 'fiber agglomeration' within the internal structure, increasing porosity and weakening the matrix's compactness and cohesiveness. This ultimately diminishes concrete's macroscopic strength57.

Effect of silica fume-polypropylene fiber interaction on the microstructure of concrete

The microstructure of rubber concrete specimens modified with silica fume and polypropylene fibers is vividly illustrated in Fig. 22. This figure reveals that silica fume, owing to its smaller particle size, effectively fills smaller pores. Consequently, it enhances the adhesion between the polypropylene fiber and the rubber concrete matrix, resulting in improved compactness of the rubber concrete. Additionally, silica fume, characterized by its high specific surface area, reacts swiftly with Ca(OH)2 to generate hydration heat. This heat facilitates the hydration of cement, leading to an increased production of hydration products, thereby augmenting the concrete's strength. When subjected to a load, the specimen's supportive skeleton structure composed of randomly distributed fibers within the concrete, collaborates with the silica fume. This combination effectively hinders the formation and propagation of cracks, thereby enhancing the mechanical properties of the concrete58. Hence, an optimal blend of silica fume and polypropylene fibers can significantly mitigate the occurrence and progression of cracks in rubber concrete. This also elevates the mechanical properties of rubber concrete, providing a robust foundation for the production of high-strength, high-toughness rubber concrete.

Conclusion

-

(1)

Both normal concrete and rubber concrete exhibited significant aggregate fracturing after failure, and the specimens were unable to maintain integrity. Upon the addition of polypropylene fibers, although numerous cracks appear on the specimen surface, only a few fragments detach, demonstrating more ductile failure characteristics.

-

(2)

As the polypropylene fiber content increased, the compressive strength, splitting tensile strength, and flexural strength of the specimens initially increased and then decreased. At a fiber content of 0.1%, all three strength parameters reached their maximum values, offering an increase of 11%, 20.8%, and 19.3% respectively compared to rubber concrete without polypropylene fiber modification. Furthermore, the incorporation of 10% silica fume to concrete with a polypropylene fiber content of 0.1% significantly enhanced the mechanical properties of the specimens, leading to improvements of 13.7%, 26.6%, and 16.6% in the three strength parameters compared to the specimens without silica fume.

-

(3)

In dynamic compression tests, with constant silica fume content, the dynamic compressive strength of the specimens initially increased and then decreased as the fiber content increased. Notably, when the silica fume and polypropylene fiber contents of the rubber concrete were 10% and 0.1% respectively, the dynamic compressive strength of the silica fume-polypropylene rubber concrete reached its maximum value of 58.61 MPa.

-

(4)

SEM analysis revealed that polypropylene fibers randomly distributed three-dimensionally to form a skeleton structure within the concrete. Meanwhile, the silica fume filled the pores between the cement paste, reducing matrix porosity. Additionally, it reacts with Ca(OH)2 produced during cement hydration to form C–S–H gel, further repairing cracks on the surface of coarse aggregates. These synergistic effects contribute to a more dense concrete structure and greater adhesion.

Data availability

The datasets used and/or analyzed during the current study available from the corresponding author on reasonable request.

References

Nedeljković, M., Visser, J., Šavija, B., Valcke, S. & Schlangen, E. Use of fine recycled concrete aggregates in concrete: A critical review. J. Build. Eng. 38, 102196. https://doi.org/10.1016/j.jobe.2021.102196 (2021).

Wang, B., Yan, L., Fu, Q. & Kasal, B. A comprehensive review on recycled aggregate and recycled aggregate concrete. Resour. Conserv. Recycl. 171, 105565. https://doi.org/10.1016/j.resconrec.2021.105565 (2021).

Karunarathna, S., Linforth, S., Kashani, A., Liu, X. & Ngo, T. Effect of recycled rubber aggregate size on fracture and other mechanical properties of structural concrete. J. Clean. Prod. 314, 128230. https://doi.org/10.1016/j.jclepro.2021.128230 (2021).

Sukontasukkul, P. Use of crumb rubber to improve thermal and sound properties of pre-cast concrete panel. Constr. Build. Mater. 23(2), 1084–1092. https://doi.org/10.1016/j.conbuildmat.2008.05.021 (2009).

Bala, A. & Gupta, S. Thermal resistivity, sound absorption and vibration damping of concrete composite doped with waste tire Rubber: A review. Constr. Build. Mater. 299, 123939. https://doi.org/10.1016/j.conbuildmat.2021.123939 (2021).

Bu, C. et al. Research progress on rubber concrete properties: A review. J. Rubber Res. 25(2), 105–125. https://doi.org/10.1007/s42464-022-00161-8 (2022).

Gao, X., Yang, J., Zhu, H. & Xu, J. Estimation of rubberized concrete frost resistance using machine learning techniques. Constr. Build. Mater. 371, 130778. https://doi.org/10.1016/j.conbuildmat.2023.130778 (2023).

Ismail, M. K. & Hassan, A. A. A. Impact resistance and acoustic absorption capacity of self-consolidating rubberized concrete. ACI Mater. J. https://doi.org/10.14359/51689359 (2016).

Feng, W. et al. Experimental study on the effect of strain rates on the dynamic flexural properties of rubber concrete. Constr. Build. Mater. 224, 408–419. https://doi.org/10.1016/j.conbuildmat.2019.07.084 (2019).

Gupta, T., Chaudhary, S. & Sharma, R. K. Mechanical and durability properties of waste rubber fiber concrete with and without silica fume. J. Clean. Prod. 112, 702–711. https://doi.org/10.1016/j.jclepro.2015.07.081 (2016).

Salehi, H. & Mazloom, M. Opposite effects of ground granulated blast-furnace slag and silica fume on the fracture behavior of self-compacting lightweight concrete. Constr. Build. Mater. 222, 622–632. https://doi.org/10.1016/j.conbuildmat.2019.06.183 (2019).

Zhang, M. H. & Islam, J. Use of nano-silica to reduce setting time and increase early strength of concretes with high volumes of fly ash or slag. Constr. Build. Mater. 29, 573–580. https://doi.org/10.1016/j.conbuildmat.2011.11.013 (2012).

Yoo, D. Y. & Banthia, N. Impact resistance of fiber-reinforced concrete: A review. Cement Concr. Compos. 104, 103389. https://doi.org/10.1016/j.cemconcomp.2019.103389 (2019).

Makita, K. et al. Drop-weight test for RC frame made of polypropylene fiber-reinforced concrete. J. Adv. Concr. Technol. 16(1), 36–45. https://doi.org/10.3151/jact.16.36 (2018).

Wang, D., Ju, Y., Shen, H. & Xu, L. Mechanical properties of high performance concrete reinforced with basalt fiber and polypropylene fiber. Constr. Build. Mater. 197, 464–473. https://doi.org/10.1016/j.conbuildmat.2018.11.181 (2019).

Agrawal, D. et al. Experimental effect of pre-treatment of rubber fibers on mechanical properties of rubberized concrete. J. Market. Res. 23, 791–807. https://doi.org/10.1016/j.jmrt.2023.01.027 (2023).

Youssf, O., Swilam, A. & Tahwia, A. M. Performance of crumb rubber concrete made with high contents of heat pre-treated rubber and magnetized water. J. Market. Res. 23, 2160–2176. https://doi.org/10.1016/j.jmrt.2023.01.146 (2023).

Abdal, Q. I. & Noaman, A. T. Effect of combination between hybrid fibers and rubber aggregate on rheological and mechanical properties of self-compacting concrete. Constr. Build. Mater. 414, 135038. https://doi.org/10.1016/j.conbuildmat.2024.135038 (2024).

Su, Q. & Xu, J. Durability and mechanical properties of rubber concrete incorporating basalt and polypropylene fibers: Experimental evaluation at elevated temperatures. Constr. Build. Mater. 368, 130445. https://doi.org/10.1016/j.conbuildmat.2023.130445 (2023).

Youssf, O. et al. Development of crumb rubber concrete for practical application in the residential construction sector: Design and processing. Constr. Build. Mater. 260, 119813. https://doi.org/10.1016/j.conbuildmat.2020.119813 (2020).

Yasser, N., Abdelrahman, A., Kohail, M. & Moustafa, A. Experimental investigation of durability properties of rubberized concrete. Ain Shams Eng. J. 14, 102111. https://doi.org/10.1016/j.asej.2022.102111 (2023).

Ren, F., Mo, J., Wang, Q. & Ho, J. C. M. Crumb rubber as partial replacement for fine aggregate in concrete: An overview. Constr. Build. Mater. 343, 128049. https://doi.org/10.1016/j.conbuildmat.2022.128049 (2022).

Wang, L. et al. The influence of fiber type and length on the cracking resistance, durability and pore structure of face slab concrete. Constr. Build. Mater. 282, 122706. https://doi.org/10.1016/j.conbuildmat.2021.122706 (2021).

Ganorkar, K., Goel, M. D. & Chakraborty, T. Dynamic Strength Enhancement of Concrete in Split Hopkinson Pressure Bar Test. Composite Materials 175–181 (CRC Press, 2023). https://doi.org/10.1201/9781003352358-16.

Feng, W. et al. Structural effects and real strain-rate effects on compressive strength of sustainable concrete with crumb rubber in split Hopkinson pressure bar tests. Arch. Civil Mech. Eng. https://doi.org/10.1007/s43452-022-00457-x (2022).

Chen, L., Zhang, X. & Liu, G. Analysis of dynamic mechanical properties of sprayed fiber-reinforced concrete based on the energy conversion principle. Constr. Build. Mater. 254, 119167. https://doi.org/10.1016/j.conbuildmat.2020.119167 (2020).

Yan, Z., Dai, F., Zhu, J. & Xu, Y. Dynamic cracking behaviors and energy evolution of multi-flawed rocks under static pre-compression. Rock Mech. Rock Eng. 54, 5117–5139. https://doi.org/10.1007/s00603-021-02564-2 (2021).

Oyunbileg, D., Amgalan, J., Batbaatar, T. & Temuujin, J. Evaluation of thermal and freeze-thaw resistances of the concretes with the silica fume addition at different water-cement ratio. Case Stud. Constr. Mater. 19, e02633. https://doi.org/10.1016/j.cscm.2023.e02633 (2023).

Demie, S., Nuruddin, M. F. & Shafiq, N. Effects of micro-structure characteristics of interfacial transition zone on the compressive strength of self-compacting geopolymer concrete. Constr. Build. Mater. 41, 91–98. https://doi.org/10.1016/j.conbuildmat.2012.11.067 (2013).

Abdelmonem, A., El-Feky, M. S., Nasr, E. S. A. R. & Kohail, M. Performance of high strength concrete containing recycled rubber. Constr. Build. Mater. 227, 116660. https://doi.org/10.1016/j.conbuildmat.2019.08.041 (2019).

Zheng, L., Sharon Huo, X. & Yuan, Y. Experimental investigation on dynamic properties of rubberized concrete. Constr. Build. Mater. 22, 939–947. https://doi.org/10.1016/j.conbuildmat.2007.03.005 (2008).

Dou, Y. et al. Modification of rubber particles and its application in rubberized concrete. J. Build. Eng. 51, 104346. https://doi.org/10.1016/j.jobe.2022.104346 (2022).

Li, Z. et al. Influence of basalt fiber and polypropylene fiber on the mechanical and durability properties of cement-based composite materials. J. Build. Eng. 90, 109335. https://doi.org/10.1016/j.jobe.2024.109335 (2024).

Cao, S. et al. CT scanning of internal crack mechanism and strength behavior of cement-fiber-tailings matrix composites. Cement Concr. Compos. 116, 103865. https://doi.org/10.1016/j.cemconcomp.2020.103865 (2021).

Wang, Y., Nejati, F., Edalatpanah, S. A. & Goudarzi Karim, R. Experimental study to compare the strength of concrete with different amounts of polypropylene fibers at high temperatures. Sci. Rep. https://doi.org/10.1038/s41598-024-59084-6 (2024).

Cui, Y., Wang, L., Liu, J., Liu, R. & Pang, B. Impact of particle size of fly ash on the early compressive strength of concrete: Experimental investigation and modelling. Constr. Build. Mater. 323, 126444. https://doi.org/10.1016/j.conbuildmat.2022.126444 (2022).

Sanjuán, M. Á., Argiz, C., Gálvez, J. C. & Moragues, A. Effect of silica fume fineness on the improvement of Portland cement strength performance. Constr. Build. Mater. 96, 55–64. https://doi.org/10.1016/j.conbuildmat.2015.07.092 (2015).

Valizadeh, A., Hamidi, F., Aslani, F. & Shaikh, F. U. A. The effect of specimen geometry on the compressive and tensile strengths of self-compacting rubberised concrete containing waste rubber granules. Structures. 27, 1646–1659. https://doi.org/10.1016/j.istruc.2020.07.069 (2020).

Xu, J., Fu, Z., Han, Q., Lacidogna, G. & Carpinteri, A. Micro-cracking monitoring and fracture evaluation for crumb rubber concrete based on acoustic emission techniques. Struct. Health Monit. 17(4), 946–958. https://doi.org/10.1177/1475921717730538 (2017).

Geng, K. et al. Exploring the brittleness and fractal characteristics of basalt fiber reinforced concrete under impact load based on the principle of energy dissipation. Mater. Struct. https://doi.org/10.1617/s11527-022-01891-2 (2022).

Mostofinejad, D., Aghamohammadi, O., Bahmani, H. & Ebrahimi, S. Improving thermal characteristics and energy absorption of concrete by recycled rubber and silica fume. Dev. Built Environ. 16, 100221. https://doi.org/10.1016/j.dibe.2023.100221 (2023).

Gupta, T., Sharma, R. K. & Chaudhary, S. Impact resistance of concrete containing waste rubber fiber and silica fume. Int. J. Impact Eng. 83, 76–87. https://doi.org/10.1016/j.ijimpeng.2015.05.002 (2015).

Gesoglu, M., Güneyisi, E., Hansu, O., İpek, S. & Asaad, D. S. Influence of waste rubber utilization on the fracture and steel–concrete bond strength properties of concrete. Constr. Build. Mater. 101, 1113–1121. https://doi.org/10.1016/j.conbuildmat.2015.10.030 (2015).

Ashokan, A., Rajendran, S. & Dhairiyasamy, R. A comprehensive study on enhancing of the mechanical properties of steel fiber-reinforced concrete through nano-silica integration. Sci. Rep. https://doi.org/10.1038/s41598-023-47475-0 (2023).

Zhao, Y. et al. Synergistic effect of silica fume and ultra-fine glass microsphere on macro properties and hydration of coarse-aggregate UHPC. Constr. Build. Mater. 408, 133695. https://doi.org/10.1016/j.conbuildmat.2023.133695 (2023).

Yang, L. et al. Preparation, performance test and microanalysis of hybrid fibers and microexpansive high-performance shaft lining concrete. Constr. Build. Mater. 223, 431–440. https://doi.org/10.1016/j.conbuildmat.2019.06.230 (2019).

Ahmad, J. et al. A review on failure modes and cracking behaviors of polypropylene fibers reinforced concrete. Buildings. 12(11), 1951. https://doi.org/10.3390/buildings12111951 (2022).

Balcikanli Bankir, M. & Sevim, U. K. Performance optimization of hybrid fiber concrete according to mechanical properties. Constr. Build. Mater. 261, 119952. https://doi.org/10.1016/j.conbuildmat.2020.119952 (2020).

Lai, D., Demartino, C. & Xiao, Y. High-strain rate compressive behavior of fiber-reinforced rubberized concrete. Constr. Build. Mater. 319, 125739. https://doi.org/10.1016/j.conbuildmat.2021.125739 (2022).

Lai, D., Demartino, C. & Xiao, Y. High-strain rate tension behavior of fiber-reinforced rubberized concrete. Cement Concr. Compos. 131, 104554. https://doi.org/10.1016/j.cemconcomp.2022.104554 (2022).

Li, H., Tu, H. & Weng, Y. Correction to: Investigation on the quasi-static mechanical properties and dynamic compressive behaviors of ultra-high performance concrete with crumbed rubber powders. Mater. Struct. https://doi.org/10.1617/s11527-022-01962-4 (2022).

Demirhan, S. et al. Impact behaviour of nanomodified deflection-hardening fibre-reinforced concretes. Mag. Concr. Res. 72(17), 865–887. https://doi.org/10.1680/jmacr.18.00541 (2020).

Fan, H., Yu, H. & Ma, H. Dynamic increase factor(DIF) of concrete with SHPB tests: Review and systematic analysis. J. Build. Eng. 79, 107666. https://doi.org/10.1016/j.jobe.2023.107666 (2023).

Zhang, B. et al. Effects of fibres on ultra-lightweight high strength concrete: Dynamic behaviour and microstructures. Cement Concr. Compos. 128, 104417. https://doi.org/10.1016/j.cemconcomp.2022.104417 (2022).

Chen, Z., Li, L. & Xiong, Z. Investigation on the interfacial behaviour between the rubber-cement matrix of the rubberized concrete. J. Clean. Prod. 209, 1354–1364. https://doi.org/10.1016/j.jclepro.2018.10.305 (2019).

Copetti, C. M., Borges, P. M., Squiavon, J. Z., da Silva, S. R. & de Oliveira Andrade, J. J. Evaluation of tire rubber surface pre-treatment and silica fume on physical-mechanical behavior and microstructural properties of concrete. J. Clean. Prod. 256, 120670. https://doi.org/10.1016/j.jclepro.2020.120670 (2020).

Zhou, M. et al. Mechanical properties and microstructure of ITZs in steel and polypropylene hybrid fiber-reinforced concrete. Constr. Build. Mater. 415, 135119. https://doi.org/10.1016/j.conbuildmat.2024.135119 (2024).

Abna, A. & Mazloom, M. Flexural properties of fiber reinforced concrete containing silica fume and nano-silica. Mater. Lett. 316, 132003. https://doi.org/10.1016/j.matlet.2022.132003 (2022).

Author information

Authors and Affiliations

Contributions

Chenyue Han: Conceptualization, Methodology, Writing-Original draft preparation. Jianyong Pang: Writing-review & editing, Supervision. Shi Hu: Resources, Writing-review & editing, Supervision. Chunchun Yang: Resources, Writing-review & editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Han, C., Pang, J., Hu, S. et al. Study on static and dynamic mechanical properties and microstructure of silica fume-polypropylene fiber modified rubber concrete. Sci Rep 14, 12573 (2024). https://doi.org/10.1038/s41598-024-63341-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-63341-z

- Springer Nature Limited