Abstract

ZnO based piezoelectric nanogenerators (PENG) hold immense potential for harvesting ambient vibrational mechanical energy into electrical energy, offering sustainable solutions in the field of self-powered sensors, wearable electronics, human–machine interactions etc. In this study, we have developed flexible ZnO-based PENGs by incorporating ZnO microparticles into PDMS matrix, with ZnO concentration ranging from 5 to 25 wt%. Among these, the PENG containing 15 wt% ZnO exhibited the best performance with an open-circuit output voltage/short-circuit current of ~ 42.4 V/2.4 µA. To further enhance the output performance of PENG, p-type NiO was interfaced with ZnO in a bulk hetero-junction geometry. The concentration of NiO was varied from 5 to 20 wt% with respect to ZnO and incorporated into the PDMS matrix to fabricate the PENGs. The PENG containing 10 wt% NiO exhibits the best performance with an open-circuit output voltage/short-circuit current of ~ 65 V/4.1 µA under loading conditions of 30 N and 4 Hz. The PENG exhibiting the best performance demonstrates a maximum instantaneous output power density ~ 37.9 µW/cm2 across a load resistance of 20 MΩ under loading conditions of 30 N and 4 Hz, with a power density per unit force and Hertz of about ~ 0.32 µW/cm2·N·Hz. The enhanced output performance of the PENG is attributed to the reduction in free electron concentration, which suppresses the internal screening effect of the piezopotential. To assess the practical utility of the optimized PENG, we tested the powering capability by charging various commercial capacitors and used the stored energy to illuminate 10 LEDs and to power a stopwatch displays. This work not only presents a straightforward, cost-effective, and scalable technique for enhancing the output performance of ZnO-based PENGs but also sheds light on its underlying mechanism.

Similar content being viewed by others

Introduction

Piezoelectric nanogenerators (PENG) have attracted significant attention owing to the advancements in low power electronics and the increasing demand for portable devices. PENGs have emerged as a potential candidate in many self-powered applications, such as self-powered UV detection, gas sensing, biomedical devices, footstep counting, and environmental monitoring1,2,3,4,5,6. In addition, the need for frequent replacing/recharging and disposal issue of bulky batteries used in sensors has prompted researchers to explore self-powering alternatives.

Several materials have been investigated for the fabrication of PENGs such as BaTiO3, MoS2, ZnO, PVDF, PZT, LiNbO3, AlN, KNbO3 and PMN-PT etc.7,8,9,10,11,12,13,14,15,16. Among them ZnO has been chosen due to its lead-free, semiconducting, biocompatible, low-cost and well established growth techniques. However, the screening of piezoelectric voltage due to the presence of free electrons in ZnO limits its effective utilization in the fabrication of PENG17,18. Due to the presence of oxygen vacancies and zinc interstitials ZnO act like a n-type semiconductor. Many approaches have been opted to neutralize the excess electrons in ZnO which screens the piezoelectric potential such as doping, plasma treatment, annealing, fabrication of thin film based p–n junction and bulk interfacing of p and n type of material etc.9,19,20,21,22,23.The utilization of plasma treatment, annealing and doping techniques in enhancing the output characteristics of PENGs is hindered by the reversible effects induced by plasma treatment or annealing24 and the reliance on toxic and expensive dopants.

The fabrication of heterojunctions and p-n junctions holds significant technological importance for enhancing performance of semiconductor in various devices, such as semiconductor lasers, LEDs, photodetectors, and solar cells25. There are reports based on p–n junction heterojunction in PENGs to reduce the free electron induced screening of piezopotential and thereby enhancing its output characteristics, though extensive studies in this direction are scarcely available. Similar works were reported in the case of ZnO by interfacing with p-type organic and inorganic materials such as Spiro-MeOTAD, P3HT:PCBM, PEDOT:PSS, Cu2O, CuO, NiO and CuI etc.21,23,26,27,28,29,30. The organic p-type materials have demonstrated enhanced charge transfer properties but their practical implementation is hindered by there inherent instability, high cost, susceptibility to contamination, and large band gaps31,32. In order to circumvent these issues, interfacing ZnO with more stable and cost-effective inorganic p-type semiconductors emerged as a plausible alternative. Conventionally, thin-film based p-n junctions were fabricated using expensive deposition techniques such as atomic layer deposition, sputtering, pulsed layer deposition, and metal organic chemical vapor deposition. However, the bulk interfacing of p and n materials facilitates intimate mixing, thereby enhancing the interface area by formation of numerous p-n interfaces within a single layer33. The bulk-interfaced p–n junction can be deposited via simple synthesis routes on large-area flexible substrates at low temperature34, thereby reducing fabrication costs and enhancing scalability. Therefore, we have adopted this straightforward, cost-effective, and scalable approach involving the bulk interfacing of inorganic p-type NiO and n-type ZnO to ameliorate the output characteristics of PENGs.

In this work, p-type NiO was chosen to form bulk heterojunction with ZnO due to its cost-effectiveness and high hole concentration. The PENG with 15 wt% concentration of ZnO in PDMS demonstrated the best output performance with open-circuit output voltage/short-circuit current values of ~ 42.4 V/2.4 µA. To further enhance the output performance of PENG, various bulk heterojunctions of NiO and 15 wt% concentration of ZnO in PDMS were fabricated. Among them the PENG with 10 wt% NiO concentration exhibits best output performance with open-circuit output voltage/short-circuit current values ~ 65 V/ 4.1 µA. The enhancement in output performance of PENG was due to the reduced screening effect of piezopotential due to free electrons. Powering capability of the fabricated PENG was demonstrated by charging various commercial capacitors and finally the stored energy in capacitor was used to power 10 LEDs and stopwatch display.

Experimental section

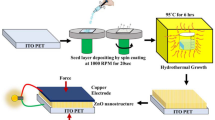

The high purity (99.9995%) ZnO and NiO to fabricate the PENGs. ZnO was annealed at 550 ºC for 3 h in oxygen ambient, since it is already reported that PENG fabricated using annealed ZnO shows higher output as compared to non-annealed ZnO9. Annealed ZnO was finely grounded for 30 min using mortar pestle to avoid agglomeration. NiO was grounded with ZnO using mortar pestle to interface n-type ZnO and p-type NiO in bulk form. To fabricate ZnO- PENG, ZnO with different concentrations from 5 to 25 wt% was incorporated into PDMS matrix thoroughly using continuous magnetic stirring for 30 min. The prepared ZnO:PDMS composite was spin coated at 650 rpm for 45 s over the flexible ITO coated PET substrate. The deposited ZnO:PDMS composites were dried at 75 °C for 3 h inside oven. The final PENG devices were fabricated with sandwich device configuration PET/ITO/ZnO:PDMS/ITO/PET, which was realized by mechanically integrating the ITO coated PET over ZnO:PDMS composite surface. In case of ZnO-NiO based PENG the entire procedure of fabrication is same with NiO concentration varied from 5 to 20 wt% with respect to ZnO. The final connections were taken from the top and bottom electrodes of the device.

The ZnO and NiO structural analysis was conducted via X-ray diffraction, utilizing Cu-Kα radiation with a wavelength of 1.5405 Å. The morphological details were investigated using a field emission scanning electron microscope (FESEM) with a JEOL JSM-7610 F. Vibrational modes were investigated using Raman spectroscopy with a micro-Raman spectrometer (STR) fitted with a 532 nm argon-ion laser source operating at 2.5 mW power and a 50X magnification objective lens. Photoluminescence measurements were carried out using a 30 mW He–Cd laser operating at 325 nm as an excitation source. Luminescence data were collected and detected using a spectrometer (Triax 550, Jobin Yvon, France) connected to a CCD detector (Andor, UK). Electrical measurements were carried out utilizing a Keithley 2636B source measure unit. Furthermore, the characterization of the piezoelectric nanogenerator was performed using a linear motor with controlled force and frequency. The output characteristics of the piezoelectric nanogenerator were measured across a Lecroy oscilloscope (Waverunner 8104) and a Stanford low-noise current pre-amplifier (SRS-SR570) for voltage and current measurement, respectively.

Results and discussions

Figure 1a shows the x-ray diffraction pattern (XRD) of ZnO which exhibits hexagonal wurtzite structure of ZnO (P63mc)35. Figure 1b illustrates the XRD pattern of NiO exhibiting cubic rock salt crystal structure with space group (Fm-3 m)36. Both the materials show sharp characteristics peak which exhibits the high crystallinity of the materials.

Figure 1c–e shows the Raman spectra of ZnO, NiO and ZnO-NiO interfaced samples, respectively. The Raman spectra of ZnO shows five Raman peaks at 330 cm−1, 382 cm−1, 438 cm−1, 530 cm−1 and 580 cm−1. The peak at 330 cm−1 shows multiphonon progression associated with E2high–E2low second-order vibration mode37. The peaks at 382 cm−1 and 438 cm−1 represent the A1TO mode and the E2high optical mode vibrations respectively which show the hexagonal wurtzite phase of ZnO with high crystallinity38. The two minor peaks at 530 cm−1 and 580 cm−1 were assigned to A1LO and E1LO vibrational modes39.The Raman spectra of NiO exhibit five distinct combinations of longitudinal optical (LO), transverse optical (TO), and magnon vibrational modes detected at frequencies of 476 cm−1, 724 cm−1, 904 cm−1, 1087 cm−1, and 1419 cm−140. These modes correspond to the one-phonon 1 TO mode, the two-phonon 2 TO mode, the combination of LO and TO vibrational modes (LO + TO), two LO mode vibrational modes, and a two-magnon mode (2 M)40,41,42.The Raman spectra of the ZnO-NiO interfaced sample exhibits peaks that corresponds to ZnO and NiO, eliminates the possibility of Ni doping within ZnO or change in the chemical composition. These findings suggest the formation of possible interface between n-type ZnO and p-type NiO which leads to the neutralization of excess electrons in ZnO, resulting in a lowering of screening effect tending to the enhancement in the piezoelectric potential.

Figure 2a shows the SEM image of annealed ZnO microparticles, with particle sizes ranging from 1 to 5 µm. The size of ZnO microparticles were advantageous for establishing multiple interfaces with NiO nanoparticles, given the nano-dimensions of NiO. The rice-like morphology of the NiO nanoparticles is shown in Fig. 2b. Figure 2c displays the SEM image of the ZnO-NiO interfaced sample, illustrating the formation of multiple interfaces resulting from the grinding of NiO nanoparticles with ZnO microparticles, where the smaller NiO nanoparticles adhere to the larger ZnO microparticles. Figure S2a in supplementary material shows the statistical distribution of size of ZnO-NiO bulk heterojunction particles ranging from 1.26 to 6.035 µm, with an average particle size of 2.14 µm. Figure S2b in supplementary material shows the cross-sectional image of ZnO15/NiO10:PDMS which shows the uniform distribution of particles inside the PDMS matrix. To verify the chemical composition of these nanoparticles, an elemental analysis was performed on an area of the ZnO-NiO interfaced sample, as shown in Fig. 2d. Figure 2e,f exhibits the elemental maps of Ni and Zn, respectively, confirming the presence of NiO and ZnO in the sample. The elemental mapping clearly indicates that the nanoparticles correspond to NiO, whereas the microparticles correspond to ZnO. Therefore, the SEM images and elemental analysis confirm the formation of multiple interfaces between NiO nanoparticles and ZnO microparticles. Figure S3 of supplementary material shows the EDS spectra of ZnO/NiO heterojunction inside PDMS, presence of both the elements implies the integrity of heterojunction inside PDMS.

Piezoelectric nanogenerators (PENG) working principle is based on the direct piezoelectric effect, generating voltage across a material when force is applied. Initially, we optimized the ZnO concentration in PDMS by varying it from 5 to 25 wt% relative to PDMS. Subsequently, PENGs were fabricated using these compositions and subjected to a continuous force of 30 N at a frequency of 4 Hz for testing. As shown in Fig. 3a,b, the open-circuit output voltage/short-circuit current of the PENGs exhibited an increase from ~ 27 V/1.32 µA to ~ 42.4 V/2.4 µA with the increase in ZnO wt% up to 15 wt%. However, the output characteristics decreased to ~ 24.5 V/1.17 µA and ~ 23 V/1.15 µA for 20 wt% and 25 wt%, respectively. The observed enhancement in output characteristics with increased ZnO concentration correlates with the higher concentration of piezoelectric ZnO in the PDMS matrix. The decline in output performance beyond 15 wt% is attributed to Maxwell–Wagner interfacial polarization due to the presence of PDMS and ZnO as two different phases in the composite9. The higher concentration of ZnO within the PDMS matrix leads to an increased number of interfaces with PDMS, promoting Maxwell–Wagner interfacial polarization, consequently enhancing the overall dielectric constant of the composite43. Equation (1)44 shows the output voltage (V) of piezoelectric nanogenerator, Where, d is the piezoelectric coefficient, ε0 is the permittivity of free space and εr is the relative permittivity, F is the external force on the device, t is the thickness of the piezoelectric composite and A is the area of the device.

(a) Open-circuit output voltage and (b) short-circuit output current variation with concentration of ZnO in PDMS matrix, (c) open-circuit output voltage and (d) short-circuit output current variation with concentration of NiO with respect to ZnO, (e) Open-circuit output voltage and (f) short-circuit output current of PENG with best performance (ZnO15-NiO5:PDMS).

The piezoelectric output voltage is directly proportional to the ZnO concentration but inversely proportional to the dielectric constant of composite. The abrupt increase in dielectric constant at higher ZnO concentrations due to the Maxwell–Wagner effect contribution is responsible for the deterioration in output performance beyond 15 wt%.

To enhance the output performance of the PENG, we have interfaced p-type NiO with n-ZnO with specific interest of reducing the free electron concentration in ZnO. We have simply grinded the NiO in different concentration ranging from 5 to 20 wt% with respect to optimized ZnO concentration in PDMS. The grinded interfaced ZnO-NiO is then incorporated into PDMS matrix to fabricate PENGs. The PENGs were tested under the same conditions of force and frequency i.e. 30 N and 4 Hz. The open-circuit output voltage/short-circuit current of the PENG enhanced from ~ 42.4 V/2.4 µA to ~ 65 V/4.1 µA with increase in concentration of NiO with respect to ZnO from 0 wt% to 10 wt% (as shown in Fig. 3c,d). With further increase in concentration of NiO the output of the PENG decreased to ~ 51 V/3.9 µA and ~ 44 V/3.2 µA for 15 wt% and 20 wt%, respectively. In Fig. 4a, the screening of the piezoelectric effect due to free electrons is illustrated. As shown in Fig. 4b, when a force is applied to the ZnO material, a voltage develops across it due to the direct piezoelectric effect. Consequently, the free electrons within the material migrate towards the positive potential side, inducing a polarization opposite to the piezoelectric potential generated by the force application. As shown in Fig. 4c, to mitigate the presence of excess electrons, multiple interfaces of n-ZnO/p-NiO have been fabricated through bulk interfacing. These interfaces effectively deplete the electron concentration near the junction area, thereby reducing the overall electron concentration within the ZnO material. Consequently, the screening of the piezoelectric potential is also diminished due to the reduction in electron concentration. To confirm the contribution of PDMS and NiO to the piezoelectric output, we fabricated two PENGs: one with PDMS and the other with NiO:PDMS in a sandwiched structure. We have performed measurements on both PENGs. Figure S1 in the supplementary material displays the output voltage/output current of both PENGs, which were ~ 0.2 mV/0.1 nA. This output is negligible compared to the output of PENGs containing ZnO. This suggests that the piezoelectric output signal generated by the PENG is solely attributed to ZnO. To investigate the reason of enhancement in output performance with NiO interfacing and validate the explanation the explanation, room temperature photoluminescence and I-V measurements has been carried out on the pelletized samples of ZnO and ZnO-NiO10. Photoluminescence and I–V measurements has been carried out on the pelletized samples of ZnO and ZnO-NiO10.

Figure 5a shows the photoluminescence spectra of ZnO and ZnO-NiO10 interfaced samples. The strong characteristic near band edge emission (NBE) peak for ZnO was observed at ~ 372 nm (3.33 eV) is red shifted to ~ 376 nm (3.29 eV) for ZnO-NiO10 interfaced samples. This observed red shift is attributed to the Burstein Moss (BM) shift, signifying a decrease in carrier concentration upon interfacing with NiO45. In addition to NBE, both the samples exhibit midgap luminescence originates from intrinsic defects. ZnO and ZnO:NiO10 samples shows luminescence peak at ~ 498 nm (~ 2.5 eV), which can be attributed to originated from oxygen vacancies defects45,46. Oxygen vacancies generally act as electron donor defect to increase the carrier concentration in ZnO. With NiO interfacing, the intensity of the oxygen vacancy peak is decreased implying a reduction in electron-donating oxygen vacancies and consequently a decline in electron concentration within the ZnO. Figure 5b shows the semi-log plot of current density versus applied voltage (J–V) for ZnO and ZnO-NiO10 interfaced samples. The current density of the ZnO is decreased from 234.4 to 113 µA/cm2 with NiO interfacing, which further confirms the reduction of carrier concentration in ZnO with NiO interfacing. So, it is concluded that the enhancement in output performance of the PENG with NiO interfacing is due to the reduction in electron concentration in ZnO which is responsible for the screening of piezoelectric potential due to carrier concentration. However, the decline in output performance when incorporating NiO beyond 10 wt% might be attributed to an excessive presence of holes in the composite material. When an external force is applied to the PENG, the piezoelectric potential developed within the material. However, the surplus of holes induces an opposing space charge polarization inside the material, thereby further screening the piezoelectric potential and subsequently reducing the output performance. Hence, the interplay between electron and hole concentrations is crucial for minimizing the screening of the piezoelectric potential. Current across various loads connected to the PENG was measured in order to determine the instantaneous output power of optimized PENG. Equation (2) was used to evaluate the output power density of the PENG:

where I represent the current measured across various load resistances R, and A denotes the area of the PENG device. The variation of output current and output power density with externally connected load is shown in Fig. 6a. When the connected load across the PENG was varied from 10 kΩ to 1 GΩ, the current density decreased from 2.05 to 0.04 µA/cm2. The maximum instantaneous output power density of ~ 37.9 µW/cm2 was observed across a load resistance of 20 MΩ under loading conditions of 30 N and 4 Hz. The power density/ (Force × Hz) under the mentioned loading condition is ~ 0.32 µW/cm2 N Hz, which is consistent with earlier reported results46. To demonstrate the powering ability of the optimized PENG the output of the PENG was rectified using full wave rectifier IC (W04M). As shown in the circuit of Fig. 6b, the output of the PENG was coupled directly to the input of the rectifier IC, and the output of the IC was connected to the commercial capacitors. Figure 6c shows the charging of commercial capacitors of 1 µF, 3.3 µF, 4.7 µF and 10 µF using rectified output of the PENG. The capacitor of 1 µF stored the maximum voltage of ~ 20.1 V in 6 min of tapping. The stored energy was used directly to flash 10 commercial LEDs and to power a stopwatch display as shown in Fig. 6d. Thus, the proposed bulk interfacing of p-NiO and n-ZnO offers a straightforward, cost-effective, and scalable technique to enhance the output performance of ZnO-based PENG. This is achieved by annulment of excess electrons, thereby reducing the screening effect of the piezoelectric potential. Moreover, the optimized PENG demonstrates the capability of harvesting vibrational energy to power LEDs and a stopwatch display.

Conclusion

ZnO:PDMS based PENGs were fabricated by varying the concentration of ZnO from 5 wt% to 25 wt%. PENG with 10 wt% of ZnO shows the best output performance with open-circuit output voltage/short-circuit current of ~ 42.4 V/2.4 µA. The output performance of the ZnO:PDMS based PENG was improved by a straightforward, cost-effective, and scalable technique of bulk interfacing with p-type NiO. The PENG with 10 wt% of NiO with respect of ZnO exhibits the best enhanced output characteristics of ~ 65 V/4.1 µA with a maximum instantaneous output power of ~ 37.9 µW/cm2. The enhancement in output performance is due to the annulation of free charge carrier responsible for screening of generated piezoelectric potential. The rectified output of the PENG was used to charge various commercial capacitors. The capacitor of 1 µF stored the maximum voltage of ~ 20.1 V. The stored energy was used to power 10 commercial LEDs and stopwatch display.

Data availability

The data that supports the findings of this study are available within the article.

References

Zhang, D., Yang, Z., Li, P., Pang, M. & Xue, Q. Flexible self-powered high-performance ammonia sensor based on Au-decorated MoSe2 nanoflowers driven by single layer MoS2-flake piezoelectric nanogenerator. Nano Energy 65, 103974. https://doi.org/10.1016/j.nanoen.2019.103974 (2019).

Xu, Q. et al. Self-cleaning and self-powered UV sensors for highly reliable outdoor UV detection. ACS Appl. Electron. Mater. 2, 1628–1634. https://doi.org/10.1021/acsaelm.0c00215 (2020).

Sun, M. et al. Nanogenerator-based devices for biomedical applications. Nano Energy 89, 106461. https://doi.org/10.1016/j.nanoen.2021.106461 (2021).

Mahapatra, A. et al. Flexible ZnO:PVDF based free standing piezoelectric nanogenerator for vibrational energy harvesting and wearable shoe insole pedometer sensor. J. Alloys Compounds 960, 170898. https://doi.org/10.1016/j.jallcom.2023.170898 (2023).

Rahman, M. T. et al. Natural wind-driven ultra-compact and highly efficient hybridized nanogenerator for self-sustained wireless environmental monitoring system. Nano Energy 57, 256–268. https://doi.org/10.1016/j.nanoen.2018.12.052 (2019).

Mahapatra, A., Ajimsha, R. S. & Misra, P. Self-powered high responsivity ultraviolet radiation sensor by coupling ZnO based piezoelectric nanogenerator and photodetector. Appl. Phys. Lett. 124, 103503. https://doi.org/10.1063/5.0191001 (2024).

Su, H. et al. Enhanced energy harvesting ability of polydimethylsiloxane-BaTiO3-based flexible piezoelectric nanogenerator for tactile imitation application. Nano Energy 83, 105809. https://doi.org/10.1016/j.nanoen.2021.105809 (2021).

Faraz, M., Singh, H. H. & Khare, N. A progressive strategy for harvesting mechanical energy using flexible PVDF-rGO-MoS2 nanocomposites film-based piezoelectric nanogenerator. J. Alloys Compounds 890, 161840. https://doi.org/10.1016/j.jallcom.2021.161840 (2022).

Mahapatra, A., Ajimsha, R. S. & Misra, P. Oxygen annealing induced enhancement in output characteristics of ZnO based flexible piezoelectric nanogenerators. J. Alloys Compounds 913, 165277. https://doi.org/10.1016/j.jallcom.2022.165277 (2022).

Lu, L., Ding, W., Liu, J. & Yang, B. Flexible PVDF based piezoelectric nanogenerators. Nano Energy 78, 105251. https://doi.org/10.1016/j.nanoen.2020.105251 (2020).

Vakulov, Z. et al. Piezoelectric energy harvester based on LiNbO3 thin films. Materials 13, 3984. https://doi.org/10.3390/ma13183984 (2020).

Bairagi, S., Shahadat, M., Mulvihill, D. M. & Ali, W. Mechanical energy harvesting and self-powered electronic applications of textile-based piezoelectric nanogenerators: A systematic review. Nano Energy 111, 108414. https://doi.org/10.1016/j.nanoen.2023.108414 (2023).

Ganeshkumar, R., Cheah, C. W., Xu, R., Kim, S.-G. & Zhao, R. A high output voltage flexible piezoelectric nanogenerator using porous lead-free KNbO3 nanofibers. Appl. Phys. Lett. 111, 013905. https://doi.org/10.1063/1.4992786 (2017).

Zheng, F. et al. Sm-doped PIN-PMN-PT transparent ceramics with high curie temperature, good piezoelectricity, and excellent electro-optical properties. ACS Appl. Mater. Interfaces 15, 7053–7062. https://doi.org/10.1021/acsami.2c19865 (2023).

Guan, Y. et al. A self-powered wearable piezoelectric nanogenerator for physiological monitoring based on lead zirconate titanate/microfibrillated cellulose@polyvinyl alcohol (PZT/MFC@PVA) composition. Chem. Eng. J. 460, 141598. https://doi.org/10.1016/j.cej.2023.141598 (2023).

Mahapatra, A. et al. Textile-integrated MoS2-PDMS single electrode triboelectric nanogenerator for vibrational energy harvesting and biomechanical motion sensing. Nano Energy 116, 108829. https://doi.org/10.1016/j.nanoen.2023.108829 (2023).

Bhadwal, N., Ben Mrad, R. & Behdinan, K. Review of zinc oxide piezoelectric nanogenerators: Piezoelectric properties. Compos. Struct. Power Output Sensors 23, 3859. https://doi.org/10.3390/s23083859 (2023).

Li, F., Peng, W. & He, Y. Bilateral piezoelectric charge modulation as a perspective of piezo-phototronic effect in tri-/multi-layer structured optoelectronics. Nano Energy 113, 108537. https://doi.org/10.1016/j.nanoen.2023.108537 (2023).

Kim, J., Kim, Y., Kim, Y., Lee, C. & Lee, J.-H. High performance and direct current piezoelectric nanogenerators using lithium-doped zinc oxide nanosheets. Energy Technol. 11, 2201453. https://doi.org/10.1002/ente.202201453 (2023).

Sun, Y. et al. Suppressing piezoelectric screening effect at atomic scale for enhanced piezoelectricity. Nano Energy 105, 108024. https://doi.org/10.1016/j.nanoen.2022.108024 (2023).

Shin, S.-H., Lee, M. H., Jung, J.-Y., Seol, J. H. & Nah, J. Piezoelectric performance enhancement of ZnO flexible nanogenerator by a CuO–ZnO p–n junction formation. J. Mater. Chem. C 1, 8103–8107. https://doi.org/10.1039/C3TC31664E (2013).

Yin, B. et al. Piezoelectric performance enhancement of ZnO flexible nanogenerator by a NiO–ZnO p–n junction formation. Nano Energy 14, 95–101. https://doi.org/10.1016/j.nanoen.2015.01.032 (2015).

Pandey, R., Maria Joseph Raj, N. P., Singh, V., Iyamperumal Anand, P. & Kim, S.-J. Novel interfacial bulk heterojunction technique for enhanced response in ZnO nanogenerator. ACS Appl. Mater. Interfaces 11, 6078–6088. https://doi.org/10.1021/acsami.8b19321 (2019).

Esquinazi, P., Höhne, R., Han, K.-H., Spemann, D., Setzer, A., Diaconu, M., Schmidt, H., & Butz, T. Induced magnetic order by ion irradiation of carbon-based structures. In: Makarova, T., & Palacio, F. (Eds.), Carbon Based Magnetism, pp. 437–462 (Elsevier, Amsterdam, 2006). https://doi.org/10.1016/B978-044451947-4/50020-7.

Sze, S. M., & Kwok, K. N. Semiconductor devices: Physics and technology, 2nd ed (John Wiley & Sons, 2008).

Lee, K. Y. et al. P-type polymer-hybridized high-performance piezoelectric nanogenerators. Nano Lett. 12, 1959–1964. https://doi.org/10.1021/nl204440g (2012).

Zhang, X. et al. Improvement in the Piezoelectric Performance of a ZnO Nanogenerator by a ZnO/Spiro-MeOTAD ps-n Heterojunction. Phys. Status Solidi (a) 216, 1800717. https://doi.org/10.1002/pssa.201800717 (2019).

Dahiya, A. S. et al. Organic/inorganic hybrid stretchable piezoelectric nanogenerators for self-powered wearable electronics. Adv. Mater. Technol. 3, 1700249. https://doi.org/10.1002/admt.201700249 (2018).

Lei, J. et al. Flexible piezoelectric nanogenerator based on Cu2O–ZnO p–n junction for energy harvesting. RSC Adv. 5, 59458–59462. https://doi.org/10.1039/C5RA09878E (2015).

Liu, C. et al. Interface engineering on p-CuI/n-ZnO heterojunction for enhancing piezoelectric and piezo-phototronic performance. Nano Energy 26, 417–424. https://doi.org/10.1016/j.nanoen.2016.05.041 (2016).

Pitchaiya, S. et al. A review on the classification of organic/inorganic/carbonaceous hole transporting materials for perovskite solar cell application. Arab. J. Chem. 13, 2526–2557. https://doi.org/10.1016/j.arabjc.2018.06.006 (2020).

Hidalgo Castillo, T. C. et al. Simultaneous performance and stability improvement of a p-type organic electrochemical transistor through additives. Chem. Mater. 34, 6723–6733. https://doi.org/10.1021/acs.chemmater.2c00632 (2022).

Beek, W. J. E., Wienk, M. M., Kemerink, M., Yang, X. & Janssen, R. A. J. Hybrid zinc oxide conjugated polymer bulk heterojunction solar cells. J. Phys. Chem. B 109, 9505–9516. https://doi.org/10.1021/jp050745x (2005).

Jagadamma, L. K. et al. Efficient inverted bulk-heterojunction solar cells from low-temperature processing of amorphous ZnO buffer layers. J. Mater. Chem. A 2, 13321–13331. https://doi.org/10.1039/C4TA02276A (2014).

Varshney, D., & Dwivedi, S. Structure, morphology, optical and magnetic response of ZnO, Mn3O4 and doped Zn0.5Mn0.5O nanoparticles as-synthesized using a chemical co-precipitation method. Semicond. Sci. Technol. 31, 035017. https://doi.org/10.1088/0268-1242/31/3/035017 (2016).

Devi, P., Rohilla, S., Saini, J. & Patwa, R. Structural characterization of nanocomposites of NiO/H2O4Sn3 prepared by coprecipitation method. ECS Trans. 107, 15291. https://doi.org/10.1149/10701.15291ecst (2022).

Sahai, A. & Goswami, N. Structural and vibrational properties of ZnO nanoparticles synthesized by the chemical precipitation method. Phys. E Low Dimens. Syst. Nanostruct. 58, 130–137. https://doi.org/10.1016/j.physe.2013.12.009 (2014).

Kumar, Y. et al. Controlling of ZnO nanostructures by solute concentration and its effect on growth, structural and optical properties. Mater. Res. Express 2, 105017. https://doi.org/10.1088/2053-1591/2/10/105017 (2015).

Paul, B. et al. Nano-bio effects: Interaction of ZnO and DNA-bases. Nano-Struct. Nano-Objects 31, 100898. https://doi.org/10.1016/j.nanoso.2022.100898 (2022).

Sekar, S., Kim, D. Y. & Lee, S. Excellent oxygen evolution reaction of activated carbon-anchored NiO nanotablets prepared by green routes. Nanomaterials 10, 1382. https://doi.org/10.3390/nano10071382 (2020).

Wang, D. et al. Spin–phonon coupling in NiO nanoparticle. J. Appl. Phys. 128, 133905. https://doi.org/10.1063/5.0022668 (2020).

Mironova-Ulmane, N. et al. Structural and magnetic properties of nickel oxide nanopowders. Solid State Phenomena 168–169, 341–344. https://doi.org/10.4028/www.scientific.net/SSP.168-169.341 (2011).

Zhang, X. et al. Enhancing dielectric and piezoelectric properties of micro-ZnO/PDMS composite-based dielectrophoresis. Mater. Des. 192, 108783. https://doi.org/10.1016/j.matdes.2020.108783 (2020).

Xu, T.-B. 7—Energy harvesting using piezoelectric materials in aerospace structures. In: F.-G. Yuan (Ed.), Structural Health Monitoring (SHM) in Aerospace Structures, pp. 175–212 (Woodhead Publishing, 2016). https://doi.org/10.1016/B978-0-08-100148-6.00007-X.

Yu, C.-F., Sung, C.-W., Chen, S.-H. & Sun, S.-J. Relationship between the photoluminescence and conductivity of undoped ZnO thin films grown with various oxygen pressures. Appl. Surf. Sci. 256, 792–796. https://doi.org/10.1016/j.apsusc.2009.08.061 (2009).

Ajimsha, R. S., Mahapatra, A., Das, A. K., Sahu, V. K. & Misra, P. High output power density owing to enhanced charge transfer in ZnO-based triboelectric nanogenerator. Energy 263, 125646. https://doi.org/10.1016/j.energy.2022.125646 (2023).

Acknowledgements

One of the authors Mr. Abhinav Mahapatra acknowledges the financial support from RRCAT, Department of Atomic Energy, Govt. of India and HBNI Mumbai. The authors are thankful to Prof. S.S. Roy of Department of Physics, School of Natural Sciences, Shiv Nadar Institution of Eminence (SNIoE) for extending the FESEM and Raman facility. The authors are grateful to Dr. S.K. Rai, Dr. Pooja Gupta of APSUD, RRCAT, Indore for extending the XRD facility for measurements. The authors are thankful to Mr. Rakesh Kaul, Head, Laser Materials Processing Division of RRCAT, for his continuous support and encouragement during the work.

Author information

Authors and Affiliations

Contributions

A.M. and R.A. conceived the idea of the study. A.M. performed the XRD, piezoelectric and electrical measurements. R.A., A.M. and P.M. performed the PL measurements. D.D. performed the FESEM and RAMAN measurements. A.M. and R.A. analyzed the results. A.M., R.A. and P.M. prepared and revised the manuscript. All authors reviewed and finalized the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mahapatra, A., Ajimsha, R.S., Deepak, D. et al. Tuning ZnO-based piezoelectric nanogenerator efficiency through n-ZnO/p-NiO bulk interfacing. Sci Rep 14, 11871 (2024). https://doi.org/10.1038/s41598-024-62789-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-62789-3

- Springer Nature Limited