Abstract

A series of bifunctional hexagonal MOFs have been successfully constructed by the introduction of various amine functional groups within the unsaturated Cu-based MOF, HKUST, to access amino-modified frameworks. The prepared compounds are cost-effective and display high chemical and thermal stability. They were effectually exploited as efficacious and superb heterogeneous catalysts in rapid and facile Knoevenagel condensation reactions for a variety of substrates containing different electron-donating and electron-withdrawing substituents with very high conversion, good reusability under mild conditions, and very short reaction time. The contaminant presence of Lewis acid and basic sites resulted in efficient condensation reactions by the prepared catalysts.

Similar content being viewed by others

Introduction

Knoevenagel condensation is one of the most widely employed reactions in the industry which is used to produce imperative intermediates for pharmaceuticals, fine chemicals, functional polymers, and biologically active materials1–3. The fundamental condensation reactions took place between aromatic carbonyl compounds and activated methylene groups to construct carbon–carbon bonds4–6.

Various homogeneous catalysts were utilized in the condensation reactions such as ammonium salts, diverse amine groups and complexes, and organometallic catalysts7–9. However, homogeneous systems deficiencies and limitations such as catalyst recovery, difficult and costly product separation make researchers develop strategies to form efficient heterogeneous catalysts10. Therefore, different heterogeneous catalysts such as zeolites, mesoporous silica, metal oxides, and ionic liquids were ascertained to employ in condensation reactions11. Although developing appropriate catalysts is still a challenging issue for scientists.

For this purpose, porous crystalline compounds have attracted Scientific attention toward their research owing to their unique characterization as high surface area and well-ordered structures and porosity12–14. Among different categories of porous crystalline structure, the newly developed metal–organic frameworks (MOFs) which are constructed from metal ion clusters bridged by multidentate organic linkers, are exclusively exploited in various valuable applications such as catalysis, drug delivery, adsorption, separation and etc.15–17. These compounds are considered a new generation of catalysts with widespread research interest in recent decades due to their distinctive properties such as tunable pore size, high thermal stability, designable channels, high specific surface area, recoverability, tunable structures, etc. which make them exceptional heterogeneous catalysts18–20.

The presence of basic sites within the structure can promote and accelerate the Knoevenagel condensation reactions and is vital for reaction progress21–23. Amine functional groups are one of the good electrondonating groups that utilize in diverse reactions where basic sites are required24–26. Thus, MOFs with basic functional groups have been widely investigated for condensation reactions in recent years27–29. On the other hand, MOFs have organic ligands and unsaturated metal center sites which can undergo post-synthetic modification (PSM). Therefore, designing and applying ligands with appropriate functional groups is a crucial strategy for the fabrication of modified MOFs with novel structural characteristics and desired applications.

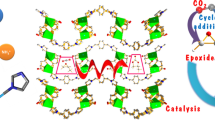

With the above consideration in mind, in this work, HKUST was synthesized by solvothermal method and various linear amine functional groups were introduced into the unsaturated metal centers of the framework with refluxing method (Fig. 1). The prepared structures were utilized as bifunctional superb heterogeneous catalysts for the facile Knoevenagel condensation reactions between different benzaldehyde derivatives and malononitrile. The performance of the catalysts was compared with each other under mild reaction conditions.

Experimental section

Materials and instrumentation

Materials and instrumentation are explained in supporting information.

Synthesis of catalysts

Synthesis of HKUST

According to the previously reported procedure, for synthesis, 3.6 mmol cupper (II) nitrate trihydrate (865 mg) and 2 mmol of trimesic acid (420 mg) were separately dissolved in 12 ml of deionized water and ethanol, respectively30. The obtained solutions were mixed together and stirred for 5 min at room temperature and transferred to a 50-ml Teflon-lined steel autoclave, heated at 120 °C for 24 h. The obtained blue powder was filtered by centrifuging and washed with a mixture of ethanol and deionized water in the same proportion and then activated by drying at 150 °C for 24 h.

Synthesis of HKUST-ED

In a typical procedure, 0.1 g of activated HKUST was suspended in 20 ml toluene following by the addition of 50 µl (0.7 mmol) ethylene diamine. The suspension refluxed for 16 h, cooled to room temperature, isolated by filtration. The resulting participate was washed with dichloromethane to eliminate unreacted ligands and dried at 100 °C for 3h.

Synthesis of HKUST-PhDA

This compound was synthesized under reflux conditions by treating HKUST and 1,2-phenylene diamine. A solution of 1,2-phenylene diamine (8o mg, 0.5 mmol) in 30 ml dichloromethane was prepared and added to a suspension containing 0.1 g of activated HKUST in 10 ml toluene. The reaction mixture was refluxed for 16 h and the resulting powder was collected by centrifuging, washed with dichloromethane, and dried at 100 °C for 3h.

Synthesis of HKUST-DA

The synthesis procedure for HKUST-DA is completely similar to HKUST-PhDA synthesis method. The difference is that 70 mg of 1,4-diaminobutane (0.8 mmol) is used instead of 1,2-phenylene diamine.

Synthesis of HKUST-DiT

In a typical procedure, 86 µl (0.8 mmol) of diethylene triamine was added to a suspension containing 0.1 g of activated HKUST in 30 ml. The light-blue powder formed was separated by filtration, washed with dichloromethane several times to purify. Therefore, the final product was dried at 100 °C for 3h.

General procedure for Knoevenagel condensation reactions

To a 25 ml of round-bottomed flask containing 10 ml ethanol, malononitrile (66 mg, 1 mmol) was added. Then 10 mg of the prepared catalyst and 1mmol of benzaldehyde substrate was introduce to the aforementioned solution. The reaction mixture was stirred at room temperature for 5 min. The catalyst was isolated after the completion of the catalytic process and the ultimate filtered solution was characterized by gas chromatography.

Results and discussion

Characterization of catalysts

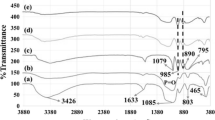

The FT-IR spectra of the pristine and modified structures was demonstrated in Fig. S1. As shown in the FT-IR spectrum of HKUST, the characteristic bands at 728 and 762 cm−1 were related to the out-of-plane deformation vibration of C‒H groups in the phenyl rings31. The emerged bands at 1378 and 1642 cm−1 can be attributed to the symmetric and asymmetric stretching vibration of carboxylate functional groups32. In addition, the broad stretching vibration band of the hydroxyl group of water molecules appeared at 3450 cm−1. The FT-IR spectra of HKUST-ED, HKUST-PhDA, HKUST-DA, and HKUST-DiT were represented in Figs. S1b, S1S1c, S1d, and S1e, respectively. The FT-IR spectra of functionalized structures are identical to the pristine MOF after incorporating diverse amine functional groups into the framework confirming successful modification of the framework. Moreover, the peak that is related to the N–H amine functional groups appeared at about 2700–3500 cm−1. On the other hand, it can be observed that the amount of amine functional groups loaded within the structure is very low (about 13–24%, Table S1). This low amount of loading causes the peaks related to N–H of amine group overlap with the broad band of the hydroxyl group of water molecules and eventually, the peaks related to N–H Amines cannot be seen well.

PXRD patterns of the as-synthesized and modified framework are presented in Fig. 2. XRD patterns of the pristine and functionalized framework corroborated well with the stimulated one and also the main peaks are well consistent with simulated data30. All prepared frameworks retained their crystallinity structures even after the introduction of amine functional groups into the frameworks demonstrating the chemical stability and structural integrity and robustness of the accumulated compounds. The XRD patterns of these samples, match well with CIF with CCDC 987,873.

N2 adsorption–desorption isotherms were measured at low temperatures in order to identify the nature of porosity and surface area of the prepared frameworks. The textural parameters and N2 adsorption–desorption isotherms of the synthesized material are presented in Table 1 and Fig. 3, respectively. Based on the results, type I isotherms was revealed for both pristine HKUST and modified structures. Furthermore, the amount of surface area and pore volume for HKUST is 1363 m2/g and 0.58 cm3/g, respectively. After the introduction of amine functional groups into the framework, the relevant amount was decreased to 983 m2/g and 0.46 cm3/g, 929 m2/g and 0.42 cm3/g, 894 m2/g and 0.37 cm3/g, and 683 m2/g and 0.31 cm3/g for HKUST-ED, HKUST-DA, HKUST-DiT, and HKUST- PhDA, respectively. The decrement in surface area and pore volume amount affirmed the successful incorporation and modification of frameworks.

In order to evaluate the morphology of the prepared compounds, scanning electron micrograph analysis was carried out and the result micrographs are presented in Fig. 4. According to the obtained SEM images, the morphology of HKUST is characterized by a well-defined octahedral structure (Fig. 4, b). The morphology of structures remained unchanged after modification affirming the successful introduction of desired groups into the structures (Fig. 4c-f). Moreover, TEM image of one of the modified structures (HKUST-ED) are depicted in Fig. S2.

TGA analysis was accomplished in order to investigate the thermal behavior and stability of the prepared frameworks and the results are shown in Fig. S3. Accordingly, for HKUST and functionalized frameworks, two weight losses were observed. The first weight loss in the TG curve of HKUST at about 70–120 °C belonged to the removal of coordinated and guest H2O molecules in the structure. The next weight loss that was perceived with the temperature increasing at about 350 °C, corresponds to structural collapse and degradation. Similarly, the functionalized frameworks have thermal stability up to 350 °C. Thus, the prepared frameworks demonstrate high thermal stability behavior.

The amount of amine functional groups loaded within the structure was acquired by elemental analysis and the results are summarized in Table S1. Based on the results, the amount of amine groups loaded into the framework was obtained due to the afforded experimental nitrogen percent. Therefore, the amount of loading for HKUST-ED, HKUST-PhDA, HKUST-DA, and HKUST-DiT were 13.5, 24.1, 18.3, and 21.7%, respectively.

With the above consideration in mind and according to all obtained results, amine functional groups were incorporated into the structure through the coordination of nitrogen atoms to the unsaturated metal centers in the framework33–35.

Catalytic activity of the prepared frameworks

At first, efforts were made to synthesize HKUST, and then the incorporation of various amine functional groups was carried out into the framework. For functionalization, ethylene diamine, 1,3-phenylene diamine, 1,4-diaminobutane, and diethylene triamine were utilized in order to enhance the catalytic activity. The obtained frameworks named HKUST-ED, HKUST-PhDA, HKUST-DA, and HKUST-DiT and are also considered catalysts 1, 2, 3, and 4, respectively. The prepared catalysts were used for facile and rapid Knoevenagel condensation reactions under mild conditions to form an α, β-unsaturated ketones.

To figure out the role of amine functional group in condensation reactions, some experimental reactions were performed and the results are summarized in Table 2. First, the reaction was accomplished without the addition of any catalyst in the reaction media, and no conversion was observed for this reaction (Table 2, Entry 1). Second, the condensation reaction was performed in the presence of the pristine MOF (HKUST), and no substantial conversion was perceived in this case (Table 2. Entry 2). Next, in the case of utilization of either the physical mixture of amine groups with HKUST or the sole amine functional group, the reaction cannot proceed with a remarkable conversion (Table 2, Entries 3, 4, respectively). However, in the case of the physical mixture slight progress can be observed, but sequestration is a major problem in this case. In the case of using the prepared catalyst, complete progress of the reaction is observed and the conversion rate of 100% was obtained (Table 2, Entry 5).

Knoevenagel condensation reactions

The catalytic activity of prepared catalysts (1, 2, 3, and 4) was investigated in Knoevenagel condensation reactions in terms of activity, selectivity, and reusability. For this purpose, benzaldehyde and malononitrile were chosen as substrate models in order to perform Knoevenagel condensation reactions. Different parameters such as time, amount of catalyst, temperature, and solvent were optimized and the results are displayed in Figs S4-7, respectively. According to the results, the condensation reaction was carried out within 5 min and at ambient temperature, in the presence of 10 mg of catalyst with an excellent conversion rate of 100%. In addition, Ethanol was designed as the optimized solvent of the reaction. Based on the results, protic solvents act better than aprotic solvents due to their polarity and the ability to stabilize intermediates (Fig. S7). Both ethanol and acetonitrile demonstrate high conversion for condensation reaction, but ethanol was elected due to its lower toxicity.

The obtained superb results led to examine different aromatic aldehydes with either electron-donating or electron-withdrawing functional groups in condensation reaction and the results are summarized in Table 3. As the results demonstrate, in a very short reaction time, all substrate converts to their related product (α, β- unsaturated ketone) with high conversion rates. It is worth noting that in these reactions the selectivity is 100% and α, β-unsaturated ketone is the sole product of the reaction. The type of substituent has a significant effect on the reaction efficacy. According to the results, benzaldehydes with electron-withdrawing functional groups act better than benzaldehydes with electron-donating groups, and higher conversion was obtained for them (Table 3, entries 2–6). Among various applied electron-withdrawing substitutes including nitro, chlorine, and bromine functional groups, the trend of catalytic performance enhanced as the following process; NO2 > Cl > Br. Also, the presence of substitution in the ortho position compared to the para position causes more activity of the catalyst (Table 3, entries 3,4). On the other hand, between diverse electron-donating benzaldehydes utilized in Knoevenagel condensation reactions containing methoxy and methyl groups, the increase in the catalytic performance of the substituents is as follows; OCH3 > CH3 (Table 3, entries 7–11). In the case of using hydroxybenzaldehyde, no catalytic activity and reaction progress was observed (Table 3, entry 12). Furthermore, when using 2,6- dichlorobenzaldehyde and 3,4- dimethoxybenzaldehyde as substrates, the catalytic activity reduced compared to the mono-substitute owing to the increased steric hindrance (Table 3, entries 5,9).

For further conformation, 13CNMR, 1HNMR, and FT-IR analysis were carried out for some products and the results were displayed in Figs S8-S6 which confirmed the formation of products.

Moreover, the catalytic activity of catalyst 1 was examined in Knoevenagel condensation reaction of benzyl alcohol with different contents of ethylene diamine loaded into the framework, and the results were represented in Table S2. As results shown, by decreasing the amount of loaded ethylene diamine, the catalytic performance of 1 was also reduced and less catalytic activity is observed.

The plausible mechanism for Knoevenagel condensation reaction

The proposed mechanism for Knoevenagel condensation reaction of benzaldehyde with malononitrile in the presence of catalyst 1 was illustrated in Fig. 5. On the basis of the proposed mechanism, metal centers and incorporated amine groups within the framework act as Lewis acid and basic sites, respectively. In the first step, carbonyl groups on benzaldehyde were activated by the metal ions of MOF, and simultaneously basic sites in the framework deprotonated malononitrile and formed a carbanionic intermediate (Fig. 5, pathway I). Subsequently, the next step continues with the attack of the carbanionic anion on the polarized carbonyl group and a new intermediate was generated (Fig. 5, pathway II). Ultimately, the final product was constituted with the elimination of H2O molecules and the catalyst was regenerated to participate in the next cycle at the same time (Fig. 5, pathway III). Therefore, based on the proposed mechanism, the presence of basic sites is indispensable for the reaction progress36, 37.

Comparison of the catalytic performance of the synthesized compounds

Knoevenagel condensation reactions were performed in the presence of catalysts with various amine functional groups. The trend of catalytic performance of utilized catalysts is as the following process; 1 > 2 > 3 > 4. Based on the aforementioned trend, catalyst 1 with ethylenediamine functional group exhibited the best results due to its proper orientation, availability of corresponding electron pairs, and free rotation of amine groups. In the case of using phenylene diamine as basic site in the framework (catalyst 2), the electron pairs of the amine group are involved in resonance with the aromatic ring. With this regard, despite the proper orientation, a weaker performance was observed compared to ethylenediamine functional groups. In the case of using catalyst 3, the farther distance of amine groups from metal ion centers, and sterically hindrance increment resulted in the worse performance of the catalyst and lower results were observed. Catalyst 4 is the least efficacious catalyst among the utilized catalysts. Although this catalyst has more basic sites, it exhibits weaker activity compared to others due to increased steric hindrance.

In order to investigate the catalytic performance of the synthesized frameworks, a comparison was made between the prepared catalyst and other previously reported heterogeneous catalysts based on MOFs applied in Knoevenagel condensation reaction. The mentioned compounds are compared in terms of activity with each other and the results are listed in Table 4. Based on the results, our synthesized catalyst revealed a substantial increment in catalytic activity. Furthermore, other advantages of the prepared catalysts include simplicity, effectiveness, very short reaction time, and accomplishing the reaction at room temperature.

The recyclability of the prepared catalysts was carried out via consecutive Knoevenagel condensation reactions under the optimized reaction conditions and the results are presented in Figs. S17-19. According to the results in Fig. S17, the catalyst can be recycled for five sequential runs without considerable loss of its activity. Moreover, the PXRD pattern and FT-IR spectra which depicted in Figs. S18 and S19, respectively revealed that the catalyst retains its crystallinity and structural integrity.

Conclusion

In summary, an unsaturated Cu-based MOF, HKUST, was constructed and successfully modified with diverse amine functional groups. The prepared heterogeneous catalysts were applied as efficient catalysts for rapid and facile Knoevenagel condensation reactions. The Knoevenagel products were achieved with high conversion under mild conditions and very short reaction time compared to other previously reported catalysts. Other unique characteristics of the prepared catalysts include recyclability, the cost-effectiveness of the synthesized catalysts, and performing reactions at room temperature.

Data availability

The datasets used and/or analyzed during the current study available from the corresponding author on reasonable request.

References

Cai, K., Tan, W., Zhao, N. & He, H. Design and assembly of a hierarchically micro-and mesoporous MOF as a highly efficient heterogeneous catalyst for Knoevenagel condensation reaction. J Crystal Growth Design 20, 4845–4851 (2020).

Aljaddua, H. I., Alhumaimess, M. S. & Hassan, H. M. CaO nanoparticles incorporated metal organic framework (NH2-MIL-101) for Knoevenagel condensation reaction. J Arabian J Chem 15, 103588 (2022).

Ramesh, S., Devred, F. & Debecker, D. P. NaAlO2-promoted mesoporous catalysts for room temperature knoevenagel condensation reaction. ChemistrySelect 5, 300–305 (2020).

Heravi, M. M., Janati, F. & Zadsirjan, V. Applications of Knoevenagel condensation reaction in the total synthesis of natural products. J Monatshefte für Chemie-Chemi Monthly 151, 439–482 (2020).

Mangala, K. & Sreekumar, K. Polycarbosilane-supported titanium(IV) catalyst for Knoevenagel condensation reaction. Appl Organometall Chem 27, 73–78 (2013).

Lin, W. et al. A layered metal-organic framework with acidic sites as a multiphase catalyst for Knoevenagel condensation. Z. Anorg. Allg. Chem. 649, e202300008 (2023).

Ortiz-Bustos, J., Cruz, P., Pérez, Y. & del Hierro, I. Prolinate-based heterogeneous catalyst for Knoevenagel condensation reaction: Insights into mechanism reaction using solid-state electrochemical studies. J Molecular Catalysis 524, 112328 (2022).

Paliwal, K. S., Mitra, A., Biswas, T., Mandal, S. & Mahalingam, V. Dicationic ionic liquid modified chitosan as a sustainable heterogeneous catalyst for knoevenagel condensation reactions. J Journal of Molecular Engineering Materials 10, 2240001 (2022).

Kumari, K., Choudhary, P., Sharma, D. & Krishnan, V. Amine-functionalized graphitic carbon nitride as a sustainable metal-free catalyst for knoevenagel condensation. J Ind Eng Chem Res 62, 158–168 (2022).

Mannarsamy, M. & Prabusankar, G. Highly active copper (I)-chalcogenone catalyzed Knoevenagel condensation reaction using various aldehydes and active methylene compounds. J Catalysis Lett 152, 2327–2332 (2022).

Kumar, Y., Shabir, J., Gupta, P. & Kumar, L. S. Design and development of amine functionalized mesoporous cubic silica particles: a recyclable catalyst for knoevenagel condensation. J Catalysis Lett 152, 1506–1516 (2022).

Saghian, M., Dehghanpour, S. & Sharbatdaran, M. “Ship in a bottle” Porph@ MOMs as highly efficient catalysts for selective controllable oxidation and insights into different mechanisms in heterogeneous and homogeneous environments. J New J Chem 42, 12872–12881 (2018).

Wang, J.-S. et al. Au@ Cu (II)-MOF: Highly efficient bifunctional heterogeneous catalyst for successive oxidation–condensation reactions. J InorganChem 55, 6685–6691 (2016).

Horoshenkov, K. V. A review of acoustical methods for porous material characterisation. J Int. J. Acoust. Vib 22, 92–103 (2017).

Saghian, M., Dehghanpour, S. & Sharbatdaran, M. Unique and efficient adsorbents for highly selective and reverse adsorption and separation of dyes via the introduction of SO 3 H functional groups into a metal–organic framework. J RSC Adv 10, 9369–9377 (2020).

Mallakpour, S., Nikkhoo, E. & Hussain, C. M. Application of MOF materials as drug delivery systems for cancer therapy and dermal treatment. J Coordin Chem Rev 451, 214262 (2022).

M. Saghian, S. Dehghanpour, M. Sharbatdaran, Removal of molybdenum from wastewater using modified amino-functional framework: A study of the adsorption properties, Environmental progress & sustainable energy, (2022) e14035.

Uzun, A. & Keskin, S. Site characteristics in metal organic frameworks for gas adsorption. J Progress Surface Sci 89, 56–79 (2014).

Saghian, M., Dehghanpour, S. & Sharbatdaran, M. Cyano-bifunctional MOFs as superior catalysts for carbon dioxide fixation under co-catalyst and solvent free conditions. J Appl Catalysis A General 612, 117982 (2021).

Kim, M. et al. MOF-derived nanoporous carbons with diverse tunable nanoarchitectures. J Nature Protocols 17, 1–42 (2022).

Tran, U., Le, K. & Phan, N. Expanding applications of metalorganic framework ZIF-8 as an efficient heterogeneous catalyst for the Knoevenagel reaction. J ACS Catal 1, 120–127 (2011).

Taher, A., Lumbiny, B. J. & Lee, I.-M. A facile microwave-assisted Knoevenagel condensation of various aldehydes and ketones using amine-functionalized metal organic frameworks. J Inorganic Chem Commun 119, 108092 (2020).

Wang, X.-S. et al. An anion metal-organic framework with lewis basic sites-rich toward charge-exclusive cationic dyes separation and size-selective catalytic reaction. Inorg. Chem. 55, 2641–2649 (2016).

Saghian, M., Dehghanpour, S. & Sharbatdaran, M. Linear amine functionalized MOFs designed as superior bifunctional catalysts for CO2 cycloaddition under co-catalyst and solvent free condition. J Appl Organ Chem 37, e6973 (2022).

Nguyen, Q. T., Do, X. H., Cho, K. Y., Lee, Y.-R. & Baek, K.-Y. Amine-functionalized bimetallic Co/Zn-zeolitic imidazolate frameworks as an efficient catalyst for the CO2 cycloaddition to epoxides under mild conditions. J CO2 Utiliz 61, 102061 (2022).

Saghian, M., Dehghanpour, S. & Sharbatdaran, M. Amine-functionalized frameworks as highly actives catalysts for chemical fixation of CO2 under solvent and co-catalyst free conditions. J CO2 Utiliz 41, 101253 (2020).

Yang, Y., Yao, H.-F., Xi, F.-G. & Gao, E.-Q. Amino-functionalized Zr (IV) metal–organic framework as bifunctional acid–base catalyst for Knoevenagel condensation. J Mol Catalysis A Chem 390, 198–205 (2014).

Ghobakhloo, F., Azarifar, D., Mohammadi, M., Keypour, H. & Zeynali, H. Copper (II) Schiff-Base Complex Modified UiO-66-NH2 (Zr) metal-organic framework catalysts for knoevenagel condensation-michael addition–cyclization reactions. J Inorg Chem 61, 4825–4841 (2022).

Song, X. et al. Three amino-functionalized alkaline earth metal-organic frameworks as catalysts for knoevenagel condensation. J ChemistrySelect 5, 11510–11516 (2020).

Schlichte, K., Kratzke, T. & Kaskel, S. Improved synthesis, thermal stability and catalytic properties of the metal-organic framework compound Cu3 (BTC) 2. J Microporous Mesoporous Mater 73, 81–88 (2004).

Xie, Y. et al. Small titanium-based MOFs prepared with the introduction of tetraethyl orthosilicate and their potential for use in drug delivery. J ACS Appl Mater Interfaces 10, 13325–13332 (2018).

Xie, W. & Wan, F. Basic ionic liquid functionalized magnetically responsive Fe3O4@ HKUST-1 composites used for biodiesel production. J Fuel 220, 248–256 (2018).

Cabello, C. P., Berlier, G., Magnacca, G., Rumori, P. & Palomino, G. T. Enhanced CO2 adsorption capacity of amine-functionalized MIL-100(Cr) metal–organic frameworks. CrystEngComm 17, 430–437 (2015).

Hwang, Y. K. et al. Amine grafting on coordinatively unsaturated metal centers of MOFs: consequences for catalysis and metal encapsulation. Angew. Chem. 120, 4212–4216 (2008).

Vo, T. K., Kim, W.-S. & Kim, J. Ethylenediamine-incorporated MIL-101 (Cr)-NH 2 metal-organic frameworks for enhanced CO 2 adsorption. Korean J Chem Eng 37, 1206–1211 (2020).

Gogoi, C., Nagarjun, N., Rana, A., Dhakshinamoorthy, A. & Biswas, S. Diamino group-functionalized Zr-based metal–organic framework for fluorescence sensing of free chlorine in the aqueous phase and Knoevenagel condensation. J Dalton Trans 51, 6964–6975 (2022).

Ren, Y., Lu, J., Jiang, O., Cheng, X. & Chen, J. Amine-grafted on lanthanide metal-organic frameworks: three solid base catalysts for Knoevenagel condensation reaction. J Chinese J Catal 36, 1949–1956 (2015).

Luan, Y. et al. A general post-synthetic modification approach of amino-tagged metal–organic frameworks to access efficient catalysts for the Knoevenagel condensation reaction. J Mater Chem A 3, 17320–17331 (2015).

Ezugwu, C. I., Mousavi, B., Asraf, M. A., Luo, Z. & Verpoort, F. Post-synthetic modified MOF for Sonogashira cross-coupling and Knoevenagel condensation reactions. J Catal 344, 445–454 (2016).

Opanasenko, M. et al. Comparison of the catalytic activity of MOFs and zeolites in Knoevenagel condensation. J Catal Sci Technol 3, 500–507 (2013).

Dhakshinamoorthy, A., Heidenreich, N., Lenzen, D. & Stock, N. Knoevenagel condensation reaction catalysed by Al-MOFs with CAU-1 and CAU-10-type structures. J CrystEngComm 19, 4187–4193 (2017).

Hartmann, M. & Fischer, M. Amino-functionalized basic catalysts with MIL-101 structure. J Microporous Mesoporous Mater 164, 38–43 (2012).

Neogi, S., Sharma, M. K. & Bharadwaj, P. K. Knoevenagel condensation and cyanosilylation reactions catalyzed by a MOF containing coordinatively unsaturated Zn (II) centers. J Mol Catal A Chem 299, 1–4 (2009).

Rambabu, D., Ashraf, M., Gupta, A. & Dhir, A. Mn-MOF@ Pi composite: synthesis, characterisation and an efficient catalyst for the Knoevenagel condensation reaction. J Tetrahedron Lett 58, 4691–4694 (2017).

Schejn, A. et al. Fe 3 O 4@ ZIF-8: magnetically recoverable catalysts by loading Fe 3 O 4 nanoparticles inside a zinc imidazolate framework. J Dalton Trans 44, 10136–10140 (2015).

Masoomi, M. Y., Beheshti, S. & Morsali, A. Mechanosynthesis of new azine-functionalized Zn (II) metal–organic frameworks for improved catalytic performance. J Mater Chem A 2, 16863–16866 (2014).

Zhang, P. et al. Microwave-assisted, Ni-induced fabrication of hollow ZIF-8 nanoframes for the knoevenagel reaction. J Crystal Growth Design 18, 3841–3850 (2018).

Almáši, M., Zeleňák, V., Opanasenko, M. & Čejka, J. A novel nickel metal–organic framework with fluorite-like structure: gas adsorption properties and catalytic activity in Knoevenagel condensation. J Dalton Trans 43, 3730–3738 (2014).

Fan, W. et al. A stable amino-functionalized interpenetrated metal-organic framework exhibiting gas selectivity and pore-size-dependent catalytic performance. J Inorg Chem 56, 13634–13637 (2017).

Author information

Authors and Affiliations

Contributions

M.S.: Conceptualization; formal analysis; investigation; writing-original draft. S.D.: Conceptualization; investigation; project administration; resources; supervision; writing-review and editing. Z.B.: formal analysis.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Saghian, M., Dehghanpour, S. & bayatani, Z. A facile, rapid procedure for Knoevenagel condensation reaction catalyzed by efficient amino-bifunctional frameworks under mild conditions. Sci Rep 13, 15563 (2023). https://doi.org/10.1038/s41598-023-42832-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-42832-5

- Springer Nature Limited