Abstract

This work presents the simple synthesis of a green and novel Palladium based magnetic nanocatalyst with effective catalytic properties and reusability. These heterogeneous catalysts were prepared by the anchoring of Pd(0) on the surface of ZrFe2O4 MNPs coated with a di-substituted adenine (Ade) compound as a green linker. The as-synthesized ZrFe2O4@SiO2@Ade-Pd MNPs were methodically characterized over different physicochemical measures like VSM, EDX, Map, SEM, TEM, ICP, and FT-IR analysis. The catalytic activity of ZrFe2O4@SiO2@Ade-Pd was carefully examined for the room-temperature Carbon–Carbon coupling reaction in acetonitrile as a solvent. It is worth noting that the synthesized solid catalyst can be easily recovered with a bar magnet and reused for five cycles without decrease of catalytic activity.

Similar content being viewed by others

Introduction

In recent years, one of the important achievements of scientists is the discovery of C–C coupling reactions in the presence of complexes containing transition metals such as copper and palladium. Among transition metal complexes, Pd is one of the best choices, due to its selectivity in coupling reactions, high activity, and simple complex preparation. The Suzuki–Miyaura cross-coupling reaction, which involves the coupling of phenylboronic acid and aryl halide, is used as an efficient and simpler method to prepare biphenyls1,2,3. Carbon–carbon and carbon–heteroatom cross-coupling reactions based on transition metal catalyst systems have revolutionized synthetic methodologies for the synthesis of simple to complex organic structures4,5,6,7,8,9,10,11. These types of reactions have wide applications in the synthesis of agricultural, pharmaceutical, and chemical compounds of electronic materials12,13,14,15,16,17,18,19,20,21,22.

Aromatic amines are ubiquitous in natural products and synthetic purposeful materials which include pharmaceuticals and drugs, agrochemicals, perfumes, and flavors23,24. Also, the development of synthetic protocols for Carbon–Nitrogen bonds have executed significant significance in each academia and industry25. The Buchwald–Hartwig reaction represents a transition metal–promoted versatile catalytic approach for the formation of Carbon–Nitrogen bonds26.

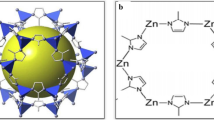

Research and development of efficient and new nanomaterials as catalyst support is a big challenge in modern organic synthesis27,28,29,30,31. Recently, nanostructured materials, especially magnetic nanoparticles, have been used as widely used supports in the synthesis of magnetic nanocatalysts due to their easy preparation and operation, high surface area, and easy recovery by the magnetic field, which leads to optimization of operating cost. One of the most obvious advantages of magnetic nanoparticles is their simple separation from the reaction mixture by a bar magnet. Among heterogeneous catalysts, ZrFe2O4 have been greatly favored since they are simply synthesized and surface modified using a magnet. However, various catalysts can be supported on ZrFe2O4 nanoparticles, because they can be easily separated after several consecutive uses in the reaction.

In this research project, we report the synthesis and structural characterization of a green and novel nanocatalyst to stabilize Pd ions and to investigate their utility as a green and efficient nanocatalyst in the Buchwald–Hartwig Cross‑coupling and Suzuki–Miyaura cross-coupling reaction.

Experimental

Preparation of ZrFe2O4@SiO2@Ade-Pd

For the synthesis of ZrFe2O4@SiO2@Ade-Pd nanocatalyst, first ZrFe2O4@SiO2@n-Pr-Cl were synthesized by the co-precipitation method. To synthesize the ZrFe2O4@SiO2@Ade-Pd complex, 3 g of the prepared ZrFe2O4@SiO2@n-Pr-Cl was dispersed in 50 mL toluene by sonication for 65 min. Then, 5 mmol of adenine and Et3N (10 mmol) were added into the flask and stirred at 90˚C for 60 h at 60 °C under N2 conditions. After the reaction completion, the obtained ZrFe2O4@SiO2@Ade were separated by magnetic decantation, washed with EtOAc and n-hexane, and then dried at 80 °C in an oven for 21 h. Finally, to prepare ZrFe2O4@SiO2@Ade-Pd organometallic catalytic complex, a mixture of ZrFe2O4@SiO2@Ade (2.0 g), Pd(OAc)2 (0.1 g) and 75 ml ethanol was added into the flask and, then, N2 gas was charged into the flask and, finally, it was stirred at 75 °C for 48 h under reflux conditions. Then, NaBH4 (8 mmol) was added into the flask and stirred for 8 h. Next, after completion of the reaction, the final complex ZrFe2O4@SiO2@Ade-Pd was separated and washed with H2O and ethanol and, finally, dried under vacuum at 55 °C (Scheme 1).

Preparation of Buchwald–Hartwig cross‑coupling

In a typical run, iodoarene (0.5 mmol), Et3N (0.5 mmol), and arylamine (0.6 mmol) were dissolved in EtOH (4 mL). The ZrFe2O4@SiO2@Ade-Pd (0.01 g) was added to the mixture, and the resultant mixture was stirred at reflux conditions. The reaction progress was monitored by TLC. Upon the reaction completion, the ZrFe2O4@SiO2@Ade-Pd was separated using a magnet, and then, EtOAc (3 × 4 mL) was added to the reaction mixture. Then the organic phase was separated and dried with the MgSO4, and then the organic solvent was removed at room temperature. The products were purified by silica gel column chromatography (Scheme 2).

Preparation of C–C cross‑coupling reaction

A mixture of PhB(OH)2 (0.6 mmol), aryl halides (0.5 mmol), and K2CO3 (0.7 mmol) in the presence of ZrFe2O4@SiO2@Ade-Pd (0.01 g) was dissolved in Acetonitrile and stirred at room temperature as the mild conditions for appropriate time which is shown in Table 3. Once the reaction was completed, was monitored by TLC technique in Hexane. After the completion of the reaction, the nanocatalyst was separated by magnetic filtration and the product was washed with EtOAc, and the organic layer was dried over anhydrous sodium sulfate. Then EtOAc was evaporated and the pure products were obtained in excellent yields (Scheme 3).

Selected NMR data

4-Methoxy-1,1'-biphenyl:1H NMR (400 MHz, CDCl3): δH = 6.96–7.27 (m, 9H), 4.06 (s, 3H) ppm.

1,1'-Biphenyl]-4-amine:1H NMR (400 MHz, CDCl3): δH = 7.19–7.92 (m, 9H), 4.24 (s, 2H) ppm.

2-methyl-4-nitro-1,1'-biphenyl: 1H NMR (400 MHz, CDCl3): δH = 7.39–7.73 (m, 8H), (s, 3H) ppm.

Diphenylamine:1H NMR (400 MHz, DMSO): δH = 7.86–7.92 (m, 5H), 8.41–8.47 (m, 5H), 8.89 (s, 1H) ppm.

4-methoxy-N-phenylaniline: 1H NMR (400 MHz, DMSO): δH = 7.15–8.04 (m, 7H), 8.56 (m, 1H), 4.46 (s, 3H) ppm.

Catalyst characterizations

The prepared ZrFe2O4@SiO2@Ade-Pd nanocatalyst was characterized by Map, SEM, XRD, FT-IR, EDS, ICP, and TGA techniques.

As shown in Fig. 1, the FTIR spectra of different intermediates and desired catalysts were investigated in the range 400–4000 cm−1. The addition of each layer to the previous one leads to the observation of characteristic peaks of newly added functional groups in the spectrum which proves the formation of a new layer. The absorption bands for ZrFe2O4 (Fig. 1a), ZrFe2O4@SiO2 (Fig. 1b), and ZrFe2O4@SiO2@n-Pr (Fig. 1c) were consistent with our previous reports respectively. Figure 1d, the successful substitution reaction of NH2 with terminal Cl groups on the modified surface of ZrFe2O4 MNPs was confirmed through the presence of absorption bands in the range of 1530 and 1097 cm−1 assigned to Carbon–Nitrogen and Nitrogen–Hydrogen vibration bands, respectively. These spectra reveal that the surface of ZrFe2O4 MNPs is successfully modified with organic layers. More importantly, the bending vibration of NH2 in the FTIR spectrum of ZrFe2O4@SiO2@Ade-Pd support (Fig. 1e), is shifted which confirmed the coordination of nitrogen atom of amino groups to Pd (0).

XRD analytical techniques are used to identify the phase of crystalline materials. Also, the obtained results are consistent with the standard patterns of the ZrFe2O4 crystal structure. Then, the XRD pattern of the nanocatalyst shows that the ZrFe2O4 phase has not been changed during the modifications with a different organic functional group (Fig. 2).

The TGA was investigated for the quantitative determination of the complex (Ade-Pd) supported on the surface of ZrFe2O4 magnetic nanoparticles. The little quantity of weight loss (3%) below 250 °C is due to the removal of adsorbed solvents and OH groups (Fig. 3a). As shown in Fig. 3b, for ZrFe2O4@SiO2@Ade-Pd, there is a weight loss of 8% between 250 and 700 °C related to the breakdown of the ZrFe2O4@SiO2@Ade-Pd moieties. The obtained results from TGA analysis confirmed the successful support of Ade-Pd on the surface of ZrFe2O4 MNPs.

The EDS technique was used to analyze the elemental components of the synthesized catalyst. EDS spectrum of ZrFe2O4@SiO2@Ade-Pd indicates the existence of Zr, O, N, Fe, Si, C, and Pd elements (Fig. 4a). Also, the Morphology of ZrFe2O4@SiO2@Ade-Pd was studied by SEM (Fig. 4b–d). The average size of magnetic nanoparticles calculated from images taken from SEM microscopy was estimated at around 156 nm with the least possible agglomerate (Fig. 4b) Therefore, highly active sites are available for the immobilization of Pd on the surface of ZrFe2O4 nanoparticles.

After the five cycles, the recovered nanocatalyst was characterized by SEM, showing almost the same results as the freshly synthesized nanocatalyst with no significant changes (Fig. 5e–h). A comparison of FT-IR spectra of the nanocatalyst after recycling is shown in Fig. 5I. There are no changes in the FT-IR of ZrFe2O4@SiO2@Ade-Pd after recovery, which confirmed the stability of this nanocatalyst.

The scanning electron microscopy images show that the size of the nanocatalyst particles is in the nanometer range (134–178 nm) with a sphere-like structure. These observations were verified with the achieved data from transmission electron microscopy images (Fig. 6j–m).

The surface area and pore structure of the ZrFe2O4@SiO2@Ade-Pd were probed with N2 adsorption − desorption isotherm measurements. The obtained results show that the BET-specific surface area is 11.7 m2 g−1 for the catalyst (Fig. 7).

Also, with the help of ICP analysis, the amount of palladium in the primary nanocatalyst and the amounts of Pd leaching after recycling of the nanocatalyst were studied by using ICP analysis. Based on such analysis, the amounts of Pd in fresh and reused catalysts are 2.4 × 10−4 mol g−1 and 2.2 × 10−4 mol g−1 respectively, which shows that Pd leaching from the ZrFe2O4@SiO2@Ade-Pd framework is very low.

As illustrated in Fig. 8, the magnetic behavior of a) ZrFe2O4, and (b) ZrFe2O4@SiO2@Ade-Pd was also investigated using VSM technics. As expected, the decrease in saturation magnetization from about 41 emu/g to about 29 emu/g, is related to the newly coated layer and confirmed the successful formation of the desired catalyst.

Catalytic studies

Buchwald–Hartwig cross-coupling reaction catalyzed by ZrFe2O4@SiO2@Ade-Pd

In the next step, to determine the optimum conditions, the catalytic activity of ZrFe2O4@SiO2@Ade-Pd in the reaction between aniline with iodoarene was studied as a model reaction (Table 1). The effects of different factors such as the amount of base, temperature, catalyst, and different solvents on the reaction result were investigated (Table 1). The progress of the reaction became checked by way of TLC, and after completion, the reaction product was extracted with ethyl acetate. The reaction was then screened for a range of catalyst loading in Et3N base, with the use of EtOH solvent at 60 °C, and 0.02 g gave the best result. Among different bases, Et3N was the most productive for reaction at 60 °C. Also, the reaction responded best in H2O at 60 °C with Et3N as a base in the presence of 0.02 g ZrFe2O4@SiO2@Ade-Pd nanocatalyst.

As shown in Table 2, to show the chemoselectivity of the presented protocol, a wide range of arylamine derivatives was prepared by the coupling of substituted aryl halides and secondary amines under stabilized conditions.

In the proposed mechanisms illustrated in Scheme 4, a plausible reaction mechanism for promoting the Buchwald − Hartwig amination reaction under ZrFe2O4@SiO2@Ade-Pd nanocatalysis can be proposed. More precisely, the reaction of the aryl halide with the nanocatalyst could also promote the formation of an intermediate, ArPdX (I). Then from the intermediate reaction with an arylamine to form intermediate (II). Finally, for Buchwald − Hartwig amination reactions, the product is formed through the base-assisted elimination of X–H from intermediate (III) by latter reductive elimination and regenerates ZrFe2O4@SiO2@Ade-Pd MNPs.

The ZrFe2O4@SiO2@Ade-Pd complex was then utilized as catalyst for the C–C cross-coupling reaction. Initial experiments with iodobenzene (1 mmol) as the substrate was conducted to optimize the reaction conditions including the amount of nanocatalysts, solvents, and base (Table 3). Also, the effect of different catalyst loadings on the model reaction was examined in Acetonitrile as solvent with phenylboronic acid as the phenylating agent at room temperature. in the absence of nanocatalyst, the reaction did not give the biphenyl product after 2 days. It should be noted that changing the amount of catalyst has a very important effect on the reaction. When 0.005–0.03 g of nanocatalyst based on Pd content was used as the nanocatalyst, the reaction afforded the desired product in 30–99% yields and 0.02 g gave the best result. whilst increasing the amount of the catalyst to 0.03 g could enhance the reaction rate significantly, but did not increase the yield of the product obviously. Further screening of the nanocatalyst quantities revealed that the use of 0.02 g ZrFe2O4@SiO2@Ade-Pd was the optimal choice. The use of PEG-400, EtOH, or MeOH as the solvent also produced the desired product in very good yields of 81–92%, but Acetonitrile was the best choice. Replacement of K2CO3 with Na2CO3, Cs2CO3, Et3N, t-BuOK, NaOH, or KOH as the base resulted in a decreased yield of the corresponding product, and a long reaction time was needed. According to the observed results, the optimal conditions for this reaction are ZrFe2O4@SiO2@Ade-Pd nanocatalyst (0.02 g), K2CO3 (2 mmol) as the base in the Acetonitrile at 25 °C.

After obtaining the optimal conditions for the coupling reaction of C6H5B(OH)2 with C6H5I (Iodobenzene), the scope of the catalytic activity of ZrFe2O4@SiO2@Ade-Pd was extended to the coupling of other aryl halides with phenylboronic acid. Therefore, various aryl chlorides, aryl iodides, and aryl bromides were investigated in the cross-coupling reaction with phenylboronic acid in the presence of ZrFe2O4@SiO2@Ade-Pd MNPs (Table 4). For example, both electron-deficient and electron-rich aryl halides underwent Suzuki reaction smoothly under mild conditions to afford the desired biphenyl derivatives in 57–99% yield.

The proposed mechanism for the Suzuki reaction in the presence of ZrFe2O4@SiO2@Ade-Pd is shown in Scheme 5. The general catalytic cycle for Suzuki cross-coupling involves three fundamental steps: oxidative addition, transmetalation, and reductive elimination as demonstrated in Scheme 5, The oxidative addition of aryl halides to ZrFe2O4@SiO2@Ade-Pd complex is the initial step to give intermediate I, a ZrFe2O4@SiO2@Ade-Pd species. The presence of amines as the electron-donating groups on the Adenine ligand can activate the Pd (0) catalyst such that the Ar-X bond can be easily broken along with the formation of the Pd-Ar and Pd-X bond. Next, under the participation of the base, an organoborane compound reacts with intermediate I in transmetalation to afford intermediate II.

This is followed by reductive elimination to regenerate the original ZrFe2O4@SiO2@Ade-Pd species to give the desired product.

Catalyst recyclability

In another check, to investigate the recyclability of the magnetic nanocatalyst, the Iodobenzene with phenylboronic acid was examined as a model reaction in EtOH using 0.02 g of ZrFe2O4@SiO2@Ade-Pd. The nanocatalyst was separated by a bar magnet from the reaction mixture and washed several times with EtOH and then with H2O several times. The nanocatalyst was used over five runs without any significant loss of activity (Fig. 9).

In the next step, to demonstrate the merit of ZrFe2O4@SiO2@Ade-Pd we compared the results of the Suzuki reaction with the previously reported in the literature. As shown in Table 5, in comparison with other nanocatalysts employed for the synthesis of biphenyl, by iodobenzene, ZrFe2O4@SiO2@Ade-Pd indicated significant catalytic activity in terms of the high yield and best reaction time.

Conclusion

This work reports the investigation of an efficient procedure to prepare ZrFe2O4@SiO2@Ade-Pd a green, novel, recoverable magnetic nanocatalyst. The prepared catalyst, ZrFe2O4@SiO2@Ade-Pd, was identified via EDS, SEM, VSM, TEM, XRD, TGA, and FTIR. The new nanocatalyst was used for the synthesis of the Buchwald–Hartwig Cross‑coupling and Suzuki reaction. Furthermore, this new ZrFe2O4@SiO2@Ade-Pd can be readily prepared from commercially available materials. Also, it can be mentioned good catalytic activity, easy separation, and reusability of the introduced nanocatalyst.

Data availability

All data generated or analysed during this study are included in this published article [and its supplementary information files].

Change history

03 April 2024

A Correction to this paper has been published: https://doi.org/10.1038/s41598-024-58184-7

21 May 2024

This article has been retracted. Please see the Retraction Notice for more detail: https://doi.org/10.1038/s41598-024-62395-3

References

Kotha, S., Khedkar, P. & Dommaraju, Y. Synthetic applications of rongalite: A green tool in the service of Diels–Alder chemistry and beyond. Tetrahedron Lett. 60, 631–648 (2019).

Taheri Kal Koshvandi, A., Heravi, M. M. & Momeni, T. Current applications of Suzuki-Miyaura coupling reaction in the total synthesis of natural products: An update. Appl. Organomet. Chem. 32, e4210 (2018).

Chen, Z. et al. A heterogeneous single-atom palladium catalyst surpassing homogeneous systems for Suzuki coupling. Nat. Nanotechnol. 13, 702–707 (2018).

Ashraf, M. A., Liu, Z., Zhang, D. & Alimoradi, A. L-lysine-Pd complex supported on Fe3O4 MNPs: A novel recoverable magnetic nanocatalyst for Suzuki C–C cross-coupling reaction. Appl. Organomet. Chem. 34, e5668 (2020).

Tamoradi, T., Daraie, M. & Heravi, M. M. Synthesis of palladated magnetic nanoparticle (Pd@Fe3O4/AMOCAA) as an efficient and heterogeneous catalyst for promoting Suzuki and Sonogashira cross-coupling reactions. Appl. Organomet. Chem. 34, e5538 (2020).

Heravi, M. M., Asadi, S., Hoseini Chopani, S. M. & Jaderi, E. N-heterocyclic carbene–palladium complex onto graphene oxide and poly (ethylene glycol) (PEG) applied as superior catalyst for the Suzuki-Miyaura cross-coupling reaction in water. Appl. Organomet. Chem. 34, e5805 (2020).

Chen, M.-T. et al. N, N′-bridged binuclear NHC palladium complexes: A combined experimental catalytic and computational study for the Suzuki reaction. Appl. Organomet. Chem. 34, e5870 (2020).

Kandathil, V. et al. NHC-Pd complex heterogenized on graphene oxide for cross-coupling reactions and supercapacitor applications. Appl. Organomet. Chem. 34, e5924 (2020).

Kanchana, U. S., Diana, E. J., Mathew, T. V. & Anilkumar, G. Palladium-catalyzed cross-coupling reactions of coumarin derivatives: An overview. Appl. Organomet. Chem. 34, e5983 (2020).

Lakshmidevi, J. et al. Pd(5%)-KIT-6, Pd(5%)-SBA-15 and Pd(5%)-SBA-16 catalysts in water extract of pomegranate ash: A case study in heterogenization of Suzuki–Miyaura reaction under external base and ligand free conditions. Sustain. Chem. Pharm. 19, 100371 (2021).

Lakshmidevi, J., Naidu, B. R. & Venkateswarlu, K. CuI in biorenewable basic medium: Three novel and low E-factor Suzuki–Miyaura cross-coupling reactions. Mol. Catal. 522, 112237 (2022).

Aabaka, S. R. et al. Nanocellulose supported PdNPs as in situ formed nano catalyst for the Suzuki coupling reaction in aqueous media: A green approach and waste to wealth. J. Organomet. Chem. 937, 121719 (2021).

Gorji, S. & Ghorbani-Vaghei, R. Ag nanoparticles stabilized on basalt fibers as a novel, stable, and reusable catalyst for Suzuki–Miyaura coupling reactions. Appl. Organomet. Chem. 35, e6018 (2021).

Han, C. et al. Enhanced support effects in single-atom copper-incorporated carbon nitride for photocatalytic suzuki cross-coupling reactions. Appl. Catal. B 320, 121954 (2023).

Azizollahi, H., Eshghi, H. & García-López, J.-A. Fe3O4-SAHPG-Pd0 nanoparticles: A ligand-free and low Pd loading quasiheterogeneous catalyst active for mild Suzuki–Miyaura coupling and C–H activation of pyrimidine cores. Appl. Organomet. Chem. 35, e6020 (2021).

Akbarzadeh, P. & Koukabi, N. Easy conversion of nitrogen-rich silk cocoon biomass to magnetic nitrogen-doped carbon nanomaterial for supporting of Palladium and its application. Appl. Organomet. Chem. 35, e6039 (2021).

Chen, M.-T., Lin, Y.-H. & Jian, K.-H. (N-Heterocyclic carbene) ion-pair palladium complexes: Suzuki–Miyaura cross-coupling studies in neat water under mild conditions. Appl. Organomet. Chem. 34, e5955 (2020).

Gaikwad, V. V., Mane, P. A., Dey, S. & Bhanage, B. M. Xantphos-ligated palladium dithiolates: An unprecedented and convenient catalyst for the carbonylative Suzuki–Miyaura cross-coupling reaction with high turnover number and turnover frequency. Appl. Organomet. Chem. 34, e5255 (2020).

Lei, Y., Zhu, W., Wan, Y., Wang, R. & Liu, H. Pd nanoparticles supported on amphiphilic porous organic polymer as an efficient catalyst for aqueous hydrodechlorination and Suzuki-Miyaura coupling reactions. Appl. Organomet. Chem. 34, e5364 (2020).

Chen, J., Zhang, J., Zhang, Y., Xie, M. & Li, T. Nanoporous phenanthroline polymer locked Pd as highly efficient catalyst for Suzuki-Miyaura Coupling reaction at room temperature. Appl. Organomet. Chem. 34, e5310 (2020).

Asgari, M. S., RashidiRanjbar, P., Rahimi, R. & Mahdavi, M. Synthesis of arylidene—Isoquinolinones bearing combretastatin skeleton by cyclocarbopalladation/cross coupling tandem Heck–Suzuki Miaura reactions using nano catalyst Pd@Py-IL-SPION. Appl. Organomet. Chem. 34, e5279 (2020).

Kandathil, V., Kempasiddaiah, M., Nataraj, S. K., Somappa, S. B. & Patil, S. A. DNA as a bioligand supported on magnetite for grafting palladium nanoparticles for cross-coupling reaction. Appl. Organomet. Chem. 34, e5357 (2020).

Li, C.-J. Reflection and perspective on green chemistry development for chemical synthesis—Daoist insights. Green Chem. 18, 1836–1838 (2016).

JohanssonSeechurn, C. C. C., Kitching, M. O., Colacot, T. J. & Snieckus, V. Palladium-catalyzed cross-coupling: A historical contextual perspective to the 2010 nobel prize. Angew. Chem. Int. Ed. 51, 5062–5085 (2012).

Zhu, S., Li, H., Li, Y., Huang, Z. & Chu, L. Exploring visible light for carbon–nitrogen and carbon–oxygen bond formation via nickel catalysis. Org. Chem. Front. 10, 548–569 (2023).

Mohite, S. B. et al. O-benzoylhydroxylamines: A versatile electrophilic aminating reagent for transition metal-catalyzed C–N bond-forming reactions. Top. Curr. Chem. 381, 4 (2022).

Zhang, H., Zhu, J.-H., Hou, F., Quan, Z.-J. & Wang, X.-C. A catalytic system with high efficiency and recyclability based on Suzuki and Heck reaction in aqueous admicellar medium. Appl. Organomet. Chem. 34, e5495 (2020).

Muniyappan, N. & Sabiah, S. Synthesis, structure, and characterization of picolyl- and benzyl-linked biphenyl palladium N-heterocyclic carbene complexes and their catalytic activity in acylative cross-coupling reactions. Appl. Organomet. Chem. 34, e5421 (2020).

Çakır, S. & Türkmen, H. Synthesis of water soluble Pd-piperidoimidazolin-2-ylidene complexes and their catalytic activities in neat water. Appl. Organomet. Chem. 34, e5499 (2020).

Niknam, E., Panahi, F. & Khalafi-Nezhad, A. Immobilized Pd on a NHC functionalized metal–organic framework MIL-101(Cr): an efficient heterogeneous catalyst in Suzuki−Miyaura coupling reaction in water. Appl. Organomet. Chem. 34, e5470 (2020).

Alamgholiloo, H., Rostamnia, S. & Noroozi Pesyan, N. Extended architectures constructed of thiourea-modified SBA-15 nanoreactor: A versatile new support for the fabrication of palladium pre-catalyst. Appl. Organomet. Chem. 34, e5452 (2020).

Mohammadkhanni, A. & Bazgir, A. Palladium supported SBA-functionalizd 1,2-dicarboxylic acid: The first Pd-based heterogeneous synthesis of fluorenones. Mol. Catal. 447, 28–36 (2018).

Mohammadinezhad, A. & Akhlaghinia, B. Fe3O4@Boehmite-NH2-CoII NPs: An inexpensive and highly efficient heterogeneous magnetic nanocatalyst for the Suzuki–Miyaura and Heck–Mizoroki cross-coupling reactions. Green Chem. 19, 5625–5641 (2017).

Amini, M. M., Mohammadkhani, A. & Bazgir, A. Dicarboxylic acid-functionalized MCM-41 with embedded palladium nanoparticles as an efficient heterogeneous catalyst for C–C coupling reactions. ChemistrySelect 3, 1439–1444 (2018).

Das, T., Uyama, H. & Nandi, M. Pronounced effect of pore dimension of silica support on Pd-catalyzed Suzuki coupling reaction under ambient conditions. New J. Chem. 42, 6416–6426 (2018).

Acknowledgements

This work was funded by the Researchers supporting project Number (RSP2023R429), King Saud University, Riyadh, Saudi Arabia.

Author information

Authors and Affiliations

Contributions

M.J.S., H.E.N.K., G.G.R.O., M.A., D.K.S. Funding acquisition, Supervision, Resources, Conceptualization, Writing-review & editing. K.Y., M.S., A.I.,* R.A.-S., Investigation, Validation, Methodology.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this Article was revised: The original version of this Article contained an error in Figures 1 and 5.

This article has been retracted. Please see the retraction notice for more detail: https://doi.org/10.1038/s41598-024-62395-3

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Saadh, M.J., Khasawneh, H.E.N., Ortiz, G.G.R. et al. RETRACTED ARTICLE: Synthesis and characterization of ZrFe2O4@SiO2@Ade-Pd as a novel, recyclable, green, and versatile catalyst for Buchwald–Hartwig and Suzuki–Miyaura cross-coupling reactions. Sci Rep 13, 14728 (2023). https://doi.org/10.1038/s41598-023-37680-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-37680-2

- Springer Nature Limited