Abstract

In this study, Co-DAT‐MOF powder was prepared via the solvothermal method using 4, 6-diamino-2-thiopyrimidine as the organic linker and Co(NO3)2·6H2O. The synthesized catalysts are characterized using XRD, FT-IR, TGA, SEM, BET, NH3-TPD, and ICP-OES techniques. SEM analysis clearly indicated the formation of nanosheet microspheres. NH3-TPD-MS was employed as a means of identifying the various strengths of acid sites and their relative abundance in an attempt to explain the effect of the catalyst surface acid sites. We identified a new acidic feature in Co-DAT‐MOF catalyst, related to the presence of desorption peaks in the NH3-TPD profiles. The activity of Co-DAT‐MOF catalyst for the synthesis of multicomponent reactions correlates with lewis acidity. In addition, Co-DAT‐MOF exhibited excellent performance for the synthesis of pyrroloacridine-1(2H)-one and chromeno [2, 3- d] pyrimidin-8-amines, as well as good reusability and recyclability.

Similar content being viewed by others

Introduction

So far, a wide variety of materials, as supports for solid bases, have been studied ranging from inorganic materials1,2,3,4,5,6,7 to organic ones8. Apparently, the support effect is of vital role in determining surface properties, activity, and selectivity of the catalysts9. Metal–organic frameworks (MOFs) have received a lot of attention due to their physical and chemical properties such as high surface area10, pore volumes11, high thermal and chemical stabilities12, and variety of pore dimensions/topologies13. In this sense, metal–organic frameworks (MOFs) have been widely applied in various areas i.e. catalysis14,15,16,17,18,19,20,21,22,23,24,25,26,27, luminescence28, drug delivery29, sensors30, gas storage31 and separation32. Besides, they are capable of being applied as energy storage33, magnetic and ion-conducting properties34, and conversion35. Multicomponent reactions (MCRs) are one-pot highly efficient transformations utilizing three or more components to afford single products with greater efficiency and atom economy36. Moreover, this strategy represents an efficient strategy towards sustainable synthesis. Recently, considerable attention has been paid toward the one-pot multicomponent reactions, due to the fact that they can be broadly applied in order to prepare the biologically relevant or natural-product-like molecular frameworks. Pyrroloacridine-1(2H)-one is an organic compound based on pyridine. Besides, this nucleus which is one of the most significant core structures can be regarded as an important part of most natural and unnatural heterocyclic compounds, has been identified as a vital drug for the treatment of cardiovascular diseases and is known as a calcium channel modulator37. There are different methods to synthesis acridines derivatives from dimedone, aldehyde and aniline derivatives, or ammonium acetate using various catalysts38. We started our study by employing isatin instead of an aldehyde with dimedone, and aniline derivatives for the synthesis of spiro[oxindole-acridine] compounds. Chromenes and their derivatives are very important heterocycles as they display a wide spectrum of biological activities; including, antimicrobial39, antioxidants40, antitumor41, antiproliferative42 and antifungal agent43,44,45. Thus, the development of synthetic strategies for the synthesis of molecules containing chromene and pyrimidine rings are of interest to both organic and medicinal chemists. In this contribution report, the synthesis of Co-DAT‐MOF was generated from the reaction of 4, 6-diamino-2-thiopyrimidine with Co(NO3)2.6H2O under solvothermal conditions. The obtained Co-DAT‐MOF demonstrated high catalytic activity for the synthesis of pyrroloacridine-1(2H)-one and chromeno [2, 3- d] pyrimidin-8-amines. Topological structure of Co-DAT‐MOF is shown in Fig. 1.

Experimental section

Synthesis of cobalt-based metal organic framework

For the preparation of Co-DAT‐MOF, 4, 6-Diamino-2-thiopyrimidine (1 mmol), and Co(NO3)2.6H2O(1 mmol) were dissolved in 20 mL of DMF and 5 mL of H2O. After, the sample was placed in an ultrasonic bath (2.75 L, 380/350 W, UNSPSC 42281712) filled with water by a clamp, and sonicated at room temperature and atmospheric pressure for 20 min. The ultrasonic time was 15 min, and the ultrasonic power was 100 W. Then, mixture transferred into teflon-lined stainless-steel autoclave and heated at 160 ˚C for 15 h. The precipitate was collected, washed with ethyl acetate and dried at 60 °C in the vacuum.

General procedure for the one-pot synthesis of 7, 10-diaryl7H-benzo[7,8]chromeno[2,3d] pyrimidin -8-amine derivatives

A stirring mixture of an aldehydes (2 mmol) of α-naphthol (1 mmol), malononitrile (1 mmol), Co-DAT‐MOF (50 mg) and EtOH (5 mL) was heated under refluxing conditions in an oil bath, followed by the addition of ammonium acetate (2 mmol) at the same temperature (80 °C). Upon completion, 20 mL of ethyl acetate was added to the reaction mixture to separate the catalyst using centrifugation. The filtrate was concentrated under vacuum. The crude products were purified by recrystallization by ethyl acetate and n-hexane (1:6).

General procedure for the one-pot synthesis of 4, 4-dimethyl-2-phenyl-4, 5-dihydropyrrolo[2,3,4-kl] acridin-1(2H)-one

A solution of an aniline (1 mmol), dimedone (1 mmol), isatin (1 mmol), and Co-DAT‐MOF (60 mg) in 2 mL PEG was allowed to stir at 110 °C for the appropriate time. On completion of the reaction (monitored by TLC analysis), the reaction mixture was cooled to 25 °C. At the end of reaction, 20 mL of ethyl acetate was added to the reaction mixture to separate the catalyst using centrifugation. The filtrate was concentrated under vacuum. The crude products were purified by recrystallization by ethyl acetate and n-hexane (1:6).

Results and discussion

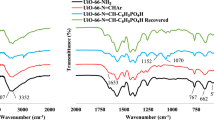

The catalytic system has been studied by XRD, FT-IR, TGA, BET, TPD NH3, ICP-OES, and SEM techniques. Moreover, Fig. 2 comparatively shows the FT-IR spectra of a free ligand, Co (NO3)3.6H2O and Co-DAT‐MOF. In the FT-IR spectrum of free ligand(Fig. 2b), the peaks positioned at 1566, 1675, and 2518 cm−1 were related to stertching vibration of C = N, bending vibration of NH, and stertching band of S–H, respectively. The spectrum of the Co-DAT‐MOF, the absorption of S–H stretching band was disappeared because of the formation of Co-S bond between 4,6-Diamino-2-thiopyrimidine and Co. In addition, the bending vibration of N–H, for Co-P-MOF structure shifted to the lower wavenumber (1652 cm−1) which results demonstrate Co ions can be regarded as the ions modified on the surface of the ligand.

The overall morphology of the Co-DAT‐MOF (Fig. 3) indicates that microspheres were synthesized using this simple solvothermal method. As shown in the high-magnification SEM images, the microspheres are composed of numerous ultrathin nanosheets.

In order to investigate the crystal structure of Co-DAT‐MOF nanocatalyst, we used XRD pattern(Fig. 4). The XRD of the Co-DAT‐MOF shows the main peak at 11.78 which corresponds to the standard pattern46.

TGA used to shows the weight loss of Co-DAT‐MOF under air atmosphere (Fig. 5). The first weight loss of 9 wt% occurs below 300 °C, corresponding to the elimination of bound DMF molecules. It also indicates a loss of one DMF molecule per host lattice. The second weight loss of 21 wt% over the temperature range of 320–550 °C can be ascribed to the decomposition of Co-DAT‐MOF and formation of cobalt oxide.

The nitrogen adsorption–desorption isotherm of the Co-DAT‐MOF shown in Fig. 6 could be categorized as type IV with hysteresis loops in the range of 0.64–0.96 P/P0, the existence of abundant pores. The Brunauer–Emmett–Teller (BET) specific surface area was 2.5 m2 g−1. The BJH pore size calculations using the adsorption branch of the nitrogen isotherm indicate a micropore peak at about 1.66 nm for Co-DAT‐MOF (Fig. 7).

The NH3-TPD pattern of the Co-DAT‐MOF catalyst is shown in Fig. 8, Table 1 and peaks desorption of NH3 are observed. The peak observed at (95–300 °C) is attributed to weak acid sites and the peak at a range of temperatures (300–475 °C) to strong acidic sites. In the case of exceeding this temperature (475 °C) during the NH3-TPD measurements, the thermal decomposition of samples could occur and the evolved gases could be misinterpreted as ammonia because the employed detector (TCD) did not enable the identify the evolved gases.

Catalytic studies

Applicability of Co-DAT‐MOF was investigated for the synthesis of pyrroloacridine-1(2H)-one and chromeno [2, 3- d] pyrimidin-8-amines. In the first part, a direct synthesis of Chromeno [2, 3- d] pyrimidin-8-amines via combination of, 4-Chlorobenzaldehyde, α-naphthol, malononitrile, and ammonium acetate in the presence of Co-DAT‐MOF was presented (Fig. 9). Initially, the effect of solvents (PEG, DMF, EtOH, H2O) was also investigated and it was observed that the reaction was highly effective with EtOH. Furthermore, the progress of the reaction depended on the amount of Co-DAT‐MOF; the reaction was found to complete in the presence of 50 mg of this catalyst. The control experiment confirmed that the reaction did not occur in the presence of Co (NO3)3.6H2O, and 4, 6-Diamino-2-thiopyrimidine as acatalyst (Table 2, entry 11–12). The reaction when conducted at room temperature and 60 °C, the yields observed were very low (Table 2, entries 5 and 6). The ideal temperature for the reaction was found to be 80 °C. Subsequently we performed the synthesis of diverse chromeno [2, 3- d] pyrimidin-8-amines with different substituted aldehyde under optimized reaction condations (Table 3). Both electron-withdrawing and electron-donating substituents on the aldehydes were found to work reasonably well, giving moderate to good yields of the final products. A plausible mechanism for the formation of chromeno [2, 3- d] pyrimidin-8-amines derivatives has been described in Fig. 10.

The catalytic activity of Co-DAT‐MOF was evaluated for synthesis pyrroloacridine-1(2H)-one derivatives based on the one-pot three-component reaction of amine, dimedone, and isatin. We performed the reaction by conducting the reaction of aniline, dimedone and isatin as a model to optimize the process conditions in the presence of Co-DAT‐MOF (Fig. 11). We also tested the influence of solvents and found out that DMF, and PEG afforded the final products (Table 4). However, higher yields were obtained when PEG was used as the solvent. Then, the influence of temperature on the progress of the reaction was evaluated. Lower yields of the desired product was observed while decreasing the reaction temperature. Afterwards the specific amounts of the catalyst (30, 40, 50, 60 mg) were utilized in the process. In addition, the control experiment confirmed that the reaction did not occur in the absence of the catalyst (Table 4, entry 8). In order to broaden the scope of the developed protocol, a wide range of amines were examined for the synthesis of pyrroloacridine-1(2H)-one (Table 5). The amines containing the electron-donating as well as electron-withdrawing substituents were compatible under the optimized reaction and provided good to excellent yield of the corresponding pyrroloacridine-1(2H)-one.

Moreover, a plausible mechanism on the basis of the previous publications for the synthesis of pyrroloacridine-1(2H)-one derivatives has been shown in Fig. 12.

Heterogeneity studies

Hot filtration

Hot filtration is another technique to know the heterogeneity of a reaction. Hot filtration technique was carried out for the synthesis 4, 4-dimethyl-2-phenyl-4,5-dihydropyrrolo[2,3,4-kl]acridin-1(2H)-one. The catalyst was separated from the reaction mixture by a simple filtration when the reaction proceeded past 50% completion. We have observed that no further reaction occurred after the separation of the catalyst which means that the Co catalyst remains on the surface during the reaction.

One of the most important features of the catalyst is the ability to be recycled. To this aim, the reusability of the mesoporous catalyst has been investigated for the synthesis of 4, 4-dimethyl-2-phenyl-4, 5-dihydropyrrolo [2,3,4-kl] acridin-1(2H)-one using the reaction aniline, dimedone, and isatin. Figure 13 displays that the catalyst could be retrieved by simple filtration and recycled at least 4 times without important loss of its high catalytic activity. Also, the amounts of cobalt leaching after recycling of catalyst was analyzed using ICP-OES. Base on such analysis, the amounts of cobalt in fresh and reused catalyst are 0.065 mol.g−1 and 0.061 mol.g−1 respectively, which shows that cobalt leaching from Co-DAT‐MOF is very low.

The recovered catalyst was analyzed to prove stability and the recoverability using FT-IR, and XRD techniques. The FT-IR spectrum and XRD pattern of the recovered Co-DAT‐MOF indicate that this catalyst can be recycled without any change in its structure (Figs. 4 and 14).

Comparison of the catalyst

The activity of the prepared catalyst for synthesis of chromeno [2, 3- d] pyrimidin-8-amines was compared with previously reported data in the literature. From Table 6, it is clear that Co-DAT‐MOF worked remarkably well to give the desired product within 60 min in 98% yield in shorter reaction.

Conclusions

The Co-DAT‐MOF was successfully synthesized using a facile solvothermal method and characterized using XRD, FT-IR, TGA, BET, TPD-NH3, ICP-EOS, and SEM techniques. The Co-DAT‐MOF particles have a microspheres shape, and good thermal stability. To explore the acidic properties of applied Co-DAT‐MOF, the NH3-TPD technique was employed. The peak observed at (95–300 °C) is attributed to weak acid sites, and the peak at range of temperatures (300–475 °C) to strong acidic sites. The N2 sorption isotherm shows that Co-DAT‐MOF possesses type IV sorption isotherm. The catalyst was found to be highly efficient and could be reused for four catalytic cycles. This study provides a novel strategy to synthesis of pyrroloacridine-1(2H)-one and chromeno [2, 3-d] pyrimidin-8-amines.

Data availability

All data generated or analysed during this study are included in this published article [and its supplementary information files].

References

Trueba, M. & Trasatti, S. P. γ-Alumina as a support for catalysts: A review of fundamental aspects. Eur. J. Inorg. Chem. 2005, 3393–3403 (2005).

Huo, J., Wei, H., Fu, L., Zhao, C. & He, C. Highly active Fe36Co44 bimetallic nanoclusters catalysts for hydrolysis of ammonia borane: The first-principles study. Chin. Chem. Lett. 34, 107261 (2023).

Wei, T. et al. Metal–organic framework-derived Co3O4 modified nickel foam-based dendrite-free anode for robust lithium metal batteries. Chin. Chem. Lett. https://doi.org/10.1016/j.cclet.2022.107947 (2022).

Huang, Z. et al. Highly efficient oxidation of propane at low temperature over a Pt-based catalyst by optimization support. Environ. Sci. Technol. 56, 17278–17287 (2022).

Zhang, N. et al. Synchronously constructing the optimal redox-acidity of sulfate and RuOx Co-modified CeO2 for catalytic combustion of chlorinated VOCs. J. Chem. Eng. 454, 140391 (2023).

Ou, C. H., Pan, Y. M. & Tang, H. T. Electrochemically promoted N-heterocyclic carbene polymer-catalyzed cycloaddition of aldehyde with isocyanide acetate. Sci. China Chem. 65, 1873–1878 (2022).

Wang, H. et al. Chiral 1, 2-diaminocyclohexane-α-amino acid-derived amidphos/ag (I)-catalyzed divergent enantioselective 1, 3-dipolar cycloaddition of azomethine ylides. Heterocycles 104, 123–139 (2022).

Kaur, P., Hupp, J. T. & Nguyen, S. T. Porous organic polymers in catalysis: Opportunities and challenges. ACS Catal. 1, 819–835 (2011).

Keyvanloo, K., Huang, B., Okeson, T., Hamdeh, H. H. & Hecker, W. C. Effect of support pretreatment temperature on the performance of an iron Fischer-Tropsch catalyst supported on silica-stabilized alumina. Catalysts 77, 8 (2018).

Jiang, H. L. & Xu, Q. Porous metal-organic frameworks as platforms for functional applications. Chem Comm. 47, 3351–3370 (2011).

Bao, S. J. et al. A stable metal-organic framework with suitable pore sizes and rich uncoordinated nitrogen atoms on the internal ss.rface of micropores for highly efficient CO2 capture. J. Mater. Chem. A 3, 7361–7367 (2015).

Howarth, A. J. et al. Chemical, thermal and mechanical stabilities of metal–organic frameworks. Nat. Rev. Mater. 1, 1–15 (2016).

Parkes, M. V., Staiger, C. L., Perry, J. J. IV., Allendorf, M. D. & Greathouse, J. A. Screening metal–organic frameworks for selective noble gas adsorption in air: Effect of pore size and framework topology. Phys. Chem. Chem. Phys. 15, 9093–9106 (2013).

Ghorbani-Choghamarani, A. & Taherinia, Z. Chiral cobalt-peptide metal-organic framework (Co-P-MOF): As an efficient and reusable heterogeneous catalyst for the asymmetric sulfoxidative cross-coupling reaction using poly sulfinylpiperazine. Synth. Met. 263, 116362 (2020).

Ghorbani-Choghamarani, A. & Taherinia, Z. Fe3O4@ GlcA@ Cu-MOF: A magnetic metal-organic framework as a recoverable catalyst for the hydration of nitriles and reduction of isothiocyanates, isocyanates, and isocyanides. ACS Comb. Sci. 22, 902–909 (2020).

Su, T. Y., Lu, G. P., Sun, K. K., Zhang, M., & Cai, C. ZIF-derived metal/N-doped porous carbon nanocomposites: efficient catalysts for organic transformations. Catal. Sci. Technol. (2022).

Phan, N. T., Nguyen, T. T., Nguyen, C. V. & Nguyen, T. T. Ullmann-type coupling reaction using metal-organic framework MOF-199 as an efficient recyclable solid catalyst. Appl. Catal. 457, 69–77 (2013).

Lustig, W. P. et al. Metal-organic frameworks: functional luminescent and photonic materials for sensing applications. Chem. Soc. Rev. 46, 3242–3285 (2017).

Madasamy, K., Kumaraguru, S., Sankar, V., Mannathan, S. & Kathiresan, M. A Zn based metal organic framework as a heterogeneous catalyst for C-C bond formation reactions. N. J. Chem. 43, 3793–3800 (2019).

Chen, Z., Chen, J. & Li, Y. Metal–organic-framework-based catalysts for hydrogenation reactions. Chin. J. Catal. 38, 1108–1126 (2017).

Hu, M. L. et al. Taking organic reactions over metal-organic frameworks as heterogeneous catalysis. Micropor. Mesopor. Mat. 256, 111–127 (2018).

Nguyen, L. T., Nguyen, T. T., Nguyen, K. D. & Phan, N. T. Metal-organic framework MOF-199 as an efficient heterogeneous catalyst for the aza-Michael reaction. Appl. Catal. 425, 44–52 (2012).

Rafiee, Z. Fabrication of efficient Zn-MOF/COF catalyst for the Knoevenagel condensation reaction. J. Iran. Chem. Soc. 18, 2657–2664 (2021).

Phan, N. T., Le, K. K. & Phan, T. D. MOF-5 as an efficient heterogeneous catalyst for Friedel-Crafts alkylation reactions. Appl. Catal. 382, 246–253 (2010).

Luz, I., Xamena, F. L. I. & Corma, A. Bridging homogeneous and heterogeneous catalysis with MOFs: “Click” reactions with Cu-MOF catalysts. J. Catal. 276, 134–140 (2010).

Lee, J. et al. Strategies in metal-organic framework-based catalysts for the aerobic oxidation of alcohols and recent progress. Bull. Korean Chem. Soc. 42, 359–368 (2021).

Ma, P. et al. Heterogeneous amorphous Cu-MOF-74 catalyst for C-N coupling reaction. ChemistrySelect 3, 10694–10700 (2018).

Lustig, W. P. et al. Metal-organic frameworks: Functional luminescent and photonic materials for sensing applications. Chem. Soc. Rev. 46, 3242–3285 (2017).

Wang, L., Zheng, M. & Xie, Z. Nanoscale metal–organic frameworks for drug delivery: A conventional platform with new promise. Mater. Chem. B 6, 707–717 (2018).

Kreno, L. E. et al. Metal-organic framework materials as chemical sensors. Chem. Rev. 112, 1105–1125 (2012).

Ma, S. & Zhou, H. C. Gas storage in porous metal-organic frameworks for clean energy applications. ChemComm 46, 44–53 (2010).

Zhao, X., Wang, Y., Li, D. S., Bu, X. & Feng, P. Metal-organic frameworks for separation. Adv. Mater. 30, 1705189 (2018).

Wang, L. et al. Metal-organic frameworks for energy storage: Batteries and supercapacitors. Coord. Chem. Rev. 307, 361–381 (2016).

Xu, Z., Wong, Y. L., Xiao, R. & Hou, Y. Electronic and ionic conductivity of metal-organic frameworks. In Comprehensive Supramolecular Chemistry II 399–423 (Elsevier, 2017).

Ding, M., Flaig, R. W., Jiang, H. L. & Yaghi, O. M. Carbon capture and conversion using metal–organic frameworks and MOF-based materials. Chem. Soc. Rev. 48, 2783–2828 (2019).

Ganem, B. Strategies for innovation in multicomponent reaction design. Acc. Chem. Res. 42, 463–472 (2009).

Yang, H. K. et al. Synthesis and biological evaluation of pyrrolidine-based T-type calcium channel inhibitors for the treatment of neuropathic pain. J. Enzyme Inhib. Med. Chem. 33, 1460–1471 (2018).

Khojastehnezhad, A., Rahimizadeh, M., Eshghi, H., Moeinpour, F. & Bakavoli, M. Ferric hydrogen sulfate supported on silica-coated nickel ferrite nanoparticles as new and green magnetically separable catalyst for 1, 8 dioxodecahydroacridine synthesis. Chin. J. Catal. 35, 376–382 (2014).

Khafagy, M. M., Abd El-Wahab, A. H., Eid, F. A. & El-Agrody, A. M. Synthesis of halogen derivatives of benzo [h] chromene and benzo [a] anthracene with promising antimicrobial activities. Il Farmaco 57, 715–722 (2002).

Sivaguru, P., Sandhiya, R., Adhiyaman, M. & Lalitha, A. Synthesis and antioxidant properties of novel 2H-chromene-3-carboxylate and 3-acetyl-2H-chromene derivatives. Tetrahedron Lett. 57, 2496–2501 (2016).

Okasha, R. M. et al. Design of new benzo [h] chromene derivatives: Antitumor activities and structure-activity relationships of the 2, 3-positions and fused rings at the 2, 3-positions. Molecules 22, 479 (2017).

Luque-Agudo, V. et al. Synthesis and antiproliferative activity of new 2-glyco-3-nitro-2H-chromenes. Bioorg. Chem. 87, 112–116 (2019).

Thareja, S. et al. Novel chromeneimidazole derivatives as antifungal compounds: Synthesis and in vitro evaluation. Acta Pol. Pharm. 67, 423–427 (2010).

Liu, W. et al. Natural products-based fungicides: Synthesis and antifungal activity against plant pathogens of 2H-chromene derivatives. Chem. Biodivers. https://doi.org/10.1002/cbdv.202200802 (2022).

Zhang, R. R. et al. HMicrowave-assisted synthesis and antifungal activity of novel coumarin derivatives: Pyrano [3, 2-c] chromene-2, 5-diones. Eur. J. Med. Chem. 116, 76–83 (2016).

Yan, W. et al. Downsizing metal–organic frameworks with distinct morphologies as cathode materials for high-capacity Li-O2 batteries. Mater. Chem. Front. 1, 1324–1330 (2017).

Shaterian, H. R. & Noura, S. Mildly basic ionic liquid catalyzed pseudo four component synthesis of 7, 10-diaryl-7 H-benzo [7, 8] chromeno [2, 3-d] pyrimidin-8-amine derivatives under solvent-free conditions. RSC Adv. 4, 60543–60547 (2014).

Taherinia, Z., Ghorbani-Choghamarani, A. & Hajjami, M. Decorated peptide nanofibers with Cu nanoparticles: An efficient catalyst for the multicomponent synthesis of chromeno [2, 3-d] pyrimidin-8-amines, quinazolines and 2H-indazoles. ChemistrySelect 4, 2753–2760 (2019).

Li, C. & Zhang, F. Single step incorporation of isatin to enaminone: A recyclable catalyst towards assembly of diverse four ring fused pyrrolo [2, 3, 4-kl] acridin-1-ones. RSC Adv. 6, 75359–75364 (2016).

Kefayati, H., Narchin, F. & Rad-Moghadam, K. An unexpected multicomponent reaction leading to 2-arylpyrrolo [2, 3, 4-kl] acridin-1 (2H)-ones. Tetrahedron Lett. 53, 4573–4575 (2012).

Kanakaraju, S., Prasanna, B., Basavoju, S. & Chandramouli, G. V. P. Ionic liquid catalyzed one-pot multi-component synthesis, characterization and antibacterial activity of novel chromeno [2, 3-d] pyrimidin-8-amine derivatives. J. Mol. Struct. 1017, 60–64 (2012).

Ghorbani-Choghamarani, A., Bastan, H. & Taherinia, Z. New microsphere cobalt complex: Preparation and catalytic consideration for the synthesis of some heterocyclic compounds. ChemistrySelect 5, 15130–15136 (2020).

Acknowledgements

The authors would like to thank the research facilities of Ilam University and Bu-Ali Sina University for financial support of this research project.

Author information

Authors and Affiliations

Contributions

A.G.-C.: Funding acquisition, Supervision, Conceptualization, Resources, Writing-review & editing. Z.K.: Methodology, Validation, Investigation. Z.T.: Validation, Investigation, Methodology, Writing-original draft.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ghorbani-Choghamarani, A., Kakakhani, Z. & Taherinia, Z. 4,6-Diamino-2-thiopyrimidine-based Cobalt Metal Organic Framework (Co-DAT‐MOF): green, efficient, novel and reusable nanocatalyst for synthesis of multicomponent reactions. Sci Rep 13, 7502 (2023). https://doi.org/10.1038/s41598-023-34001-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-34001-5

- Springer Nature Limited