Abstract

In this work, a series of innovative metal oxide impregnated waste-derived activated carbons (MO/AC) was synthesized and used to purify the simulated biohydrogen based on the concept of CO2 removal from the gas stream. Effects of metal oxide types (CaO, SrO and MgO) and contents of the best metal oxides on the morphology and the CO2 adsorption capacity from the biohydrogen were investigated. It was found that both metal oxide types and contents played an important role on the adsorbent textural property and surface chemistry as well as the CO2 adsorption capacity. Among all synthesized adsorbent, the MgO-impregnated AC with 12 wt.% MgO (12MgO/AC) exhibited the highest CO2 adsorption capacity of around 94.02 mg/g. With this successive adsorbent, the biohydrogen with the H2 purity higher than 90 mol% can be achieved from the gas stream with 50 mol% CO2 for the first 2 min of adsorption period in a fixed bed reactor. The mechanism of CO2 adsorption occurred via a combined process of the physisorption and chemisorption. Besides, the 12MgO/AC exhibited a high recyclability after several repetitive adsorption/desorption cycles.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Introduction

The production of H2 via the biological process is one of the currently hottest issues in the field of bioenergy because of its low energy requirement in comparison with the production of H2 from fossil fuels. Typically, there are three classical biological processes used to produce the biohydrogen including bio-photolysis, photo-fermentation and dark fermentation1. Based on the technical feasibility considered in terms of stability, simplicity and productivity, the dark fermentation is the technical challenge2. Via this successive process, the principal compositions of produced biohydrogen are H2 and CO23, in which approximately 56% of H2 was obtained at 35 °C and 1 atm4. A high H2 purity of the produced biogas can be obtained using various purification processes such as cryogenic process5, absorption6,7,8, membrane separation6,9,10,11 or their combined process12,13. Nevertheless, each process exhibits both technical benefits and drawbacks. For example, the cryogenic process exhibits the capability to purify the CO2-rich gas stream (CO2 ~ 90%) and able to produce liquid CO2, but it is the energy intensive and complex3. The absorption is able to recover high CO2 quantity from a low pressure gas stream with low energy requirement for H2 compression; however it requires extensive energy for solvent recovery and has a solvent loss3,7. The membrane separation requires the minimal utility in operation and allows an in-situ and continuous flow of biohydrogen, but it gives a low product purity and recovery and also requires the pre-filter/coalescer and/or the gas compression system3,9. Another possible process might be the adsorption14,15,16, because of its high efficiency to produce high purity biohydrogen, environmentally friendly, ease of operation and control3,17,18,19.

The biohydrogen purification via the adsorption is carried out based on the concept of the CO2 removal from the biohydrogen stream using an effective adsorbent that has fast adsorption kinetics, high adsorption capacity and selectivity as well as high recyclability20. Among the promising adsorbents (e.g. zeolites, chalcogenides, metal-organic frameworks (MOF) or resin21), the carbonaceous materials exhibit an outstanding property related to a high CO2 selectivity compared with H2 selectivity22. Recently, it was reported that the CO2 selectivity of bare ACs was limited by both pore size and average particle size in the presence of high CO2 concentration (~ 46.4 mol%), while it was limited by solely average particle size in the presence of low CO2 concentration (~14.9 mol%)23. A significant CO2 reduction in biohydrogen from 46.4% to less than 4.3% was obtained at 10 °C and about 2 MPa using a two-stage adsorption. The resin-derived AC displayed the CO2 adsorption capacity of 92.8% from a H2/CO2 mixture in the presence of 70 mol% CO2 at 25 °C and 1.2 bar24. The ionic liquid-impregnated activated carbon (IL/AC) was able to adsorb CO2 of around 90% from an equimolar H2/CO2 gas mixture at 30 °C for 6 h16. The carbon nanoflake hybrid synthesized from the starch powder in the presence of metal oxide and amine exhibited the CO2 adsorption capacity up to 6.77 mmol/g at 25 °C and 1 atm25, attributed to its high surface area and mesopore-micropore morphology. The 12 wt.% chitosan-impregnated palm shell-based activated carbon (CHI/AC) completely adsorbed CO2 from a CO2/H2/N2 mixture (50:30:20 by volume) up to at least 5 cycles under the adsorption pressure of 4 bar at 298 K14, due to the presence of appropriate nitrogen containing surface functional groups on the surface of AC. The impregnation of KOH, KI, CuSO4, Na2CO3, and ZnC4H6O4 on the AC surface importantly improved the CO2 adsorption capacity of AC26. Among all explored chemical-impregnated AC, the zinc acetate impregnated AC exhibited the highest CO2 adsorption capacity of 63.61 mg/g AC at 1 bar, because of the existence of abundant nano-porosity and high BET surface area26.

As described above, it can presume that the effectiveness of the biohydrogen purification depends significantly on types and properties of adsorbents. For economic and sustainability perspectives, the synthesis of AC from biomass or wastes (e.g. agriculture-, household- or industry wastes) is the key issue because of their plentiful and worthwhile. In this work, the spent chopsticks were used as raw materials to synthesize AC due to their massive dumping every day in our country. Based on our published works, it was found that the spent chopstick-derived AC obtained from the chemical activation exhibited higher CO2 adsorption capacity than those obtained from the physical activation of around 35.8%21,27. This is because the chemical activation can effectively promote the formation of appropriate surface area, porosity as well as the surface functional groups, which were responsible for the CO2 adsorption. Based on the acid property of CO2, the presence of appropriate quantity of basic sites can promote the CO2 adsorption through the acid-base interaction28,29. Therefore, the strengthened CO2 adsorption capacity of the chopstick-derived AC synthesized by physical activation was conducted by the impregnation of metal oxides on the surface of AC. Effects of various metal oxide types including CaO, SrO, MgO and contents of the best metal oxides on the morphology and CO2 adsorption capacity were systematically investigated and reported.

Methods

Chemicals and precursor materials

All chemicals employed in this work were analytical or GR grade including gaseous nitrogen (N2; 99.999%, Alternative Chem), hydrogen (H2; 99.99%, Alternative Chem), carbon dioxide (99.99% CO2, Alternative Chem), calcium nitrate tetrahydrate (Ca(NO3)2⋅4H2O, KemAus), strontium nitrate (Sr(NO3)2, Himedia) and magnesium nitrate hexahydrate (Mg(NO3)2⋅6H2O, PanReac Applichem). The carbonaceous material employed in this work was the spent disposable wooden chopsticks. Prior to utilization, they were crushed by a knife mill and sieved to get an average particle size between 0.21 and 4.76 mm. Their dry basis compositions were displayed in our previous published work27.

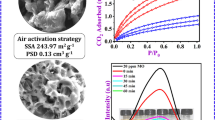

Preparation of AC and metal oxide-impregnated AC

A sequential process of carbonization and steam activation was carried out to synthesize ACs from spent disposable wooden chopsticks for the biohydrogen purification application (Fig. 1a). As brief, the crushed spent disposable wooden chopsticks were first dried in air at 105 °C for 3 h to eliminate some free moisture and then subjected to carbonize in a cylindrical stainless-steel reactor under the N2 atmosphere at a constant flow rate of 1 L/min. The carbonization temperature and time were respectively fixed at 500 °C and 15 min with a heating rate of 10 °C/min27. When the carbonization was complete, the obtained biochar was then carried out to the activation process using steam as the physical activator. The activation process was carried out at 700 °C for 2 h in a horizontal fixed bed reactor under N2 atmosphere (1 L/min) using a steam flow rate of 8 mL/min27, yielding the chopstick-derived AC denoted as AC.

To strengthen the CO2 adsorption capacity of the AC, the metal oxide-impregnated ACs (xMO/ACs; x is the weight percent of respective impregnated metal oxides), the procedure proposed by Hidayu30 was adopted as shown in Fig. 1b. Initially, a certain quantity of Ca(NO3)2⋅4H2O was dissolved in 50 mL deionized (DI) water and added by 4 g of ACs. The slurry was rigorously shaken via the orbital shaker (CTL, Model SK3) at 200 rpm at room temperature for 24 h. Then, the solid portion was separated from the aqueous solution by the vacuum filtration and dried overnight in oven (Binder, Model ED115) at 105 °C. The obtained dried solid was then thermal treated in a circular stainless-steel reactor under N2 atmosphere (1 L/min) at 750 °C for 1 h with a constant heating rate of 10 °C/min, getting x wt.% of CaO impregnated ACs (xCaO/AC). The similar preparation procedure was carried out for SrO and MgO using Sr(NO3)2 and Mg(NO3)2⋅6H2O as the chemical precursors, respectively.

Characterization

The physicochemical characteristics of all synthesized spent disposable wooden chopsticks-derived AC were determined as follows. High-resolution image and elemental identification were determined by scanning electron microscopy and energy dispersive X-ray spectrometry (SEM-EDX; IT-500HR JEOL). The presence of chemical bonding and functional groups was qualitative analyzed by Fourier-transform infrared spectroscopy (FTIR; FT/IT-6800 JASCO). The crystallite structures were identified by X-ray diffractometry (XRD; D2 Phaser, Bruker) and Raman spectroscopy (Perkin Elmer Spectrum GX). The textural properties were explored via N2 adsorption isotherms using Multipoint Surface Area Analyzer (Micromeritics, Tristar II3020) using the Brunauer-Emmett-Teller (BET) methods. All samples were first degassed at temperature of 300 °C for 10 h in N2 atmosphere and analyzed at temperature of 77 K. The quantity of basic site on the surface of adsorbents was determined via the CO2 temperature-programmed desorption (CO2-TPD, BELCAT-B). Prior to analyzation, approximately 50 mg was pretreated at 200 °C for 30 min under constant helium (He) flow rate of 30 mL/min. The textural properties of the parental AC were partially taken from our published work27.

Adsorption capacity test

The biohydrogen employed in this work was simulated by mixing the commercial H2 and CO2 at particular molar ratios in the range of 10–50 mol%. The adsorption capacity of all xMO/AC samples was tested via the CO2 adsorption from the simulated biohydrogen in a horizontal glass tube reactor having an inside diameter of 8 mm ID and 600 mm length at constant temperature of 25 °C and 1 atm. In each experiment, approximately 2 g of adsorbents was dried at 105 °C for 5 h to eliminate free moisture and then carefully packed in a glass column. The simulated biohydrogen gas with the specific CO2 concentration in the range of 10 to 50 mol % was then supplied throughout the system at a constant flow rate of 100 mL/min. The flow rate of biohydrogen was precisely controlled by mass flow controllers (S48-2-HMT, Horiba). As the adsorption was proceeded, the concentration of outlet gas stream was analyzed by gas chromatography (GC, Shimadzu GC-8A) with a thermal conductivity detector (TCD) at the INJ/DET temperature of 120 °C, column temperature of 100 °C, and current of 100 mA.

The quantity of adsorbed CO2 via the as-synthesized adsorbents expressed in terms of mg CO2 per gram of bulk adsorbent was calculated according to Eq. (1)27. All reported adsorption capacities were the averaged values obtained from at least three trials with the relative errors of less than 3%.

Reusability test

The reusability of used adsorbents was carried out by a low temperature thermal treatment. After the fresh adsorbent was used to adsorb 50 mol% CO2 from the simulated biohydrogen at a total flow rate of 100 mL/min at 25 °C and 1 atm, it was carefully taken from the adsorption reactor and subjected to the thermal treatment in air at temperature of 105 °C and ambient pressure. Afterward, the regenerated adsorbent was introduced to adsorb CO2 from the simulated biohydrogen at identical adsorption condition. The repetitive adsorption/desorption cycles were carried out for 6 times and the quantity of adsorbed CO2 on each regenerated adsorbent was determined according to Eq. (1).

Results and discussion

Effect of impregnated MO type

The surface morphology of parental AC and 9MO/AC samples with the magnification of 5000x were displayed in Fig. 2 (left). The AC samples showed a clear and smooth surface with almost uniform dispersion of circular pores. All the 9MO/AC samples exhibited noticeably low appearance pores compared with those of the original AC sample. Besides, they displayed the presence of impregnated MO as clearly confirmed by the EDX images as shown in Fig. 2 (right), thereby causing the blurriness surface.

Figure 3 shows the FTIR spectra of the parental AC and 9MO/AC samples. The FTIR spectrum of the parental AC showed peaks of aromatic C–H out-of-plane bending mode at a wavenumber lower than 920 cm−131, C–O stretching vibration of surface groups such as ethers, esters, cyclic ethers, lactonic groups, phenolic groups, and also carboxylic acids and cyclic anhydrides at wavenumber of 920–1300 cm−132 and C=C stretching vibration of sp2 hybridized carbon at wavenumber of 1480–1650 cm−1. Intense spectra appeared a wavenumber of 2350 cm−1 due to atmospheric CO233,34. The FTIR spectra of the 9MO/ACs exhibited almost similar band position with respect to the parental AC with a more intense band of C–O stretching vibration of ether at 920–1100 cm-1 and polyaromatic C=C stretching vibration of sp2 hybridized carbons at 1500 cm−132. Unlike the EDX analysis, the presence of impregnated MO was not obviously observed.

Representative FTIR spectra of the AC27 and 9MO/AC samples.

Figure 4a presented the XRD spectra of the 9MO/AC samples together with the AC sample. It was obviously seen that the original AC displayed two broad diffraction peaks at 2θ of 20–30° and 40–50°, due to the presence of amorphous carbon structure generated from the disordered carbon rings35,36. Two spike peaks observed at 2θ of 29.76° and 30.79° could be due to the presence of oxide species of raw material-contained minerals such as K2O species (JCPDS card no. 26-1327)37. However, they were disappeared after the metal oxide impregnation, probably due to the reduction of K2O with carbon (C) at the temperature higher than 700 °C38. The XRD spectra of 9CaO/AC exhibited a well-defined peak at 2θ of 44.63°, assigning to the crystal plane of CaO as (200) (JCPDS card no. 77-2376)39. Besides, additional peak appeared at 2θ of 34.02° corresponding to the presence of Ca(OH)2 as (101) plane (JCPDF 1-1079) was observed, indicating a low stability of crystal CaO structure40. The diffraction peaks of 9SrO/AC sample exhibited the characteristic peaks of SrO crystal planes as (110), (111), (200) and (220) at 2θ of 25.6°, 26.8°, 35.6° and 50.2°, respectively (JCPDS card no. 01–075-0263)41,42. The presence of Sr(OH)2 was also found in the 9SrO/AC structure, diagnosing from the peak at 2θ of 44.6° which was corresponding to the (211) plane of Sr(OH)242. The XRD patterns of 9MgO/AC samples illustrated two diffraction peaks at 42.9° and 62.3°, indicating the (200) and (220) lattice planes of the MgO cubic structure (JCPDS card no. 4-829)43,44. The average crystallite sizes of all impregnated MO were then estimated from the full width at half maximum (FWHM) of the peaks (200), (110) and (200) planes for CaO, SrO and MgO, respectively, using the Scherrer equation (Eq. (2))45. As listed in Table 1, the 9CaO/AC sample exhibited the largest average CaO crystallite size of 47.2 nm, while the 9MgO/AC sample showed the smallest average MgO crystallite size of 9.3 nm, which might play the role on their textural property.

To intensively explore the crystallographic structure of all xMO/AC samples, the Raman spectra was then carried out. As shown in Fig. 5a, two spectra were observed for all synthesized 9MO/AC samples at 1336 and 1597 cm−1, corresponding to the D band and G band of the graphitic carbon, respectively33. Typically, the D band depicts the A1g breathing mode, which represents the disordered and defective structures, while the G band corresponds to the E2g symmetry modes, which represents the presence of high crystallite and ordered structure of graphitic carbon20,46. For all samples, the D band intensity were close to the G band intensity, indicating the presence of high defective or disordered structures in all synthesized ACs. As recently reported, the adsorbents with high defective structures normally exhibited a high surface area and porous structure, which could strongly interact with the gas adsorption capacity47. Among all adsorbents, the AC exhibited a sharper and higher spectrum of both D band and G band than other samples, suggesting its high crystallite structures compared with other adsorbents. Quantitatively, the intensity ratio of G band and D band (IG/ID) of all samples was estimated and tabulated in Table 1. It can be obviously seen that the AC exhibited the highest value of IG/ID of 1.45, indicating its high crystallite and ordered structure compared with other samples. Interestingly, all 9MO/AC samples exhibited comparable values of IG/ID in the range of 1.02–1.09, which were lower than that of unimpregnated AC. This suggested that the impregnation of metal oxides including CaO, SrO and MgO increased the defective and disordered structures of the resultant ACs. However, different types of impregnated metal oxides did not significantly change the crystallographic structure of all xMO/AC samples.

Regardless of the textural property, all 9MO/AC samples exhibited the Type I(b) isotherm of N2 adsorption/desorption (Fig. 6a) according to the recent IUPAC classification48. Impregnation of CaO, SrO and MgO diminished the surface area and differential pore volumes of the parental AC as shown in Table 1. The decreased surface area and pore volume in the presence of respective MO was probably due to the deposition of MO on the walls and/or pore blocking49. Among all samples, the 9MgO/AC showed the best textural property considered in terms of high surface area and pore volume. This might be due to the presence of small crystallite size of MgO particles that required lower impregnated surface of AC as well as a pore blockage, thus providing higher available area for N2 adsorption. Another possible reason is due to the catalytic effects of Mg ions in MgO, which can energize at high temperature and intercalate into the carbon matrix to create new pores in carbon-based materials50.

The number of basic sites of as-synthesized AC samples was then estimated using the CO2-TPD under the same analysis condition. As shown in Fig. 7a, with the exception of 9CaO/AC, two desorbed peaks were detected at temperatures below 200 °C and temperature between 200 and 500 °C, which were attributed to the desorbed CO2 and/or decomposition of weak- and medium basic sites, respectively51. The amount of desorbed CO2 can be computed from the integrated peaks area at the temperature below 200 °C after the blank- and based line corrections according to Eq. (3)52.

As summarized in Table 1, the AC exhibited the basic site density of 0.007 mmol/g, which was 2.7–3.6 times lower than that of 9MO/AC samples. Different types of impregnated MO displayed a diversity in basic site density, which can be ranked as the order of 9MgO/AC > 9SrO/AC > 9CaO/AC.

The equilibrium CO2 adsorption of all synthesized 9MO/AC adsorbents in the presence of 50 mol% CO2 in the biohydrogen at 25 °C and 1 atm was summarized in Table 1. It is noteworthy to note that all impregnated AC exhibited comparable or higher CO2 adsorption capacity than that of un-impregnated one, although they had a worse surface property considered in terms of surface area and pore volume. This suggests that the basic site also played a crucial role on the CO2 adsorption via the acid-basic interaction according to the acid property of CO253. That is, the unpaired electrons of the basic surface functional groups can initiate a well interaction with the CO2 molecules, resulting to the enhancement of CO2 adsorption via the chemical adsorption21. Among all synthesized 9MO/AC samples, the 9MgO/AC exhibited the highest CO2 adsorption capacity of 89.46 mg/g at identical adsorption condition. This is probably due to the synergetic effect of textural property and surface chemistry of the 9MgO/AC that can promote the CO2 adsorption capacity.

Effect of impregnated MgO content

The effect of impregnated MgO contents on the surface morphology of AC was first explored in this part. The xMgO/AC samples with different MgO contents in the range of 6–15 wt.% exhibited almost similar external features with respect to the parental sample (figure not shown). As shown in Fig. 8, an acceptable distribution of MgO nanoparticles on the parental AC was observed together with some well-developed pores.

The XRD spectra of as-synthesized xMgO/AC samples were also depicted in Fig. 4b. Apart from the broad peaks of amorphous carbon at 2θ of 20–30o and 40–50°, all xMgO/AC samples exhibited the main characteristic peaks of MgO cubic structure at 2θ of 42.9° and 62.3°, corresponding to the crystal planes of (200) and (220). The XRD intensity of these peaks increased as the increase of MgO content. Via the Scherrer equation, the average crystallite sizes of all impregnated MgO were quantitative estimated and summarized in Table 1. As expected, their average crystallite sizes increased as the increased MgO contents, probably due to the agglomeration of MgO nanoparticles on the AC surface.

The effect of MgO content on the crystallographic structure of AC was also explored using Raman spectra. As shown in Fig. 5b, a typical Raman spectrum was observed for all xMgO/AC samples. That is, the D band spectrum was observed at 1336 cm-1, while the G band spectrum was observed at 1597 cm-1. As summarized in Table 1, all xMgO/AC samples exhibited a considerably low values of IG/ID compared with the parental AC, indicating their low crystallinity or, in other words, their high disordered structure of graphitic carbon. Besides, it can be noticed that the impregnation of MgO in the range of 6–15 wt.% affected slightly the crystallographic structure of the obtained samples.

Regarding the effect of impregnated MgO on the textural property, the addition of MgO at all contents decreased the intensity of N2 adsorption/desorption isotherms compared with the parental AC as depicted in Fig. 6b. The quantitative values of surface area and pore volume of all xMgO/AC samples were summarized in Table 1. Among all xMgO/AC samples, the 12MgO/AC samples exhibited the highest surface area and pore volume. This suggested that an appropriate content of impregnated MgO (~12 wt.%) exhibited an effective energetic ability to create some pores as well as surface area in the carbon matrix. Although too high MgO content (e.g. 15 wt.% in this case) might exhibit a higher energetic ability to create some pores, it could possibly induce the pore blockage by the MgO itself, which in turn reduced the textural property. The CO2-TPD of xMgO/AC samples also displayed the desorbed CO2 and/or decomposition peaks of weak and medium basic sites as shown in Fig. 7b. On the weight basis, the comparable basic site density was obtained for all xMgO/AC samples as listed in Table 1, suggesting that the impregnation of MgO in the range of 9–15 wt.% slightly affected the basic site density of the obtained adsorbents. The CO2 adsorption capacities of all xMgO/AC samples from the biohydrogen with 50 mol% CO2 at a total flow rate of 100 mL/min, temperature of 25 °C and pressure of 1 atm were measured and displayed in Table 1. As expected, the 12MgO/AC sample exhibited the highest CO2 adsorption capacity of 94.02 mg/g, which was higher than the unimpregnated AC of around 10.4%. This is attributed to its high textural properties and basic site density.

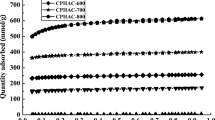

Figure 9a displays the effect of CO2 concentrations in the biohydrogen on the CO2 adsorption capacity of the 12MgO/AC. It was found that the CO2 adsorption increased as the progress of adsorption time and reached a plateau after 4–6 min. Besides, the CO2 adsorption capacity increased as the increase of CO2 concentrations in the mixture. This is attributed to the fact that a high concentration gradient between bulk phase and adsorbent surface can initiate a high driving force for CO2 transfer to the adsorption site, and consequently improved the adsorption capacity of adsorbent54. Quantitatively, the equilibrium adsorptions of the 12MgO/AC were around 45.41, 56.32, 76.58, 84.16 and 94.02 mg/g in the presence of CO2 in the biohydrogen of 10, 20, 30, 40 and 50 mol%, respectively. Concentrations of CO2 and H2 in the outlet gas stream leaving the adsorption process was depicted in Fig. 9b. A well separation between CO2 and H2 was observed at the early adsorption period. Almost pure H2 was evolved during the first 2–4 min and the CO2 was emitted afterward. The breakthrough time of CO2 exhibited a direct proportion to the CO2 concentration in the inlet stream. That is, the gas stream with a high CO2 concentration displayed a faster breakthrough time than that with a low CO2 concentration. For a gas mixture with 50 mol% CO2, the as-synthesized 12MgO/AC was able to capture CO2 from the biohydrogen and allowed the production of the H2-rich stream with the H2 purity up to 90% for the first 2 min of adsorption period. This phenomenon allows the use of the proposed material as an adsorbent for biogas purification in the solid-gas reactor such as the circulating fluidized bed reactor because this reactor effectively work even through it has a short contact time21.

Table 2 summarizes the biohydrogen purification by adsorption via several types of adsorbents at 25 °C. It can be noticed that the ability of the biohydrogen purification by the concept of CO2 removal varied from task to task. For instance, the hybridized N-doped porous AC and Fe2O3 (NDPAC/Fe2O3) exhibited the highest CO2 adsorption capacity of 297.9 mg/g, while the zinc acetate -impregnated AC (ZnAC2/AC) showed the adsorption capacity of 63.61 mg/g. The variation in CO2 adsorption capacity might be attributed to the differences of adsorbent property coming from the utilization of different raw materials, synthesis methods or impregnated substances as well as conditions and reactors used to purify the biohydrogen. Nevertheless, the CO2 adsorption capacity of the 12MgO/AC synthesized in this work was on par to those reported previously.

Due to the CO2 adsorption by AC is the heterogeneous in nature55, the interactive energy between adsorbate and adsorbent is not constant56. Therefore, the estimation of the perception of the isosteric heat of adsorption might benefit for the thermal management of the adsorption process. Figure 10a displays the adsorption isotherm of CO2 of the synthesized 12MgO/AC at 25 and 70 °C and 1 atm. As expected, a high CO2 adsorption was well achieved at low temperature due to the exothermic behavior of the CO2 adsorption process. From these isotherms, the value of isosteric heat of adsorption can be estimated from the Clausius-Clapeyron equation (Eq. (4))56.

As shown in Fig. 10b, plots of \(\ln P_{{{\text{CO}}_{2} }}\) versus the reciprocal absolute temperature showed a linear line with negative slope, which allowed to calculate the isosteric heat of adsorption. The variation of isosteric heat of adsorption against the adsorbed CO2 quantity was displayed in Fig. 10c. It can be noticed that high values of isosteric heat were observed at low surface coverages, indicating a strong adsorbate-adsorbent interaction57. A gradual decrease of isosteric heat was observed as the increase of amount adsorbed CO2 and reached a plain when the adsorbed CO2 was higher than 4.4 mg/g. This might be due to the limitation of available active site to interact with the CO2 molecules, leading to a weak interaction between them. Based on the obtained results, the isosteric heat of adsorption at high adsorbed CO2 was slightly fluctuate in narrow range with the average value of 34.7 ± 1.16 kJ/mol, which was higher than a pure physical adsorption (< 20 kJ/mol), but lower than a pure chemical adsorption (90–100 kJ/mol)58. This suggested that the adsorption mechanism of CO2 on the 12MgO/AC was a combined mechanism of physisorption and chemisorption.

The reusability of the best adsorbent (12MgO/AC) was also explored and benchmarked with the parental AC or the unimpregnated chopstick-derived AC reported in our previous work27. As shown in Fig. 11, the CO2 adsorption capacity of both adsorbents decreased as the increased adsorption cycles. This suggests that the adsorption mechanism importantly affected the regeneration efficiency. That is, the proposed regeneration procedure can effectively remove only some weak and/or medium adsorbed CO2. However, it cannot effectively dispose some strong adsorbed CO2. At the 5th reuse, the drops of CO2 adsorption capacity of the parental AC and 12MgO/AC were around 15.96 and 9.96%, respectively.

Benchmarking of CO2 adsorption capacity 25 °C and 1 atm between 12MgO/AC and unimpregnated AC27 after the thermal regeneration.

Conclusion

The strengthened CO2 adsorption of the spent chopstick-derived ACs was carried out via the impregnation of several metal oxides including CaO, SrO and MgO on their surface. The preliminary results depicted that the impregnation of such metal oxides affected the crystallographic structure, textural property, basic site density as well as the CO2 adsorption capacity of the obtained adsorbents. The crystallographic structure insignificantly affected the CO2 adsorption capacity, while both textural property and basic site density played a crucial role. Among all MO/AC samples, the 12MgO/AC exhibited the highest CO2 adsorption capacity compared with other synthesized adsorbents. A high purity biohydrogen of greater than 90 mol% H2 can be achieved via this successive adsorbent in a high CO2 concentration (~50 mol%). The adsorption mechanism occurred via a combined process of the physisorption and chemisorption. The lessening of CO2 adsorption capacity of around 9.96% was observed via the best adsorbent over the six adsorption/desorption cycles.

Data availability

All data generated or analyzed during this study are included in this published article.

Abbreviations

- C A :

-

Calibration factor (mmol CO2/area unit)

- C in :

-

Inlet concentration of CO2 (mmol/min)

- C out :

-

Outlet concentration of CO2 (mmol/min)

- D :

-

Average crystallite size (nm)

- K :

-

Dimensionless shape factor (0.94)

- M W :

-

Molecular weight of CO2 (g/mol)

- P :

-

Pressure of CO2 (atm)

- q :

-

CO2 adsorption capacity of adsorbent (mg/g)

- \(q_{{{\text{CO}}_{2} }}\) :

-

Amount of CO2 (mmol/g)

- Q st :

-

Isosteric heat of adsorption (kJ/mol)

- R :

-

Gas constant (8.314 J/molK)

- t :

-

Adsorption time (min)

- T :

-

Absolute temperature (K)

- w :

-

Amount of adsorbent (g)

- β :

-

Half-height peak width in radians

- λ :

-

X-ray wavelength (0.15406 nm)

- θ B :

-

Bragg angle corresponding to the peak maximum

References

Das, D., Khanna, N. & Dasgupta, C. N. Biohydrogen Production: Fundamentals and Technology Advances (CRC Press, 2014).

Das, D. & Veziroglu, T. N. Advances in biological hydrogen production processes. Int. J. Hydrogen Energy 33, 6046–6057 (2008).

Muin, N. A. A. et al. A short review on various purification techniques suitable for biohydrogen-mixed gases. J. Energy Saf. Technol. https://doi.org/10.11113/jest.v3n2.52 (2020).

Morsy, F. M. CO2-free biohydrogen production by mixed dark and photofermentation bacteria from sorghum starch using a modified simple purification and collection system. Energy 87, 594–604 (2015).

Xu, G. et al. An improved CO2 separation and purification system based on cryogenic separation and distillation theory. Energies 7, 3484–3502 (2014).

Rohani, R., Chung, Y. T. & Mohamad, I. N. Purification of biohydrogen produced from palm oil mill effluent fermentation for fuel cell application. Korean Chem. Eng. Res. 57, 469–474 (2019).

Azira, A. M. N. & Aisah, A. U. E3S Web of Conferences 01012 (EDP Sciences, 2019).

Kazakov, A., Dunikov, D. & Mitrokhin, S. AB5-type intermetallic compounds for biohydrogen purification and storage. Int. J. Hydrogen Energy 41, 21774–21779 (2016).

Bakonyi, P., Nemestóthy, N. & Bélafi-Bakó, K. Biohydrogen purification by membranes: An overview on the operational conditions affecting the performance of non-porous, polymeric and ionic liquid based gas separation membranes. Int. J. Hydrogen Energy 38, 9673–9687 (2013).

Chen, H., Xiao, Y. & Chung, T.-S. Synthesis and characterization of poly (ethylene oxide) containing copolyimides for hydrogen purification. Polymer 51, 4077–4086 (2010).

He, X., Lei, L. & Dai, Z. Green hydrogen enrichment with carbon membrane processes: Techno-economic feasibility and sensitivity analysis. Sep. Purif. Technol. 276, 119346 (2021).

Li, B., He, G., Jiang, X., Dai, Y. & Ruan, X. Pressure swing adsorption/membrane hybrid processes for hydrogen purification with a high recovery. Front. Chem. Sci. Eng. 10, 255–264 (2016).

Mehrpooya, M., Mousavi, S. A., Asadnia, M., Zaitsev, A. & Sanavbarov, R. Conceptual design and evaluation of an innovative hydrogen purification process applying diffusion-absorption refrigeration cycle (Exergoeconomic and exergy analyses). J. Cleaner Prod. 316, 128271 (2021).

Foungchuen, J., Pairin, N. & Phalakornkule, C. Impregnation of chitosan onto activated carbon for adsorption selectivity towards CO2: Biohydrogen purification. KMUTNB Int. J. Appl. Sci. Technol. 9, 197–209 (2016).

Delgado, J. A., Águeda, V. I., Uguina, M. A., Brea, P. & Grande, C. A. Comparison and evaluation of agglomerated MOFs in biohydrogen purification by means of pressure swing adsorption (PSA). Chem. Eng. J. 326, 117–129 (2017).

Yusuf, N. et al. IOP Conference Series: Materials Science and Engineering 012071 (IOP Publishing, 2020).

Yan, T., Li, T., Wang, R. & Jia, R. Experimental investigation on the ammonia adsorption and heat transfer characteristics of the packed multi-walled carbon nanotubes. Appl. Therm. Eng. 77, 20–29 (2015).

McEwen, J., Hayman, J.-D. & Yazaydin, A. O. A comparative study of CO2, CH4 and N2 adsorption in ZIF-8, Zeolite-13X and BPL activated carbon. Chem. Phys. 412, 72–76 (2013).

Chen, S., Fu, Y., Huang, Y., Tao, Z. & Zhu, M. Experimental investigation of CO2 separation by adsorption methods in natural gas purification. Appl. Energy 179, 329–337 (2016).

Othman, F. E. C. et al. Activated carbon nanofibers incorporated metal oxides for CO2 adsorption: Effects of different type of metal oxides. J. CO2 Util. 45, 101434 (2021).

Phadungbut, P. et al. Adsorptive purification of CO2/H2 gas mixtures of spent disposable wooden chopstick-derived activated carbon: Optimal synthesis condition. Sep. Purif. Technol. 291, 120948 (2022).

Abdeljaoued, A., Relvas, F. & Mendes, A. Simulation and experimental results of a PSA process for production of hydrogen used in fuel cells. J. Environ. Chem. Eng. 6, 338–355 (2018).

Zhang, X.-X. et al. Optimal activated carbon for separation of CO2 from (H2+ CO2) gas mixture. Pet. Sci. 15, 625–633 (2018).

Gil, M. et al. Carbon adsorbents for CO2 capture from bio-hydrogen and biogas streams: Breakthrough adsorption study. Chem. Eng. J. 269, 148–158 (2015).

Anuar, S. A., Wan Isahak, W. N. & Masdar, M. S. Carbon nanoflake hybrid for biohydrogen CO2 capture: Breakthrough adsorption test. Int. J. Energy Res. 44, 3148–3159 (2020).

Sidek, M. et al. Effect of impregnated activated carbon on carbon dioxide adsorption performance for biohydrogen purification. Mater. Res. Express 6, 015510 (2018).

Koo-Amornpattana, W. et al. Valorization of spent disposable wooden chopstick as the CO2 adsorbent for a CO2/H2 mixed gas purification. Sci. Rep. 12, 1–16 (2022).

Petrovic, B., Gorbounov, M. & Soltani, S. M. Influence of surface modification on selective CO2 adsorption: A technical review on mechanisms and methods. Microporous Mesoporous Mater. 312, 110751 (2021).

Caglayan, B. S. & Aksoylu, A. E. CO2 adsorption on chemically modified activated carbon. J. Hazard. Mater. 252, 19–28 (2013).

Hidayu, A. & Muda, N. Preparation and characterization of impregnated activated carbon from palm kernel shell and coconut shell for CO2 capture. Proc. Eng. 148, 106–113 (2016).

Yang, T. & Lua, A. C. Characteristics of activated carbons prepared from pistachio-nut shells by physical activation. J. Colloid Interface Sci. 267, 408–417 (2003).

Acevedo, S., Giraldo, L. & Moreno-Piraján, J. C. Adsorption of CO2 on activatedcarbons prepared by chemical activation with cupricnitrate. ACS Omega 5, 10423–10432 (2020).

Sreńscek-Nazzal, J. et al. Modification of commercial activated carbons for CO2 Adsorption. Acta Phys. Polonica A 129, 394–401 (2016).

Zhao, X. et al. Removal of Cr6+ ions from water by electrosorption on modified activated carbon fibre felt. R. Soc. Open Sci. 5, 180472 (2018).

Tang, Y.-B., Liu, Q. & Chen, F.-Y. Preparation and characterization of activated carbon from waste ramulus mori. Chem. Eng. J. 203, 19–24 (2012).

Abdul Rani, N. H., Mohamad, N. F., Matali, S. & Kadir, S. A. S. A. in Key Engineering Materials. 44-48 (Trans Tech Publ).

Husin, H. et al. IOP Conference Series: Materials Science and Engineering 012008 (IOP Publishing, 2018).

Otowa, T., Nojima, Y. & Miyazaki, T. Development of KOH activated high surface area carbon and its application to drinking water purification. Carbon 35, 1315–1319 (1997).

Roy, A., Gauri, S. S., Bhattacharya, M. & Bhattacharya, J. Antimicrobial activity of CaO nanoparticles. J. Biomed. Nanotechnol. 9, 1570–1578 (2013).

Oliveira, H. S. et al. Improvement on CO2 capture by CaO pellet modified with carbon nanotubes. Int. Nano Letters 10, 141-149. (2020).

Iqbal, M. Z., Faisal, M. M., Sulman, M., Ali, S. R. & Alzaid, M. Facile synthesis of strontium oxide/polyaniline/graphene composite for the high-performance supercapattery devices. J. Electroanalyt. Chem. 879, 114812 (2020).

Sarmin, S. et al. Palm oil derived alkyd resin synthesis catalyzed by SrO/Sr(OH)2 nanoparticles. J. Crit. Rev. 7, 2131–2139 (2020).

Ma, X., Cao, M. & Hu, C. MgO modified nanoporous carbon composites for methanol separation. RSC Adv. 3, 10396–10402 (2013).

Shahkarami, S., Dalai, A. K. & Soltan, J. Enhanced CO2 adsorption using MgO-impregnated activated carbon: Impact of preparation techniques. Ind. Eng. Chem. Res. 55, 5955–5964 (2016).

Badoga, S., Dalai, A. K., Adjaye, J. & Hu, Y. Combined effects of EDTA and heteroatoms (Ti, Zr, and Al) on catalytic activity of SBA-15 supported NiMo catalyst for hydrotreating of heavy gas oil. Ind. Eng. Chem. Res. 53, 2137–2156 (2014).

de Paula, F.-G. et al. Structural flexibility in activated carbon materials prepared under harsh activation conditions. Materials 12, 1988 (2019).

Liu, Y. & Wilcox, J. CO2 adsorption on carbon models of organic constituents of gas shale and coal. Environ. Sci. Technol. 45, 809–814 (2011).

Thommes, M. et al. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 87, 1051–1069 (2015).

Zhao, G. et al. Efficient porous carbon-supported MgO catalysts for the transesterification of dimethyl carbonate with diethyl carbonate. J. Mol. Cataly. A 327, 32–37 (2010).

Przepiórski, J., Czyżewski, A., Pietrzak, R. & Tryba, B. MgO/CaO-loaded porous carbons for carbon dioxide capture. J. Therm. Anal. Calorim. 111, 357–364 (2013).

Mi, B. et al. Nitrogen-doped porous carbon derived from bamboo shoot as solid base catalyst for Knoevenagel condensation and transesterification reactions. Catalysts 8, 232 (2018).

Bhatta, L. K. G. et al. Investigation of CO2 adsorption on carbon material derived from Mesua ferrea L. seed cake. J. Environ. Chem. Eng. 3, 2957–2965 (2015).

Naksusuk, S. & Tangsathitkulchai, C. Carbon dioxide capture in a fixed bed of coconut shell activated carbon impregnated with sodium hydroxide: Effects of carbon pore texture and alkali loading. Eng. J. 23, 29–48 (2019).

Kubonova, L., Obalová, L., Vlach, O., Troppová, I. & Kalousek, J. Modelling of NO adsorption in fixed bed on activated carbon. Chem. Process Eng. 32, 367–377 (2011).

Khosrowshahi, M. S. et al. The role of surface chemistry on CO2 adsorption in biomass-derived porous carbons by experimental results and molecular dynamics simulations. Sci. Rep. 12, 1–19 (2022).

Abdulsalam, J., Mulopo, J., Bada, S. O. & Oboirien, B. Equilibria and isosteric heat of adsorption of methane on activated carbons derived from south African coal discards. ACS Omega 5, 32530–32539 (2020).

Raganati, F., Alfe, M., Gargiulo, V., Chirone, R. & Ammendola, P. Isotherms and thermodynamics of CO2 adsorption on a novel carbon-magnetite composite sorbent. Chem. Eng. Res. Design 134, 540–552 (2018).

Ammendola, P., Raganati, F. & Chirone, R. CO2 adsorption on a fine activated carbon in a sound assisted fluidized bed: Thermodynamics and kinetics. Chem. Eng. J. 322, 302–313 (2017).

Redondas, V. et al. Hydrogen production from food wastes and gas post-treatment by CO2 adsorption. Waste Manag. 32, 60–66 (2012).

Acknowledgements

The authors acknowledge the Mahidol University research scholarship (Basic Research Fund: fiscal year 2021) that funded this work.

Author information

Authors and Affiliations

Contributions

W.K. and M.H. designed the project, N.K., W.K. and M.H. conceived the experiment with the help from P.P., N.K. and M.H. conducted the experiment, S.R and W.J. supported equipment, W.K. and M.H. analyzed the results and wrote the manuscript. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Koo-amornpattana, W., Phadungbut, P., Kunthakudee, N. et al. Innovative metal oxides (CaO, SrO, MgO) impregnated waste-derived activated carbon for biohydrogen purification. Sci Rep 13, 4705 (2023). https://doi.org/10.1038/s41598-023-31723-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-31723-4

- Springer Nature Limited

This article is cited by

-

Biohydrogen From Waste Feedstocks – Materials, Methods and Recent Developments

BioNanoScience (2023)