Abstract

Near 100% of diffractive efficiency for diffractive optical elements (DOEs) is one of the most required optical performances in broadband imaging applications. Of all flat DOEs, none seems to interest researchers as much as Two-Materials Composed Diffractive Fresnel Lens (TM-DFL) among the most promising flat DOEs. An approach of the near 100% of diffractive efficiency for TM-DFL once developed to determine the design rules mainly takes the advantage of numerical computation by methods of mapping and fitting. Despite a curved line of near 100% of diffractive efficiency can be generated in the Abbe and partial dispersion diagram, it is not able to analytically elaborate the relationship between two optical materials that compose the TM-DFL. Here, we present a theoretical framework, based on the fundaments of Cauchy's equation, Abbe number, partial dispersion, and the diffraction theory of Fresnel lens, for obtaining a general design formalism, so to perform the perfect material matching between two different optical materials for achieving the near 100% of diffractive efficiency for TM-DFL in the broadband imaging applications.

Similar content being viewed by others

Previous researches on diffractive Fresnel lens (DFL)

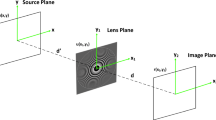

In the thinning of optical lenses, following the principle of Equal Optical Path Difference, the surface relief of a spherical lens with radius R and refractive index n(λ) is processed to construct a Diffractive Fresnel Lens (DFL) with multiple concentric Fresnel Zone (FZ) on the surface1,2,3,4,5,6,7,8,9,10,11, as shown in Fig. 1.

Usually, exploiting the 2pπ phase (where p is a positive integer) as the Equal Optical Path Difference is the way to configure a diffractive Fresnel lens (DFL)12,13,14,15,16,17,18. The so-called DFL is generally referred to p = 1. According to the basic diffractive optics theory of DFL presented by Dale A. Buralli12, as shown in Fig. 1, the radial FZ structure possesses the following relations.

where ri is the i-th FZ radius, \(\mathrm{f}\)0 is the design focal length, \(\uplambda\)0 is the design wavelength, \(\Lambda\)i is the spacing between the i-th FZ and the i + 1-th FZ, h is the FZ height, D is the FZ diameter, and rmax is the outermost FZ radius.

Due to the dispersion, generally the parallel incident white light with different wavelengths, ranging from 400 to 700 nm, is focused by DFL at different focal points on the optical axis. The optical power varies linearly with the wavelength of the incident light, as shown in Fig. 2, where fR, fG, and fB presenting the focal points focused by the red, green, and blue light respectively.

Furthermore, according to the above-mentioned theory of DFL12, the diffraction focus and efficiency of a light source with a single wavelength can be determined by the following equations.

where \(\uplambda\)0 is the design wavelength, ƒ0 is the design focal length, \(\uplambda\) is the wavelength, f is the focal length, m is the diffracted order, η is the diffractive efficiency, α is the detuning factor, n(λ) is the refractive index of DFL as a function of wavelength λ, and n(λ0) is the refractive index at λ = λ0.

For instance, the wavelength dependent diffractive efficiency η(λ) of the optical materials of PMMA (Microchem 495 PMMA resist19) is calculated by Eqs. (3), (6), and (7) for the design wavelength at λ0 = 0.587 μm, FZ height at h = 1.17 μm, and the diffracted order at m = 1, 2, and 3, as shown in Fig. 3.

The calculation results reveal that most of the diffraction energy transmitted from the white incident light focused in the diffracted order at m = 1 and only a small portion of the diffraction energy contributed to the diffracted order at m = 2, 3, while the rest of the energy from the higher diffracted order being not considered because of the less contribution to the diffractive efficiency. Furthermore, in the spectrum of visible light, according to Eqs. (6) and (7), 100% diffractive efficiency can only be achieved in conditions of the diffracted order at m = 1, λ = \(\uplambda\)0 = 0.587 µm, and α = 1. Equation (6) describes how the diffractive efficiency drops off when the incident wavelength λ deviates away from the design wavelength λ0. More practically, the overall diffractive efficiency is generally evaluated with the mean value of spectrum distribution, as following equations.

where \(\overline{\eta }_{m}\) is the averaged diffractive efficiency in the diffracted order at m and \(\overline{\eta }_{T}\) is the total averaged diffractive efficiency. For the parallel incident white light source, substituting the wavelength at \(\uplambda\) 1 = 0.4 μm and \(\uplambda\) 2 = 0.7 μm into Eqs. (8) and (9), \({\overline{\eta }}_{1}\)= ~ 85.2%, \({\overline{\eta }}_{2}\)= ~ 8.2%, and \({\overline{\eta }}_{3}\)= ~ 1.2% are obtained in the diffracted order at m = 1, m = 2 and m = 3 respectively.

Consequently, the total diffractive efficiency from m = 1 to m = 3 comes up with \({\overline{\eta }}_{T}\) = 94.8%. In other words, there is still a certain portion of the incident light transmitted to other higher diffracted order (m > 3). For the diffracted order at m = 1 and h = 1.17 μm, about 15% of the incident light energy is disappeared. As a result, such light becomes the stray light and eventually deteriorates the imaging quality of DFL.

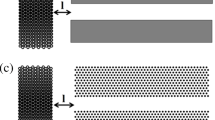

A solution to make up for the energy loss in the first diffracted order was first presented by Kenneth J. Weible in 199920. In their research result, a blazed grating, composed of two optical materials, including glass (Schott BaF52 glass) and PC (polycarbonate), was proposed to improve the diffractive efficiency for the diffracted order at m = 1 (i.e. α = 1) by exploiting the refractive index difference Δn(λ) = n1(λ) − n2(λ) being proportional to wavelength λ. When the refractive index difference satisfies Δn(λ)/λ=constant at all wavelengths λ in the spectrum of visible light, all the incident light energy in the higher diffracted order is all transferred into the first diffracted order, as to achieve the objective of 100% diffractive efficiency. Furthermore, B. H. Kleemann mentioned the design concepts for the blazed grating composed of two optical materials in 200821 and particularly named such structure as Common depth EA–DOEs. In contrast to the term “Common depth”, a singlet DFL composed of two optical materials is called Two-Materials Composed Diffractive Fresnel Lens (TM-DFL) in this study.

According to Kenneth’s research20, two transparent optical materials of glass22 and PC23, as shown in Fig. 4a and b, are used for explaining the difference in the diffractive efficiency between a Single-Material Composed Diffractive Fresnel Lens (SM-DFL), i.e. the conventional DFL, and TM-DFL. For SM-FDL, the average diffractive efficiency \({\overline{\eta }}_{1}\) 84.9% is calculated by Eqs. (6), (7), and (8) for the diffracted order at m = 1 and the incident wavelength at λ = 400–700 nm, as shown in Fig. 4c. Besides, for TM-DFL, the diffractive efficiency \({\overline{\eta }}_{1}\)=94.3%, as shown in Fig. 4d, is obtained by the same calculations above with a modified tuning factor α in Eq. (10) which contains the refractive index n2(λ) and n2(λ0) of the second material.

Although TM-DFL can improve the diffractive efficiency of the conventional SM-DFL, the requirement for Δn(λ) \(\propto\) λ is not perfectly satisfied. As a result, it is hard to achieve the theoretical 100% diffractive efficiency.

In fact, Andrew Wood24 indicated that in the case of SM-DFL composed with materials existing in nature, the detuning factor α in Eq. (7) could hardly retain the needs for α = 1 when λ deviated away from the design wavelength λ0. Moreover, as previously described, the regular materials, i.e. glass and PC, found by Kenneth J. Weible20 were able to increase the average diffractive efficiency from 85 to 94%, but it still required more effort to realize the theoretical 100% diffractive efficiency.

Latest works on the optical design of TM-DFL: a numerical framework for the design of broadband DOEs

To overcome the above-mentioned problems, Daniel Werdehausen in 201925 proposed to use dispersion-engineered nanocomposites for artificially generating a refractive index difference Δn(λ) to satisfy the requirement for \(\mathrm{n}(\lambda)\propto\) λ. According to this definition25, the so-called nanocomposites are produced by adding a proper volume fraction of nanoparticles with a diameter smaller than 5 nm, such as Diamond, ZrO2, TiO2, ITO (indium tin oxide), and AZO (aluminum-doped zinc oxide) (presented as green stars), to the existing polymeric materials, such as PMMA (poly(methyl methacrylate)), COP (cyclic olefin copolymer), PC (polycarbonate), and PS (polystyrene) (presented as blue stars), to adjust the optical parameters of materials nd, vd, and Pg,F. Though such new nd, vd, and Pg,F (presented as orange points) do not exist in nature, they can be tailored within a certain range (presented as pink area) in both the Abbe diagram and partial dispersion diagram, as respectively shown in Fig. 4a and b25. For instance, by adding TiO2 nanoparticles with different volume fraction to the polymeric material PC, the distribution of nd-vd can extend to cover a region in 17 < vd < 28 and 1.6 < nd < 1.85 while the distribution of PgF-vd covers a region in 17 < vd < 28 and 0.58 < PgF < 0.65.

Furthermore, the same research team in 202026 proposed a design method of mapping and fitting based on the numerical computation for matching the material refractive index of TM-DFL to achieve the light diffractive efficiency higher than 99.9%. According to DOEs’ phase profiles change across the different dispersion regimes26, the material parameters of material 1(Mat.1) are first selected and set at nd,1 = 1.8, vd,1 = 60, and Pg,F,1 = 0.55. By the method of mapping, the material parameters nd,2, vd,2, and Pg,F,2 of material 2(Mat. 2) are discretely varied to calculate the distribution of the average diffractive efficiency \(\overline{\eta }\) in the Abbe diagram. Similarly, the distribution of the average diffractive efficiency \(\overline{\eta }\) in the partial dispersion diagram is calculated and drawn. For later discussion, the diffractive efficiency \({\overline{\eta }\left({n}_{d,2}{,v}_{d,2}\right)}_{mat1}\) and \({\overline{\eta }\left({P}_{\mathrm{g},F,2}{,v}_{d,2}\right)}_{mat1}\) are defined as a function of (nd,2, vd,2) and (Pg,F,2, vd,2) respectively. The subscript Mat.1 in both function \(\overline{\eta }\) stands for the values of the material parameters nd,1, vd,1, and Pg,F,1 of Mat.1 being fixed as a constant.

The major feature of the mapping method is to discretely modulate nd,2, vd,2, Pg,F,2 of Mat. 2 in a large region to calculate and set up both diffractive efficiency map of \({\overline{\eta }\left({n}_{d,2}{,v}_{d,2}\right)}_{mat1}\) and \({\overline{\eta }\left({P}_{\mathrm{g},F,2}{,v}_{d,2}\right)}_{mat1}\), so to find the black dotted curved lines where the calculated nd,2, vd,2, Pg,F,2 of Mat. 2 matches to the selected nd,1, vd,1, and Pg,F,1 of Mat.1 for achieving the near 100% diffractive efficiency. Hereafter, the black dotted curved line in \({\overline{\eta }\left({n}_{d,2}{,v}_{d,2}\right)}_{mat1}\) is named as Abbe characteristic curve of the near 100% of diffractive efficiency, or Abbe characteristic curve in brief, while the other one in \({\overline{\eta }\left({P}_{\mathrm{g},F,2}{,v}_{d,2}\right)}_{mat1}\) is named as partial dispersion characteristic curve of the near 100% of diffractive efficiency, or partial dispersion characteristic curve in brief. Finally, the most suitable material parameters nd,2, vd,2, and Pg,F,2 can be determined by comparing the producible nanocomposites for completing the optimal match of parameters in two nanocomposite materials.

Furthermore, applying the mathematical fitting to the Abbe characteristic curve, a natural exponential function is obtained, as below.

where a = 1.839, b = 0.9919, and c = 0.8782. Note that these values are determined only for nd,1 = 1.8, vd,1 = 60, and Pg,F,1 = 0.55. To acquire the general relationship between a, b, c, and the material parameters of MAT.1, ten of the Abbe characteristic curves with different values of nd,1, ranging from 1.5 to 2.0, are used to fit to obtain the nd,1 dependence of a, b, and c as below.

However, the fitting to the partial dispersion characteristic curve, is not discussed26.

Major issues left by latest works

In summary, to achieve the optical parameters match for two nanocomposite materials in TM-DFL, the above-mentioned design method of mapping and fitting by the numerical computation26 confronts the following issues.

-

(1)

The methods of mapping can obtain a single Abbe characteristic curve and partial dispersion characteristic curve through a big volume of numerical computations at a time while losing efficiency and accuracy.

-

(2)

The fitting method can describe the Abbe characteristic curve as Eq. (11) which is a function of nd,1 in a special form of a natural exponential function with 1/3 power. In addition to the fitting accuracy or error, it is not a general equation for the analytical evaluation of the system. The so-called “analytical evaluation” refers to analyze the variance in the entire system caused by the parameter variation without using massive numerical computations. In other words, it is a qualitative and quantitative way to get insight into the general physical behaviors of a system by theoretical formulas.

-

(3)

Three coefficients a, b, and c of the Abbe characteristic curve merely contains nd,1 of Mat.1 without any further relation with vd,1 and Pg,F,1 of Mat.1.

-

(4)

There is no fitting applied to the partial dispersion characteristic curve for the analytical evaluation on the relationship among parameters, i.e. (nd,1, vd,1, and Pg,F,1) and (nd,2, vd,2, and Pg,F,2) between two materials.

New method: a theoretical framework for general design formalism

In contrast, we present a new method of analytical evaluation based on theoretical formulas in this study. More exactly, two characteristic curve formulas of the near 100% of diffractive efficiency are derived from the theories of Cauchy's equation, Abbe number, and partial dispersion as well as the diffractive theory of Fresnel lens. Besides, to achieve the purposes of the perfect parameters match between two optical materials in TM-DFL and the objectives of the general analyses on the optical behavior of TM-DFL, it completely solves the above-mentioned disadvantages of the numerical computation-based methods of mapping and fitting.

For the optical theory of DFL, the previous theoretical Eqs. (1)–(9) completely describe the relationship among the diffractive efficiency, the wavelength of the incident light, and material refractive index, where Eqs. (1)–(4) provide the design of the geometric shape of Fresnel lens, Eqs. (5)–(7) provide the focal length and diffractive efficiency after the incident light interactive with DFL, and Eqs. (8)–(9) provide the overall evaluation of diffractive efficiency.

For DFL, 2π phase shift is the necessary condition for reaching 100% diffractive efficiency which can be acquired when \(\mathrm{h}\Delta \mathrm{n}({\uplambda }_{0})={\uplambda }_{0}\), where h is the FZ height, Δn(\({\uplambda }_{0}\)) = n(\({\uplambda }_{0}\))-1 is the refractive index difference, n(\({\uplambda }_{0}\)) is the material refractive index of DFL at \(={\uplambda }_{0}\),\(\uplambda\) is the wavelength of the incident light, and λ0 is the design wavelength. Further, “1” in the Δn is the refractive index of air. That is, the incident light directly contacts the air after going through DFL. Since the refractive index of air is almost irrelevant to \(\uplambda\), it is no way to satisfy the condition Δn(\()\propto\uplambda\). Consequently, the diffractive efficiency drops off significantly when λ deviating away from λ0. Therefore, TM-DFL is used to effectively overcome the efficiency issue caused by the refractive index of air. For this purpose, Eq. (3) is modified as below to generate a 2π phase shift when TM-DFL is used to replace DFL.

where \({n}_{1}\left({\lambda }_{0}\right)\) and \({n}_{2}\left({\lambda }_{0}\right)\) are the value of two material refractive indexes in TM-DFL at \(={\uplambda }_{0}\).

Moreover, the detuning factor α in Eq. (7) also needs a modification as in Eq. (10). Practically, the two optical materials used for TM-DFL have to satisfy the following requirements, including (1) optically transparent in the visible spectrum, (2) practical in mass production, and (3) Δn(λ)\(\propto\). As the transparent materials existing in nature can hardly satisfy all the above conditions, especially for (3). Consequently, an optical material with an artificially tailorable refractive index, such as nanocomposite, is necessary for the realization of TM-DFL. The core of this research is to build up a theoretical foundation for the design of TM-DFL with the near 100% of diffractive efficiency by connecting theories of Cauchy's equation, Abbe number, partial dispersion, and the diffractive theory of Fresnel lens all together to derive the equation of Abbe characteristic curve and partial dispersion characteristic curve as below.

Solution for coefficients of Cauchy's equation

In general, the refractive index n(λ) of transparent optical materials in the spectrum of visible light can be calculated by Cauchy's Eq. (16).

where n(λ) is the refractive index depending on the light wavelength, λ is the wavelength of light in vacuum, and A, B, C are coefficients. Moreover, the dispersion of transparent optical materials can be defined with Abbe number and partial dispersion, as below.

where nd, nF, nC, and ng are the refractive indices of materials at the wavelengths of the Fraunhofer d, F, C and g spectral lines (referring to wavelength λd = 587.56 nm, λF = 486.13 nm, λC = 656.28 nm, and λ g = 435.83 nm). First, nd, nF, nC, ng and λd, λF, λC, λg are substituted into Eq. (16) to obtain the following equations.

Coefficients A, B, and C are solved as below.

where

Coefficients A, B, C of Cauchy's equation in Eqs. (23)–(25) clearly present the refractive index as a function of nd, vd, Pg,F, and wavelengths of Fraunhofer d, F, C, and g spectral lines.

Derivation of Abbe characteristic curve

As mentioned above, Eq. (6) is a general equation of diffractive efficiency while Eq. (10) defines the detuning factor α of TM-DFL which is a function of refractive index difference Δn(λ). For all wavelengths in the spectrum of visible light, the FZ height satisfying Δn(λ)h=λ is the key to direct the diffraction energy of all wavelengths toward 100% of diffractive efficiency at the diffracted order m = 1. By substituting α = 1 and λ0 = λd into Eqs. (10) and (15) the following equation is obtained.

By expanding Eq. (30), it obtains

For TW-FDL, Eqs. (30)–(31) related to the TM-DFL describe the necessary conditions to achieve the near 100% of diffractive efficiency for all wavelengths at \(\uplambda =\) 400–700 nm and the diffracted order at m = 1. According to the definition in Eq. (17), let the Abbe number vd,2 of Mat.2 be defined as below

where nd,2, nF,2, and nC,2 are the refractive indices of Mat.2 at the wavelengths of the Fraunhofer d, F, and C spectral lines. Substituting Eq. (31) into Eq. (32), it obtains

where nFC,1 = nF,1 − nC,1, λFC = λF − λC, and nd,1, nF,1, and nC,1 are the refractive indices of Mat.1 at the wavelengths of the Fraunhofer d, F, and C spectral lines. Following equation is reformed by multiplying (nd,1 − 1)/(nd,1 − 1).

Substituting Eq. (34) into Eq. (33), it obtains

where vd,1 is the Abbe number of Mat.1. Accordingly, both formulas (33) and (35) depict the same Abbe characteristic curves for TM-DFL with the same calculated results. However, formula (35) provides a clearer scope to know how nd,2 is affected by nd,1 and vd,1 of Mat.1. More accurately, formula (35) can be considered as a general formula of nd,2 as a function of vd,2, nd,1, vd,1, λ F, λC, and λd. A general form of a function of nd,2 is defined as below.

Unlike the conventional methods based on numerical computation, formulas (33) and (35) can accurately and immediately calculate and draw the Abbe characteristic curve in the Abbe diagram without the need for numerous numerical computations. The general behavior of nd,2 in Eq. (36) will be elaborated in the later discussion.

Derivation of partial dispersion characteristic curve

According to the definition in Eq. (18), let the partial dispersion Pg,F,2 of Mat.2 be defined as below.

where ng,2, nF,2, and nC,2 are the refractive indices of Mat.2 at the wavelengths of the Fraunhofer g, F, and C spectral lines. Substituting Eq. (31) into Eq. (37), it obtains

where λgF = λg − λF and nd,12 = nd,1 − nd,2. Similarly, substituting Eq. (34) into Eq. (38), it obtains

Accordingly, both formulas (38) and (39) depict the same partial dispersion characteristic curves for TM-DFL with the same calculated results. However, formula (39) provides a more clear scope to know how Pg,F,2 is affected by nd,1, vd,1 and Pg,F,1 of Mat.1. More accurately, formula (39) can be considered as a general formula of Pg,F,2 since it is a function of nd,1, vd,1, Pg,F,1, nd,2, vd,2, λF, λg, λd. A general form of a function of Pg,F,2 is defined as below.

Unlike the conventional methods based on numerical computation, formulas (38) and (39) can accurately and immediately calculate and draw the partial dispersion characteristic curve in the partial dispersion diagram without the need for numerous numerical computations. The general behavior of Pg,F,2 in formula (39) will be elaborated in the later discussion.

Usually, as mentioned previously, the analytical evaluation is a way to look into the general physical behavior of a system, such as nd2 and Pg,F,2 in formula (36) and (40), by applying the partial differential to the system at each parameter, such as parameters of optical materials of TM-DFL, so to understand the system response Δnd2 and ΔPg,F,2, given as below.

Clearly, It is no necessary to apply the same process of partial differential to both nd2 and Pg,F,2 against the light wavelength λd, λF, λC, and λg because it is no reason to change the definition of Fraunhofer line.

In summary, in contrast to the conventional method26, formulas (33), (35), (38), and (39) presented in this study can obtain the Abbe and partial dispersion characteristic curves of TM-DFL without numerous computations. Further, an analytical evaluation for getting more insight into the general physical behavior of TM-DFL is elaborated on below.

Results

Hereafter, based on an example of TW-DFL26, we first present a quantitative result in comparison with the one obtained by the conventional method.

According to the example, the optical parameters of Mat.1 are first selected and set to nd,1 = 1.8, vd,1 = 60, and Pg,F,1 = 0.55. Then, by the numerical computation based mapping method, the Abbe and partial dispersion diagrams are produced to generate the Abbe and partial dispersion characteristic curves. Finally, the maximum achieved diffractive efficiency can be found at η = ~ 99.1%, nd,2 = 1.7, vd,2 = 18.4 for the Abbe characteristic curves, and η = ~ 99.9%, vd,2 = 15.2, Pg,F,2 = 0.3 for the partial dispersion characteristic curves. Meanwhile, the Abbe characteristic curve is fitted by Eq. (11) to obtain the coefficients a = 1.839, b = 0.9919, c = 0.8782.

In contrast, in our studies, the Abbe and partial dispersion characteristic curves are obtained by our formulas (35) and (39) respectively, as shown in Fig. 5a and b. There are two Abbe characteristic curves on the same Abbe diagram shown in Fig. 5a, where the green solid line is our result guaranteed by the near 100% diffractive efficiency at each point on the curve while the yellow dotted line is the fitting result of above-mentioned research26. Apparently, the smaller vd,2 the larger difference shows the qualitative difference between the two methods. Also, a quantitative difference of the mean value is calculated to 0.0064. In the industrial measurement of the refractive index, this value of 0.0064 is large enough to be easily measured (note: the measurement precision of the Abbe refractometer in the market is 0.0002). In other words, the mapping and fitting methods cause non-negligible errors. Regarding the partial dispersion characteristic curve depicted on the partial dispersion diagram in Fig. 5b, it is no way to do the analytical comparison since no fitting data provided by the above-mentioned research26.

Discussions

In summary, a theoretical formula-based analytical method is proposed in our studies to improve the disadvantages of the numerical computational-based mapping and fitting method. More definitely, the theory of Cauchy's equation, Abbe number, partial dispersion, and the diffractive theory of Fresnel lens are blended into optically connecting two different nanocomposite materials in TM-DFL for achieving the near 100% diffractive efficiency with all wavelengths in the visible spectrum at the first diffracted order. In addition to perfectly matching optical parameters between two materials without numerous computations, it also satisfies the objective of general analysis for TM-DFL in both quantitative and qualitative evaluations. The major features of the optical behavior of TM-DFL in our study are elaborated below.

Feature 1: The general behavior of nd,2 (vd,2): dependent on nd,1 and vd,1 only, but independent on Pg,F,1

As shown in Fig. 6a, the Abbe characteristic curves of Mat.2 in the Abbe diagram is calculated by formula (35) for nd,2(vd,2) at nd,1 = 2.0, 1.9, 1.8, 1.7, 1.6, 1.5, and vd,1 = 50, 40, 30. When vd,2 is fixed, it shows a feature: the larger nd,1, the larger nd,2. When nd,1 is fixed, nd,2(vd,2) is split into a subset of lines at vd,1 = 30, 40, 50, for showing another feature: the less vd,1, the larger nd,2. Apparently, the Abbe characteristic curves of Mat.2 is nothing to do with Pg,F,1 because Pg,F,1 is not included in formula (35).

Dependence of nd,2 (vd,2) and Pg,F,2 (vd,2). (a) nd,2 (vd,2) is dependent on nd,1 and vd,1 only but independent on Pg,F,1, where nd,2 is split into a subset of lines at vd,1 = 30, 40, 50 when nd,1 is fixed. (b, c) Pg,F,2 (vd,2) is dependent on Pg,F,1 and vd,1 only but independent on nd,1 where Pg,F,2 is constant when nd,1 is varied in the wide range from 2 to 1.5.

Feature 2: the general behavior of Pg,F,2 (vd,2): dependent on Pg,F,1 and vd,1 only, but independent on nd,1

The partial dispersion characteristic curve of Mat.2 in the partial dispersion diagram is calculated by formula (39). Despite nd,1 being an explicit parameter in formula (39), the final calculation is irrelevant to nd,1. To analytically prove the independence of nd,1, first we need to prove ΔPg,F,2/Δnd,1 = 0 at all Δnd,1 and ΔPg,F,1 = Δvd,1 = Δvd,2 = 0, as below.

By taking the partial derivative of Pg,F,2 in formula (39) to nd,1 and nd,2, it obtains

Since nd,2 is a function of nd,1, taking the partial derivative of nd,2 in formula (35) to nd,1, it obtains

Substituting Eq. (44) into Eq. (43), it obtains

The sum of terms in the square brackets in Eq. (45) is always zero after completing the calculation with all parameters in the square brackets. Further, results showing the independency of nd,1 by the direct calculation of Pg,F,2 (vd,2) in formula (39), under conditions (1) nd,1 = 2, 1.75, 1.5, vd,1 = 50, and Pg,F,1 = 0.7, 0.55, 0.35 and (2) nd,1 = 2, 1.75, 1.5, vd,1 = 30, and Pg,F,1 = 0.7, 0.55, 0.35, are done and shown in Fig. 6b and c respectively. Accordingly, Pg,F,2 (vd,2) depends on Pg,F,1 and vd,1 only, but not depend on nd,1.

Feature 3: Pg,F,2(vd,2) is linear, i.e. ΔPg,F,2/Δ vd,2 = constant

By taking the partial derivative of Pg,F,2 in formula (39) to vd,2 and nd,2, it obtains

Since nd,2 is a function of vd,2, taking the partial derivative of nd,2 in formula (35) to vd,2, it obtains

Using Eq. (34) to replace nFC,1 in Eq. (47), then substituting Eq. (47) into Eq. (46), the local slope of Pg,F,2 is obtained as below.

Let’s move back to the partial dispersion characteristic curve Pg,F,2 in Fig. 6b. In the previous discussion, we know that Pg,F,2 depends on Pg,F,1 and vd,1 only, but not depend on nd,1. Here, we are going to prove one more feature of the linearity in Pg,F,2. Referring to Table 1, there are three columns, represented as Pg,F,2(i) being a simple form used to replace the term of Pg,F,2(vd,2(i)), show the data of Pg,F,2 at different row i which is calculated by formula (39) with the related material parameters nd,1, vd,1, Pg,F,1, nd,2, vd,2, included in formula (39). Another three columns, represented as S(i), show the data of the local slope directly calculated by Eq. (48) with the related material parameters \({n}_{d,1},{\mathrm{v}}_{d,1},{P}_{\mathrm{g},F,2},{n}_{d,2},{\mathrm{v}}_{d,2}\) included in Eq. (48). Further, more three columns, represented as ΔPg,F,2(i)/Δvd,2(i), show the local slope by directly dividing ΔPg,F,2(i) = Pg,F,2(i) − Pg,F,2(i + 1) by Δvd,2(i) = vd,2(i) − vd,2(i + 1). As a result, the quantitative calculations in Table 1 illustrate the linearity of Pg,F,2 when the equality of ΔPg,F,2(i)/Δvd,2(i) = S(i) = constant is satisfied at all i = 1, 19.

Feature 4: precision (error) of theoretical arithmetic

Further, let’s check out how well the material parameters nd,2, Pg,F,2, vd,2 in Mat.2 can match up with the predetermined materials nd,1, Pg,F,1, and vd,1 in Mat.1 to satisfy the near 100% diffractive efficiency.

According to Cauchy Eqs. (16)–(29), n1 (\(\uplambda\)) of Mat.1 and n2(\(\uplambda\)) of Mat.2 can be calculated by both the predetermined nd,1, Pg,F,1, vd,1 and the calculated nd,2(vd,2), Pg,F,2(vd,2) respectively. Then, the detuning factor \(\mathrm{\alpha }\)(\(\uplambda\)) is calculated by substituting n1(\(\uplambda\)) and n2(\(\uplambda\)) into Eq. (10). Finally, according to Eqs. (6) and (8), the diffractive efficiency \({\overline{\eta }}_{m}\) is calculated to achieve 99.95% (corresponding to the term “near 100%” used in our research) at the diffracted order m = 1 and wavelength from λ1 = 400 nm to λ2 = 700 nm. Regarding the difference in 0.05% diffractive efficiency, it is reasonable to infer that the error of 0.05% is caused by the miss of the higher approximation terms in the Cauchy Eq. (16). For the exact 100% diffractive efficiency, it can be simply obtained in the following way. Following the same treatments mentioned above, after n1(\(\uplambda\)) of Mat.1 being obtained, the FZ height h is calculated first by substituting nd,1 and nd,2 into Eq. (30), then n2(\(\uplambda\)) is obtained according to Eq. (31). Finally, do the same works again to get \(\mathrm{\alpha }\)(\(\uplambda\)) = 1 and η(λ) = 100% at all the wavelength in the visible light spectrum.

Feature 5: the optical behavior of convergence and divergence

In general, for the conventional DFL, the diffractive efficiency is determined by the FZ height h, the refractive index difference Δn, and the incident light wavelength λ while the optical focusing power is determined by the Δn and the curvature 1/R of the surface relief of DFL. Let’s take up the example used in Fig. 5a and b to further probe into the focusing power related to TM-FDL. As shown in both Figs, the Abbe characteristic curves nd,2(vd.2) and the partial dispersion characteristic curve Pg,F,2(vd,2) are calculated according to formula (35) and (39) respectively. Also, following the previous treatments given in Feature 4 above, an FZ height h is plotted with the respect to vd.2, as shown in Fig. 7a, by employing Eq. (30) for matching h with Δn(λ) at λ = λd, i.e. h(vd,2) = λd/(nd,1 – nd,2(vd,2)) where nd,1 ≡ n1 (λd) and nd,2 ≡ nd,2(vd,2), to guarantee the near 100% diffractive efficiency at the first diffracted order and all wavelengths of the incident light in the visible spectrum. Interestingly, there exists a singularity of h at vd,2 = 60 where vd,2 = vd,1 and nd,2 = nd,1. Consequently, the optical behavior of TM-DFL is categorized into three regions as below.

-

(1)

Transparent region: As shown in Fig. 7a, TM-DFL becomes optical transparent when vd,2 = vd,1 = 60 and nd,2 = nd,1 = 1.8. In other words, both FZ height h and focal length f0 approach to infinity when TM-FDL is composed of two same optical materials,

-

(2)

Focusing region: As shown in Fig. 7b and c, TM-DFL is equipped with the focusing power when vd,2 < vd,1, h > 0, nd,2 < nd,1, and Pg,F,2 < Pg,F,1

-

(3)

Divergent region: As shown in 7(b) and 7(c), TM-DFL is equipped with the divergent power when vd,2 > vd,1, h < 0, nd,2 > nd,1, and Pg,F,2 > Pg,F,1

Optical behavior of convergence and divergence in TM-DFL. (a) FZ height h is calculated and plotted as a function of vd.2, where TM-DFL becomes optical transparent when vd,2 = vd,1 = 60. (b, c) TM-DFL is equipped with the focusing power when vd,2 < vd,1, h > 0, nd,2 < nd,1, and Pg,F,2 < Pg,F,1, while TM-DFL is equipped with the divergent power when vd,2 > vd,1, h < 0, nd,2 > nd,1, and Pg,F,2 > Pg,F,1.

Conclusions

In our studies, we develop a theoretical framework to obtain a general formalism for the design of TM-DFL in broadband imaging applications. Unlike the existed approach of the numerical computation based methods of mapping and fitting, the optical theories related to Cauchy's equation, Abbe number, and partial dispersion, as well as the diffraction theory of Fresnel lens, have been perfectly blended into a new foundation for working out a TM-DFL with a precise material matching that can theoretically achieve a near 100% diffractive efficiency. The derivation of Equations for the calculations of nd,2(vd,2) and Pg,F,2(vd,2) is elaborated. Also, physical behaviors of nd,2(vd,2) and Pg,F,2(vd,2) are illustrated and proved, including (1) the independence of Pg,F,1 in nd,2(vd,2), (2) the independence of nd,1 in Pg,F,2(vd,2), (3) the linearity and constant slope of Pg,F,2(vd,2), (4) beyond 0.05% of the theoretical error in the calculation of diffractive efficiency, and (5) the optical behavior of convergence and divergence. We believe that our new approach will be an effective and precise way to achieve a near 100% diffractive efficiency for the design of TM-DFL.

References

Delano, E. Primary aberrations of meniscus Fresnel lenses. JOSA. 66(12), 1317–1320 (1976).

Jordan, J. A. et al. Kinoform lenses. Appl. Opt. 8, 1883–1887 (1970).

Close, D. H. Holographic optical elements. Opt. Eng. 14(5), 145408 (1975).

Sweatt, W. C. Describing holographic optical elements as lenses. JOSA. 67(6), 803–808 (1977).

Lalanne, P. Waveguiding in blazed-binary diffractive elements. JOSA A. 10, 2517–2520 (1999).

Yu, N. et al. Light propagation with phase discontinuities: Generalized laws of reflection and refraction. Science 334(6054), 333–337 (2011).

Lalanne, P. & Chavel, P. Metalenses at visible wavelengths: Past, present, perspectives. Laser. Photonics. Rev. 11(3), 1600295 (2017).

Banerji, S. et al. Imaging with flat optics: Metalenses or diffractive lenses?. Optica. 6(6), 805–810 (2019).

Engelberg, J. & Levy, U. The advantages of metalenses over diffractive lenses. Nat. Commun. 11(1), 1–4 (2020).

O’Shea, D. C. et al. Diffractive Optics: Design, Fabrication And Test Vol. 62 (SPIE Press, 2004).

Kress, B. C. Field Guide to Digital Micro-Optics (SPIE, 2014).

Buralli, D. A., Morris, G. M. & Rogers, J. R. Optical performance of holographic kinoforms. Appl. Opt. 28(5), 976–983 (1989).

Swanson, G. J., Binary optics technology: The theory and design of multi-level diffractive optical elements, Massachusetts. I. Tech. (1989).

Faklis, D. & Morris, G. M, Spectral properties of multiorder diffractive lenses. Appl. Opt. 34(14), 2462–2468 (1995).

Sales, T. R. & Morris, G. M, Diffractive–refractive behavior of kinoform lenses. Appl. Opt. 36(1), 253–257 (1997).

Moreno, V. et al. High efficiency diffractive lenses: Deduction of kinoform profile. Am. J. Phys. 65(6), 556–562 (1997).

Yang, J. et al. Chromatic analysis of harmonic Fresnel lenses by FDTD and angular spectrum methods. Appl. Opt. 57(19), 5281–5287 (2018).

Werdehausen, D. et al. Flat optics in high numerical aperture broadband imaging systems. J. Opt. 22(6), 065607 (2020).

Microchem 495 PMMA Resist. https://refractiveindex.info/?shelf=other&book=pmma_resists&page=Microchem495.

Weible, K. J. et al. Achromatization of the diffraction efficiency of diffractive optical elements. Proc. SPIE. 3749, 378–379 (1999).

Kleemann, B. H. et al. Design concepts for broadband high-efficiency DOEs. J. Eur. Opt. Soc. Rapid. 3, 08015 (2008).

Schott BaF52 Glass. https://refractiveindex.info/?shelf=organic&book=polycarbonate&page=Sultanova.

Polycarbonate (PC). https://refractiveindex.info/?shelf=organic&book=polycarbonate&page=Sultanova.

Wood, A. et al. Infrared hybrid optics with high broadband efficiency. Proc. SPIE. 1, 5874 (2005).

Werdehausen, D. et al. Dispersion-engineered nanocomposites enable achromatic diffractive optical elements. Optica. 6(8), 1031–1038 (2019).

Werdehausen, D. et al. General design formalism for highly efficient flat optics for broadband applications. Opt. Express. 28(5), 6452–6468 (2020).

Acknowledgements

This study was supported by the Ministry of Science and Technology of Taiwan under contract No. 110-2218-E-011-009-MBK & 110-2221-E-011-149.

Author information

Authors and Affiliations

Contributions

M.Y.L., C.Y.C. directed the project. M.Y.L. & T.A.C. created the data. M.Y.L. & C.H.C. calculated the data. C.Y.C. optimized calculation processing with M.Y.L. C.H.C. & T.A.C. M.Y.L., C.H.C. & T.A.C. designed and performed the simulation result. All authors contributed to discussions.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lin, MY., Chuang, CH., Chou, TA. et al. A theoretical framework for general design of two-materials composed diffractive fresnel lens. Sci Rep 11, 15466 (2021). https://doi.org/10.1038/s41598-021-94953-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-021-94953-4

- Springer Nature Limited

This article is cited by

-

Diffractive optical computing in free space

Nature Communications (2024)

-

Azimuthal rotation-controlled nanoinscribing for continuous patterning of period- and shape-tunable asymmetric nanogratings

Microsystems & Nanoengineering (2024)