Abstract

Industrial waste has been rapidly increased day by day because of the fast-growing population which results environmental pollutions. It has been recommended that the disposal of industrial waste would be greatly reduced if it could be incorporated in concrete production. In cement concrete technology, there are many possibilities to use waste materials either as cement replacement or aggregate in concrete production. Two major industrials waste are glass and marble waste. The basic objective of this investigation is to examine the characteristics of concrete waste glass (WG) as binding material in proportions 10%, 20% and 30% by weight of cement. Furthermore, to obtain high strength concrete, waste marble in proportion of 40%, 50% and 60% by weight cement as fine aggregate were used as a filler material to fill the voids between concrete ingredients. Fresh properties were evaluated through slump cone test while mechanical performance was evaluated through compressive strength and split tensile strength which were performed after 7 days, 28 days and 56 days curing. Results show that, workability of concrete decreased with incorporation of waste glass and marble waste. Furthermore, mechanical performance improved considerably up 20% and 50% substitution of waste glass and waste marble respectively. Statistical approach of Response Surface Methodology (RSM) was used optimize both waste materials in concrete. Results indicate better agreement between statistical and experimental results.

Similar content being viewed by others

Introduction

Concrete is the most widely used construction material all over the world due to its high structural strength and durability. Concrete is an extremely heterogeneous mix of aggregate (coarse aggregate CA and fine aggregate FA) cement, and water. Aggregate may affect the performance and durability of concrete but can also limit the strength of concrete. FA (Fine aggregate) is an important ingredient of concrete. The highly used FA (fine aggregate) is the natural sand of the river. The worldwide usage of natural sand of the river is very high because of the extended use of concrete. In specific, the requirement for natural sand of rivers is thoroughly high in growing countries due to the growth of infrastructure. The lack of enough amount of river sand to make cement concrete is disturbing the rise of the construction industry in different parts of the country1,2.

The yearly worldwide production of cement has hit 2.8 billion tons and is predicted to rise to about 4 billion tons annually. The cement business is facing threats like raise in cost in the supply of energy, demands to diminish the emissions of CO2, and raw materials supply in large amount3,4.

Sustainable construction usage means responsible management and making of a healthy built environment considering ecology and efficiency of resources5. Being economical and multipurpose, concrete just turned into major construction material all over the world, but it has consequences on the environment6. The making of cement which is a major component of concrete is a key cause of emissions of greenhouse gases.

Nowadays, the Ordinary Portland Cement market is headed by China, which is held responsible for 57.3% of worldwide usage7. Like the rest of the construction industry, the cement also industry is facing unparalleled taunts conveying to energy assets, emissions of CO2 and the alternative use of materials. Green taxes are an extra cost that is engaged if emissions are not restricted, possibly causing a doubling in the cement price by 20308. Different industrial by-products have been used effectively as SCMs, which include fly ash, ground granulated blast furnace slag (GGBS) and silica fume (SF)9.

Another material which has prospective as an SCM, but has not yet attained the same commercial success as glass waste10. Researches indicated that glass has a chemical structure and phase which is comparable to conventional SCMs11. It is plenteous, can be of low economic value and is frequently land filled12. Usage of glass waste in the brick and ceramic production process is discussed in a recent study13. Using glass waste to substitute cement may decrease the cost of concrete and the usage of cement, thereby straight decrease the carbon dioxide CO2 emission which is connected to cement production14.

Glass show pozzolanic behaviors if the particle size is less than 75microns. Silica from glass reacts with calcium hydrates (CaOH) converts it into calcium silicate hydrate (C–S–H)15. It has been also reported that glass starts to show pozzolanic behaviors if the particle size is less than 150 microns but the pozzolanic behaviors increased as the particle size of reduced 35 microns show better results than 150 micons16. Many researcher’s reported that waste can be successfully used as a binding material in concrete16,17,18. A study show that waste glass can be used up to 20% substitution without negative effect on performance of concrete19. It has been reported that waste glass considerably improved mechanical performance of concrete20. That show that durability aspects of also improved with incorporation of waste glass21. Some studies show that, workability concrete reduced with addition of waste glass which enhance compaction efforts leading to porous concrete which adversely affect mechanical and durability aspects of concrete20. It has been suggested that filler materials could be added to waste glass concrete, which fills voids between ingredients of concrete, giving dense concrete22. Different materials can used as filler materials including stone dust, waste tiles, ceramic materials, waste foundry sand23. In this research, waste marble has been used as filler material.

Since ancient times, marble has been frequently used as a building material. The industry’s disposing of the marble powder material, which consist of a very fine powder, today composes one of the environmental issues around the globe2,24. Usage of the marble dust in different industrial areas especially the paper, agriculture, glass, and construction industries would help to protect the environment25. During the mining process and in the polishing of marble stone, marble dust is perceived as a waste material26. A study show that marble can successfully utilize as a construction material27. Many developed countries have put in motion legal regulations concerning the recovery of structural waste aiming to reduce the amount of waste and to ensure waste recycling28. Consider the example of Japan in front of us; a country that successfully increased the recycling rate of concrete waste up to 98% using waste material as aggregate29. They recognized that the Marble Stone slurry produced during processing corresponds to about 40% of the final product from the stone industry30. The Resistance to the acid of concrete containing waste marble was marginally low in comparison to that of control concrete31. Suggest that Marble slurry can be easily used in the construction industry to prepare Cement Concrete32.

Research significance

A brief literature review show that, a lot of researchers successfully utilize waste glass as binding materials. However, a review paper show that knowledge about waste glass is still scare and further research was recommended to explore the performance of concrete with the incorporation of waste glass10. Furthermore, most of the researcher focus on mechanical performance of concrete while durability aspects of concrete are still scare except some of the researchers. Additionally waste glass increased mechanically performance of concrete due to its pozzolanic reaction but concrete still have pore voids in harden state which adversely effects mechanical and durability performance of concrete. Therefore, it is essential to add filler material (waste marble) in to waste glass concrete which fill voids between concrete ingredients, resulting more dense and durable concrete. A study concluded that waste marble can be successfully utilize as filler materials in concrete and further research was recommended that pozzolanic material must be added to obtain high strength durable concrete22. Therefore, in this research, waste glass was used as binding material (pozzolanic material) while waste marble was as filler material. A detail investigation was conducted in terms of mechanical strength and durability performance of concrete. Furthermore, for optimization, a statistical approach (response surface methodology) was used to develop a statistical model. According to authors best information, no such types of research is present in open literature.

Experimental setup

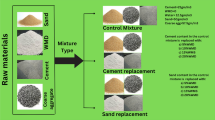

Materials

Cement

Ordinary Portland cement under ASTM C150 Type-133 is utilized throughout the experimental work for the making of the mix for all batches and its physical properties are shown in Table 1.

Waste glass

Waste Glass has been procured from Gunj glass factory, Hassanabdal, Pakistan. The particle size of glass equal to or less than that of the cement particle size is achieved by grinding the waste glass through a ball mill grinding machine at the Pakistan Council of scientific and industrial research (PCSIR) lab Peshawar. The chemical composition of GP is shown in Table 2. Furthermore, result of XRD was shown in Fig. 1 which indicate large quartz peak are absorb in 25 degrees to 35-degree angle. Also, minor peaks of quartz and other chemical were also observed at different angle. It can notice that chemical composition of waste glass is more than 70% which show that, waste glass can be used as binding material (pozzolanic material)22.

Fine aggregate

Natural sand in saturated dry condition (SSD) was used as a fine which was obtained from local market Risalpur Pakistan. Standard ASTM33/C33M-1334 was used for gradation (sieve analysis) of fine aggregate as shown in fig. Fine aggregate is according to the standard ASTM33/C33M-1334 and all the fine aggregate fall with in upper and lower limit as per ASTM C33/C33M-1334 as shown in Fig. 2a. Results of its physical property were shown in Table 3.

Waste marble

Waste marble was procured from Pak marble factory industrial zone Peshawar Pakistan and ground at PCSIR lab Peshawar. Standard ASTM33/C33M-1334 was used for gradation (sieve analysis) of waste marble. Particle size distribution of waste marble was according to the standard ASTM33/C33M-1334 and all the particle of waste marble fall with in upper and lower limit as per ASTM C33/C33M-1334 as shown in Fig. 2a. Results of physical properties waste marble were shown in the Table 3.

Coarse aggregate

Normal weight coarse aggregate (crush stone) in saturated dry condition (SSD) was obtained from local market risalpur Pakistan. Standard (ASTM33/C33M-13)34 was used for gradation (sieve analysis) of coarse aggregate. Figure 2b shows of coarse aggregate gradation curve. Coarse aggregate is according to the standard ASTM33/C33M-1334 and all the aggregate fall with in upper and lower limit as per ASTM C 33/C33M-1334 as shown in Fig. 2b. Results of its physical property are shown in Table 3.

Water

Portable water was used for the preparation of concrete mix and curing of specimens which was taken from the concrete laboratory (Military College of engineering and technology Risalpur, Pakistan). The water was ensured to be clean and free from reactive agents or organic impurities.

Testing procedure and concrete mix proportion

Workability of concrete were measured through slump cone test as per ASTM standard35. Compressive strength test is performed under the standard procedure of ASTM36 for cylindrical specimens having standard dimensions as 150 mm diameter and 300 mm length. Similar cylinders were casted and tested for spit tensile strength as per ASTM standard. To evaluate density, and water absorption of concrete, 100 mm cubes were casted and tested as per ASTM37. According to ASTM standard38 was used for drying shrinkage tests. A 100 mm cubical sample were casted to evaluate acid resistance of concrete which was cured 4% sulfuric acid for specified period. To maintain 4% concentration acid, change every week. Acid attacks was calculated in terms of mass loss in percentage due to attack of sulfuric acid. All tests were conducted after 7 days, 28 days and 56 days of curing. Three sample were casted for each mix and mean value was consider result of that test.

Casting of experimental work consist of three different phases. First phase was the casting of control sample which consists of ordinary Portland cement, natural fine, and coarse aggregate. The second set consists of partial replacement of cement with glass while the third set consist of partial replacement of sand with waste marble. Instead of mixing procedure is initiated, the essential amount of ingredients was weighed by system of weighing. Rate of mixer is kept constant 30 rev/min for blending of ingredients. Initially, crush was put into the drum and then sand, each ingredient was dry blended then essential amount of OPC, and water was inserted with the passage of time and blending were performed around 10 min for all batches. Waste glass was used as cement replacement in proportion of 10%, 20% and 30% while waste marble was used as fine aggregate in proportion of 40%, 50% and 60%. Furthermore, the quantification of materials per m3 was displayed in Table 4.

Results and discussion

Fresh property

Workability of concrete

Workability fresh concrete is a mix property which includes the different requirements of stability, mobility, compatibility, finish ability and placeability39. Mechanical performance and durability aspects of concrete mainly depends on workability of concrete. Poor workability required more compactions affords resulting voids in harden with lower density which result less mechanical strength. Also, poor workability results lower durability of concrete as harmful ingredient can easily penetrate through these voids which cause degradation of concrete. Therefore, workability is one of the prime factors that must be consider during mix design of concrete. According to past researcher’s, waste glass and marble waste decreased workability of concrete22. Therefore, 1.0% (4.25 kg) superplasticizer by weight of cement is kept constant throughout study.

Figure 3 show workability of concrete with varying dose waste glass and marble waste. Test result show that workability of concrete decreased with incorporation of waste glass and waste marble having maximum workability with 0% addition of waste glass and marble waste while minimum workability with 30% and 60% substitution of waste glass and marble waste. It is due to physical feature of waste glass and waste marble i-e rough surface texture which increased the internal friction between concrete ingredients which required more water and cement paste for lubrication. Furthermore, the formation of CSH due to pozzolanic reaction of waste glass and marble waste enhance the viscosity of concrete leading to less workable concrete. Similar results were reported by past researcher’s22,40. Although some of study show that workability concrete increased with incorporation of waste marble and waste glass due to filling voids in between concrete ingredients resulting less cement paste is required for lubrication12,41.

Mechanical performance

Compressive strength

Figure 4 shows compressive strength of concrete with different proportion ration of waste glass and marble waste. Test results indicate that compressive strength increase up to 20% substitution of waste glass and then decreased gradually having maximum strength with 20% substation of waste as comparison to the reference concrete. It is due to fact that glass is a pozzolanic material that reacts with calcium hydrate (CH) which is form during hydration process of cement. calcium hydrate (CH) is by product which remain uncreative forming weak zone in concrete. It has been also reported that, calcium hydrate (CH) react with different chemical present in cement cause degradation of concrete40. Silica present in waste glass react with calcium hydrate (CH) and convert it in calcium silicate hydrate (CSH) gel which Provide additional binding property, leading to more compressive strength.

The formation of calcium silicate hydrate (CSH) gel from calcium hydrate (CH) were observed through X-ray diffraction (XRD) test. XRD analysis were conducted at the age of 28 days to investigate the mineralogical composition and to assess the measure of CH and CSH in control and glass powder substituted batches. Peaks of CSH at 34° and 62° were selected for analysis. These peaks and their pattern can be observed from the Fig. 5. Normal peaks of CSH can be observed in the control samples which shows normal CSH amount in concrete without any substitution. Similarly, higher and sharp peaks of quartz at 28° and 47° (2 θ) can be observed almost in same pattern in each sample in each sample which ensure the presence of crystalline silica in glass powder. This crystalline silica increases with the increasing percentage of glass powder. The CSH peaks get increased with increasing substitution of glass powder at 10% and 20% replacement of cement by glass as compared to control sample while at 30% replacement of cement by glass the CSH peaks were observed higher than control sample and 10% and less than 20%. The CSH amount is increased at 10% and 20% replacement of cement by glass due to the pozzolanic activity of glass powder through which it utilizes the available CH in concrete and produce CSH gel. On the other hand, CSH amount at 30% was observed less than that at 20% replacement which is due to the remaining unreactive amount of excessive glass powder for which there is no CH available to react with glass powder and so it remains unreactive and also results in lowering the strength of concrete. The XRD results confirm that performance and strength development of glass powder as mineral addition as a substitution of ordinary Portland cement. However, at higher dosage of waste glass, compressive strength of concrete decreased due dilution effect which cause alkali silica reaction. Also, at higher dosage, compaction process become more difficult due to lack of workability, leading to pore in harden concrete resulting less compressive strength.

As for waste marble concern, compressive strength increased up to 50% substitute of waste marble and then declined as compared to the control mix as shown in Fig. 4 having maximum strength at 50% substation of waste marble. It is due to fact that marble waste acts as micro filler because marble waste is less fineness modulus as compared to sand which fills voids in fine and coarse aggregate leading to compact dense mass, resulting more compressive strength. Also, it has been reported that marble waste shows pozzolanic reaction which convert CH in to CSH gel if the particles size less than 100 micron. Gradation curve of marble waste show that 20% marble waste particle size is than 100 microns which contribute as a pozzolanic material. Also marble waste aggregate has higher carbonate content than the natural aggregate, which improves the aggregate cement paste bond that is the reason for the increase in compressive strength of concrete at different curing ages31. However, at higher dose, compressive strength decreased because of less workability which cause porous concrete.

A relative analysis for compressive strength at different age of curing were caried out in which 28 days of control compressive strength was taken as reference strength, from different dose of waste glass and waste marble compare as shown in Fig. 6. At 7 days of curing, compressive strength is 18.5% less than at 20% substation of waste glass while compressive strength is 22% less than as at 50% substitution of marble waste as compared to reference concrete (28 days control strength). At 28 days of curing, compressive strength is 21% more than at 20% substation of waste glass while compressive strength is 12% more than as at 50% substitution of marble waste as compared to reference concrete (28 days control strength). At 56 days of curing, compressive strength is 23 more than at 20% substation of waste glass while compressive strength is 17% more than as at 50% substitution of marble waste as compared to reference concrete (28 days control strength).

Response surface methodology is a statistical tool, and its main purpose is to optimize a response or output which can be influenced by several factors or input variables. The response or output can be represented graphically in a three-dimensional space or with a contours plot. The optimization process considered all responses simultaneously to achieve a concrete mix design that will be favorable for all investigated responses42. When there is more than one response, then it important to find the combine optimum dosage of both materials that does not optimize only one response43. In this study dose of waste materials is independent variable while strength is dependent variable which depend on substation dose of waste materials.

To investigate the combined effects of waste glass and marble waste on the compressive strength, a 3D response surface and contour plot were developed with help of statistical software (Minitab). Figure 7a, b shows 3D response surface and contour plot software for compressive strength at 28 days curing. For optimum dose of waste glass and marble, 15% waste glass and 30% waste marble were selected giving compressive strength 33 MPa. Same dose of 15% waste glass and 30% waste marble was casted and experimentally tested. It can observe that experimental and predicted strength were comparable. Furthermore, different substitution ration of waste glass and marble waste were selected from contour plot. Same substitution ration of waste glass and marble waste were casted and experimentally tested in laboratory for verification experimental and predicted strength.

Figure 8 show correlation of experimental value and predicted value from contour plot. A strong correlation is existed in experimental value and predicted value having R2 value greater than 90%.

Split tensile strength

Figure 9 shows split tensile strength of concrete with different proportion ration of waste glass and marble waste. Similar to the compressive strength, split tensile strength increase up to 20% substitution of waste glass and then decreased gradually having maximum split tensile strength with 20% substation of waste glass as comparison to the reference concrete. It is due to pozzolanic reaction waste glass which give additional CSH gel which enhance the binding property of concrete. It is worth to mention that waste glass improved split tensile strength more effectively than compressive strength. it is due to fact that, split tensile strength main depend on cement paste strength which holds the aggregate together during tensile strength22 while binding property of paste is improved due to pozzolanic reaction of waste glass. However, at higher dose, split tensile strength is reduced due dilution effect which alkali silica reaction as well as lack of workability which results void in harden concrete.

As for waste marble concern, split tensile strength increased up to 50% substitute of waste marble and then declined as compared to the control mix as shown in Fig. 9 having maximum split tensile strength at 50% substation of waste marble. It is due to fact that marble waste acts as micro filler which fills voids in fine and coarse aggregate leading to compact dense mass, resulting more compressive strength. During crushing Marble waste particle is rough texture as compared to natural sand which is form due erosion. Rough surface texture of marble particle improved split tensile strength. Also, it has been reported that marble waste shows pozzolanic reaction which convert CH in to CSH gel if the particles size less than 100 micron. Gradation curve of marble waste show that 20% marble waste particle size is than 100 microns which contribute as a pozzolanic material. Also marble waste aggregate has higher carbonate content than the natural aggregate, which improves the aggregate cement paste bond that is the reason for the increase in split tensile strength of concrete at different curing ages31. However, at higher dose, compressive strength decreased because of less workability which cause porous concrete.

A relative analysis for split tensile strength at different age of curing were caried out in which 28 days of control compressive strength was taken as reference strength, from different dose of waste glass and waste marble compare as shown in Fig. 10. At 7 days of curing, split tensile strength is 4.5% less than at 20% substation of waste glass while split tensile strength is 15% less than as at 50% substitution of marble waste as compared to reference concrete (28 days control strength). At 28 days of curing, split tensile strength is 36% more than at 20% substation of waste glass while split tensile strength is 24% more than as at 50% substitution of marble waste as compared to reference concrete (28 days control strength). At 56 days of curing, split tensile strength is 49% more than at 20% substation of waste glass while split tensile strength is 37% more than as at 50% substitution of marble waste as compared to reference concrete (28 days control strength).

To investigate the combined effects of waste glass and marble waste on the split tensile strength, a 3D response surface and contour plot were developed with help of statistical software (Minitab). Figure 11 shows 3D response surface and contour plot software for split tensile strength at the age 28 days curing. For optimum dose of waste glass and waste marble, 15% waste glass and 30% waste marble were selected giving split tensile strength 5.5 MPa. Same dose of 15% waste glass and 30% waste marble was casted and experimentally tested. It can observe that experimental and predicted strength were comparable. Furthermore, different substitution ration of waste glass and marble waste were selected from contour plot. Same substitution ration of waste glass and marble waste were casted and experimentally tested in laboratory for verification experimental and predicted strength.

Figure 12 show correlation of experimental value and predicted value from contour plot. A strong correlation is existed in experimental value and predicted value having R2 value greater than 90%.

Durability

Density

Figure 13 shows density of concrete at 28 days of curing with different proportion ration of waste glass and marble waste. density of concrete increase up to 20% substitution of waste glass and then decreased gradually having maximum density with 20% substation of waste glass as comparison to the reference concrete.

It is due to pozzolanic reaction waste glass which increased the viscosity of cement paste around the aggregate due to additional CSH gel leading more dense concrete. However, at higher dose, compaction process become more difficult which results more pore in harden concrete leading to less dense concrete. As for waste marble concern, density increased up to 50% substitute of waste marble and then declined as compared to the control mix as shown in Fig. 13 having maximum density at 50% substation of waste marble. It is due to fact that marble waste acts as micro filler which fills voids in fine and coarse aggregate leading to compact dense concrete. However, at higher dose, density decreased because of less workability which cause porous concrete. Therefore, a higher dose of superplasticizer is required.

Compressive strength mainly depends on density of concrete. Density of concrete is directly proportional to strength of concrete; higher density results more compact concrete with less voids leading to more strength of concrete and vice versa. Figure 14 shows correlation between density and compressive strength of concrete. Therefore, a strong relation is existing between compressive strength and density of concrete having R2 value more than 90%.

Water absorption

Water absorption can be also used to detect durability of concrete. Higher water absorption led to degradation of concrete leading to less durable concrete. Higher water absorption also results frost and thaw action. Figure 15 shows water absorption of concrete with different proportion ration of waste glass and marble waste. water absorption of concrete increase up to 20% substitution of waste glass and then decreased gradually having minimum water absorption with 20% substation of waste glass as comparison to the reference concrete.

It is due to pozzolanic reaction waste glass which increased the concentration CSH gel leading more dense concrete which results less water absorption. However, at higher dose, compaction process become more difficult which results more pore in harden concrete leading to more water absorption. As for waste marble concern, water absorption decreased up to 50% substitute of waste marble and then declined as compared to the control mix as shown in Fig. 15 having minimum water absorption at 50% substation of waste marble. It is due to fact that marble waste acts as micro filler because of its fineness, marble waste has ability to fills voids in fine and coarse aggregate leading to compact dense concrete which results less water absorption. However, at higher dose, water absorption increased because of less workability which cause porous concrete.

Water absorption directly depends on concrete density. Higher density means more dense concrete with less void ratio. Figure 16 show correlation between water absorption and density of concrete. Therefore, a strong correlation is existing in between water absorption and density of concrete having R2 value greater than 90%.

Acid resistance

Various aggressive acids available, like as HCL (hydrochloric acids), NHO3 (nitric acids) and H2SO4 (sulfuric acids) etc. In this study, H2SO4 (sulfuric acids) is considered as an acid attack, on the concrete specimens with different proportions of waste glass and marble waste.

Figure 17 shows Acid resistance of different dosages of waste glass and marble waste. Acid resistance increased with incorporation of waste glass up to 20% substitution by weight of cement having minimum acid resistance at 20% of waste glass as compared to control mix. It is due to formation CSH gel which enhance the density of cement paste around the aggregate which results that acid cannot penetrate easily into the concrete body. Marble waste also improved acid resistance of concrete due micro filling voids in concrete ingredients. However, at higher dosage of waste glass and waste marble, acid resistance decreased due less workability of concrete which enhance compaction affords resulting more porous concrete23.

Acid resistance directly depend on density of concrete. Higher density results more resistance to acid due loess voids through which acid cannot easily penetrate through concrete body which cause degradation of concrete. Therefore, a strong correlation between density and acid resistance of concrete. Figure 18 show correlation between density and acid resistance of concrete. It can observe that a strong correlation is exist between density and acid resistance having R2 value greater than 90%.

Drying shrinkage

Dry shrinkage of concrete can also affect durability of concrete. Water and chemical can easily inter onto the concrete body through small shrinkage cracks on the surface of concrete causing deterioration of concrete which results less durable concrete. Drying shrinkage with respect to time for varying dosage of waste glass and waste marble is given in Fig. 19.

Waste glass decreased dry shrinkage considerably. It has been reported that dry shrinkage is basically movement of cement paste while aggerate restrict these movement40. According to past literature drying shrinkage is affected by the concrete porosity and stiffness40. The formation C–S–H (calcium silicate hydrate gel) due to pozzolanic reaction cause more dense concrete which might be caused to decrease shrinkage. Marble waste also shows positive impact on dry shrinkage due to micro filling voids in concrete ingredient. It has been also reported that fly ash considerably reduced drying shrinkage to filling micro pore in concrete which enhance internal compactness of concrete22.

Conclusions

In this research, Waste glass is being replaced as binding material in a proportion of 10%, 20% and 30%, and marble waste is being replaced as fine aggregate in the proportion of 40%, 50% and 60%. Based on experimental works, the following conclusion has been made.

-

Workability of fresh concrete decreased as the percentage of waste glass and marble increased. It is due to physical nature of waste glass and waste marble (Rough surface texture).

-

Mechanical performance of concrete was considerably improved with incorporation waste glass and waste marble. It is due to the pozzolanic reaction as well as micro filling of waste glass and waste marble.

-

Compressive strength of 20% and 50% substitution of waste glass and waste marble is 28 MPa and 27 MPa which is 21% and 12% higher than reference concrete respectively.

-

Application of statistics optimum of waste glass and waste marble shows compressive strength 33 MPa which 38% higher than reference.

-

Maximum split tensile strength was obtained at combine ratio of 15% waste glass and 30% waste marble having split tensile strength of 5.5 Mpa which were 65% higher than from reference concrete.

-

Based on work results, the predicted value from statistical analysis and the experimental value was comparable.

-

In increased of concrete density, water absorption, acid resistance and dry shrinkage were observed with incorporation of waste glass and waste marble as comparison of reference concrete.

Demand for cement and natural aggregate is growing in the construction sector day by day which cause depletion of natural resources. Keeping the above points in mind, it can be safe to say that waste and waste marble can be safely utilized in concrete. So, reserving natural resource by using waste material like waste glass and waste marble, it is a viable option to help the environment by making concrete eco-friendly, sustainable and non-aggressive to the environment.

Change history

01 August 2023

This article has been retracted. Please see the Retraction Notice for more detail: https://doi.org/10.1038/s41598-023-39449-z

References

Sankh, A. C., Biradar, P. M., Naghathan, S. J. & Ishwargol, M. B. Recent trends in replacement of natural sand with different alternatives. In Proceedings of the International Conference on Advances in Engineering and Technology 59–66 (2014).

Ahmad, W. et al. A scientometric review of waste material utilization in concrete for sustainable construction. Case Stud. Constr. Mater. 15, e00683 (2021).

Benhelal, E., Zahedi, G., Shamsaei, E. & Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean Prod. 51, 142–161 (2013).

Ahmad, J. et al. A study on mechanical and durability aspects of concrete modified with steel fibers (SFs). Civ. Eng. Archit. 8, 814–823 (2020).

Du Plessis, C. A strategic framework for sustainable construction in developing countries. Constr. Manag. Econ. 25, 67–76 (2007).

Naik, T. R. Sustainability of concrete construction. Pract. Period Struct. Des. Constr. 13, 98–103 (2008).

Imbabi, M. S., Carrigan, C. & McKenna, S. Trends and developments in green cement and concrete technology. Int. J. Sustain. Built Environ. 1, 194–216 (2012).

Council WB. World Business Council for Sustainable Development. Cem Sustain Initiat Cem Ind Energy CO2 Perform Get Numbers Right (2009).

Islam, G. M. S., Islam, M. M., Akter, A. & Islam, M. S. Green construction materials-Bangladesh perspective. In Proceedings of the International Conference on Mechanical Engineering and Renewable Energy (2011).

Rashad, A. M. Recycled waste glass as fine aggregate replacement in cementitious materials based on Portland cement. Constr. Build. Mater. 72, 340–357 (2014).

Ryou, J., Shah, S. P. & Konsta-Gdoutos, M. S. Recycling of cement industry wastes by grinding process. Adv. Appl. Ceram. 105, 274–279 (2006).

Byars, E. A., Zhu, H. & Meyer, C. Use of waste glass for construction products: Legislative and technical issues. In Recycling and Reuse of Waste Materials 827–838 (Thomas Telford Publishing, 2003).

Andreola, F. et al. Recycling of industrial wastes in ceramic manufacturing: State of art and glass case studies. Ceram. Int. 42, 13333–13338 (2016).

Hasanbeigi, A., Price, L. & Lin, E. Emerging energy-efficiency and CO2 emission-reduction technologies for cement and concrete production: A technical review. Renew. Sustain. Energy Rev. 16, 6220–6238 (2012).

Subramani, T. & Ram, S. B. S. Experimental study on concrete using cement with glass powder. Dep. Civ. Eng. VMKV Eng. Coll. Vinayaka Mission Univ. Salem, India 5, 43–53 (2015).

Tamanna, N. et al. Pozzolanic properties of glass powder in cement paste. J. Civ. Eng. Sci. Technol. 7, 75–81 (2016).

Mahmoud, A. S., Yassen, M. M. & Hama, S. M. Effect of glass powder as partial replacement of cement on concrete strength and stress-strain relationship. In 2019 12th International Conference on Developments in eSystems Engineering (DeSE) 109–114 (IEEE, 2019).

Srivastava, V., Gautam, S. P., Agarwal, V. C. & Mehta, P. K. Glass wastes as coarse aggregate in concrete. J. Environ. Nanotechnol. 3, 67–71 (2014).

Harrison, E., Berenjian, A. & Seifan, M. Recycling of waste glass as aggregate in cement-based materials. Environ. Sci. Ecotechnol. 4, 100064 (2020).

Okeke, K. L. & Adedeji, A. A. A Review on the Properties of Concrete incorporated with Waste Glass as a Substitute for Cement.

de Oliveira, L. A. P., Gomes, J. C. & Santos, P. Mechanical and Durability Properties of Concrete with Ground Waste Glass Sand (Artig em encontro Cient Int, 2008).

Ahmad, J. et al. Mechanical properties of sustainable concrete modified by adding marble slurry as cement substitution. AIMS Mater. Sci. 8, 343–358 (2021).

Ahmad, J., Aslam, F., Zaid, O. et al. Mechanical and durability characteristics of sustainable concrete modified with partial substitution of waste foundry sand. Struct. Concr.

Corinaldesi, V., Moriconi, G. & Naik, T. R. Characterization of marble powder for its use in mortar and concrete. Constr. Build. Mater. 24, 113–117 (2010).

Karaşahin, M. & Terzi, S. Evaluation of marble waste dust in the mixture of asphaltic concrete. Constr. Build. Mater. 21, 616–620 (2007).

Hebhoub, H. et al. Use of waste marble aggregates in concrete. Constr. Build. Mater. 25, 1167–1171 (2011).

Sufian, M. et al. An experimental and empirical study on the use of waste marble powder in construction material. Materials (Basel) 14, 3829 (2021).

Ismail, S. & Ramli, M. Engineering properties of treated recycled concrete aggregate (RCA) for structural applications. Constr. Build. Mater. 44, 464–476 (2013).

Dosho, Y. Development of a sustainable concrete waste recycling system. J. Adv. Concr. Technol. 5, 27–42 (2007).

Shirulea, P. A. Rahmanb, A. & Guptac, R. D. Partial replacement of cement with marble dust powder. Int. J. Adv. Eng. Res. Stud. ISSN2249 8974 (2012).

Kore, S. D. & Vyas, A. K. Impact of marble waste as coarse aggregate on properties of lean cement concrete. Case Stud. Constr. Mater. 4, 85–92 (2016).

Kuswah, R. E. P. S., Sharma, I. C. & Chaurasia, P. B. L. Utilization of marble slurry in cement concrete replacing fine aggregate. Am. J. Eng. Res. 4, 55–58 (2015).

Cement AP ASTM C150 of the following type: 1. Concr which will be contact with Sew Type II, Moderate Sulfate Resist 2.

ASTM C 33/C33M. Stand specification concrete aggregates. Annu. B ASTM Stand. 4, 498–505 (2008).

Grout, F. ASTM C 476, except with a maximum slump of 4 inches, as measured according to ASTM C 143. C 143M.

C39/C39M A. Standard test method for compressive strength of cylindrical concrete specimens. Annu B ASTM Stand (2003).

ASTM C. Standard test method for density, absorption, and voids in hardened concrete. C642-13 (2013).

Sun, W., Chen, H., Luo, X. & Qian, H. The effect of hybrid fibers and expansive agent on the shrinkage and permeability of high-performance concrete. Cem. Concr. Res. 31, 595–601 (2001).

Aggarwal, Y. & Siddique, R. Microstructure and properties of concrete using bottom ash and waste foundry sand as partial replacement of fine aggregates. Constr. Build. Mater. 54, 210–223 (2014).

Ahmad, J. et al. Mechanical and durability characteristics of sustainable coconut fibers reinforced concrete with incorporation of marble powder. Mater. Res. Express 8, 075505 (2021).

Malik, M. I. et al. Study of concrete involving use of waste glass as partial replacement of fine aggregates. IOSR J. Eng. 3, 8–13 (2013).

Awolusi, T. F., Oke, O. L., Akinkurolere, O. O. & Sojobi, A. O. Application of response surface methodology: Predicting and optimizing the properties of concrete containing steel fibre extracted from waste tires with limestone powder as filler. Case Stud. Constr. Mater. 10, e00212 (2019).

Oehlert, G. W. Design and Analysis of Experiments: Response Surface Design (Kluwer Academic Publishers, 2000).

Acknowledgements

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University for funding this work through a group research program under grant number RGP. 2/129/42.

Author information

Authors and Affiliations

Contributions

J.A.; Paper writing, experimental work. F.A.; Methodology, supervision, conceptual. R.M.G.; Evaluation, Monitoring, Resources. J.D.P.G.; Supervision, Revision. S.M.A.Q.; Conceptual, Grammatically Improvement. A.B.; Formatting, Software work.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article has been retracted. Please see the retraction notice for more detail: https://doi.org/10.1038/s41598-023-39449-z

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ahmad, J., Aslam, F., Martinez-Garcia, R. et al. RETRACTED ARTICLE: Effects of waste glass and waste marble on mechanical and durability performance of concrete. Sci Rep 11, 21525 (2021). https://doi.org/10.1038/s41598-021-00994-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-021-00994-0

- Springer Nature Limited

This article is cited by

-

Influence of Slag, Silica Fume and Waste Tire Wire on High-Strength Characteristics of Geopolymer Concrete Cured Under Ambient and Oven Conditions

International Journal of Civil Engineering (2024)

-

Environmental feasibility of recycling construction and demolition waste

International Journal of Environmental Science and Technology (2024)

-

Self-Compacting Concrete with Partially Substitution of Waste Marble: A Review

International Journal of Concrete Structures and Materials (2023)

-

Machine learning intelligence to assess the shear capacity of corroded reinforced concrete beams

Scientific Reports (2023)

-

Strength and Durability Properties of Waste Glass Based Self Compacting Concrete: A Review

Silicon (2023)