Abstract

There have been several reports about the difficulties in removing 3.5-mm titanium locking screws from plates due to the stripping or rounding of the hexagonal screw socket. We investigated whether stripping the locking screw sockets can be prevented by using different screwdrivers or interposing materials into the socket during removal. We overtightened 120 3.5-mm titanium locking screws (Depuy Synthes, Paoli, PA) equally into locking plates on sawbone tibia models, applying a uniform torque of 4.5 Nm, exceeding the recommended torque of 1.5 Nm. Twenty screws each were removed using a straight-handle 2.5-mm screwdriver, T-handle screwdriver, hex key wrench, and straight-handle screwdriver with a non-dominant hand. In addition, 20 screws were removed using foil from a suture packet inserted into the screw socket or using parts of a latex glove inserted into the screw socket. The incidence rates of screw stripping using the straight-handle screwdriver, T-handle screwdriver, hex key wrench, non-dominant hand, foil interposition, and latex glove interposition were 75%, 40%, 35%, 90%, 60%, and 70%, respectively. When a T-handle screwdriver or hex key wrench was used, the probability of screw stripping was 4.50 times (odds ratio = 4.50, 95% confidence interval = 1.17 to 17.37, p = 0.03) and 5.57 times (odds ratio = 5.57, 95% confidence interval = 1.42 to 21.56, p = 0.01) lower than that with the straight-handle screwdriver, respectively. Foil or latex glove interpositions did not prevent screw stripping. Thus, in the current experimental study, T-handle screwdriver or hex key wrench usage decreased the incidence rate of screw stripping during removal compared to straight-handle screwdriver use.

Similar content being viewed by others

Introduction

Locking plates can provide high fixation stability for reliable healing in various fractures. These plates are usually manufactured from titanium alloys with higher biocompatibility, higher fatigue strength, and lower risk of infection and are isoelastic with the bone compared to stainless steel1,2,3,4,5,6,7. However, titanium is prone to cross-threading or cold welding under strong metal-to-metal contact7,8,9. There have been several reports about the difficulties in removing 3.5-mm titanium locking screws from the locking plates after healing of the fractured bone3,5,10,11,12,13,14,15,16. Removal is challenging when the hexagonal socket of the screw is stripped, rendering the drivers useless. Various techniques have been suggested to remove stripped locking screws6,9,14,15,17,18. However, once the screw is stripped, the surgery duration is prolonged, despite the broken screw or stripped screw removal techniques, which increases the possibility of complications such as more bleeding, infection, neurovascular injury, and even iatrogenic fractures4,9,11. Therefore, the prevention of screw stripping is essential.

Appropriate use of aiming sleeves and torque-limiting screwdrivers is important to prevent cross-threading or overtightening of the screws during insertion. However, there are few suggestions that can be followed during screw removal to prevent screw stripping7,19. Some authors suggest the insertion of aluminum foil or part of a sterile glove into the screw socket to increase the friction between the driver and the socket; nevertheless, these tips are anecdotal, and none have been proven effective4,19,20,21,22. Currently, star-shaped (hexalobular) sockets, which are less prone to stripping, are now widely used for locking screws4,23. However, conventional locking screws with hexagonal sockets, widely used in the past and still used, may require removal someday.

We performed an experimental study on sawbone tibia models to determine whether the incidence of stripping of the hexagonal socket of 3.5-mm titanium locking screws (Depuy Synthes, Paoli, PA) can be minimized by using a T-handle driver with a relatively larger dimension of the driver tip or a hex key wrench. We also tested whether there was a difference in the incidence of screw stripping by using the dominant hand and the non-dominant hand. In addition, we tested whether the interposition of the aluminum foil or parts of the latex glove into the screw socket effectively reduces the incidence of screw stripping.

Materials and methods

Preparation of jammed locking screws into the locking plates

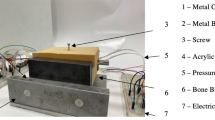

We prepared 6 sawbone tibia models and 12 3.5-locking compression plates (LCPs, Depuy Synthes) with 10 holes each and 120 3.5-mm titanium locking screws (Depuy Synthes). Two plates were attached to each sawbone tibia model. To overtighten and jam the locking screws into the locking plates with the same amount of torque, a torque driver with the torque limit set at 4.5 Nm was used. A total of 120 screws were overtightened by applying a torque of 4.5 Nm, which exceeded the recommended torque of 1.5 Nm for the 3.5-mm locking screw insertion (Fig. 1). The torque of 4.5 Nm was finalized by slowly overtightening the locking screw into the locking plate, starting with a torque of 1.5 Nm with subsequent increments of 0.5 Nm. We used a torque driver that could adjust the torque by 0.05 Nm (Fig. 1). When the torque was set at 4.0 Nm, 1 out of 5 (20%) screws was stripped during removal using a straight-handle 2.5-mm driver (Depuy Synthes), and at 4.5 Nm, 3 out of 5 (60%) screws were stripped. We found that over 5.0 Nm, the screw socket was stripped during the insertion. Thus, we set 4.5 Nm as the torque limit for the study.

To overtighten and jam the locking screws into the locking plates by applying an identical torque, a torque driver with the torque limit set at 4.5 Nm was used (upper left box). A total of 120 screws were overtightened by applying an identical torque of 4.5 Nm, which exceeded the recommended torque of 1.5 Nm for the 3.5-mm locking screw insertion.

Removal of jammed locking screws

A straight-handle 2.5-mm screwdriver (Depuy Synthes), a T-handle screwdriver (Acumed, Hillsboro, OR), and a hex key wrench (Wera Werkzeuge GmbH, Wuppertal, Germany) were used to remove 20 screws each (Fig. 2).

(a) Various types of 2.5-mm screwdrivers are presented. A 2.5-mm straight-handle screwdriver (Depuy Synthes, Paoli, PA) (①), a 2.5-mm driver tip (Acumed, Hillsboro, OR) connected to a T-handle (②), and a 2.5-mm hex key wrench (Wera Werkzeuge GmbH, Wuppertal, Germany) (③) were used to remove the locking screws. (b) The dimension of the 2.5-mm hexagonal screwdriver tip (Acumed) was slightly larger than that made by the other manufacturer (Depuy Synthes), such that it could hold the 3.5-mm titanium locking screw (Depuy Synthes) without the screw-holding sleeve.

Twenty screws were removed with a straight-handle screwdriver using the non-dominant hand. Twenty screws were removed with a foil from a suture packet inserted into the screw socket, and 20 were removed with parts of a latex glove inserted into the screw socket using the straight-handle driver and the dominant hand (Fig. 3). When the foil was placed over the screw socket and the screwdriver tip was inserted into the socket, the foil was punctured by the driver tip such that the interposition of the foil inside the socket was not possible. Therefore, we wrapped the tip of the driver with the foil to engage the driver tip in the screw socket until it reached full depth.

We counted the number of stripped screws that could not be removed and compared the incidence rate of stripping with different screwdrivers and the interposition of foil or parts of latex gloves. Screw stripping was defined as rounding of the hexagonal screw socket such that the screw could not be removed with the screwdriver.

Statistical analysis

We performed a pilot study on 20 3.5-mm titanium locking screws jammed into the locking plate to determine the appropriate sample size for the study. As a result, 8 out of 10 (80%) and 3 out of 10 (30%) screws were stripped using the straight-handle driver and the T-handle screwdriver, respectively. Assuming 95% power and a 0.05 significance level, 20 samples in each group were calculated to detect a decrease in the incidence of screw stripping from 80% in the control group to 30% in the experimental group24. In a previous study on the correlation between the socket design of the locking screws and screw stripping, 10 screws were used for each group of 9 socket designs4. We decided that 20 screws for each group would be appropriate for the study. We used the chi-square test to determine the significance of the association between the binary outcomes (stripped and irremovable screws/removed screws) and the use of different screwdrivers or the interposition of materials. A chi-square test was performed on the two-way contingency table with the row variable set as the use of different screwdrivers or the interposition of materials (use of straight-handle screwdriver/use of other type of screwdrivers or interposition of materials) and the column variable set as the binary outcomes (stripped and irremovable screws/removed screws). The use of straight-handle screwdrivers was used as the reference. We calculated the odds ratio and its 95% confidence interval (95% CI) on this two-way contingency table to measure the association between the use of different screwdrivers or interposition of materials and prevention of screw stripping. We used Fisher's exact test to analyze whether the non-dominant hand was associated with a high incidence of screw stripping. Statistical significance was set at p < 0.05. Statistical analysis was performed using SPSS version 22.0 (IBM Corporation, Armonk, NY, USA).

Ethics approval

This study was approved by the IRB of Hallym University Kangnam Sacred Heart Hospital (IRB-2020-12-015). The study did not involve humans or animals.

Results

The results are presented in Table 1. When the straight-handle screwdriver, T-handle screwdriver, and hex key wrench were used to remove the 3.5-mm titanium locking screws, 15 (75%), 8 (40%), and 7 (35%) screws were stripped (Fig. 4).

Values are given as the number and the percentage in parentheses.

The probability of stripping the screw was reduced by 4.50 times (odds ratio = 4.50, 95% CI = 1.17 to 17.37, p = 0.03), and 5.57 times (odds ratio = 5.57, 95% CI = 1.42 to 21.56, p = 0.01) when the T-handle screwdriver and the hex key wrench were used, respectively, compared to that using the straight-handle screwdriver (Table 2). Foil interposition or latex glove interposition during screw removal did not prevent screw stripping (Table 2).

When the non-dominant hand was used with the straight-handle screwdriver, the incidence rate of screw stripping increased compared to when using the dominant hand. However, the difference was not statistically significant (90% vs. 75%, p = 0.41) (Tables 2,3). The probability of stripping the screw was reduced by 13.50 times (odds ratio = 13.50, 95% confidence interval = 2.43 to 74.87, p = 0.002), and 16.71 times (odds ratio = 16.71, 95% confidence interval = 2.97 to 93.89, p = 0.001) when the dominant hand was used with the T-handle screwdriver and the hex key wrench, respectively, compared to that using the non-dominant hand with the straight-handle screwdriver (Table 3).

Discussion

The LCP (Depuy Synthes) has been introduced as a new standard of AO plating osteosynthesis. It is widely used for various fractures, such as comminuted tibia fractures, or even in joint sparing salvage surgery after articular oncological resections3,4,5,6,7,25. However, there are reports of difficulties in removing 3.5-mm titanium locking screws due to stripping of hexagonal sockets3,5,10,16. This may be because titanium is more malleable than stainless steel, and the difference in the mechanical resistance between the stainless-steel screwdriver and the titanium screw may lead to stripping of the titanium screw. Titanium has a high degree of biocompatibility, which leads to increased osteointegration and thus a higher risk of screws becoming encased17,26. Furthermore, LCP is used for the minimally invasive plate osteosynthesis technique. Hence, when the locking screw hole of the plate is not well exposed, the locking screw may be inserted at the wrong angle and jam into the plate22. During screw removal, the screwdriver may sometimes engage with the screw at an incorrect angle, or the driver tip may not be fully engaged in the screw socket before the screwdriver is turned. The surgeon can feel the first slippage of the screwdriver inside the socket. A biomechanical study demonstrated up to a 50% decrease in the maximal torque values after a single event of screwdriver slippage13. Although the straight handle is easy to rotate when there is no considerable resistance, as in screw insertion, when a high torque for the counterclockwise rotation force is required to remove a jammed locking screw, the straight-handle screwdriver is relatively thin for a full grip compared to the T-handle. The axis of the straight-handle driver may not be in alignment with the axis of the screw when considerable wrist movement is required in addition to finger movement to rotate the screwdriver. This may cause the tip of the driver to deviate inside the screw socket (Fig. 5). When the driver tip is not evenly in contact with the socket because of this deviation and is in contact only with certain parts, the stress is concentrated at the point of contact. The driver tip reams that part of the socket leading to stripping. Compared to the straight-handle screwdriver, the T-handle screwdriver and hex key wrench can transfer the counterclockwise rotation force to the screw with less deviation of the axis of the driver tip from the axis of the screw. This can maximize the contact area between the driver tip and the screw socket to prevent screw stripping.

(a) With a long lever arm, a greater force can be produced with a smaller force across the pivot. (b) When a high torque during counterclockwise rotation force is required to remove a jammed locking screw, a straight handle is relatively thin for a full grip compared to the T-handle, and the axis of the straight-handle driver may not be aligned with the axis of the screw. This may cause the driver tip to deviate inside the screw socket. When the driver shaft is long, it can work as a long lever arm to create a greater force at the driver tip to ream and strip the socket. (c, d) The hex key wrench and T-handle driver can transfer the counterclockwise rotation force to the screw with less deviation of the axis of the driver tip from the axis of the screw, which can maximize the contact area between the driver tip and the screw socket to prevent screw stripping.

However, for convenience during screw insertion, most manufacturers provide a straight-handle driver; moreover, the 2.5-mm straight-handle screwdriver (Depuy Synthes) is commonly provided by the scrub nurse to remove 3.5-mm titanium locking screws (Depuy Synthes). The diameter, length, and design of the 2.5-mm hexagonal driver tip can differ between the products by different manufacturers. Many manufacturers provide a screwdriver shaft that can be connected to the power tool for power insertion of the screws. This screwdriver shaft can be connected to the T-handle. We recommend that surgeons source the largest available 2.5-mm driver tip with sharp edges by testing the engagement of the driver tip in the screw socket, checking how firmly it can hold the screw, and reserving it for screw removal. In some situations, surgeons may have to change their position to use their dominant hand for screw removal. But some may prefer to use their non-dominant hand rather than change their position to use the dominant hand. Because one inadvertent missed turn of the screwdriver with the non-dominant hand can ream the socket, leading to screw stripping, we recommend that surgeons use their dominant hand for screw removal on all occasions13.

This study has some limitations. First, the clinical setting in real patients is different from that in the sawbone model trial. Therefore, we could only simulate the overtightening of the locking screw head into the plate. Osteointegration of the screw threads with the bone could not be simulated17. Strong cortical bone ingrowth at the terminal flutes of the screw can cause screw stripping; however, this situation could not be simulated with sawbone models27. Second, the amount of torque that leads to screw stripping can be different in different cases. However, for the experimental study, we overtightened all locking screws by applying a 4.5-Nm torque. The results may be different, with different torques applied to overtighten the screw. Third, although the interposition of the foil or parts of the latex glove did not significantly decrease the incidence of screw stripping in the current study, it may potentially be effective with different torques applied on the screws. However, we believe that the interposition of the material can impede the engagement of the driver tip into the screw socket to its full depth, which can lead to a decrease in the contact area (Fig. 6).

Fourth, we tested only the 3.5-mm titanium locking screws, which are the most widely used screws, from one manufacturer. These results may not apply to other screws made by different manufacturers. Moreover, we used new screwdrivers for the current experiment. In the clinical setting, used screwdrivers may have blunt or rounded edges of the hexagonal driver tip resulting in different outcomes. Finally, we acknowledge that without the clinical application and the outcomes, it cannot be concluded that the T-handle driver with a relatively larger 2.5-mm driver tip or the hex key wrench will decrease the incidence of screw stripping. We are now prospectively collecting the clinical results of using the T-handle driver (Acumed) to remove3.5-mm titanium locking screws (Depuy Synthes). There are several screw removal devices that are designed to remove stripped screws5,15,22. We suggest that manufacturers should provide a screwdriver specialized for screw removal to prevent screw stripping. This should be equipped with a T-handle and a larger dimension of driver tip, such as 2.6 mm, that can be in complete contact and engagement with the screw socket.

Conclusion

There have been several reports about the difficulties in removing 3.5-mm titanium locking screws from the locking plate due to the stripping of the hexagonal screw socket. However, there is a lack of research on methods to prevent screw stripping during screw removal. We hypothesized that screw stripping can be prevented by using different screwdrivers or interposing materials into the socket during removal. We performed an experimental study on swabone tibia models, and tested the incidence rate of screw stripping using a straight-handle screwdriver, T-handle screwdriver, hex key wrench, non-dominant hand, foil interposition, and latex glove interposition. In the current experimental study;

-

The use of a T-handle screwdriver reduced the incidence of screw stripping by 4.50 times compared to the use of a straight-handle screwdriver.

-

The use of a hex key wrench decreased the incidence of screw stripping by 5.57 times compared to the use of a straight handle screwdriver;

-

The interposition of foil or parts of the latex glove into the screw socket did not decrease the incidence of screw stripping.

A future study on the surface morphology of stripped screws using emission scanning electron microscopy may enable a more accurate analysis of the effects of different screwdrivers on screw stripping. Furthermore, clinical application results are required to confirm the above findings.

Data availability

The datasets used and analyzed during the current study are presented in Table 1.

References

Xue, Z., Xu, H., Ding, H., Qin, H. & An, Z. Comparison of the effect on bone healing process of different implants used in minimally invasive plate osteosynthesis: Limited contact dynamic compression plate versus locking compression plate. Sci. Rep. 6, 37902. https://doi.org/10.1038/srep37902 (2016).

Feng, X. et al. Lateral migration resistance of screw is essential in evaluating bone screw stability of plate fixation. Sci. Rep. 11, 12510. https://doi.org/10.1038/s41598-021-91952-3 (2021).

Neumann, H. et al. Complications during removal of conventional versus locked compression plates: Is there a difference?. Int Orthop. 41, 1513–1519. https://doi.org/10.1007/s00264-016-3352-7 (2017).

Lin, C. H., Chao, C. K., Tang, Y. H. & Lin, J. Improving socket design to prevent difficult removal of locking screws. Injury 49, 585–592. https://doi.org/10.1016/j.injury.2018.01.036 (2018).

Bae, J. H., Oh, J. K., Oh, C. W. & Hur, C. R. Technical difficulties of removal of locking screw after locking compression plating. Arch. Orthop. Trauma Surg. 129, 91–95. https://doi.org/10.1007/s00402-008-0769-5 (2009).

Kim, S. J. & Kim, M. U. A simple technique for removing a locking compression plate with a stripped locking screw. J. Orthop. Trauma. 26, e51–e53. https://doi.org/10.1097/BOT.0b013e318220ac51 (2012).

Ehlinger, M., Adam, P., Simon, P. & Bonnomet, F. Technical difficulties in hardware removal in titanium compression plates with locking screws. Orthop. Traumatol. Surg. Res. 95, 373–376. https://doi.org/10.1016/j.otsr.2009.03.020 (2009).

Reynolds, K. J., Mohtar, A. A., Cleek, T. M., Ryan, M. K. & Hearn, T. C. Automated bone screw tightening to adaptive levels of stripping torque. J. Orthop. Trauma. 31, 321–325. https://doi.org/10.1097/BOT.0000000000000824 (2017).

Kumar, G. & Dunlop, C. Case report: A technique to remove a jammed locking screw from a locking plate. Clin Orthop Relat Res. 469, 613–616. https://doi.org/10.1007/s11999-010-1508-0 (2011).

Cronin, P. K., Watkins, I. T., Riedel, M., Kaiser, P. B. & Kwon, J. Y. Implant removal matrix for the upper extremity orthopedic surgeon. Arch. Bone Jt. Surg. 8, 99–111. https://doi.org/10.22038/abjs.2019.36525.1962 (2020).

Kaiser, P. B. et al. Implant removal matrix for the foot and ankle orthopaedic surgeon. Foot Ankle Spec. 12, 79–97. https://doi.org/10.1177/1938640018791015 (2019).

Marmor, M., Mirick, G. & Matityahu, A. Screw stripping after repeated cortical screw insertion-can we trust the cancellous “bailout” screw?. J Orthop Trauma. 30, 682–686. https://doi.org/10.1097/BOT.0000000000000685 (2016).

Behring, J. K., Gjerdet, N. R. & Mølster, A. Slippage between screwdriver and bone screw. Clin Orthop Relat Res. 404, 368–372. https://doi.org/10.1097/00003086-200211000-00054 (2002).

Singh, H., Sharma, R., Gupta, S., Singh, N. & Singh, S. Easy and inexpensive technique for removal of round headed, jammed locking screws in distal tibial interlocking plate. J. Orthop. Case Rep. 5, 35–37. https://doi.org/10.13107/jocr.2250-0685.302 (2015).

Kumar, A., Saini, M., Jameel, J. & Khan, R. “Turn the tail, not the head”: A simple, quick and inexpensive technique for the safe removal of jammed/stripped locking screws. Eur. J. Orthop. Surg. Traumatol. 30, 1119–1123. https://doi.org/10.1007/s00590-020-02667-6 (2020).

Musters, G. D., van Hensbroek, P. B., Ponsen, K. J., Luitse, J. S. & Goslings, J. C. Locking Compression Plates are more difficult to remove than conventional non-locking plates. Eur. J. Trauma Emerg. Surg. 39, 159–162. https://doi.org/10.1007/s00068-012-0245-3 (2013).

Iwata, T., Nozawa, S., Maeda, M. & Akiyama, H. New technique for removal of screws with damaged heads. Orthopedics 40, e911–e914. https://doi.org/10.3928/01477447-20170602-01 (2017).

Gupta, R., Singh, H., Singh, A. & Garg, S. Hollow mill for extraction of stripped titanium screws: An easy, quick, and safe technique. J. Surg. Tech. Case Rep. 6, 9–11. https://doi.org/10.4103/2006-8808.135135 (2014).

Franklin, M. D., Gandham, S. & Boyce, C. N. Stripped screwhead removal—a simple glove technique. Ann. R. Coll. Surg. Engl. 101, 227. https://doi.org/10.1308/rcsann.2018.0208 (2019).

Pattison, G., Reynolds, J. & Hardy, J. Salvaging a stripped drive connection when removing screws. Injury 30, 74–75. https://doi.org/10.1016/s0020-1383(98)00207-1 (1999).

Bhutta, M. A., Dunkow, P. D. & Lovell, M. E. A simple technique for removal of screws with damaged heads. Ann. R. Coll. Surg. Engl. 85, 207. https://doi.org/10.1308/003588403321661442 (2003).

Georgiadis, G. M., Gove, N. K., Smith, A. D. & Rodway, I. P. Removal of the less invasive stabilization system. J. Orthop. Trauma 18, 562–564. https://doi.org/10.1097/00005131-200409000-00014 (2004).

Pearce, A. I. et al. Effect of surface topography on removal of cortical bone screws in a novel sheep model. J. Orthop. Res. 26, 1377–1383. https://doi.org/10.1002/jor.20665 (2008).

Kang, H. Sample size determination and power analysis using the G*Power software. J. Educ. Eval. Health Prof. 18, 17. https://doi.org/10.3352/jeehp.2021.18.17 (2021).

Umer, M., Abbas, K., Khan, S. & Rashid, H. U. Locking compression plate in musculoskeletal oncology “a friend in need”. Clin. Orthop. Surg. 5, 321–326. https://doi.org/10.4055/cios.2013.5.4.321 (2013).

Moroni, A., Faldini, C., Rocca, M., Stea, S. & Giannini, S. Improvement of the bone-screw interface strength with hydroxyapatite-coated and titanium-coated AO/ASIF cortical screws. J. Orthop. Trauma 16, 257–263. https://doi.org/10.1097/00005131-200204000-00007 (2002).

Dougherty, P. J., Kim, D. G., Meisterling, S., Wybo, C. & Yeni, Y. Biomechanical comparison of bicortical versus unicortical screw placement of proximal tibia locking plates: A cadaveric model. J. Orthop. Trauma 22, 399–403. https://doi.org/10.1097/BOT.0b013e318178417e (2008).

Acknowledgements

This work was supported by the Hallym University Research Fund (HURF-2020-47).

Author information

Authors and Affiliations

Contributions

All authors contributed to the conception of the study. H.N.K. performed the experiment. H.J.L. and H.N.K. wrote the manuscript (original draft). Y.U.P. and S.J.K. reviewed the manuscript (review & editing).

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lee, HJ., Park, Y.U., Kim, S.J. et al. Screw stripping and its prevention in the hexagonal socket of 3.5-mm titanium locking screws. Sci Rep 11, 21324 (2021). https://doi.org/10.1038/s41598-021-00720-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-021-00720-w

- Springer Nature Limited