Abstract

Bathocuproine (BCP) is a well-studied cathode interlayer in organic photovoltaic (OPV) devices, where it for standard device configurations has demonstrated improved electron extraction as well as exciton blocking properties, leading to high device efficiencies. For inverted devices, however, BCP interlayers has shown to lead to device failure, mainly due to the clustering of BCP molecules on indium tin oxide (ITO) surfaces, which is a significant problem during scale-up of the OPV devices. In this work, we introduce C70 doped BCP thin films as cathode interlayers in inverted OPV devices. We demonstrate that the interlayer forms smooth films on ITO surfaces, resulting from the introduction of C70 molecules into the BCP film, and that these films possess both improved electron extraction as well exciton blocking properties, as evidenced by electron-only devices and photoluminescence studies, respectively. Importantly, the improved cathode interlayers leads to well-functioning large area (100 mm2) devices, showing a device yield of 100%. This is in strong contrast to inverted devices based on pure BCP layers. These results are founded by the effective suppression of BCP clustering from C70, along with the electron transport and exciton blocking properties of the two materials, which thus presents a route for its integration as an interlayer material towards up-scaled inverted OPV devices.

Similar content being viewed by others

Introduction

Organic photovoltaic (OPV) devices based on small molecules and polymers have attracted a great interest in recent decades due to their appealing properties being eco-friendly, potentially low-cost, lightweight, mechanically flexible and semi-transparent1,2,3,4. Within vacuum processed OPV, several research and development efforts have been conducted over the years, and the commercial potential of the technology is also demonstrated by e.g. the company Heliatek, showing that mass production of the technology from roll-to-roll technology is a viable route for commercialization5,6,7. Owing to the fast progressing research in the OPV field in general, the power conversion efficiency (PCE) of single-junction OPVs has today reached 14.9%8,9, while the PCE of tandem OPV cells has crossed over 17%10, employing typically used bulk-heterojunctions as the active layers. While bilayer devices have show less progress, they potentially offer a route for minimizing charge recombination effects due to the separated electron and hole charge transport pathways. L. Calio et al. recently reported the PCE of 5.66% for vacuum deposited bilayer OPVs based on tetraphenyldibenzoperiflanthen (DBP) donor and Fullerene (C70) acceptor incorporating efficient exciton blocking layers11.

Fullerenes and their derivatives are still widely used as electron acceptors in OPV devices due to their high electron mobility as well as electron affinity, which promotes efficient charge separation at the organic electron donor/acceptor (D/A) interface, when used in combination with a suitable donor such as DBP investigated in this work12,13,14,15,16. In order to efficiently extract electrons out from the electron acceptor, and minimize losses at the cathode interface, a layer that acts both as exciton blocking (EBL) and electron transporting (ETL) is needed in between the cathode and electron acceptor layer17,18. Such combined EBLs and ETLs blocks photo-generated excitons from quenching at the cathode electrode, while extracting electrons (and not holes) efficiently out from the acceptor, through an ideally zero energy barrier at that interface19. Potentially, such layers also provide a transparent spacer to optimize the optical field distribution within the active layer, and thus enhance the OPV performance even further20,21,22. Peumans et al.23 introduced for the first time a BCP (2,9-dimethyl-4,7-diphenyl-1,10-phenanthroline) layer as a combined EBL and ETL in between the electron acceptor and cathode in bilayer, standard configuration OPV cells based on CuPc and fullerene, C60.

Bathocuproine (BCP) is widely used as ETL and EBL material in OPVs. BCP has a highest occupied molecular orbital (HOMO) level at 7.0 eV and lowest unoccupied molecular orbital (LUMO) at 3.5 eV24,25. Despite the relatively high lying LUMO level, BCP efficiently transports electrons from the acceptor to the cathode due to the formation of a BCP-metal complex, formed when the metal cathode is evaporated on top of the BCP layer26. Additionally, BCP works as an EBL and electron selective contact due to its relatively low lying HOMO level of 7.0 eV compared to the HOMO level of e.g. C70 at 6.1 eV27. The exciton blocking properties of BCP results in a higher charge generation yield at the D-A interface, which again leads to enhanced device performance through enhanced short-circuit current densities28,29,30. Work reported by Gommans et al. has documented that BCP also can act as an optical spacer layer, to best exploit optical interference effects in OPV cells31.

Several studies have focused on the function of BCP as ETL and EBL in OPV devices with standard device architecture24,31,32, highlighting the aforementioned properies. In our previous study, an area-dependent behavior of BCP used as ETL and EBL in inverted OPV devices was reported33. It was observed that while scaling up the OPV device area, the performance and device yield of the inverted OPV devices decrease significantly compared to standard configuration cells, which was demonstrated to be due to the clustering of BCP on ITO surfaces33,34. While BCP on small device areas works well as both EBL and ETL, the probability of BCP clusters penetrating the active layer (approx. 50 nm thick in that study) increases for increased device area. This potentially results in electrical shunting of the inverted OPV devices, which dramatically decrease the device yield for up-scaled cells. In recent work, this has also been demonstrated to lead to faster degradation of inverted OPV devices based on pure BCP ETL and EBL layers35. The integration of Ag doped BCP layers in inverted OPVs as buffer layers has previously been reported on36,37. However, although these layers provide improved electrical properties, Ag doped BCP may lead to unwanted exciton quenching processes in the fullerene acceptor layer and thus deteriorate the device performance37. Such quenching processes between metals and adsorbed molecules are well-know38.

Incorporation of interlayers or buffer layers fabricated from a blend of two or more organic materials is a common practice in OPV devices. The blended layers potentially improve the device performance by enhancing the electrical properties at the respective interface (interlayers), and/or the optical properties of the devices (interlayers or buffer layers)17,39,40. Bartynski et al. used a blend of C60 and BCP layer as ETL and EBL in standard OPV devices that improved the electron conductivity, while efficiently blocking excitons and reducing exciton-polaron recombination27. Furthermore, Xiao et al. reported that a blend of BPhen:C60 increases the electron conductivity and, as well, decreases exciton recombination effects in the devices41. Liu et al. used a BCP:C60 layer as EBL and ETL in standard configuration OPV devices to optimize the optical properties of the devices, and also the device lifetime42. However, compared to C60, C70 offers higher stability upon air exposure43, and also a higher conductivity43, which may be beneficial when used as an interlayer material in organic photovoltaic devices.

In this work, we studied bathocuproine:fullerene (BCP:C70) acting as ELB and ETL functional blends in inverted architecture OPV devices, as sketched in Fig. 1a. The optimization of the BCP:C70 ratio as well as the thickness of the blend layer was investigated. The optimized BCP:C70 layers were employed in inverted OPV devices having active areas of up to 100 mm2, and the results were compared against inverted OPVs based on pure BCP layers. The investigation shows that the BCP:C70 blends suppress the clustering of BCP on top of ITO surfaces, leading to a significantly improved device performance and especially device yield for up-scaled inverted OPV devices.

Results and Discussion

Figure 1 shows the inverted bilayer OPV device architecture studied in this work, having BCP:C70 as ETL and EBL, as well as a schematic energy diagram of the device stack made from literature reported energy level values. DBP possesses a high optical absorption strength in the visible wavelength regime and a HOMO level at 5.5 eV44, making it a good match to fullerene acceptors such as C60 and C7011.

Figure 2a shows an atomic force microscopy (AFM) image of 3 nm pure BCP deposited on top of an ITO coated glass substrate. The clustering of BCP occurs due to a large interface energy between ITO and BCP33, and may take place immediately after BCP deposition even at room temperature34. Such clustering can be explained by Ostwald ripening, in which some aggregates grow at the expense of others by adsorbing molecules from the surrounding surface area45. At larger surface area, the probability of forming clusters that cause device shunts are larger33, making device upscaling more challenging in inverted OPV architectures. One possible solution to overcome BCP aggregation is to conduct co-evaporation with another organic small molecule in order to obtain smoother films34. As shown in Fig. 2b, doping C70 molecules into the BCP film via co-evaporation is effective in preventing the aggregation of BCP molecules, resulting in a nano-grained surface on ITO.

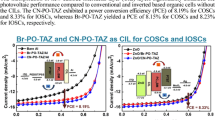

As reported in our previous work, the optimized BCP ETL thickness for small area inverted DBP/C70 based bilayer OPV devices is 1.5 nm33, which was therefore chosen as initial ETL thickness in this work. Optimization results from 2 mm2 inverted OPV cells with various ratios of the BCP:C70 ETL and EBL are listed in Table S1, showing that devices with 2:1 ratio show slightly higher Fill Factor (FF) with an average value of 55%, Voc with an average value of 0.82 V, as well as PCE reaching an average value of 2.28%. Even though the 2:1 blend films lead to reasonable device performance, an improvement in the short-circuit current density is not seen, compared to reference cells, which is otherwise expected from the exciton blocking properties of the interlayer. This could be due to the relatively low thickness (1.5 nm) of the blend layer.

As a next step, we turned our attention to optimizing the thickness of the ETL and EBL blend layer in 2 mm2 OPV devices. The JV characteristics and performance parameters of the OPV devices are shown in Fig. 3 and in Table 1, respectively. A summary of the performance parameters from Table 1 is plotted in Fig. 4. As shown in Fig. 4b, as the thickness of the BCP:C70 layer increases from 1.5 nm to 3 nm, the JSC also increases, which can be well explained by the exciton blocking properties of BCP46. When increasing the thickness of the BCP:C70 layer above 5 nm, the device performance parameters decrease, and the JV curves show clear s-shape characteristics (Fig. 3). The S-shape could be attributed to charge accumulation close to the active layer and ETL interface42,47,48. Charge accumulation close to the thicker ETL and EBL films could take place due to the non-ideal energy level alignment between C70 and BCP, although further studies are required to understand that interface in detail. Electron-polaron accumulation at the electron acceptor and blocking interface may lead to exciton-polaron recombination effects20,31, a well-known cause for performance drops in OPV devices49.

In order to further elaborate on the electron transport properties of the 3 nm BCP:C70 blend ETL and EBL layer, electron-only devices (EODs) were fabricated. The structure of the EODs is shown in Fig. 5b, where 0 and 3 nm of BCP:C70 (2:1) blends were investigated. In the EODs, electrons were injected into the devices through the Ag electrode and extracted out at the ITO electrode. The JV characteristics of the EODs with 3 nm BCP:C70 ETL show an improvement in the electron extraction properties at the ITO electrode, compared to EODs without the combined ETL and EBL layer (Fig. 5a). Such improvements has also recently been demonstrated for pure, ultrathin BCP layers in small area inverted OPV devices33. To this point, the exact energy level alignment scheme across the ITO/BCP:C70 interface needs to be examined in detail to point on the origin of the improved electron extraction properties. This highlights the importance of future photoelectron measurements to elucidate the detailed interfacial electronic structure and energetic alignment across the interface.

Photoluminescence (PL) intensity measurement was performed in order to elucidate the exciton blocking properties of the BCP:C70 blend layers. In Fig. 6a, PL spectra of the pristine C70 layer on ITO shows two peaks, a distinct narrow peak at around 690 nm followed by a broader peak at higher wavelengths, corresponding to characteristic electronic and vibrational modes for polycrystalline C70, as previously reported50. The PL spectra show significant increase in PL intensity from C70 when deposited on top of the 3 nm BCP:C70 layer, compared to reference stacks based on pure C70 layers. The increase in the PL intensity is attributed to the enhanced exciton blocking properties of the BCP:C70 blend layers, and thus minimum quenching at the ITO/C70 interface44. The change in the relative intensity between the two peaks in the PL spectra can be explained by reduced quenching of specific vibronic transitions, upon insertion of the new ETL.

The reduced symmetry of the C70 results in more allowed optical transitions and therefore significantly stronger absorption in the visible region compared to symmetrical C6046. However, for the investigated ETLs, we have used ultra-thin interlayers of BCP:C70 (only 3 nm at 2:1 ratio i.e. ~1 nm of C70). Hence, the impact of light absorption due to either C60 or C70 should be negligible in this case. This can be seen in Fig. 6b, where the transmittance spectra of the pure BCP as well as the C70 doped BCP:C70 (2:1) layer on ITO-coated glass are shown. Clearly 3 nm of BCP or BCP:C70 (2:1) show almost no change in optical transmittance, and thus negligible absorption when inserted as an ETL in the inverted device configuration used here. The blended ETL consists of a mixture of C70, which efficiently conducts electrons, and the wide energy gap bathocuproine (BCP) that blocks excitons, as demonstrated by our electron only devices and the photoluminescence results. This ETL therefore appears to separate excitons and electrons at the blocking interface as an effective filter, blocking excitons from quenching at the cathode, while promoting electron extraction through the same interlayer in the devices.

As demonstrated from Fig. 2, the BCP:C70 blend layer possesses a smooth surface without BCP aggregation, which otherwise is a main problem in employing BCP in large area inverted devices, due to device shunting33. As a final investigation, the optimized BCP:C70 blend layers were thus employed in cells with up-scaled device areas of 100 mm2, see Fig. 7. As a general observation, a reduced of JSC, FF (Table 2) and hence PCE were observed when increasing the active area from 2mm2 to 100mm2, which in part can be understood from the increased ITO resistance for up-scaled areas14,33,51. Devices with 3 nm BCP:C70(2:1) show VOC and JSC of 0.85 V and 4.9 mA/cm2, respectively, but low FF values of 44% (Table 2). This reduction in FF may be attributed to surface defects of the BCP:C70 layer, which may arise due to thickness variations in the very thin ETL and EBL layer. Increasing the BCP:C70 thickness leads to an enhancement of the FF, and devices with 5 nm BCP:C70(2:1) ETL and EBL show the highest Fill Factor (FF) values of 51%, and power conversion efficiencies (PCE) of 2.04% (Table 2). The performance of the OPV devices reduces significantly when the thickness of the BCP:C70 is increased to 10 nm. This can be explained by the increased series resistance and exciton-polaron recombination20,31 taking place at the acceptor and blocking layer interface. Initial aggregation could potentially also promote further recombination effects.

For the large area inverted OPV devices with the BCP:C70(2:1) layers, the device yield was at 100%, even for OPV devices with incorporated blends of up to 10 nm in thickness. This is notable when compared to inverted OPV devices based on pure BCP as ETL and EBL, where very low device yields for 100 mm2 cells are observed, mainly due to BCP clustering33. Doping of BCP with C70 thus suppresses the clustering of the BCP molecules, resulting in smoother BCP:C70 ETL and EBL on ITO surfaces, giving rise to 100% device yields even for large area devices.

Conclusion

In this work, development of inverted organic solar cells using mixed bathocuproine:fullerene (BCP:C70) electron transport and exciton blocking layers has been demonstrated. Incorporation of C70 molecules into the BCP layer suppresses clustering of the BCP molecules, resulting in smooth layers on ITO surfaces, a prerequisite for using them as efficient ETL and EBL in inverted OPV device configurations. While electron-only devices demonstrate improved electron extraction in the cells, photoluminescence studies reveals strong exciton blocking properties of the interface layer. Combining these material properties leads to well performing bilayer C70/DBP based inverted devices, reaching power conversion efficiencies up to 3.28%. While BCP clustering is know to be a severe problem for large area OPV cells, leading to significant reduction in device efficiency and device yield, the novel interlayer leads to well-functioning large area cells (100 mm2), reaching an impressive device yield of 100%. This work thus demonstrates a viable route for the use of the well-known interlayer material bathocuproine (BCP) in inverted OPV devices.

Methods

Materials and Device Fabrication

Pre-patterned ITO coated glass substrates (Kintec Company, Hong Kong) were used for 2 and 100 mm2 cell area OPV devices. The sheet resistance of ITO was approximately 15Ω/sq. The substrates were cleaned sequentially in an ultrasonic water bath with detergent, deionized water, Acetone and IPA (10 min for each) then blow dried with a nitrogen gun.

In the first step, OPV devices were fabricated on the cleaned ITO substrates with 2mm2 cell areas. The BCP:C70 (Sigma-Aldrich, Germany) blend layers with 1.5 nm thickness and different ratio (1:1, 2:1 and 4:1) were grown by co-evaporation, simultaneously depositing from two sublimation sources at a base pressure of 3 × 10−8 mbar. This was followed by 30 nm C70 at a growth rate of 0.2 Å/s and 20 nm DBP (Luminescence Technology Corp., Taiwan) deposited at 0.3 Å/s without breaking vacuum in between the steps. Then, 10 nm of molybdenum oxide (MoO3) (Sigma-Aldrich, Germany) and 100 nm of Silver (Ag) (AESpump ApS, Denmark) were deposited by thermal evaporation at a base pressure of 5 × 10−7 mbar. The deposition rates for the MoO3 and Ag were 0.3 Å/s and 0.5 Å/s, respectively.

In the second step, 2 mm2 OPV devices were fabricated using optimized BCP:C70 ratio (2:1) with different thickness (1.5, 3, 5 and 10 nm). The deposition rates for the BCP and C70 were 0.2 Å/s and 0.1 Å/s, respectively. Finally, optimized BCP:C70 blend layers were used for fabrication of the up-scale OPVs devices (100 mm2 cell area). All deposition parameters of the other layers were kept the same as in the first step. Electron-only devices (EODs), having the structure shown in Fig. 5b, were fabricated by sandwiching the BCP:C70 mixed layers between the respective contact bottom ITO and top C70 (100 nm)/BCP(10 nm)/Ag(100 nm) layers, using the same deposition rates as for OPV device fabrication.

Device Characterization

All characterizations were performed in an ambient environment. The current density-voltage (J-V) characteristics of the OPV devices were measured using a 2400 source measure unit (Keithley Instruments Inc., USA) and a class AAA solar simulator (Sun 3000, Abet Technologies Inc., USA). The J-V characteristics were measured by applying a voltage sweep from +1 to −0.5 V under a calibrated lamp intensity of 100 mW/cm2. Atomic force microscopy (AFM) images were taken using a Veeco Dimension 3100 scanning probe microscope. JV characteristics of the EODs were measured by applying a sweeping voltage from +1 to −1 V using a Keithley 2400 source measure unit (Keithley Instruments Inc., USA). For Photoluminescence (PL) intensity measurements of the ITO/C70(100 nm) and ITO/BCP:C70(3 nm)/C70(100 nm) structures, a microscope objective (Nikon E Plan 50 × 0.75 EPL) with a fluorescence microscope (Nikon Eclipse ME600) connected to a Maya2000Pro Spectrometer (from Ocean optics) was used to record the spectra. A mercury short arc lamp having a filtered excitation wavelength centered between 330–380 nm was used as excitation light source. Transmittance spectra were obtained from a Shimadzu 2700 spectrophotometer.

References

Yin, Z., Wei, J. & Zheng, Q. Interfacial Materials for Organic Solar Cells: Recent Advances and Perspectives. Advanced Science 3, 1500362 (2016).

Zheng, Y. & Xue, J. Organic Photovoltaic Cells Based on Molecular Donor-Acceptor Heterojunctions. Polymer Reviews 50, 420–453 (2010).

Lin, Y., Li, Y. & Zhan, X. Small molecule semiconductors for high-efficiency organic photovoltaics. Chemical Society Reviews 41, 4245–4272 (2012).

Torabi, N. et al. Progress and challenges in perovskite photovoltaics from single- to multi-junction cells. Materials Today Energy 12, 70–94 (2019).

Meiss, J. et al. Highly efficient semitransparent tandem organic solar cells with complementary absorber materials. Applied Physics Letters 99, 043301 (2011).

Meiss, J. et al. Efficient semitransparent small-molecule organic solar cells. Applied Physics Letters 95, 213306 (2009).

Jacoby, M. The future of low-cost solar cells. Chem. Eng. News 94, 30–35 (2016).

Zheng, Z. et al. A Highly Efficient Non-Fullerene Organic Solar Cell with a Fill Factor over 0.80 Enabled by a Fine-Tuned Hole-Transporting Layer. Advanced Materials 30, 1801801 (2018).

Yuan, J. et al. Single-Junction Organic Solar Cell with over 15% Efficiency Using Fused-Ring Acceptor with Electron-Deficient Core. Joule (2019).

Meng, L. et al. Organic and solution-processed tandem solar cells with 17.3% efficiency. Science 361, 1094–1098 (2018).

Caliò, L. et al. Benzothiadiazole–triphenylamine as an efficient exciton blocking layer in small molecule based organic solar cells. Sustainable Energy & Fuels 2, 2296–2302 (2018).

Ahmadpour, M., Liu, Y., Rubahn, H. & Madsen, M. Current Matching in Multifold DBP/C70 Organic Solar Cells With Open-Circuit Voltages of up to 6.44 V. IEEE Journal of Photovoltaics 7, 1319–1323 (2017).

Wang, Z., Sano, T., Zhuang, T., Sasabe, H. & Kido, J. DBP and C70 based inverted tandem solar cells using a simple interconnecting layer. RSC Advances 7, 34664–34668 (2017).

Mishra, A. & Bäuerle, P. Small Molecule Organic Semiconductors on the Move: Promises for Future Solar Energy Technology. Angewandte Chemie International Edition 51, 2020–2067 (2012).

Zheng, Y.-Q. et al. Highly efficient bulk heterojunction photovoltaic cells based on C70 and tetraphenyldibenzoperiflanthene. Applied Physics Letters 102, 143304 (2013).

Xiao, X., Lee, K. & Forrest, S. R. Scalability of multi-junction organic solar cells for large area organic solar modules. Applied Physics Letters 106, 213301 (2015).

Bergemann, K. J., Amonoo, J. A., Song, B., Green, P. F. & Forrest, S. R. Surprisingly High Conductivity and Efficient Exciton Blocking in Fullerene/Wide-Energy-Gap Small Molecule Mixtures. Nano Letters 15, 3994–3999 (2015).

Yip, H.-L. & Jen, A. K.-Y. Recent advances in solution-processed interfacial materials for efficient and stable polymer solar cells. Energy & Environmental Science 5, 5994–6011 (2012).

Liu, Y., Duzhko, V. V., Page, Z. A., Emrick, T. & Russell, T. P. Conjugated Polymer Zwitterions: Efficient Interlayer Materials in Organic Electronics. Accounts of Chemical Research 49, 2478–2488 (2016).

Jin, F. et al. Improvement in power conversion efficiency and long-term lifetime of organic photovoltaic cells by using bathophenanthroline/molybdenum oxide as compound cathode buffer layer. Solar Energy Materials and Solar Cells 117, 189–193 (2013).

Hirade, M. & Adachi, C. Small molecular organic photovoltaic cells with exciton blocking layer at anode interface for improved device performance. Applied Physics Letters 99, 153302 (2011).

Li, G., Zhu, R. & Yang, Y. Polymer solar cells. Nature Photonics 6, 153 (2012).

Peumans, P., Bulović, V. & Forrest, S. R. Efficient photon harvesting at high optical intensities in ultrathin organic double-heterostructure photovoltaic diodes. Applied Physics Letters 76, 2650–2652 (2000).

Huang, J., Yu, J., Lin, H. & Jiang, Y. Detailed analysis of bathocuproine layer for organic solar cells based on copper phthalocyanine and C60. Journal of Applied Physics 105, 073105 (2009).

Peumans, P. & Forrest, S. R. Very-high-efficiency double-heterostructure copper phthalocyanine/C60 photovoltaic cells. Applied Physics Letters 79, 126–128 (2001).

Tong, X., Lassiter, B. E. & Forrest, S. R. Inverted organic photovoltaic cells with high open-circuit voltage. Organic Electronics 11, 705–709 (2010).

Bartynski, A. N. et al. A Fullerene-Based Organic Exciton Blocking Layer with High Electron Conductivity. Nano Letters 13, 3315–3320 (2013).

Vogel, M., Doka, S., Breyer, C., Lux-Steiner, M. C. & Fostiropoulos, K. On the function of a bathocuproine buffer layer in organic photovoltaic cells. Applied Physics Letters 89, 163501 (2006).

Verreet, B. et al. Improved cathode buffer layer to decrease exciton recombination in organic planar heterojunction solar cells. Applied Physics Letters 102, 043301 (2013).

Stenta, C. et al. Solution Processed Bathocuproine for Organic Solar Cells. IEEE Transactions on Nanotechnology 17, 128–132 (2018).

Gommans, H. et al. On the Role of Bathocuproine in Organic Photovoltaic Cells. Advanced Functional Materials 18, 3686–3691 (2008).

Yoshida, H. Electron Transport in Bathocuproine Interlayer in Organic Semiconductor Devices. The Journal of Physical Chemistry C 119, 24459–24464 (2015).

Patil, B. R. et al. Area dependent behavior of bathocuproine (BCP) as cathode interfacial layers in organic photovoltaic cells. Scientific Reports 8, 12608 (2018).

Mori, T. & Masumoto, Y. Effect of Organic Alloy for Suppression of Polycrystallization in BCP Thin Film. Journal of Photopolymer Science and Technology 19, 209–214 (2006).

Sherafatipour, G. et al. Madsen Degradation pathways in standard and inverted DBP-C70 based organic solar cells. Scientific Reports 9, 4024 (2019).

Hao, X. et al. Novel cathode buffer layer of Ag-doped bathocuproine for small molecule organic solar cell with inverted structure. Organic Electronics 15, 1773–1779 (2014).

Wang, S., Sakurai, T., Komatsu, K. & Akimoto, K. Effect of Ag-doped bathocuproine on the recombination properties of exciton in fullerene. Journal of Crystal Growth 378, 415–417 (2013).

Avouris, P. & Persson, B. N. J. Excited states at metal surfaces and their non-radiative relaxation. The Journal of Physical Chemistry 88, 837–848 (1984).

Luo, D. Y. et al. A bi-functional structure with tunable electrical and optical properties for organic photovoltaic cells. Journal of Applied Physics 113, 224506 (2013).

Menke, S. M., Lindsay, C. D. & Holmes, R. J. Optical spacing effect in organic photovoltaic cells incorporating a dilute acceptor layer. Applied Physics Letters 104, 243302 (2014).

Xiao, X., Bergemann, K. J., Zimmerman, J. D., Lee, K. & Forrest, S. R. Small-Molecule Planar-Mixed Heterojunction Photovoltaic Cells with Fullerene-Based Electron Filtering Buffers. Advanced Energy Materials 4, 1301557 (2014).

Liu, S.-W. et al. Improving Performance and Lifetime of Small-Molecule Organic Photovoltaic Devices by Using Bathocuproine–Fullerene Cathodic Layer. ACS Applied Materials & Interfaces 7, 9262–9273 (2015).

Xi, X. et al. A comparative study on the performances of small molecule organic solar cells based on CuPc/C60 and CuPc/C70. Solar Energy Materials and Solar Cells 94, 2435–2441 (2010).

Patil, B. R., Liu, Y., Qamar, T., Rubahn, H.-G. & Madsen, M. 4P-NPD ultra-thin films as efficient exciton blocking layers in DBP/C 70 based organic solar cells. Journal of Physics D: Applied Physics 50, 385101 (2017).

Conings, B. et al. Modeling the temperature induced degradation kinetics of the short circuit current in organic bulk heterojunction solar cells. Applied Physics Letters 96, 163301 (2010).

Holliday, S., Li, Y. & Luscombe, C. K. Recent advances in high performance donor-acceptor polymers for organic photovoltaics. Progress in Polymer Science 70, 34–51 (2017).

Kumar, A., Sista, S. & Yang, Y. Dipole induced anomalous S-shape I-V curves in polymer solar cells. Journal of Applied Physics 105, 094512 (2009).

Tress, W. et al. Imbalanced mobilities causing S-shaped IV curves in planar heterojunction organic solar cells. Applied Physics Letters 98, 063301 (2011).

Coehoorn, R., Zhang, L., Bobbert, P. A. & van Eersel, H. Effect of polaron diffusion on exciton-polaron quenching in disordered organic semiconductors. Physical Review B 95, 134202 (2017).

Sibley, S. P., Argentine, S. M. & Francis, A. H. A photoluminescence study of C60 and C70. Chemical Physics Letters 188, 187–193 (1992).

Patil, B. R. et al. ITO with embedded silver grids as transparent conductive electrodes for large area organic solar cells. Nanotechnology 28, 405303 (2017).

Acknowledgements

This project has received funding from the European Union Seventh Framework Programme under grant agreement no. 607232 [THINFACE] and the RollFlex project – part-financed by Interreg Deutschland-Danmark with means from the European Regional Development Fund and the Southern Denmark Growth Forum. F.J. and F.M. thank the Iranian Ministry of Science and Technology (Tehran/Iran) for supporting their visit to the SDU NanoSYD, Mads Clausen Institute, University of Southern Denmark.

Author information

Authors and Affiliations

Contributions

F.J., B.R.P. and M.M. conceived the idea and designed the experiments. F.J. and B.R.P. fabricated the inverted configuration organic solar cells. F.J. fabricated the electron-only devices and carried out the photolumiscence tests. The work was carried out under the supervision of A.B. and M.M. All co-authors participated in the exchange and analyses of the results as well as in the editing the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jafari, F., Patil, B.R., Mohtaram, F. et al. Inverted organic solar cells with non-clustering bathocuproine (BCP) cathode interlayers obtained by fullerene doping. Sci Rep 9, 10422 (2019). https://doi.org/10.1038/s41598-019-46854-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-46854-w

- Springer Nature Limited

This article is cited by

-

Steerable fabrication of MoS2 nanoarray through one-step vacuum thermal evaporation technology

Journal of Materials Science (2021)

-

Improved performance in organic solar cells using aluminum-doped cathode-modifying layer

Applied Physics A (2021)