Abstract

We examine the impact of sorbitol admixture to the hole-conduction polymer PEDOT:PSS [poly(3,4-ethylenedioxythiophene):poly(styrene sulfonate)] on the characteristics of PEDOT:PSS/crystalline silicon heterojunction solar cells. We fabricate solar cells where the PEDOT:PSS layer is deposited as a hole-collecting contact at the cell rear, whereas the electron-collecting front is conventionally processed by means of phosphorus diffusion. Surprisingly, we observe that the admixture of the infrared-transparent sorbitol not only improves the short-circuit density of the solar cells due to the reduction of the infrared parasitic absorption, but also improves the passivation quality of PEDOT:PSS on silicon and hence the open-circuit voltage of the solar cells. The series resistance is not influenced by the admixture of sorbitol up to 4.0 wt.% sorbitol admixture in the PEDOT:PSS dispersion, but shows a pronounced increase for larger sorbitol contents. The optimal sorbitol content concerning efficiency is hence 4.0 wt.%, leading to an energy conversion efficiency of 20.4% at one sun, which is more than 1% absolute higher compared to the efficiency of the reference cells without sorbitol.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Introduction

Heterojunction solar cells combining the hole-conducting polymer poly(3,4-ethylenedioxythiophene):poly(styrene sulfonate) [PEDOT:PSS] and c-Si have demonstrated their high-efficiency potential in previous studies1,2,3,4,5,6,7,8,9. In the first fabricated PEDOT:PSS/c-Si solar cells, the organic layer was deposited to the front, leading to relatively low short-circuit current densities Jsc due to the parasitic absorption losses within the PEDOT:PSS. Moving the organic layer to the rear in the so-called ‘BackPEDOT’ cell concept10 resulted in significantly improved Jsc and led for the first time to efficiencies exceeding 20%11,12. Still it turned out that even for the BackPEDOT cell, Jsc is limited by parasitic free-carrier absorption within the PEDOT:PSS layer of infrared photons reaching the cell rear10. In the present study, we examine a promising and easy-to-implement approach to reduce the parasitic absorption in BackPEDOT cells by increasing the transparency of the PEDOT:PSS layer by adding sorbitol to the precursor dispersion. In a previous study13, we showed that sorbitol significantly increases the transparency of the PEDOT:PSS layer in the infrared and thus sorbitol can be used for effectively reducing the parasitic absorption in the PEDOT:PSS layer. Sorbitol is already established as a conductivity additive in PEDOT:PSS14,15. In this work, we fabricate solar cells to examine the impact of the sorbitol admixture on device level. In addition, we also examine the impact on surface passivation on lifetime samples. Our experimental results clearly show that the sorbitol admixture does not only positively affect the Jsc of the cells, but due to an improved surface passivation, shows also a positive impact on the open-circuit voltage Voc. Hence, the addition of sorbitol to the PEDOT:PSS dispersion has multiple advantages for PEDOT:PSS/c-Si heterojunction cells.

Experimental Details

Lifetime sample preparation

In order to assess the passivation quality of the PEDOT:PSS/c-Si interface, contactless lifetime samples are fabricated on 300 µm thick (100)-oriented p-type float-zone silicon (FZ-Si) wafers with a resistivity of 200 Ωcm. After RCA cleaning, one wafer surface is passivated by a 100 nm thick plasma-enhanced-chemical-vapor-deposited (PECVD) SiNx layer (Plasmalab 80 Plus, Oxford) with a refractive index of 2.4 at a deposition temperature of 400 °C. After SiNx deposition, the samples are dipped in 1% hydrofluoric acid (HF) for 60 seconds. The PEDOT:PSS dispersion (Clevios special grade, Clevios Heraeus GmbH), which has a solid content of 2.2 wt.% of PEDOT:PSS in water, was mixed with 1.0 to 18.0 wt.% sorbitol and stirred overnight at room temperature on a magnetic stirrer. Immediately after the HF dip, the PEDOT:PSS dispersion is deposited by spin coating at 500 revolutions per minute (rpm) for 10 seconds and subsequently 1500 rpm for 30 seconds. Subsequently, the PEDOT:PSS layer is annealed in ambient environment at a temperature of 130 °C for 10 min. Injection-dependent measurements of the effective carrier lifetime τeff(Δn) are performed using a Sinton Lifetime Tester (WCT-120, Sinton Instruments). The recombination current density parameter (also sometimes denoted ‘saturation current density’) J0 of each measured sample is extracted from the slope of the inverse lifetime 1/τeff vs. the excess carrier density Δn curve16.

Solar cell fabrication

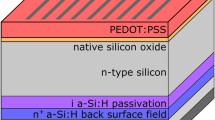

Figure 1 shows the cross-section of a BackPEDOT solar cell. For the solar cell fabrication we use 300 µm thick 6″ (100)-oriented p-type boron-doped FZ-Si wafers with resistivities of 0.5 and 1.3 Ωcm, respectively. After RCA cleaning and protecting both surfaces by a 200 nm thick dielectric SiO2 layer, 2 × 2 cm2 diffusion windows are opened by laser ablation on one wafer surface. After one more RCA cleaning sequence, the silicon surface within the ablated window is random-pyramid-textured using a KOH/isopropanol solution. Subsequently, an n+ emitter with a sheet resistance in the range 92–110 Ω/sq is formed by phosphorus in-diffusion in a quartz-tube furnace (TS 81004, Tempress) at 830 °C in a POCl3/O2 atmosphere. The wafers are then laser-cut into 2.49 × 2.49 cm2 large samples, and after additional cleaning, the phosphorus silicate glass is removed in a 1% HF solution. An 0.24 nm thick AlOx tunneling layer is then deposited by means of plasma-assisted atomic layer deposition (FlexAL, Oxford Instruments) on the front surface. Next, an aluminum grid is deposited on the cell front through a nickel shadow mask by electron beam evaporation (BAK 550, Balzers). The front surface is then coated by a surface-passivating PECVD SiNx layer (Plasmalab 80 Plus, Oxford) with a refractive index of 2.4 (6 nm) and on top of that by a SiNx antireflection coating with a refractive index of 1.9 (75 nm). Subsequently, the cells are annealed for 2 min at 320 °C in order to improve the front surface passivation and for contact formation17. Before depositing the PEDOT:PSS to the cell rear, the dielectric SiO2 protection layer at the rear is removed using 40% HF. The PEDOT:PSS dispersion (Clevios special grade, Clevios Heraeus GmbH), which has a solid content of 2.2 wt.%, was mixed with 1.0 to 7.7 wt.% sorbitol and stirred overnight on a magnetic stirrer. The PEDOT:PSS dispersion is deposited by spin-coating at 500 rpm for 10 seconds and subsequently 12000 rpm for 30 seconds. The coated PEDOT:PSS layer is annealed in ambient environment at 130 °C for 10 min. Finally, the rear surface is full-area metallized by a 1 µm thick silver layer deposited using electron beam evaporation (BAK 550, Balzers).

Results and Discussion

Surface passivation

Figure 2 shows a box plot of the measured recombination current density parameter J0.PEDOT of the PEDOT:PSS/c-Si interface as a function of the sorbitol content added to the PEDOT:PSS precursor dispersion.

Box plot of the recombination current density parameter J0.PEDOT of the PEDOT:PSS/c-Si interface as a function of the sorbitol content of the PEDOT:PSS precursor dispersion. PEDOT:PSS was applied to 9 test samples for each sorbitol concentration. The J0.SiN value of 16 fA/cm2 of the SiNx-passivated silicon surface was subtracted from the measured J0 value to account only for recombination at the PEDOT:PSS/c-Si interface.

Table 1 shows the PEDOT:PSS layer thicknesses of the lifetime samples shown in Fig. 2. The correponding total sheet resistances are also shown in Table 1. The reduction of the sheet resistance by adding more than 1.0 wt.% sorbitol agrees well with the behaviour reported in the literature that sorbitol serves as a conductivity-increasing additive14,15. The PEDOT:PSS layer thicknesses were determined using a profilometer (Dektak 150, Veeco) and the corresponding sheet resistances were measured using a Sinton lifetime tester (WCT-120, Sinton Instruments). J0.PEDOT was extracted from the measured overall J0 values by subtraction of the J0.SiN value of the SiNx-passivated wafer surface. J0.SiN was determined on both-sides-SiNx-passivated wafers with a median value of 16 fA/cm2. For silicon surfaces passivated with PEDOT:PSS without admixture of sorbitol, we measure a median J0.PEDOT value of 86 fA/cm2. We observe that with increasing sorbitol content of the PEDOT:PSS precursor dispersion the measured J0.PEDOT decreases. At a sorbitol concentration of 4.0 wt.% in the precursor dispersion, we measure a median J0.PEDOT value of 64 fA/cm2. At at a sorbitol concentration of 7.7 wt.%, a median J0:PEDOT of only 38 fA/cm2 is achieved, which means that the recombination at the PEDOT:PSS/c-Si interface is more than halved by adding 7.7 wt.% of sorbitol to the precursor solution. At even higher sorbitol concentrations of 11 wt.% and 14 wt.% the J0.PEDOT value rises to a median of 55 fA/cm2 and 58 fA/cm2 respectively. A sorbitol concentration of 18 wt.% provides a J0.PEDOT median of 49 fA/cm2. According to our results a saturation in J0.PEDOT at high sorbitol concentrations can be observed. Nardes et al.18 have shown that the addition of sorbitol reduces the work function of PEDOT:PSS for sorbitol concentration of 5 wt.%, and for higher sorbitol concentrations a saturation in the work function occurs. The positive impact of sorbitol on the electronic passivation properties of PEDOT:PSS on c-Si might be due to a change in the electronic band structure of the organic solution. It is well known from the literature that the addition of sorbitol to the PEDOT:PSS precursor dispersion reduces the work function of the PEDOT:PSS with increasing sorbitol content18,19,20,21. Our results here clearly prove that adding sorbitol to the PEDOT:PSS precursor solution significantly improves the c-Si surface passivation quality.

Solar cells

A total of 42 PEDOT:PSS/c-Si solar cells with an area of 2 × 2 cm2 were fabricated. The precursor dispersion of the spin-coated PEDOT:PSS layer on the solar cell rear was mixed with different contents of sorbitol and stirred overnight on a magnetic stirrer. We examine the impact of the sorbitol admixture on the most relevant solar cell parameters that are the open-circuit voltage Voc, the short-circuit current density Jsc, the fill factor FF and the series resistance Rs as well as the energy conversion efficiency η. The Jsc − Voc characteristics as well as the illuminated current-voltage (J–V) curves are measured under standard testing conditions at 1 sun and 25 °C using a LOANA measurement system (pv-tools, Hamelin, Germany). The series resistance Rs is determined from the measured fill factor FF, pseudo-fill factor pFF as well as the measured Jsc and Voc values using the equation:

As the open-circuit voltage Voc is very sensitive to recombination losses, the positive impact of the sorbitol admixture observed on the lifetime test samples shown in Fig. 2, should translate to increased Voc values on the solar cells with sorbitol admixture. Figure 3(a) shows the measured Voc values of each processed BackPEDOT solar cell as a function of the sorbitol concentration in the PEDOT:PSS precursor dispersion. The median parameters of the solar cells with 0.5 Ωcm base resistivity are shown in Table 2 and the parameters of the 1.3 Ωcm cells in Table 3.

(a) Measured Voc values of all processed PEDOT:PSS/c-Si solar cells for different amounts of sorbitol in the PEDOT:PSS precursor dispersion. (b) Measured Jsc values of solar cells for different amounts of sorbitol in the PEDOT:PSS precursor dispersion. Solar cells with a base resistivity of 0.5 Ωcm (red circles) and 1.3 Ωcm (blue triangles) are shown.

As can be seen from Fig. 3(a) and Tables 2 and 3, Voc increases from a median value of 655 mV to 659 mV for the 0.5-Ωcm p-Si base material and from 657 mV to 660 mV for the 1.3-Ωcm base material by adding 4.0 wt.% of sorbitol to the PEDOT:PSS precursor dispersion. At a sorbitol concentration of 5.7 wt.%, the median Voc values decrease to 650 mV for the 0.5-Ωcm cells and to 643 mV for the 1.3-Ωcm cells. While the improvement in Voc by the admixture of up to 4.0 wt.% of sorbitol is in good agreement with our lifetime study shown in Fig. 2, the reduced Voc at 5.7 wt.% admixture of sorbitol is unexpected and somewhat peculiar, but seems to be reproducible, as it was observed in all eight cell batches processed within this work. Increasing the sorbitol content further to 7.7 wt.% increases the median Voc approximately back to the state without sorbitol admixture. Nevertheless, the maximum Voc value of a single cell of 661 mV was achieved on a 0.5-Ωcm cell with 7.7 wt.% sorbitol admixture. From our experimental results obtained on 42 processed BackPEDOT cells we hence conclude that the admixture of sorbitol can have a clear positive impact on the passivation quality of the PEDPOT:PSS/c-Si junction, although not too much of sorbitol should be added. Figure 3(b) compiles the measured Jsc values of all processed PEDOT:PSS/c-Si solar cells as a function of the sorbitol concentration (median values listed in Tables 2 and 3). The solar cells with 1.3-Ωcm base material provide higher Jsc values compared to the solar cells fabricated on 0.5-Ωcm base material, which can be attributed to the much higher bulk lifetime in the silicon material with lower doping concentration. Lifetime measurements performed on the 0.5-Ωcm p-type FZ-Si material verified that the bulk lifetime of this material is 0.77 ms, whereas that of the 1.3-Ωcm material is 1.56 ms at an excess carrier density Δn of 3 × 1015 cm3. For both base materials, the addition of sorbitol to the PEDOT:PSS is positively affecting the Jsc value. For the 0.5-Ωcm material, the median Jsc increases by 0.7 mA/cm2 by adding a sorbitol concentration of 4.0 wt.% to the PEDOT:PSS dispersion. At a higher sorbitol contents of 7.7 wt.% the median Jsc increases even more by 0.9 mA/cm2 compared to the reference case without sorbitol. For the BackPEDOT cells fabricated on the 1.3-Ωcm p-Si base material, the median Jsc increases by 0.8 mA/cm2 for a sorbitol concentration of 7.7 wt.% compared to the reference without sorbitol. In this study, the highest measured Jsc on a PEDOT:PSS/c-Si solar cell with a base resistivity of 1.3 Ωcm is 39.6 mA/cm2 for a sorbitol content of 7.7 wt.% of the PEDOT:PSS precursor dispersion. From these results it becomes obvious that the addition of sorbitol to the PEDOT:PSS dispersion effectively reduces the parasitic absorption losses in PEDOT:PSS/c-Si heterojunction cells.

Figure 4 shows the measured change in the internal quantum efficiencies ΔIQE and the change in the reflectance spectra using the LOANA measurement system of two exemplary BackPEDOT solar cells for sorbitol contents in the precursor dispersion of 4.0 and 7.7 wt.%, respectively in comparison to a solar cell without sorbitol in the precursor dispersion. The long-wavelength reflectance above 1000 nm is clearly increased by adding the sorbitol to the PEDOT:PSS precursor dispersion in comparison to the solar cell without admixture of sorbitol, which is attributed to the reduced parasitic absorption in the PEDOT:PSS layer13. Moreover, ΔIQE is improved in the long-wavelengths range above 800 nm for the solar cells with sorbitol addition, which is attributed to the improvement in the rear passivation of the BackPEDOT cell and in the improved light trapping due to the reduced parasitic absorption within the PEDOT:PSS layer.

Measured change in the internal quantum efficiency (ΔIQE) (blue circles and red triangles) and change in reflectance (blue squares and red diamonds) of exemplary BackPEDOT solar cells by adding 4.0 wt.% (red symbols) and 7.7 wt.% (blue symbols) sorbitol compared to a BackPEDOT solar cell without sorbitol. The solar cells have a p-type c-Si base with a resistivity of 0.5 Ωcm and the PEDOT:PSS was spin-coated at 500 rpm for 10 seconds and subsequently at 12000 rpm for 30 seconds.

Figure 5(a) (and Tables 2 and 3) shows the series resistance Rs of the fabricated BackPEDOT solar cells as a function of the sorbitol content in the PEDOT:PSS precursor dispersion. Up to a sorbitol concentration of 4.0 wt.% the best Rs values remain at a constant low level of approximately 0.6 to 1.0 Ωcm2. However, there are also outliers with increased series resistance with values around 1.5 Ωcm2. At higher sorbitol contents, Rs shows a pronounced increase with increasing sorbitol content. Median Rs values are 1.59 Ωcm2 for a sorbitol content of 5.7 wt.% and 1.85 Ωcm2 for a sorbitol content of 7.7 wt.%. We attribute the increase in the Rs values for sorbitol contents greater than 4.0 wt.% to a degradation of the solar cell back contact due to the high thermal energy of the electron beam evaporation in combination with a presumably remaining sorbitol content in the PEDOT:PSS layer. Optical microscope images of the metallized cell rear for the different sorbitol concentrations are shown in Supplementary Fig. S1. The amount of sorbitol remaining in the PEDOT:PSS layer is probably higher for sorbitol contents greater 4 wt.% than for lower sorbitol concentrations. Therefore, we observe an increase in Rs only at high sorbitol concentrations. The best Rs value realized on a solar cell processed in this study is 0.6 Ωcm2 for a sorbitol concentration of 4.0 wt.%, which led to an efficiency of 20.2%. The achieved efficiencies of all fabricated BackPEDOT solar cells as a function of the sorbitol concentration are shown in Fig. 5(b). For PEDOT:PSS/c-Si solar cells manufactured with the PEDOT:PSS dispersion without addition of sorbitol, efficiencies range from 18.4 to 19.7%. By adding a sorbitol content to the precursor dispersion of up to 4.0 wt.%, higher cell efficiencies of up to 20.4% are achieved. If a sorbitol content of more than 4.0 wt.% is added to the precursor dispersion, the cell efficiencies decrease and range from 17.9% to 19.2% at a sorbitol content of 7.7 wt.%. The decrease in solar cell efficiencies with higher sorbitol content is attributed to the increasing Rs value. The best efficiency measured in this study on a PEDOT:PSS/c-Si solar cell is 20.4% with a sorbitol content in the precursor dispersion of 4.0 wt.%. The illuminated J–V curve and the Jsc − Voc curve of the best solar cell of this study with the corresponding solar cell parameters is shown in Fig. 6.

(a) Measured series resistance Rs of the fabricated BackPEDOT solar cells for different amounts of sorbitol in the PEDOT:PSS precursor dispersion. (b) Measured solar cell efficiency η of the fabricated solar cells for different amounts of sorbitol in the PEDOT:PSS precursor dispersion. Solar cells have been fabricated on p-type silicon wafers with a base resistivity of 0.5 Ωcm (red circles) and 1.3 Ωcm (blue triangles), respectively.

The best BackPEDOT solar cell fabricated in this study, shown in Fig. 6, provides a Voc of 660 mV and a Jsc value of 38.5 mA/cm2. A good fill factor of 80.0% is achieved due to a low Rs value of 0.73 Ωcm2. This combination of cell parameters leads to the highest efficiency achieved in this study of 20.4% for a PEDOT:PSS/c-Si solar cell with admixture of 4.0 wt.% sorbitol to the precursor dispersion. The Jsc value of 38.5 mA/cm2 achieved on this cell seems relatively low and higher Jsc values (up to 39.6 mA/cm2) were achieved on the 1.3 Ωcm p-Si base material, featuring a much higher bulk lifetime compared to the 0.5 Ωcm bulk material. Hence, there seems to be a strong contribution of the bulk recombination in the record cell of our current study and the use of better bulk material should allow to further improve the efficiency.

Conclusions

In this study, we have fabricated 42 solar cells with phosphorus-diffused front and PEDOT:PSS/c-Si heterojunction at the rear (‘BackPEDOT’ cells). We have examined the impact of adding sorbitol to the PEDOT:PSS precursor dispersion on the solar cell parameters. The recombination current density parameter J0.PEDOT of the PEDOT:PSS/c-Si interface showed a median J0.PEDOT value of 86 fA/cm2 for silicon surfaces passivated with PEDOT:PSS without admixture of sorbitol. At a sorbitol concentration of 7.7 wt.%, the median J0:PEDOT value was lowered to only 38 fA/cm2 which means that the recombination at the PEDOT:PSS/c-Si interface is effectively suppressed by the addtion of sorbitol. We also observed that the admixture of sorbitol improved the Jsc values due to the reduced parasitic absorption within the PEDOT:PSS layer, by 0.9 mA/cm2 at a sorbitol concentration of 7.7 wt.% on solar cells with a p-Si base resistivity of 0.5 Ωcm. The highest achieved Jsc value was 39.6 mA/cm2 on a solar cell with a p-Si base resistivity of 1.3 Ωcm and a sorbitol concentration of 7.7 wt.%. Due to the improvement in the surface passivation quality due to the sorbitol admixture, we observed an increase in Voc of 4.0 mV on solar cells with a base resistivity of 0.5 Ωcm. An increase of 3.0 mV was observed for solar cells with 1.3 Ωcm base resistivity for admixture of sorbitol contents of 4.0 wt.% to the PEDOT:PSS dispersion. The maximum Voc value of a single cell of 661 mV was achieved on a 0.5-Ωcm cell with 7.7 wt.% sorbitol admixture. The series resistance Rs did not change by up to 4.0 wt.% of sorbitol admixture, but showed a pronounced increase at higher sorbitol concentrations. The optimal sorbitol content concerning efficiency is hence 4.0 wt.%, leading to a median efficiency of 20.2% (5 cells), which is 1.1% absolute higher compared to the median efficiency of the reference cells without sorbitol. The highest efficiency achieved in this study was 20.4% for a sorbitol content of 4.0 wt.%. Our experimental results hence suggest that the admixture of sorbitol increases the efficiency potential PEDOT:PSS/c-Si heterojunction solar cells.

Data Availability

All data generated or analyzed during this study are included in this published article.

References

Avasthi, S., Lee, S., Loo, Y. L. & Sturm, J. C. Role of majority and minority carrier barriers silicon/organic hybrid heterojunction solar cells. Adv. Mater. 23, 5762–5766 (2011).

He, L., Jiang, C., Wang, H., Lai, D. & Rusli High efficiency planar Si/organic heterojunction hybrid solar cells. Appl. Phys. Letters 100, 073503 (2012).

Zhang, Y., Liu, R., Lee, S. T. & Sun, B. The role of a LiF layer on the performance of poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate)/Si organic-inorganic hybrid solar cells. Appl. Phys. Letters 104, 083514 (2014).

Pietsch, M., Jäckle, S. & Christiansen, S. H. Interface investigation of planar hybrid n-Si/PEDOT:PSS solar cells with open circuit voltages up to 645 mV and η of 12.6%. Appl. Phys. A 115, 1109–1113 (2014).

Wen, H. et al. Improving the organic/Si heterojunction hybrid solar cell property by optimizing PEDOT:PSS film and with amorphous silicon as back surface field. Appl. Phys. A 123, 14 (2017).

Jäckle, S. et al. Unveiling the Hybrid n-Si/PEDOT:PSS Interface. ACS Appl. Mater. Interfaces 8, 8841–8848 (2016).

Schmidt, J., Zielke, D., Lövenich, W., Hörteis, M. & Elschner, A. Organic-silicon Heterojunctions: a Promising New Concept for High-Fficiency Solar Cells. Proceedings of the 6th WCPEC, Kyoto, Japan 869–870 (2014).

Gogolin, G. et al. Demonstrating the high Voc potential of PEDOT:PSS/c-Si heterojunctions on solar cells. Energy Procedia 124, 593–597 (2017).

Schmidt, J., Titova, V. & Zielke, D. Organic-silicon heterojunction solar cells: Open-circuit voltage potential and stability. Appl. Phys. Letters 103, 183901 (2013).

Zielke, D., Pazidis, A., Werner, F. & Schmidt, J. Organic-silicon heterojunction solar cells on n-type silicon wafers: The BackPEDOT concept. Sol. Energy Mater. Sol. Cells 131, 110–116 (2014).

Zielke, D. et al. Organic-silicon solar cells exceeding 20% efficiency. Energy Procedia 77, 331–339 (2015).

Zielke, D. et al. Large-Area PEDOT:PSS/c-Si Heterojunction Solar Cells With Screen-Printed Metal Contacts. Sol RRL 1700191 (2018).

Halbich, M.-U. et al. Reduction of parasitic absorption in PEDOT:PSS at the rear of c-Si solar cells. AIP Conference Proceedings 1999, 040008 (2018).

Jonas, F. et al. Inventors; Bayer AG, assignee. Conductive coatings. European patent EP 0 686 662 B1. (24 Apr 1995).

Timpanaro, S., Kemerink, M., Touwslager, F. J., De Kok, M. M. & Schrader, S. Morphology and conductivity of PEDOT/PSS films studied by scanning tunneling microscopy. Chem. Phys. Letters 394, 339–343 (2004).

Kane, D. E. & Swanson, R. M. Measurement of the emitter saturation current by a contactless photoconductivity method. Proc. 18th IEEE PVSC, Las Vegas, USA 578–581 (1985).

Zielke, D. et al. Contact passivation in silicon solar cells using atomic‐layer‐deposited aluminum oxide layers. Phys. Status Solidi RRL 5(8), 298–300 (2011).

Nardes, A. M. et al. Conductivity, work function, and environmental stability of PEDOT:PSS thin films treated with sorbitol. Organic Electronics 9, 727–734 (2008).

Janardhanam, V. et al. Energy-level alignment and electrical properties of Al/p-type Si Schottky diodes with sorbitol-doped PEDOT:PSS as an organic interlayer. Journal of Alloys and Compounds 637, 84–89 (2015).

Park, S., Tark, S. J. & Kim, D. Effect of sorbitol doping in PEDOT: PSS on the electrical performance of organic photovoltaic devices. Current Applied Physics 11, 1299–1301 (2011).

Havare, A. K., Cana, M., Demica, S., Kusb, M. & Icli, S. The performance of OLEDs based on sorbitol doped PEDOT: PSS. Synthetic Metals 161, 2734–2738 (2012).

Acknowledgements

This work was funded by the German State of Lower Saxony and the German Federal Ministry of Economics and Energy (BMWi) within the research project “SiPoly” (contract No. 0325884A). The content is the responsibility of the authors. The publication of this article was funded by the Open Access fund of Leibniz Universität Hannover.

Author information

Authors and Affiliations

Contributions

M.-U.H. collected and analyzed the measurement data and wrote the manuscript under the guidance of J.S. D.Z. and R.G. have established and optimized the process flow. R.S.-S. and W.L. produced and provided the PEDOT:PSS dispersion.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Halbich, MU., Zielke, D., Gogolin, R. et al. Improved surface passivation and reduced parasitic absorption in PEDOT:PSS/c-Si heterojunction solar cells through the admixture of sorbitol. Sci Rep 9, 9775 (2019). https://doi.org/10.1038/s41598-019-46280-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-46280-y

- Springer Nature Limited