Abstract

TiO2 nanofibers, with mean diameter ~200 nm, were fabricated by electrospinning and successfully photosensitized with low bandgap Ag2S nanoparticles of 11, 17, 23 and 40 nm mean sizes, with corresponding loading of 4, 10, 18 and 29 wt.% Ag2S, respectively. 17 nm Ag2S@TiO2 nanofibers exhibited optimal activity in the photodegradation of methylene blue under simulated sunlight with pseudo-first order rate constant of 0.019 min−1 compared to 0.009 min−1 for pure TiO2 nanofibers. In spite of greater visible-light absorption and reduced bandgap, larger than 17 nm Ag2S nanoparticles exhibited sluggish photodegradation kinetics probably due to less photo-induced carriers generation in TiO2 and reduced electron injection rates from the larger sized Ag2S into TiO2. Furthermore, a UV-O3 surface treatment induced excess Ti3+ surface states and oxygen vacancies which synergistically enhanced the photodegradation rate constant to 0.030 min−1 for 17 nm Ag2S@TiO2 sample which is ~70% better than the previously reported for Ag2S/TiO2 hierarchical spheres. This was attributed to the efficient charge separation and transfer driven by increased visible-light absorption, bandgap narrowing and reduced electron-hole recombination rates. The present study demonstrate the potential utilization of Ag2S@TiO2 nanofibers in filtration membranes for removal of organic pollutants from wastewater.

Similar content being viewed by others

Introduction

Hazardous wastewater pollution is becoming a serious threat to human health1 which necessitates the development of green and efficient water remediation technologies. Visible-light driven photocatalysis using suitable bandgap oxide-based nanomaterials is an effective technique to chemically transform the organic pollutants into non-hazardous compounds2. Titanium dioxide (TiO2) is widely used as a photocatalyst because it is non-toxic, chemically and thermally stable and inexpensive with a strong oxidizing ability3,4,5. However, its practical use is limited by very low visible-light activity and high recombination rates of photo-induced electron-hole pairs6. The Anatase phase of TiO2 has a bandgap (Eg) of 3.2 eV which covers only 3–5% of the solar spectrum. Moreover, TiO2 is commonly used as nanoparticles (NPs) which exhibits low photodegradation rates for many organic pollutants due to agglomeration and low active area loading. Electrospinning is a relatively easy and low cost technique for synthesis of ultra-long TiO2 nanofibers (NFs) and permeable membranes7 which can facilitate the charge transportation and separation, thus, reducing the recombination rate of electron-hole pairs8, 9. In fact, Choi et al. has shown that TiO2 NFs exhibit superior photocurrent generation (factor of ~3) and hydrogen production (factor of ~7) compared to TiO2 NPs due to well-ordered and interconnected architecture and inherent meso-porosity which aids in adsorption and desorption of the reactants and products, respectively10. Similarly, enhanced photocatalytic activity of electrospun mesoporous TiO2 nanofibers was demonstrated by CO2 reduction to renewable hydrocarbon fuels11.

Many attempts have been made to enhance the photocatalytic activity of TiO2 under illumination conditions similar to solar light12, 13. These include doping transition metal ions such as Fe3+ 14, 15, Ni2+ & Ti3+ 16, Ti3+-doped TiO2 17, 18 or nonmetal atoms such as N, F and S19,20,21, dye-sensitization22,23,24, and coupling with a photosensitizer such as g-C3N4 25, MFe2O4 26, α-Fe2O3, Au, Pt and Au/Pt co-catalysts27,28,29, CdS30, 31, MoS2@zeolite32, Ag33 and Ag3PO4 34, 35. The purpose of coupling with a photosensitizer is to enhance the visible-light harvesting and promote charge separation by effective interface charge transfer between the photosensitizer and TiO2 for which the relative position of the energy band levels are critical. Recently, Ag2S has gained considerable attention as a photosensitizer for TiO2 36,37,38,39,40,41. Ag2S is a direct low bandgap semiconductor material (Eg~1.0 eV) which responds well in the whole solar energy spectrum. The conduction (CB) and valence (VB) bands of Ag2S are −0.3 eV and +0.7 eV, respectively, which is very desirable for photosensitization of TiO2 with corresponding CB and VB of −0.1 eV and +3.1 eV, respectively36. Zhang et al. demonstrated hollow Ag-Ag2S/TiO2 composite spheres with superior photocatalytic activity in reduction of Cr (VI) under both UV and visible-light42. Gholami et al. reported 15 fold enhancement of photocurrent for free standing TiO2 nanotube array, each of 125 nm diameter and 4.1 μm length, sensitized by ~17 nm Ag2S NPs37. Shan et al. demonstrated core-shell Ag/Ag2S NPs on TiO2 nanowires as a model photoelectrochemical electrode system38. Ong et al. used sequential ionic deposition to fabricate Ag2S NPs on TiO2 hierarchical spheres. Enhanced simulated solar light driven photocatalytic performance was demonstrated by water splitting with hydrogen production at 708 μmolh−1 g−1 and photodegradation of methyl orange with pseudo-first order rate constant of 0.018 min−1 39.

Immobilization of Ag2S NPs on TiO2 nanofibers (NF) is expected to give higher number of active sites. Multiple factors contribute to the photosensitization effect of Ag2S on TiO2 nanofibers such as (a) Effect of Ag2S mean size and loading amount on the injection rate of photo-induced electrons into TiO2 as well as photo-induced carriers generation rate in TiO2, (b) Effect of Ag2S mean size, loading and coverage on the light harvesting capability, (c) Effect of chemical interaction between Ag2S and TiO2 on possible lowering of the energy bandgap and the recombination rate, and (d) Effect of changing the surface chemical states and defects on TiO2 (e.g. Ti3+ and oxygen vacancies) on the carrier separation and transport. Li et al.43 deposited different amounts of Ag2S NPs on TiO2 nanorod arrays by varying the number of cycles in successive ionic layer absorption and reaction (SILAR) method. They reported an optimum 25 cycle deposition for maximum photocatalytic degradation rates of methylene orange (MO) under visible-light. However, other factors as noted above were not investigated in detail.

In this report, the combined effect of all these factors for photosensitization of TiO2 nanofibers has been experimentally investigated and optimized. We demonstrate optimal simulated solar light driven photocatalytic activity for TiO2 NFs sensitized by ~17 nm Ag2S NPs, loaded at 10 wt.%, with the synergistic effect of enhanced Ti3+ chemical states and oxygen vacancies induced by a facile UV-O3 surface treatment. Moreover, these composite nanofibers were stable over multiple cycles of photodegradation and demonstrate their potential use for water remediation.

Results and Discussion

Morphology, structure and chemical composition

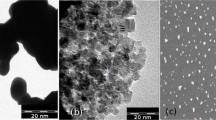

The morphology with mean sizes and distribution of Ag2S@TiO2 NFs are shown in Fig. 1. The uncoated TiO2 NFs (Fig. 1(a) inset) have a mean diameter of 195 nm and interstices of ~1 μm size, formed by the interpenetrating nanofibers network. The color of the TiO2 NFs changed instantaneously as they were dipped in the Tollens reagent with addition of 0.05 M dextrose solution indicating the formation of Ag NPs followed by washing with distilled water and ethanol. The mean size of the Ag NPs was controlled by varying the dipping time in the solution from 0.5–4 min. Figure 1(a–d) shows the successful deposition of Ag2S NPs by nucleation and growth of Ag followed by sulfurization without any structural damage to TiO2 NFs. The phase and chemical composition of the Ag2S NPs was confirmed by XPS and XRD as discussed later. The sizes of Ag2S NPs showed characteristically log-normal distribution with mean number-averaged size of 11, 17, 23 and 40 nm for dipping times of 0.5, 1, 2 and 4 min, respectively. The number-averaged sizes were statistically measured by tracing at least 100 particles, computing their areas, A, and calculating the corresponding area-equivalent diameters, D, assuming spherical shape \((D=\sqrt{4A/\pi })\). The particles remain distinct and approximately spherical for dipping times up to 2 min but most of them coalesce into bigger and mostly irregular particles after 4 min dipping. In this study, the samples will be labelled as x nm-Ag2S@TiO2 where ‘x’ is the mean size of the Ag2S NPs. The weight percent loading of Ag2S in the composite nanofibers was determined by inductively coupled plasma optical emission spectroscopy. A standard AgNO3 salt solution of 1–10 ppm was used to calibrate the emission intensity of Ag which fitted linearly with R2 value of 0.999. The weight fraction of 11, 17, 23 and 40 nm Ag2S@TiO2 composite nanofibers was found to be 4, 10, 18 and 29%, respectively, assuming that all the Ag converted to Ag2S.

TEM images of 11 nm- and 23 nm-Ag2S@TiO2 NFs in Fig. 2(a and b) also show uniform deposition of Ag2S NPs on the NF surfaces. Their sizes are comparable to those measured from the SEM images. The insets show HR-TEM images of Ag2S NPs near the NF edges. The lattices identified in 11 nm-Ag2S@TiO2 correspond to (031) and \((\bar{1}12)\) crystallographic planes with d-spacing of 0.212 and 0.178, respectively, whereas the lattice in 23 nm-Ag2S@TiO2 correspond to \((\bar{1}21)\) crystallographic plane with d-spacing of 0.196 nm. These were also confirmed by the powder XRD scans of Ag2S@TiO2 NF samples shown in the Fig. 3(a), where \((\bar{1}12)\), \((\bar{1}21)\) and (031)44 signals were easily detected (JCPDS # 14-0072, Ag2S, monoclinic). The most intense peak at 2θ = 25.3° corresponds to the (101) crystallographic plane and confirms the formation of pure Anatase TiO2 phase in all the samples45. The chemical composition was verified by the full scan XPS of TiO2, 17 nm-Ag2S@TiO2 and 17 nm-Ag2S@TiO2 + UV-O3 samples as shown in the Fig. 3(b) which confirms the presence of Ti and O in the un-coated samples and additionally, Ag and S, in the coated samples. All the samples showed C 1 s signal which is typical of the adsorbed surface contaminations. The detailed XPS analysis, discussed next, confirmed the presence of Ag2S on the NF surfaces.

Adsorption-desorption isotherm of pure TiO2 NFs and 17 nm-Ag2S@TiO2 composite NFs in Fig. 4(a) closely resembles a type-II isotherm which is typical for non-porous materials due to multilayer formation. The specific surface area of pure TiO2 NFs and 17 nm-Ag2S@TiO2 composite NFs was 7.1 and 6.6 m2/g, respectively, which is consistent with the reported value of 13.3 m2/g for control TiO2 nanofibers46. The pore size distribution in Fig. 4(b) was calculated by NLDFT method. Absence of hysteresis on desorption branch rules out the presence of mesopores, however, high intake of nitrogen at P/P0 > 0.8 could be attributed to the presence of macropores. Contribution of micropores to the total surface area as calculated by the t-plot method was found to be almost zero.

Surface chemical states of Ag2S@TiO2 nanofibers

The effect of photosensitization by Ag2S NPs and UV-O3 treatment on the surface chemical states were determined by XPS. Ti 2p signal of pure TiO2 NFs had two peaks at 464.1 and 458.4 eV which corresponds to Ti 2p1/2 and Ti 2p3/2 spin-orbit splitting, respectively, as shown in the Fig. 5(a). According to the Handbook of X-ray Photoelectron Spectroscopy47, the binding energies of Ti 2p1/2 and Ti2p3/2 in TiO2 are 464.3 and 458.8 eV, respectively. The area ratio of these two peaks is ~0.5 (33.67/66.32 = 0.507) with a binding energy difference of ~5.7 eV (464.15–458.46 = 5.69 eV) which is in good agreement with the literature48. Ti 2p signal was deconvoluted into four peaks which showed 94.3% Ti4+ and 5.7% Ti3+ oxidation state on the TiO2 NFs surface. The Ti3+ oxidation state increased to 6.7% after coating with 17 nm Ag2S NPs which confirms the lower electron density of Ti atoms in Ag2S@TiO2 NFs. Additionally, the Ti 2p peak positions shifted to higher binding energy indicating the withdrawal of valence electron charge (i.e. oxidation) owing to the strong interaction between Ag2S and TiO2 NFs49. The UV-O3 treatment further shifted the Ti 2p peaks towards higher binding energies with increase in Ti3+ surface state to 8.2% which indicates the removal of the lattice oxygen. This increase in surface Ti3+ had a significant effect on the photocatalytic activity as discussed later.

Deconvolution of O 1 s spectra of TiO2 NFs gave three peaks at 529.7, 531.8 and 533.6 eV, as shown in the Fig. 5(b), which are associated with O2− species in the lattice (TiO2), oxygen vacancies or defects (Ti3+ or Ti2O3) and chemisorbed or adsorbed oxygen species, respectively50. Similar to Ti 2p, the peaks shifted to higher binding energies after coating with Ag2S NPs and UV-O3 treatment. The Ti2O3 content increased from 27.4 to 30.2% after coating with 17 nm Ag2S NPs and further to 47.7% after the UV-O3 treatment. These results suggest that oxygen vacancies and excess electrons in Ti are generated by this process which results in the reaction Ti4+ → Ti3+ near the surface.

In the Ag 3d XPS spectra, shown in Fig. 5(c), two peaks were observed at 368.0 eV and 374.0 eV representing 3d5/2 and 3d3/2 spin-orbit pair, respectively. These peaks were shifted to 368.4 eV and 374.4 eV after UV-O3 surface treatment and indicated the presence of Ag in Ag+ form39, 51. The S 2p XPS spectra in Fig. 5(d) showed peaks at 161.09 eV and 162.19 eV representing 2p3/2 and 2p1/2 of S2− in the metal sulfides, thus, confirming the successful formation of Ag2S. Another smaller peak at 163.3 eV is assigned to the -S-S- bonding52 probably due to chemisorption and presence of excess elemental sulfur. These results are in good agreement with the oxidation state of Ag2S in the literature53. Again, these peaks are slightly shifted after UV-O3 surface treatment with emergence of another peak at 169.12 eV due to SO4 2− formation by the surface oxidation of sulfur.

Photocatalytic performance and mechanism

The Ag2S mean size, coverage of TiO2, and UV-O3 surface treatment had a profound effect on the photocatalytic performance. The photocatalytic activity of Ag2S@TiO2 NFs were evaluated by monitoring the photodegradation of MB. In a typical experiment, 5 mg of the composite NFs was dispersed in 10 ml of 10 ppm MB solution and kept in dark for 30 min under continuous stirring to attain a complete adsorption-desorption equilibrium54. The suspension was then illuminated by a 100 W Xenon arc lamp and photodegradation monitored by the UV-Vis spectrophotometer by measuring the absorbance of MB solution at regular time intervals. The C/Co as a function of the irradiated time, where Co is the initial MB solution concentration after the adsorption-desorption equilibrium has been attained, is shown in the Fig. 6(a). All samples showed pseudo-first order photodegradation kinetics with a rate constant of 0.011 min−1 for pure TiO2 NFs which increases to 0.015 min−1 and 0.019 min−1 after photosensitization by 11 nm and 17 nm Ag2S NPs, respectively. Remarkably, the rate constant significantly increases to 0.030 min−1 after a 2 hr UV-O3 surface treatment on 17 nm-Ag2S@TiO2 sample which is ~70% better than 0.018 min−1 reported for Ag2S NPs on TiO2 hierarchical spheres39. This was attributed to the generation of excess Ti3+ surface states and oxygen vacancies, as shown by the XPS results, which facilitated the charge separation process and reduced the electron-hole recombination. We previously reported enhanced photocatalytic activity under UV irradiation for TiO2 NPs (P25 Degussa) loaded polyacrylonitrile NFs due to excess Ti3+ surface defects and enhanced hydrophilicity induced by a UV-O3 surface treatment55. These NFs showed stable performance when tested over 5 cycles of photodegradation as shown in the Fig. 6(b). Please note that the slight decrease in performance is attributed to ~10% material weight loss during the repeated separation and re-use over 5 cycles. The stability of the samples after photodegradation was investigated by SEM and XRD. The phase, size and loading remained stable with no signs of leaching as shown in the Supplementary Information Fig. 1s.

(a) Comparative photocatalytic performance (C/Co) of pure and Ag2S sensitized TiO2 NFs under simulated solar light irradiation (inset: pseudo-first order kinetics), (b) Photocatalytic performance of 17 nm-Ag2S@TiO2 NFs over 5 cycles, and (c) Photocatalytic performance in the presence of radical scavengers.

The radical trapping experiments were carried out to identify the main active oxidation species for photodegradation of MB. As shown in the Fig. 6(c), the photocatalytic efficiencies of the composite nanofibers significantly decreased from 97% to 54%, 62%, 65%, and 73% after the addition of ascorbic acid (as O2 −• scavenger), sodium sulfate (as e− scavenger), sodium oxalate (as h+ scavenger), and isopropanol (as •OH scavenger), respectively. This indicates that the photoinduced electrons react with dissolved O2 molecules to yield O2 −• radicals, while the positively charged holes (h+) react with OH− derived from H2O to form •OH radicals. Thus, all these play a significant role in the photodegradation of MB.

Optical properties of Ag2S@TiO2 nanofibers

To investigate the optical response, the absorption spectra of the Ag2S@TiO2 NFs and their corresponding Kulbelka-Munk transformation of the reflectance spectra are shown in Fig. 7(a and b), respectively. Pure TiO2 showed the expected bandgap of 3.2 eV and very weak visible-light absorption. However, the visible-light absorption increased and the bandgap decreased, monotonically, by coating with Ag2S NPs of increasing size due to the enhanced interfacial chemical interaction and coverage of TiO2 by the smaller bandgap (Eg~1 eV) Ag2S generating new midgap energy levels. However, the increased size of Ag2S will have a negative impact on the photo-induced carriers generation rate in TiO2 and injection rate of electrons from the conduction band of Ag2S into TiO2, thus, increasing their recombination probability. This was shown by the 23 nm- and 40 nm-Ag2S@TiO2 samples which, despite having a lower bandgap (Eg~2.75 eV), showed even less photocatalytic activity then pure TiO2 NFs with rate constants of 0.014 and 0.009 min−1, respectively, as shown in the Fig. 8(a). To investigate the promoted charge separation, the samples were excited by 325 nm laser which generates electron-hole pairs. The recombination of these photoexcited carriers gives photoluminescence (PL) signal with an intensity directly proportional to the electron-hole recombination process. Thus, a lower PL is desirable as it indicates a lower charge recombination which will result in a higher photocatalytic activity. As shown in the Fig. 7(c), the pure TiO2 NF showed a high PL intensity around 425 nm which significantly diminished for Ag2S photosensitized TiO2 NFs. Similar PL results are reported for Ag/TiO2 56 and Ag2O/TiO2 57 systems.

(a) Methylene blue photodegradation rate constants for all the samples. Percentage of Ti2O3 surface states (estimated form O 1 s XPS signal) and calculated bandgaps are also listed. (b) Schematic of the interfacial charge transfer processes during illumination of Ag2S sensitized TiO2 nanofibers with excess Ti3+ states and oxygen vacancies.

The synergistic effect of photosensitization and surface Ti3+ states

The enhanced photocatalytic performance of 17 nm-Ag2S@TiO2 + UV-O3 sample is attributed to the synergistic effect of photosensitization by Ag2S NPs and excess surface Ti3+ states and oxygen vacancies. The proposed effective charge transfer process between Ag2S and TiO2 due to the preferred conduction band (CB) and valence band (VB) positions of Ag2S, which are lower than corresponding bands in TiO2, is schematically depicted in the Fig. 8(b). This facilitated the generated electrons transfer from CB of Ag2S to the CB of TiO2 to effectively inhibit the electron-hole recombination. This photosensitization effect is further supplemented by the high Ti2O3 (Ti3+ state and oxygen vacancies) near the surface which leads to enhanced absorption of incident solar light below the bandgap of TiO2 (Ti4+ state) as shown in the Fig. 8(b) and reported in ref. 58. The midgap state is close to the CB which facilitates the injection of photogenerated electrons into TiO2 under simulated solar light. Moreover, the Ti3+ defects and oxygen vacancies slows down the electron-hole recombination kinetics by acting as hole traps, thus, prolonging the lifetime of the charges59.

In summary, photosensitization of electrospun TiO2 nanofibers was done by Ag2S nanoparticles with mean sizes of 11–40 nm range for enhanced simulated solar light driven photocatalytic performance. Detailed morphological and structural characterization by SEM, HR-TEM & XRD and chemical states identification by XPS confirmed the growth of Ag2S nanoparticles. The key characteristics and parameters of all the samples are shown in the Table 1. The size and coverage of Ag2S had significant effect on the photocatalytic activity with 17 nm-Ag2S@TiO2 giving the optimal activity. This was further enhanced by a surface UV-O3 treatment which introduced excess Ti3+ surface defects and oxygen vacancies and reduced the bandgap. This synergistic effect of Ag2S sensitization and UV-O3 treatment is attributed to the reduced recombination effect due to efficient charge transfer. The prepared composite NFs were stable in performance when tested over 5 cycles with a maximum photodegradation rate constant of 0.03 min−1 for the UV-O3 treated 17 nm-Ag2S@TiO2 nanofibers which is ~70% better than the previously reported value for Ag2S@TiO2 hierarchical spheres. These results demonstrate the potential of using these composite nanofibers for water remediation under sunlight.

Methods

Fabrication of TiO2 nanofibers

To fabricate TiO2 NFs by electrospinning, 1.5 g polyvinylpyrrolidone (PVP, Mw = 1,300,000 g/mol) was mixed in 10 g ethanol and 4 g acetic acid under vigorous stirring for 1 hr. Then 4 g Titanium(IV) n-butoxide (TNBT, 97%) was added in the solution and further stirred for 1 hr to generate a homogeneous electrospinning solution. This precursor solution was electrospun at 18 kV electrical potential with tip to collector distance of 18 cm with pumping rate of 0.8 mL/hr. The non-woven NF mat was left on the aluminum wired collector overnight for complete hydrolysis and annealed in air at 500 °C for 2 hr with a heating rate of 5 °C/min to obtain pure Anatase TiO2 NFs.

Fabrication of Ag2S@TiO2 nanofibers

Ag2S NPs of different size distribution were grown on TiO2 NFs by a two-step process: reduction of Ag+ to Ag followed by sulfurization of Ag to Ag2S. Typically, 0.1 M NaOH was added drop-wise in 10 mL of 0.01 M AgNO3 solution until appearance of brown precipitates. Then 1.0 M ammonia solution is added drop-wise until dissolution of all brown precipitates which indicates the formation of silver-ammonia complex [Ag(NH3)2]+, commonly known as the Tollens reagent. 10 mL of 0.05 M dextrose solution and 20 mg TiO2 NFs were added into this freshly prepared solution under magnetic stirring, resulting in the formation of Ag NPs. These Ag NPs were then sulfurized to Ag2S40 by dipping in 25 mL of 0.01 M sulfur/acetonitrile solution at 60 °C for 10 min. The Ag2S@TiO2 NFs were then washed with acetonitrile and distilled water and then dried at 60 °C in oven. The selected Ag2S@TiO2 NFs were also exposed to UV-O3 for 2 hr in a UV-Ozone plasma cleaner chamber.

Characterization

The size and morphology of Ag2S NPs and TiO2 NFs was characterized by field emission scanning electron microscopy (FE-SEM, FEI 450 Nova NanoSEM) and high resolution transmission electron microscopy (HR-TEM, Jeol JEM-2100F operating at 200 kV). The weight fraction of Ag2S in the composite nanofibers was determined by inductively coupled plasma – optical emission spectroscopy (ICP-OES, Perkin Elmer Optima 2100 DV). 3 mg of the sample was digested in 5 mL conc. HNO3 and then diluted up to 50 ml with deionized water. The surface chemical composition and oxidation states of Ti, O, Ag and S were quantified by X-ray photoelectron spectroscopy (XPS, PHI-1600) equipped with Al Kα radiation. The peak positions were calibrated to C 1 s (284.8 eV) and plotted using the CasaXPS software. The photoluminescence spectra of the composite nanofibers were recorded by exciting the samples by 325 nm wavelength laser. The crystalline phases were determined by powder X-ray diffraction (XRD, Bruker D2 Phaser). Diffuse reflectance spectra (DRS) in 200–800 nm range were taken by UV-vis-NIR spectrophotometer (Jasco, V-770) to study the light harvesting capabilities of the samples and estimate their bandgaps using Kubelka-Munk function. The specific surface area was measured using Quantachrome (NOVA 2200 e) surface area and pore size analyzer. Silica kernel with cylindrical pore morphology and NLDFT (equilibrium mode) were used for the calculation of pore volume and pore size. Surface area was measured from nitrogen adsorption-desorption isotherm by applying B.E.T. plot in relative pressure range of 0.05–0.30 P/Po.

Photocatalytic performance

The photocatalytic performance of the Ag2S@TiO2 NFs were evaluated by photodegradation of methylene blue (MB) solution in water. In a typical experiment, 5 mg of the sample was dispersed in a 10 mL solution of 10 ppm MB and kept in dark for 30 min under continuous stirring to attain a complete adsorption-desorption equilibrium on the surface of the composite NFs. Photocatalytic degradation was carried out by illuminating the suspension with simulated solar light using a commercial 100 W Xenon lamp. The analytical sample from the photocatalytic reaction was collected at regular time intervals and centrifuged. The resulting solution was analyzed by recording the absorbance of the residual MB solution with UV-vis spectrophotometer at a wavelength of 662 nm. To identify the active oxidation species responsible for the photocatalytic degradation of MB, a series of radical trapping experiments were carried out. Isopropanol as •OH scavenger (10 mM), ascorbic acid as O2 −• scavenger (0.1 mM), sodium sulfate as e− scavenger (10 mM) and sodium oxalate as h+ scavenger (10 mM) were added directly into the MB solution containing the composite photocatalysts prior to irradiation by simulated solar light.

References

Elliott, J. E. & Elliott, K. H. Tracking marine pollution. Science 340, 556–558 (2013).

Jing, L., Zhou, W., Tian, G. & Fu, H. Surface tuning for oxide-based nanomaterials as efficient photocatalysts. Chem. Soc. Rev 42, 9509–49 (2013).

Chen, X. & Selloni, A. Introduction: Titanium Dioxide (TiO2) Nanomaterials. Chem. Rev 114, 9281–9282 (2014).

Wen, J. et al. Photocatalysis fundamentals and surface modification of TiO2 nanomaterials. Cuihua Xuebao/Chinese J. Catal 36, 2049–2070 (2015).

Sajan, C. P., Wageh, S., Al-Ghamdi, A. A., Yu, J. & Cao, S. TiO2 nanosheets with exposed {001} facets for photocatalytic applications. Nano Res 9, 3–27 (2016).

Schneider, J. et al. Understanding TiO2 Photocatalysis: Mechanisms and Materials. Chem. Rev 114, 9919–9986 (2014).

Teo, W. E. & Ramakrishna, S. A review on electrospinning design and nanofibre assemblies. Nanotechnology 17, R89–R106 (2006).

Zhang, F. et al. Controllable synthesis of Ag@TiO2 heterostructures with enhanced photocatalytic activities under UV and visible excitation. RSC Adv 6, 1844–1850 (2016).

Chen, Y. L., Chang, Y. H., Huang, J. L., Chen, I. & Kuo, C. Light scattering and enhanced photoactivities of electrospun titania nanofibers. J. Phys. Chem. C 116, 3857–3865 (2012).

Choi, S. K., Kim, S., Lim, S. K. & Park, H. Photocatalytic comparison of TiO2 nanoparticles and electrospun TiO2 nanofibers: Effects of mesoporosity and interparticle charge transfer. J. Phys. Chem. C 114, 16475–16480 (2010).

Fu, J., Cao, S., Yu, J., Low, J. & Lei, Y. Enhanced photocatalytic CO2-reduction activity of electrospun mesoporous TiO2 nanofibers by solvothermal treatment. Dalt. Trans 43, 9158–65 (2014).

Li, X. et al. Engineering heterogeneous semiconductors for solar water splitting. J. Mater. Chem. A 3, 2485–2534 (2015).

Etacheri, V., Di Valentin, C., Schneider, J., Bahnemann, D. & Pillai, S. C. Visible-light activation of TiO2 photocatalysts: Advances in theory and experiments. J. Photochem. Photobiol. C Photochem. Rev 25, 1–29 (2015).

Khan, H. & Swati, I. K. Fe3+-doped Anatase TiO2 with d–d Transition, Oxygen Vacancies and Ti3+ Centers: Synthesis, Characterization, UV–vis Photocatalytic and Mechanistic Studies. Ind. Eng. Chem. Res 55, 6619–6633 (2016).

Yu, H. et al. An Efficient Visible-Light-Sensitive Fe (III)-Grafted TiO2 Photocatalyst. J. Phys. Chem. C 114, 16481–16487 (2010).

Zhang, H. et al. Ni2+ and Ti3+ co-doped porous black anatase TiO2 with unprecedented-high visible-light-driven photocatalytic degradation performance. RSC Adv 5, 107150–107157 (2015).

Ren, R. et al. Controllable Synthesis and Tunable Photocatalytic Properties of Ti3+-doped TiO2. Sci. Rep 5, 1–11 (2015).

Bharti, B., Kumar, S., Lee, H.-N. & Kumar, R. Formation of oxygen vacancies and Ti3+ state in TiO2 thin film and enhanced optical properties by air plasma treatment. Sci. Rep 6, 1–12 (2016).

Wang, J. et al. Origin of photocatalytic activity of Nitrogen-doped TiO2 nanobelts. J. Am. Chem. Soc. 131, 12290–12297 (2009).

Li, D., Haneda, H., Hishita, S. & Ohashi, N. Visible-Light-Driven N−F−Codoped TiO2 Photocatalysts. 1. Synthesis by Spray Pyrolysis and Surface Characterization. Chem. Mater 17, 2588–2595 (2005).

Zhou, P., Yu, J. & Wang, Y. The new understanding on photocatalytic mechanism of visible-light response NS codoped anatase TiO2 by first-principles. Appl. Catal. B Environ 142–143, 45–53 (2013).

Zhang, M. et al. Hierarchical Nanostructures of Copper (II) Phthalocyanine on Electrospun TiO2 Nanofibers: Controllable Solvothermal-Fabrication and Enhanced Visible Photocatalytic Properties. ACS Appl. Mater. Interfaces 3, 369–377 (2011).

Seddigi, Z. S., Ahmed, S. A., Sardar, S. & Pal, S. K. Heterodimerization at the dye sensitized TiO2 surface: an efficient strategy toward quick removal of water contaminants. Photochem. Photobiol. Sci 15, 920–927 (2016).

Kang, X. et al. Deposition of loosely bound organic D–A–π–A′ dyes on sensitized TiO2 film: a possible strategy to suppress charge recombination and enhance power conversion efficiency in dye-sensitized solar cells. J. Mater. Chem. A 2, 11229 (2014).

Liu, X. et al. A general nonaqueous sol-gel route to g-C3N4-coupling photocatalysts: the case of Z-scheme g-C3N4/TiO2 with enhanced photodegradation toward RhB under visible-light. Sci. Rep 6, 39531 (2016).

Gao, X., Liu, X., Zhu, Z., Wang, X. & Xie, Z. Enhanced photoelectrochemical and photocatalytic behaviors of MFe2O4 (M = Ni, Co, Zn and Sr) modified TiO2 nanorod arrays. Sci. Rep 6, 30543 (2016).

Liu, C. et al. Efficiently enhancing the photocatalytic activity of faceted TiO2 nanocrystals by selectively loading α-Fe2O3 and Pt co-catalysts. RSC Adv 6, 29794–29801 (2016).

Shuang, S., Lv, R., Xie, Z. & Zhang, Z. Surface Plasmon Enhanced Photocatalysis of Au/Pt-decorated TiO2 Nanopillar Arrays. Sci. Rep 6, 26670 (2016).

Wang, Y., Yu, J., Xiao, W. & Li, Q. Microwave-assisted hydrothermal synthesis of graphene based Au–TiO2 photocatalysts for efficient visible-light hydrogen production. J. Mater. Chem. A 2, 3847 (2014).

Chen, C., Zhai, Y., Li, F. & Ling, L. Photocurrent enhancement of the CdS/TiO2/ITO photoelectrodes achieved by controlling the deposition amount of Ag2S nanocrystals. Appl. Surf. Sci 356, 574–580 (2015).

Dong, W. et al. Facile synthesis of CdS@TiO2 core–shell nanorods with controllable shell thickness and enhanced photocatalytic activity under visible light irradiation. Appl. Surf. Sci 349, 279–286 (2015).

Zhang, W., Xiao, X., Zheng, L. & Wan, C. Fabrication of TiO2/MoS2@zeolite photocatalyst and its photocatalytic activity for degradation of methyl orange under visible light. Appl. Surf. Sci 358, 468–478 (2015).

Tahir, K. et al. Visible light photo catalytic inactivation of bacteria and photo degradation of methylene blue with Ag/TiO2 nanocomposite prepared by a novel method. J. Photochem. Photobiol. B Biol 162, 189–198 (2016).

Xie, J. et al. Facile synthesis of hierarchical Ag3PO4/TiO2 nanofiber heterostructures with highly enhanced visible light photocatalytic properties. Appl. Surf. Sci 355, 921–929 (2015).

Xu, J.-W., Gao, Z.-D., Han, K., Liu, Y. & Song, Y.-Y. Synthesis of magnetically separable Ag3PO4/TiO2/Fe3O4 heterostructure with enhanced photocatalytic performance under visible light for photoinactivation of bacteria. ACS Appl. Mater. Interfaces 6, 15122–31 (2014).

Neves, M. C. et al. Photosensitization of TiO2 by Ag2S and its catalytic activity on phenol photodegradation. J. Photochem. Photobiol. A Chem 204, 168–173 (2009).

Gholami, M., Qorbani, M., Moradlou, O., Naseri, N. & Moshfegh, A. Z. Optimal Ag2S nanoparticle incorporated TiO2 nanotube array for visible water splitting. RSC Adv 4, 7838 (2014).

Shan, Z., Clayton, D., Pan, S., Archana, P. S. & Gupta, A. Visible Light Driven Photoelectrochemical Properties of Ti@TiO2 Nanowire Electrodes Sensitized with Core–Shell Ag@Ag2S Nanoparticles. J. Phys. Chem. B 118, 14037–14046 (2014).

Ong, W. L., Lim, Y.-F., Ting Ong, J. L. & Ho, G. W. Room temperature sequential ionic deposition (SID) of Ag2S nanoparticles on TiO2 hierarchical spheres for enhanced catalytic efficiency. J. Mater. Chem. A 3, 6509–6516 (2015).

Liu, X., Liu, Z., Lu, J., Wu, X. & Chu, W. Silver sulfide nanoparticles sensitized titanium dioxide nanotube arrays synthesized by in situ sulfurization for photocatalytic hydrogen production. J. Colloid Interface Sci 413, 17–23 (2014).

Xie, Y., Heo, S. H., Kim, Y. N., Yoo, S. H. & Cho, S. O. Synthesis and visible-light-induced catalytic activity of Ag2S-coupled TiO2 nanoparticles and nanowires. Nanotechnology 21, 15703 (2010).

Zhang, D., Xu, G. & Chen, F. Hollow spheric Ag-Ag2S/TiO2 composite and its application for photocatalytic reduction of Cr(VI). Appl. Surf. Sci 351, 962–968 (2015).

Li, Z., Xiong, S., Wang, G., Xie, Z. & Zhang, Z. Role of Ag2S coupling on enhancing the visible-light-induced catalytic property of TiO2 nanorod arrays. Sci. Rep 6, 1–7 (2015).

Blanton, T., Misture, S., Dontula, N. & Zdzieszynski, S. In situ high-temperature X-ray diffraction characterization of silver sulfide, Ag2S. Powder Diffr 26, 114–118 (2012).

Shirke, B. S., Korake, P. V., Hankare, P. P., Bamane, S. R. & Garadkar, K. M. Synthesis and characterization of pure anatase TiO2 nanoparticles. J. Mater. Sci. Mater. Electron 22, 821–824 (2011).

Deepa, T. D. et al. Surfactant-assisted synthesis of porous TiO2 nanofibers as an anode material for secondary lithium ion batteries. Sustain. Energy Fuels 238, 37 (2017).

Moulder, J. F., Stickle, W. F., Sobol, P. E. & Bomben, K. D. Handbook of X-ray Photoelectron Spectroscopy 261 (1992).

Li, F. B., Li, X. Z. & Hou, M. F. Photocatalytic degradation of 2-mercaptobenzothiazole in aqueous La3+-TiO2 suspension for odor control. Appl. Catal. B Environ 48, 185–194 (2004).

Yang, D. et al. Synthesis of Ag/TiO2 nanotube heterojunction with improved visible-light photocatalytic performance inspired by bioadhesion. J. Phys. Chem. C 119, 5827–5835 (2015).

Park, K.-H. & Dhayal, M. High efficiency solar cell based on dye sensitized plasma treated nano-structured TiO2 films. Electrochem. commun 11, 75–79 (2009).

Jiang, D., Chen, L., Xie, J. & Chen, M. Ag2S/g-C3N4 composite photocatalysts for efficient Pt-free hydrogen production. The co-catalyst function of Ag/Ag2S formed by simultaneous photodeposition. Dalt. Trans 43, 4878–85 (2014).

Chen, R., Nuhfer, N. T., Moussa, L., Morris, H. R. & Whitmore, P. M. Silver sulfide nanoparticle assembly obtained by reacting an assembled silver nanoparticle template with hydrogen sulfide gas. Nanotechnology 19, 455604 (2008).

Fan, W., Jewell, S., She, Y. & Leung, M. K. H. In situ deposition of Ag-Ag2S hybrid nanoparticles onto TiO2 nanotube arrays towards fabrication of photoelectrodes with high visible light photoelectrochemical properties. Phys. Chem. Chem. Phys 16, 676–80 (2014).

Xu, C., Rangaiah, G. P. & Zhao, X. S. Photocatalytic degradation of methylene blue by titanium dioxide: experimental and modeling study. Ind. Eng. Chem. Res 53, 14641–14649 (2014).

Dilpazir, S., Usman, M., Rasul, S. & Arshad, S. N. A simple UV-ozone surface treatment to enhance photocatalytic performance of TiO2 loaded polymer nanofiber membranes. RSC Adv 6, 14751–14755 (2016).

Lim, S. P., Pandikumar, A., Huang, N. M. & Lim, H. N. Enhanced photovoltaic performance of silver@titania plasmonic photoanode in dye-sensitized solar cells. RSC Adv 4, 38111–38118 (2014).

Wei, N. et al. Ag2O nanoparticle/TiO2 nanobelt heterostructures with remarkable photo-response and photocatalytic properties under UV, visible and near-infrared irradiation. Appl. Catal. B Environ 198, 83–90 (2016).

Xing, M., Li, X. & Zhang, J. Synergistic effect on the visible light activity of Ti(3+) doped TiO2 nanorods/boron doped graphene composite. Sci. Rep 4, 5493 (2014).

Qiu, B. et al. Facile synthesis of the Ti3+ self-doped TiO2-graphene nanosheet composites with enhanced photocatalysis. Sci. Rep 5, 8591 (2015).

Acknowledgements

The authors would like to acknowledge Dr. Muhammad Zaheer, Dr. Murtaza Saleem Mr. Zafar Iqbal and Mr. Zajif Hussain in SBA School of Science and Engineering (LUMS) for assistance in the BET, SEM, XRD, and photoluminescence experiments, respectively.

Author information

Authors and Affiliations

Contributions

S.G. designed the experiments, synthesized all the samples, did photocatalytic experiments, interpreted the results and wrote the initial manuscript with assistance from S.A. N.M. assisted in TEM and XPS studies. S.N.A. supervised the work, prepared all the figures, interpreted the results, reviewed and corrected the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Ghafoor, S., Ata, S., Mahmood, N. et al. Photosensitization of TiO2 nanofibers by Ag2S with the synergistic effect of excess surface Ti3+ states for enhanced photocatalytic activity under simulated sunlight. Sci Rep 7, 255 (2017). https://doi.org/10.1038/s41598-017-00366-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-00366-7

- Springer Nature Limited