Abstract

The widely used stainless steels and their deformed variants are anticorrosive in ambient conditions due to passivation layers composed of chromium oxides. Conventionally, corrosion and erosion of the steels are attributed to the breakdown of such layers but seldomly to the origin that depends on surface heterogeneity at the microscopic level. In this work, the nanometer-scaled chemical heterogeneity at the surface unveiled via spectro-microscopy and chemometric analysis unexpectedly dominates the breakdown and corrosion behavior of the cold-rolled Ce-modified 2507 super-duplex stainless steels (SDSS) over its hot-deformed counterpart. Though relatively uniformly covered by a native Cr2O3 layer revealed by X-ray photoemission electron microscopy, the cold-rolled SDSS behaved poorly in passivity because of locally distributed Fe3+ rich nano-islands over the Fe/Cr oxide layer. This atomic-level knowledge provides a deep understanding of corrosion of stainless steel and is expected to benefit corrosion controls of similar high-alloyed metals.

Similar content being viewed by others

Introduction

Since the invention of stainless steel, anticorrosive properties of the chromium-iron alloy have been attributed to chromium which forms a strong oxide/oxyhydroxide that renders passive behavior in most environments. Super duplex stainless steels (SDSS) with better corrosion resistance are endowed with superior mechanical properties over conventional (austenitic and ferritic) stainless steels1,2,3. The enhanced mechanical strength enables lighter and more compact designs. In contrast, the high pitting and crevice corrosion resistance of cost-effective SDSS ensures longer lifetimes, extending their applications to pollution control, chemical vessels, and the offshore oil/gas industries4. However, the narrow hot working temperature range and poor forming properties hinder its practical applications at a large scale5. Thus, the SDSS is modified to enhance the aforesaid performances. For example, the Ce-modification was introduced to the 2507 SDSS (Ce-2507) along with a high N addition6,7,8. The rare-earth element (Ce) at a suitable concentration of 0.08 wt% is beneficial to the mechanical properties of DSS because of enhanced grain refinements and grain boundary strengths. Wear and corrosion resistance, tensile and yield strength, and hot workability were also improved9. The larger amount of N can substitute the expensive Ni content, making the SDSS more cost-effective10.

Recently, the SDSS was plastically deformed at different temperatures (cryogenic, cold, and hot) to reach superior mechanical performances6,7,8. However, the superior corrosion resistance of SDSS, resulting from the presence of a thin oxide film on the surface, is subjected to many factors, e.g., intrinsic heterogeneous microstructures resulting from the presence of multiple phases with different grain boundaries, unwanted precipitates and different responses of varied austenite and ferrite phases to deformations7. Thus, investigations of microregional properties of such thin films down to electronic structure levels become crucial to understand corrosion of the SDSS and require sophisticated experimental techniques. So far, surface-sensitive methods such as Auger electron spectroscopy11 and X-ray photoelectron spectroscopy12,13,14,15, and hard X-ray photoelectron emission microscopy (HAX-PEEM)16, while providing chemical distinctions of surface layers, typically fail to separate the chemical state of the same element at spatially different positions at the nanoscale. Few recent studies correlated the local chromium oxidation to the observed corrosion behaviors on austenitic stainless steel17, martensitic steel18, and SDSS19,20. However, these studies focused mainly on the heterogeneity in Cr (for example, Cr3+ oxidation state) on the corrosion resistance. Lateral heterogeneity in the oxidation state of the element can result from different compounds with identical composition elements, e.g., iron oxides. These compounds inherit refined sizes subjected to thermomechanical treatments, tightly adjacent to each other but vary in compositions and oxidation states16,21. Thus, unveiling the breakdown of oxide film and then pitting corrosion demands knowledge of surface heterogeneity at microscopic level. Despite the demands, a quantitative assessment, such as on lateral heterogeneity in the oxidation especially of Fe at nano-/atomic-scale, is still missing and its correlation with the corrosion resistance remains unexplored. Only recently, the chemical state of various elements, such as Fe and Ca has been quantitatively described on steel samples by soft X-ray photoemission electron microscopy (X-PEEM) at synchrotron radiation facilities at the nanoscale22. Combined with the chemically sensitive X-ray absorption spectroscopy (XAS) method, X-PEEM, involving measurement of XAS with the high spatial and spectral resolution, provides chemical information regarding the elemental composition and its chemical state within a spatial resolution down to the nanometer scale23. Such a spectro-microscopic insight into the initiation sites benefits local chemical probation and may evidence chemical variations in Fe layers spatially that have not been explored before.

The present study advances PEEM’s merits in detecting chemical distinctions at the nanoscale and brings in an insightful surface analysis approach at the atomic level to understand the corrosion behavior of Ce-2507. It employs the K-means clustering chemometrics methods24 to plot global chemical (in)homogeneities of involved elements whose chemical states are presented in a statistical representation. Unlike corrosion triggered by chromium oxide film breakdown in conventional cases, the present poor passivity then low corrosion resistance is attributed to the localized Fe3+ rich nano-islands against the vicinity over the Fe/Cr oxide layer which could be the breakdown sites of the protective oxide film and lead to corrosion.

Results and discussion

Corrosion behavior

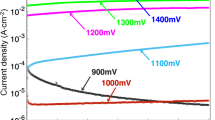

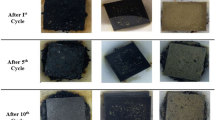

The corrosion behavior of deformed 2507 SDSS was first assessed through electrochemical measurements. Figure 1 depicts the Nyquist and Bode curves for the selected samples in acidic (pH = 1) FeCl3 aqueous solution at room temperature. The chosen electrolyte serves as a strong oxidizing agent to characterize the passive film’s breakdown propensity. Although the material did not undergo stable pitting corrosion at room temperature, the analyses provide insights into understanding potential breakdown events and following corrosion. The equivalent electrical circuit (Fig. 1d) was employed to fit the electrochemical impedance spectroscopy (EIS) spectra, and the corresponding fitting results are given in Table 1. Incomplete semicircles turned out in tests of solid solution treated and hot-deformed samples, while a compressed semicircle (Fig. 1b) in cold-rolled counterpart. In EIS spectra, the radius of the semicircle can be regarded as the polarization resistance (Rp)25,26. The Rp of the solid solution treated SDSS in Table 1 is about 135 kΩ cm−2; nevertheless, a much lower value of 34.7 and 2.1 kΩ cm−2 for hot-deformed and cold-rolled SDSS, respectively, is seen. This significant decline in Rp displays the detrimental effect of plastic deformation on passivity then corrosion resistance as it was shown in previous reports27,28,29,30.

a Nyquist, b, c Bode impedance and phase plots, and d corresponding equivalent electrical circuit model, where RS is the electrolyte resistance, Rp is the polarization resistance and QCPE is a constant phase element for modeling the non-ideal capacitance (n) of the oxide layer. The EIS measurements were carried out at open circuit potential.

One-time constant is shown in Bode plots, and the plateaus in the high-frequency range represent electrolyte resistance RS26. As the frequency decreases, the impedances increase, and negative phase angles are detected, suggesting that capacitance dominates. The phase angles increase to remain maxima in a relatively wide range of frequencies and then decrease (Fig. 1c). However, this maxima value is still smaller than 90° in these three cases, which indicates a non-ideal capacitance behavior due to the capacitance dispersion. A constant phase element (CPE), QCPE, is therefore employed to present the distribution of interfacial capacitance originating from surface roughness or heterogeneities, especially on the atomic scale, fractal geometry, electrode porosity, non-uniform potential, and current distribution associated with the geometry of electrode31,32. The impedance of CPE is:

where j is the imaginary number, and ω is the angular frequency. QCPE is a constant independent of frequency and proportional to the active exposed area to the electrolyte. n is a dimensionless power number describing the deviation from the ideal capacitive behavior of capacitors, i.e., the closer the n to 1, the closer the CPE to pure capacitance while it presents resistor if n is close to zero. A slight deviation of n close to 1 means a non-ideal capacitance behavior of the surface after the polarization test. QCPE of the cold-rolled SDSS is seen to be much higher than that of its counterparts, implying a less homogeneous surface quality.

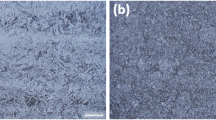

In line with most anti-corrosive features of the stainless steel, the relatively high Cr content in SDSS generally leads to the superior corrosion resistance of SDSS, which results from the presence of a passive thus protective oxide film on the surface17. Such a passive film generally has rich Cr3+ oxide and/or hydroxide with the integration of mainly Fe2+, Fe3+ oxides, and/or (oxy)hydroxides33. Despite similar surface uniformity, passive oxide layers, and no observable breakdowns on the surfaces according to micrographic determinations6,7, the corrosion behaviors differ in hot-deformed and cold-rolled SDSS, thus, requiring in-depth studies of microstructural features of the deformed steels.

Microstructural features

Microstructures of the deformed stainless steels were quantitatively studied via in-house and synchrotron high-energy X-ray radiation (Supplementary Figs. 1, 2). The detailed analysis is given in the Supplementary Information. Despite general agreements with the type of principal phases, differences in volume phase fraction are found and tabulated in Supplementary Table 1. The differences can be attributed to uneven phase fractions on the surface and in bulk subjected to different detection depths of the X-ray diffraction (XRD) with different sources of incident photon energies34. The relatively high austenite fraction in the cold-rolled sample quantified by lab-source XRD suggests better passivity then better corrosion resistance35, while more accurate and statistical results from high-energy synchrotron XRD (HE-SXRD) imply an opposite trend regarding phase fractions. Besides this, the corrosion resistance of steels also depends on the extent of grain refinement, decrease in grain size, increase in microstrain, and dislocation density induced during thermomechanical processing36,37,38. The hot-deformed sample shows a more grainy nature indicating the micron-sized grains, whereas observed smooth rings in the cold-rolled sample (Supplementary Fig. 3) infer a significant grain refinement into nanometer scale in the previous work6 which should promote passive film formation and improve corrosion resistance. The larger dislocation density usually correlates with worse pitting corrosion resistance, which matches well with the electrochemical measurement results.

Spectro-microscopic chemical inhomogeneities

Variations of microregional chemical states of essential elements were systematically examined via X-PEEM. Despite a large number of alloying elements, Cr, Fe, Ni, and Ce39 were chosen here because Cr is the key element for passive film formation, Fe is the main element of steel, Ni enhances the passivity and balances the ferrite-austenite phase structure and Ce by its modification purpose. By tuning the synchrotron beam energy, the XAS covered the main features of Cr (L2,3 edge), Fe (L2,3 edge), Ni (L2,3 edge), and Ce (M4,5 edge) from the surface for both the hot-deformed and cold-rolled Ce-2507 SDSS. The respective data analysis was carried out by including the energy calibration with the published data, for example, XAS at the Fe L2,3 edges40,41.

Figure 2 shows the X-PEEM images of the hot-deformed (Fig. 2a) and cold-rolled (Fig. 2d) Ce-2507 SDSS along with corresponding Cr and Fe L2,3 edge XAS at individually marked positions. L2,3 edge XAS probes the unoccupied 3d states after photoexcitations of electrons at the spin-orbit split levels 2p3/2 (L3 edge) and 2p1/2 (L2 edge). The information about the Cr valence states is obtained from XAS at the L2,3 edge in Fig. 2b, e. A comparison with the refs. 42,43 suggests the observation of four peaks referred to A (578.3 eV), B (579.5 eV), C (580.4 eV), and D (582.2 eV) next to the L3 edge reflecting the octahedral Cr3+ ion corresponding to Cr2O3. The experimental spectra agree with theoretical simulations as shown in panels b and e given by a crystal field multiplet calculation of the Cr L2,3 edge, using a crystal field of 2.0 eV44. Both surfaces of hot-deformed and cold-rolled SDSS are covered with relatively uniform Cr2O3 layers.

a X-PEEM thermal image of hot-deformed SDSS, corresponding b Cr L2,3 edge and c Fe L2,3 edge, d X-PEEM thermal image of cold-rolled SDSS, corresponding e Cr L2,3 edge and f Fe L2,3 edge (f). XAS spectra are plotted at various spatial positions as marked in the thermal image (a, d), and the orange dashed line in (b) and (e) represents the simulated Cr3+ XAS spectrum with a crystal field value of 2.0 eV. For X-PEEM images, a thermal color palette is used to improve the image readability in which the colors, from blue to red, is proportional to the X-ray absorption intensity (low to high).

Chemical states of the alloying element Ni and the Ce additive are kept the same for both samples, regardless of the chemical environment of these metal elements. Supplementary Figs. 5–9 show the X-PEEM image and corresponding XAS spectra at various locations for Ni and Ce on surfaces of hot-deformed and cold-rolled samples. Ni XAS shows Ni2+ oxidation state throughout the measured surface in both hot-deformed and cold-rolled samples (Supplementary Discussion). It is noted that no XAS signal could be observed for Ce in the case of the hot-deformed sample, whereas Ce3+ spectrum is observed for the cold-rolled specimen at a spot. The observation of Ce spot in cold-rolled samples suggests that Ce mainly occurs as precipitates.

No local structural changes in the XAS at the Fe L2,3 edges are observed in hot-deformed SDSS (Fig. 2c). However, the Fe matrix varies its chemical states micro-regionally in the seven randomly selected spots for cold-rolled SDSS, as revealed in Fig. 2f. Furthermore, to have an exact picture of Fe state variation in the chosen sites in Fig. 2f, local surface investigations have been implemented (Fig. 3 and Supplementary Fig. 10), wherein smaller circular regions were chosen. The Fe L2,3 edge XAS spectra of α-Fe2O3 and an octahedral Fe2+ oxide system have been simulated with crystal field multiplet calculations, using crystal fields of 1.0 (Fe2+) and 1.0 (Fe3+)44. We note that α-Fe2O3 and γ-Fe2O3 have different local symmetries45,46, Fe3O4 has combination of both Fe2+ & Fe3+,47, and FeO45 as a formally divalent Fe2+ oxide (3d6). All Fe3+ ions in α-Fe2O3 have the Oh sites only, while γ-Fe2O3 is often represented by Fe3+ t2g [Fe3+ 5/3V1/3]eg O4 spinel with vacancies at eg sites. Hence Fe3+ ions in γ-Fe2O3 have both the Td and Oh sites. As mentioned in the previous work45, although the intensity ratio for both these is different, their intensity ratio of eg/t2g is »1, whereas, in the present case, the observed intensity ratio of eg/t2g is ~1. This excludes the possibility of only Fe3+ in the present case. Considering the case of Fe3O4 which has a combination of both Fe2+ and Fe3+, it is known that weaker (stronger) first feature in L3 edge of Fe is indicative of less (more) un-occupancy in t2g state. This is the case for Fe2+ (Fe3+), suggesting that an increased first feature is indicative of increased Fe2+ content47. These results indicate the coexistence of Fe2+ and γ-Fe2O3, α-Fe2O3, and or Fe3O4 dominates composites on the cold-rolled surface.

The enlarged photoemission electron thermal image (a, c) and (b, d) XAS spectra crossing Fe L2,3 edge at various spatial positions within the chosen region 2 and E of Fig. 2d.

The obtained experimental data were plotted (Fig. 4a and Supplementary Fig. 11) and compared with those of pure compounds40,41,48. Mainly three distinct types of experimentally observed Fe L-edge XAS spectra (XAS-1, XAS-2, and XAS-3: Fig. 4a) have been noted at spatially different locations. In particular, spectrum like 2-a in Fig. 3b (referred to as XAS-1) has been observed throughout the probed area followed by the spectrum 2-b (referred to as XAS-2), whereas spectrum like E-3 in Fig. 3d (referred to as XAS-3) is observed at certain local positions. Typically, four parameters have been used to identify the existing valence states in the probed sample: (1) spectral features of L3 and L2, (2) energy positions of L3 and L2 features, (3) the energy difference of L3-L2, and (4) the intensity ratio of L2/L3. As per the visual observation (Fig. 4a), all three components of Fe, that is, Fe0, Fe2+, and Fe3+ are present on the surface of probed SDSS. The calculated intensity ratio of L2/L3 also suggests the presence of all three components.

a Comparison of observed distinct three experimental data (solid lines XAS-1, XAS-2, and XAS-3 correspond to 2-a, 2-b and E-3 in Figs. 2 and 3) with the simulated XAS spectra for Fe, Fe2+, Fe3+ octahedral with a crystal field value of 1.0 eV and 1.5 eV, respectively; b–d Measured experimental data (XAS-1, XAS-2, XAS-3) and the corresponding optimized LCF data (black solid line), and e comparison of XAS-3 spectrum with Fe3O4 (mixed Fe states) and Fe2O3 (pure Fe3+) standards.

Linear combination fitting (LCF) of the three standards40,41,48 are employed to have a quantitative picture of iron oxide compositions. LCF has been implemented for the three chosen Fe L-edge XAS spectra showing the highest contrast, that is, XAS-1, XAS-2, and XAS-3, as shown in Fig. 4b–d. For the LCF fitting, 10% Fe0 is considered for all the cases as we have observed a small shoulder in all the data along with the fact that Fe metal is the main component of steel. Indeed, the probation depth of X-PEEM for Fe (~6 nm)49 is bigger than the estimated oxidation layer thickness (slightly > 4 nm), allowing detection of signal from the iron matrix (Fe0) beneath the passivation layer. Different combinations of Fe2+ and Fe3+ were carried out to find the best possible solution for the observed experimental data. Figure 4b shows the combination of Fe2+ and Fe3+ for the XAS-1 spectrum, wherein the fractions of Fe2+ and Fe3+ are found similar ~45%, suggesting a mixed oxidation state of Fe. Whereas, for the XAS-2 spectrum, the percentage of Fe2+ and Fe3+ respectively changes to ~30 and 60%. The Fe2+ is less abundant than the Fe3+. The ratio of 1:2 for Fe2+ to Fe3 refers to the possible formation of Fe3O4 which has the same ratio between the Fe ions. Furthermore, for the spectrum the XAS-3, the percentages of Fe2+ and Fe3+ change to ~10 and 80%, suggesting higher conversion of Fe2+ to Fe3+. As noticed above, the Fe3+ may originate from α-Fe2O3, γ-Fe2O3, or Fe3O4. To understand the most probable origin of Fe3+, the XAS-3 spectrum is plotted along with different Fe3+ standards in Fig. 4e showing similarity with all the two standards when considering peak B. However, the intensity of shoulder peak (A: arise from Fe2+) and intensity ratio of B/A suggest that XAS-3 spectrum is close to but not well matched with that of γ-Fe2O3. Compared to bulk γ-Fe2O3, the Fe 2p XAS for SDSS exhibits a slightly higher intensity for peak A (Fig. 4e), suggesting higher intensity of Fe2+. Despite the similarity of XAS-3 spectrum with γ-Fe2O3, wherein Fe3+ exist both at Oh and Td site, such identifications of different valence state and coordination solely from L2,3 edge or L2/L3 intensity ratio are still a subject of ongoing discussion due to the complexity of various factors affecting the final spectrum41.

Global chemical inhomogeneities

In addition to the above spectroscopic distinctions of chemical states at selected regions of interest, global chemical heterogeneities of key elements, Cr and Fe, have been assessed by using a K-means clustering method to classify all XAS spectra obtained on the sample surfaces. Profiles of Cr L edge are set to form two optimal clusters spatially distributed in both hot-deformed and cold-rolled samples shown in Fig. 5. It is evident that no local structural changes are perceived since the two centroids of Cr XAS spectra are rather similar. The shapes of these spectra for two clusters are nearly identical to those corresponding to Cr2O342, meaning the Cr2O3 layers are relatively evenly placed on the SDSS.

For the illustration of a more complex Fe L edge map, four and five optimized clusters along with their related centroids (spectral profiles) are used for hot-deformed and cold-rolled samples, respectively. Accordingly, the percentage (%) of Fe2+ and Fe3+ can be obtained by the LCF fitting shown in Fig. 4. A pseudo electrode potential Epseudo vs. Fe0 is applied to elucidate the microscopical chemical inhomogeneity of the surface oxide film. The Epseudo is roughly estimated by the rule of mixtures,

wherein, \(\rm{E}_{\rm{Fe}/\rm{Fe}^{2 + (3 + )}}\) is the standard electrode potential for \(\rm{Fe} + 2e^ - \to \rm{Fe}^{2 + (3 + )}\), 0.440 and 0.036 V, respectively. The region with a lower potential has a higher content of Fe3+ compounds. The potential profile in the hot-deformed sample shows a lamellar-like distribution with a maximal variation of about 0.119 V (Fig. 6a, b). This potential distribution is closely related to the surface topography (Fig. 6a). No other position-related change inside the potential lamellar is observed (Fig. 6b). In contrast, the non-uniform character of the pseudopotential can be observed in the cold-rolled SDSS (Fig. 6c, d) for connections of dissimilar oxide with different Fe2+ and Fe3+ contents. Fe3+ oxide and/or (oxy)hydroxide are the main constituents of rust in steels and are permeable to oxygen and water50. Fe3+ rich islands are seen to be distributed locally in this case and can be considered as already-corroding areas. Meanwhile, the gradients in the potential field not the absolute values of potentials can be considered as an indicator to locate actively corroding areas51. This uneven distributions of Fe2+ and Fe3+ on the surface of cold-rolled SDSS could modify the local chemistry and provide more actual active surface areas in the breakdown of oxide films and corrosion reaction to allow continuous corrosion of metallic matrix beneath, leading to intrinsic heterogeneity and reducing the protective performance of the passive layer.

K-means cluster of the Fe L2,3-edge region and corresponding XAS centroids for a–c hot-deformed and d–f cold-rolled SDSS of X-PEEM. a, d The K-means cluster map superimposed on X-PEEM image. Calculated pseudo electrode potential (Epseudo) is mentioned along with K-means cluster map. Brightness, like the colors in Fig. 2, in the X-PEEM image is proportional to the X-ray absorption intensity.

Corrosion due to chemical inhomogeneity of Fe

The relatively uniform Cr but varied Fe chemical states place a different origin of oxide film breakdown and corrosion scheme in the hot-deformed and cold-rolled Ce-2507. A detailed insight has been drawn to understand this property of cold-rolled Ce-2507. Regarding the formation of Fe oxides and hydroxides in ambient air in this work that is closed to be neutral, the reaction is:

Anodic:

Cathodic reaction due to the absorption layer of water with dissolved O252:

and at sites forming Fe hydroxides,

With more dissolved oxygen, oxidation from Fe2+ to Fe3+ happens via

wherein, Fe(OH)2 and Fe(OH)3 can dehydrate to generate FeO, Fe2O3, and Fe3O4.

The above reactions happened in the following scenario based on X-PEEM determinations. The small shoulder corresponding to Fe0 is due to metallic iron beneath. The reaction of Fe metal with the environment gives rise to a layer of Fe(OH)2 (Eq. (5)), raising the Fe2+ signal in Fe L-edge XAS. Continuous exposure to the air leads to the formation of Fe3O4 and or Fe2O3 oxides following Fe(OH)252,53. The two stable species of Fe, i.e., Fe3O4 and Fe2O3 could also be formed in the Cr3+ rich protective layer, of which Fe3O4 prefers a homogeneous and adherent structure. The presence of both can give rise to mixed oxidation states (XAS-1 spectrum). The XAS-2 spectrum corresponds to mainly Fe3O4. Whereas observation of the XAS-3 spectrum at a few locations suggests the complete conversion to γ-Fe2O3. A higher intensity of peak A is resulted from signals from a beneath layer as the deployed X-ray has a penetration depth of ~50 nm.

XAS spectra suggest Fe components in the oxide films having a layered structure, integrating with the Cr oxide layer. In contrast to passivation features due to the local inhomogeneity of Cr2O3 for corrosion17, low corrosion resistance, especially for the cold-rolled sample is observed in the present case despite the homogenous Cr2O3 layer in this work. The observed behavior can be understood as the non-uniformity in the chemical oxidation state in the top layer (Fe) affecting the corrosion properties. Since homogenous stoichiometry of the top layer (Fe oxide) and the beneath layer (Cr oxide)52,53 give rise to better interaction (adhesion) between the two, leading to slow transport of metal or oxygen ions in the lattice, which in turn will increase the corrosion resistance. Thus, a continuous stoichiometry, that is, a single oxidation state of Fe is preferred over an abrupt stoichiometry change. For the hot-deformed SDSS, the surface is more uniform with a denser protective layer leading to better corrosion resistance. Whereas, for the cold-rolled SDSS, the existence of Fe3+ rich islands beneath the protective layer destroy the integrity of the surface and produce a galvanic corrosion with the nearby matrix, which leads to the drastic decrease of the Rp (Table 1) in the EIS spectrum and reduction of its corrosion resistance. Thus, Fe3+ rich islands distributed locally due to plastic deformation, primarily affect the corrosion resistance performance, a breakthrough of this work. This study thus provides a spectro-microscopic picture of corrosion resistance reduction in the studied SDSS samples by plastic deformation.

Moreover, even though rare earth alloying in duplex steel shows the betterment in their performances, the interaction of this additive element with the steel matrix individuals in regard to corrosion behavior remains elusive according to the spectro-microscopic observations. Appearances of the Ce signal (via M edge XAS) only at a few locations in the cold-rolled but vanishing in the hot-deformed SDSS suggest the local precipitation of Ce in the steel matrix rather than the homogenous alloying. Though not bringing substantial enhancements to mechanical properties of SDSS6,7, the presence of the rare-earth element reduces sizes of inclusion and is believed to suppress pitting corrosion at the initial sites54.

To summarize, this work unveils the impacts of surface inhomogeneity on corrosion of the Ce-modified 2507 SDSS by quantifying the chemical abundances of the compositions at the nanoscale. We answered a question that why stainless steels corrode even when they are covered with protective oxide layers via quantitively investigating their microstructures, element chemical states on surfaces, and using the signal processing method of K-means clustering. It is found that the Fe3+ rich islands, including its octahedral and tetrahedral coordination over the throughout features of mixed Fe2+/Fe3+, serve as the breakdown source of oxide film then the source of corrosion in cold-rolled SDSS. The Fe3+ dominated nano-islands lead to a poor corrosion resistance even in the presence of adequate stoichiometric Cr2O3 passive layers. Besides methodological progress in identifying the impact of nano-scaled chemical inhomogeneity on corrosion, the present work is hoped to inspire engineering processes to enhance the corrosion resistance of stainless steels during steelmaking.

Methods

Materials

To prepare Ce-2507 SDSS ingot for this study, mixed ingredients including Fe-Ce master alloy sealed by pure iron pipe were melted in a 150 kg intermediate frequency induction furnace to obtain molten steel and poured into a cast mould. The measured chemical composition (wt.%) is listed in Supplementary Table 2. The cast ingots were hot forged into blocks first. Subsequently, the steel in a solid solution state was obtained by annealing at 1050 °C for 60 min, and then was water quenched to room temperature. The studied samples have been investigated in detail using TEM and EBSD to study the phases, grain sizes, and morphology. More details about the sample and the production process can be found elsewhere6,7.

Deformation at different temperatures

Cylindrical specimens (ϕ10 mm × 15 mm) for hot-compression were machined with the axes of the cylinder being parallel to the deformation direction of the block. High-temperature compression was carried out using Gleeble-3800 thermo-simulation machine at various temperatures such as 1000–1150 °C under constant strain rates in the range of 0.01–10 s−1. Before deformation, specimens were heated at chosen temperatures at the rate of 10 °C s−1 and held for 2 min to eliminate any thermal gradients. After attaining temperature uniformities, the specimens were deformed to a true strain value of 0.7. After deformations, the specimens were immediately quenched by water to retain the deformed structure. The quenched specimens were then cut parallel to the compression direction. For this particular study, we have chosen specimens with hot deformation conditions as 1050 °C, 10 s−1 because of the observed higher microhardness than other samples7.

A three-phase asynchronous two-high deformation mill LG-300 was used to conduct room temperature cold rolling up to a deformation level of 90% (engineering strain) for the solid-solution Ce-2507 block-shaped (80 × 10 × 17 mm3) specimen, which gives the best mechanical performances among all other levels of deformation6. The deformation speed and the thickness reduction per single path were used as 0.2 m s−1 and 5%, respectively.

Electrochemical measurements

The Autolab PGSTAT128N electrochemical workstation was employed to perform electrochemical measurements of the SDSS after cold rolling to a 90% thickness reduction (equivalent true stain is 1.0) and after hot compression to a true strain value of 0.7 at 1050 oC, 10 s−1. The workstation has a three-electrode cell with a saturated calomel electrode as the reference electrode, a graphite counter electrode, and the SDSS specimens as the working electrode. Samples were cut into ϕ11.3 mm cylinders with a Cu wire soldered to the lateral side. Then the samples were mounted into epoxy resin, leaving a working exposure area of 1 cm2 as the working electrode (bottom surface of the cylindrical samples). To avoid producing crevices, care was taken during the curing of epoxy resin and following grinding and polishing procedures. The working surfaces were ground and polished using 1 µm diamond polishing suspension, cleaned with distilled water and ethanol, and dried in cool air. Prior to the electrochemical measurements, the as-polished samples were allowed to stand in ambient air for days for a naturally formed oxide film. Hydrous FeCl3 (6.0 wt%) solution stabilized by HCl to a pH = 1.0 ± 0.01 was used to promote corrosion of stainless steels55 due to its aggressive environment in the presence of chloride ions with the strong oxidizing ability and low pH, as suggested by ASTM G48 and A923 standards. The specimens were immersed in the test solution for 1 h before any measurement to achieve near-steady state. The impedance measurements ranged from the frequencies of 1 × 105 ~ 0.1 Hz with an amplitude of 5 mV at open circuit potential (OCP) of 0.39, 0.33, and 0.25 VSCE for solid solution, hot-deformed, and cold-rolled sample, respectively. Each electrochemical test for any specimen had been repeated at least three times under identical conditions to ensure data reproducibility.

HE-SXRD and X-PEEM

To carry out HE-SXRD measurements, rectangular blocks of dimension 1 × 1 × 1.5 mm3 duplex steels were measured to quantify the phase constituents at the Brockhouse High Energy Wiggler Beamline, CLS, Canada56. The data collection was performed in Debye-Scherrer or transmission geometry at room temperature. The X-ray wavelength calibrated from a LaB6 calibrant was 0.212561 Å corresponding to 58 keV much higher than the one of Cu Kα (8 keV) conventionally used as the incident source of lab XRD. The sample was placed at a distance of 740 mm from the detector. The probed volume of each specimen was 0.2 × 0.3 × 1.5 mm3, determined by the beam size and thickness of the specimen. An exposure time of 0.3 s was used along with 120 frames for each of these data collection using a Perkin Elmer area detector, a flat panel x-ray detector, 200 μm pixel, 40 × 40 cm2.

The X-PEEM measurement on these two selected model systems was carried out at the PEEM endstation of Beamline MAXPEEM at MAX IV laboratory (Lund, Sweden). Samples were prepared in the same way as that for electrochemical measurements. Before being exposed to synchrotron photons, the as-prepared samples had been aged in ambient air for days and degassed in an ultrahigh vacuum chamber. The energy resolution of the beamline was obtained by measuring the ion yield spectrum at the N 1 s to 1\(\pi _g^ \ast\) excitation region around hv = 401 eV in N2 with photon energy dependence of E3/2,57. The fit of the spectrum gave a ∆E (spectrum linewidth) of ~0.3 eV at the measured energy range. Therefore, the beamline energy resolution was estimated to be E/∆E = 700 eV/0.3 eV > 2000 and flux ≈1012 ph/s by utilizing a modified SX-700 monochromator with a Si 1200-line mm−1 grating for the Fe 2p L2,3 edge, Cr 2p L2,3 edge, Ni 2p L2,3 edge, and Ce M4,5 edge. The photon energy was scanned with a 0.2 eV step. At each energy, a PEEM image was recorded with a TVIPS F-216 optical fiber-coupled CMOS detector with 2 by 2 binning, which provides 1024 × 1024 pixels in the field of view of 20 μm. The exposure time of images was 0.2 s with an average number of 16 frames. The imaging energy of photoelectrons was chosen to provide the highest secondary electron signal. All measurements were performed at perpendicular incidence angles with linearly polarized photon beams. More details of the measurements can be found in the previous study58. Probation depths of the present method are estimated to ~ 4–5 nm for Cr signal and ~ 6 nm for Fe following studies of the total electron yield (TEY) detection mode59 and its application in the X-PEEM49. The depth for Cr is very close to oxidation film thickness (~4 nm)60,61 and the one for Fe is more than the thickness. The XAS collected next to the Fe L-edges is a mixture of XAS of the iron oxides and Fe0 from the matrix. In the former case, intensities of emitted electrons arise from all possible types of electrons which contribute to the TEY. As for the signal of the pure iron, however, electrons require higher kinetic energies to pass through oxide layer, reach the surface and then are collected by the analyzer. In this case, the Fe0 signal is mainly due to LVV Auger electrons, and the secondary electrons ejected by them49. Moreover, TEY intensities contributed by these electrons are attenuated during the electron escaping paths49, further lowering the Fe0 spectral signatures in the iron XAS plots.

K-means clustering for statistical map of XAS spectra

The integration of data mining in the data cube (X-PEEM data) is a crucial step to extract the relevant information (chemical or physical properties) in a multivariate approach. The K-means clustering has widely been applied in several fields, including machine vision, image processing, unsupervised pattern recognition, artificial intelligence, and classification analysis24. For instance, the K-means clustering was well-established in hyperspectral image data clustering62. In principle, for data with several objects, the K-means algorithm could easily cluster them based on their attribute’s information (photon energy characteristic). The K-means clustering is an iterative algorithm for portioning the data into K disjoint groups (clusters), where each pixel belongs to a specific cluster depending on the spatial distribution of the chemical heterogenty in the steel microstructure composition. K-means algorithm involves two phases: in the first phase, the K centroid is calculated, while in the second phase, each point is assigned to the cluster which has an adjacent centroid. The cluster centroid is defined as an arithmetic mean of the data points (XAS spectra) of that cluster. Different distances exist to define the adjacent centroid as the Euclidean distance. For an input image px,y (with x and y are pixels resolution), and the CK is cluster centroids; then this image can be segmented (clustered) into K clusters by K-means63. The summarized steps of the algorithm for K-means clustering are:

Step 1. Define the data partition by selecting the K cluster centroids.

Step 2. Calculate the memberships of all pixels based on the current centroids. For example, it is calculated by Euclidean distance, d, between the center and each pixel:

Step 3. Assign each pixel to the closest centroid. Then recalculate the positions of the K centroids as follows:

Step 4. Repeat the process (Eqs. (7) and (8)) until the convergence of centroids. The final clustering quality results are highly related to the optimum selection of the initial centroid63. For the structure of steel image PEEM data, in general, X (x × y × λ) is a 3-D array data cube, while x and y axes represent spatial information (pixels resolution) and the λ axis corresponds to the photon energy spectral pattern. The K-means algorithm is used to investigate the region of interest in X-PEEM data by employing the partitioning of pixels (cluster or sub-pieces) according to their spectral signature and extract the best centroid (XAS spectral profiles) for each analyte (cluster). It is applied to study the spatial distribution, local spectroscopic variation, oxidation behavior, and chemical state. The K-means cluster algorithm is, for instance, used for Fe L-edge and Cr L-edge regions in the hot-deformed and cold-rolled X-PEEM. Different number of K clusters (microstructural regions) were tested to find the optimum clusters and centroids. Displaying the figures, the pixels were reassigned to the proper cluster centroids. Each color distribution corresponded to one cluster center exhibiting the spatial arrangement of chemical or physical entities. The extracted centroids are linear combinations of the pure spectra.

Data availability

The data that support the findings of this study are available from the corresponding author, W.C., upon reasonable request.

References

Sieurin, H. & Sandström, R. Fracture toughness of a welded duplex stainless steel. Eng. Fract. Mech. 73, 377–390 (2006).

Adams, F. V., Olubambi, P. A., Potgieter, J. H. & Van Der Merwe, J. Corrosion resistance of duplex stainless steels in selected organic acids and organic acid/chloride environments. Anti-Corros. Methods Mater 57, 107–117 (2010).

Barella, S. et al. Corrosion and oxidation behavior of a Fe-Al-Mn-C duplex alloy. Materials 12, 2572 (2019).

Levkov, L., Shurygin, D., Dub, V., Kosyrev, K. & Balikoev, A. New generation of super duplex steels for equipment gas and oil production. E3S Web Conf. 121, 04007 (2019).

Kingklang, S. & Uthaisangsuk, V. Investigation of hot deformation behavior of duplex stainless steel grade 2507. Metall. Mater. Trans. A 48, 95–108 (2017).

Zhou, T. et al. Controlled cold rolling effect on microstructure and mechanical properties of Ce-modified SAF 2507 super duplex stainless steel. Mater. Sci. Eng. A 766, 138352 (2019).

Zhou, T. et al. Hot-deformation-induced structural and mechanical properties of Ce-modified SAF 2507 super duplex stainless steel. J. Mater. Res. Technol. 9, 8379–8390 (2020).

Zheng, Z., Wang, S., Long, J., Wang, J. & Zheng, K. Effect of rare earth elements on high temperature oxidation behaviour of austenitic steel. Corros. Sci. 164, 108359 (2020).

Li, Y., Yang, G., Jiang, Z., Chen, C. & Sun, S. Effects of Ce on the microstructure and properties of 27Cr-3.8Mo-2Ni super-ferritic stainless steels. Ironmak. Steelmak 47, 67–76 (2020).

Li, M. et al. Study of biocompatibility of medical grade high nitrogen nickel-free austenitic stainless steel in vitro. Mater. Sci. Eng. C 43, 641–648 (2014).

Vignal, V., Krawiec, H., Heintz, O. & Mainy, D. Passive properties of lean duplex stainless steels after long-term ageing in air studied using EBSD, AES, XPS and local electrochemical impedance spectroscopy. Corros. Sci. 67, 109–117 (2013).

Wang, Y., Cheng, X. & Li, X. Electrochemical behavior and compositions of passive films formed on the constituent phases of duplex stainless steel without coupling. Electrochem. Commun. 57, 56–60 (2015).

Gardin, E., Zanna, S., Seyeux, A., Allion-Maurer, A. & Marcus, P. Comparative study of the surface oxide films on lean duplex and corresponding single phase stainless steels by XPS and ToF-SIMS. Corros. Sci. 143, 403–413 (2018).

Shi, X. et al. Quantitative assessment of structural and compositional colors induced by femtosecond laser: a case study on 301LN stainless steel surface. Appl. Surf. Sci. 484, 655–662 (2019).

Lu, Y. et al. Nanosecond laser coloration on stainless steel surface. Sci. Rep. 7, 7092 (2017).

Långberg, M. et al. Lateral variation of the native passive film on super duplex stainless steel resolved by synchrotron hard X-ray photoelectron emission microscopy. Corros. Sci. 174, 108841 (2020).

Ma, L., Wiame, F., Maurice, V. & Marcus, P. Origin of nanoscale heterogeneity in the surface oxide film protecting stainless steel against corrosion. npj Mater. Degrad. 3, 29 (2019).

Yamanaka, K. et al. Surface evolution and corrosion behaviour of Cu-doped carbide-reinforced martensitic steels in a sulfuric acid solution. npj Mater. Degrad. 5, 43 (2021).

Pan, J. Studying the passivity and breakdown of duplex stainless steels at micrometer and nanometer scales – the influence of microstructure. Front. Mater. 7, 133 (2020).

Långberg, M. et al. Redefining passivity breakdown of super duplex stainless steel by electrochemical operando synchrotron near surface X-ray analyses. npj Mater. Degrad. 3, 22 (2019).

Maurice, V. & Marcus, P. Current developments of nanoscale insight into corrosion protection by passive oxide films. Curr. Opin. Solid State Mater. Sci. 22, 156–167 (2018).

Singh, H. et al. Unveiling interactions of non-metallic inclusions within advanced ultra-high-strength steel: a spectro-microscopic determination and first-principles elucidation. Scr. Mater. 197, 113791 (2021).

Shi, X. et al. Metallic contact between MoS2 and Ni via Au nanoglue. Small 14, 1704526 (2018).

Kodinariya, T. M. & Makwana, P. R. Review on determining of cluster in K-means clustering. Int. J. 1, 90–95 (2016).

Jiang, P. et al. Microstructural influence on corrosion behavior of MgZnGe alloy in NaCl solution. J. Alloys Compd. 783, 179–192 (2019).

Homayun, B. & Afshar, A. Microstructure, mechanical properties, corrosion behavior and cytotoxicity of Mg-Zn-Al-Ca alloys as biodegradable materials. J. Alloys Compd. 607, 1–10 (2014).

Srinivasan, N. et al. Plastic deformation and corrosion in austenitic stainless steel: a novel approach through microtexture and infrared spectroscopy. Corros. Sci. 111, 404–413 (2016).

Kamachi Mudali, U. et al. On the pitting corrosion resistance of nitrogen alloyed cold worked austenitic stainless steels. Corros. Sci 44, 2183–2198 (2002).

Li, Y. Z., Wang, X. & Zhang, G. A. Corrosion behaviour of 13Cr stainless steel under stress and crevice in 3.5 wt.% NaCl solution. Corros. Sci. 163, 108290 (2020).

Lv, J., Guo, W. & Liang, T. The effect of pre-deformation on corrosion resistance of the passive film formed on 2205 duplex stainless steel. J. Alloys Compd. 686, 176–183 (2016).

Lebrini, M. et al. Corrosion protection of galvanized steel and electroplating steel by decanoïc acid in aqueous solution: Electrochemical impedance spectroscopy, XPS and ATR-FTIR. Corros. Sci. 51, 1201–1206 (2009).

Jorcin, J. B., Orazem, M. E., Pébère, N. & Tribollet, B. CPE analysis by local electrochemical impedance spectroscopy. Electrochim. Acta 51, 1473–1479 (2006).

Ramya, S., Nanda Gopala Krishna, D. & Kamachi Mudali, U. In-situ Raman and X-ray photoelectron spectroscopic studies on the pitting corrosion of modified 9Cr-1Mo steel in neutral chloride solution. Appl. Surf. Sci. 428, 1106–1118 (2018).

Wang, S. et al. In-situ quantification and density functional theory elucidation of phase transformation in carbon steel during quenching and partitioning. Acta Mater. 221, 117361 (2021).

Lee, J. S., Fushimi, K., Nakanishi, T., Hasegawa, Y. & Park, Y. S. Corrosion behaviour of ferrite and austenite phases on super duplex stainless steel in a modified green-death solution. Corros. Sci. 89, 111–117 (2014).

Peguet, L., Malki, B. & Baroux, B. Influence of cold working on the pitting corrosion resistance of stainless steels. Corros. Sci. 49, 1933–1948 (2007).

Ralston, K. D. & Birbilis, N. Effect of grain size on corrosion: a review. Corrosion 66, 075005–075005-13 (2010).

Balusamy, T., Kumar, S. & Sankara Narayanan, T. S. N. Effect of surface nanocrystallization on the corrosion behaviour of AISI 409 stainless steel. Corros. Sci. 52, 3826–3834 (2010).

Roese, P., Keutner, C., Berges, U., Espeter, P. & Westphal, C. Photoemission electron microscopy as a tool for studying steel grains. Metall. Mater. Trans. A 48, 1484–1490 (2017).

Heijboer, W. M. et al. Redox behaviour of over-exchanged Fe/ZSM5 zeolites studied with in-situ soft X-ray absorption spectroscopy. Phys. Chem. Chem. Phys. 5, 4484–4491 (2003).

De Groot, F. M. F. et al. 1s2p Resonant inelastic X-ray scattering of iron oxides. J. Phys. Chem. B 109, 20751–20762 (2005).

Figueiredo, M. O. et al. Chemical study of passivating chromium oxide films by soft X-ray absorption spectroscopy. Analyst 119, 609–611 (1994).

Yitamben, E. N. et al. Correlation between morphology, chemical environment, and ferromagnetism in the intrinsic-vacancy dilute magnetic semiconductor Cr-doped Ga2Se3/Si(001). Phys. Rev. B 83, 045203 (2011).

Stavitski, E. & De Groot, F. M. F. The CTM4XAS program for EELS and XAS spectral shape analysis of transition metal L edges. Micron 41, 687–694 (2010).

Lee, H. J. et al. Valence states and occupation sites in (Fe,Mn)3O4 spinel oxides investigated by soft x-ray absorption spectroscopy and magnetic circular dichroism. J. Condens. Matter Phys. 20, 295203 (2008).

Wan, S. et al. Chemical nature of alkaline polyphosphate boundary film at heated rubbing surfaces. Sci. Rep. 6, 26008 (2016).

Sarveena, S. et al. Synthesis, phase composition, Mössbauer and magnetic characterization of iron oxide nanoparticles. Phys. Chem. Chem. Phys. 18, 9561–9568 (2016).

Suturin, S. M. et al. Tunable polymorphism of epitaxial iron oxides in the four-in-one ferroic-on-GaN system with magnetically ordered α-, γ-, ɛ-Fe2O3, and Fe3O4 layers. Phys. Rev. Mater 2, 073403 (2018).

Frazer, B. H., Gilbert, B., Sonderegger, B. R. & De Stasio, G. The probing depth of total electron yield in the sub-keV range: TEY-XAS and X-PEEM. Surf. Sci. 537, 161–167 (2003).

Tamura, H. The role of rusts in corrosion and corrosion protection of iron and steel. Corros. Sci. 50, 1872–1883 (2008).

Nazarov, A. & Thierry, D. Application of Volta potential mapping to determine metal surface defects. Electrochim. Acta 52, 7689–7696 (2007).

Tardio, S., Abel, M.-L., Carr, R. H., Castle, J. E. & Watts, J. F. Comparative study of the native oxide on 316L stainless steel by XPS and ToF-SIMS. J. Vac. Sci. Technol., A 33, 05E122 (2015).

Detriche, S. et al. XPS fast depth profile of the native oxide layers on AISI 304, 316 and 430 commercial stainless steels and their evolution with time. J. Electron Spectrosc. Relat. Phenom. 243, 146970 (2020).

Liu, C. et al. Effect of inclusions modified by rare earth elements (Ce, La) on localized marine corrosion in Q460NH weathering steel. Corros. Sci. 129, 82–90 (2017).

Tobias, R. F. & Nobe, K. Electrochemical behavior of rotating iron disks: effect of Fe(III). J. Electrochem. Soc. 122, 65–70 (1975).

Gomez, A., Dina, G. & Kycia, S. The high-energy x-ray diffraction and scattering beamline at the Canadian light source. Rev. Sci. Instrum. 89, 063301 (2018).

Aksela, S. et al. Finnish beamline at MAX‐laboratory: progress in the photon energy resolution. Rev. Sci. Instrum. 66, 1621–1623 (1998).

Cao, W. et al. X-ray photoemission electron microscope determination of origins of room temperature ferromagnetism and photoluminescence in high Co-content CoxZn1-xO films. Surf. Rev. Lett. 21, 1450058 (2014).

Abbate, M. et al. Probing depth of soft x‐ray absorption spectroscopy measured in total‐electron‐yield mode. Surf. Interface Anal. 18, 65–69 (1992).

Hamada, E. et al. Direct imaging of native passive film on stainless steel by aberration corrected STEM. Corros. Sci. 52, 3851–3854 (2010).

Fredriksson, W., Malmgren, S., Gustafsson, T., Gorgoi, M. & Edström, K. Full depth profile of passive films on 316L stainless steel based on high resolution HAXPES in combination with ARXPS. Appl. Surf. Sci. 258, 5790–5797 (2012).

Marini, F. & Amigo, J. M. Unsupervised exploration of hyperspectral and multispectral images. Data Handl. Sci. Technol 32, 93–114 (2020).

Dhanachandra, N., Manglem, K. & Chanu, Y. J. Image segmentation using K-means clustering algorithm and subtractive clustering algorithm. Procedia Comput. Sci. 54, 764–771 (2015).

Acknowledgements

The Academy of Finland (grant #311934) and National Natural Science Foundation of China (grant numbers U1804146 and 52111530068) are acknowledged for the financial supports. We thank the crew of the MAX IV laboratory for their support during the beamtime operation. Part of the research described in this paper was performed at the Canadian Light Source, a national research facility of the University of Saskatchewan, which is supported by the Canada Foundation for Innovation (CFI), the Natural Sciences and Engineering Research Council (NSERC), the National Research Council (NRC), the Canadian Institutes of Health Research (CIHR), the Government of Saskatchewan, and the University of Saskatchewan. The Center of Microscopy and Nanotechnology of the University of Oulu is also acknowledged for in house XRD characterizations.

Author information

Authors and Affiliations

Contributions

H.S., E.R. and W.C. conceived the study and H.S. developed the methodology under the project initialization and funding acquisitions from Y.X., J.K. and M.H., H.S., E.R., Y.N. and A.Z. conducted X-PEEM, H.Y. and T.Z. performed electrochemical measurement, G.K. carried out HE-SXRD, H.S., E.R., S.W., M.K. and W.C. analyzed, interpreted the results, and wrote the initial manuscript, F.M.F.G. offered advice and simulated XAS concerning the interpretation of XAS results. All authors discussed the results and contributed to the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Singh, H., Xiong, Y., Rani, E. et al. Unveiling nano-scaled chemical inhomogeneity impacts on corrosion of Ce-modified 2507 super-duplex stainless steels. npj Mater Degrad 6, 54 (2022). https://doi.org/10.1038/s41529-022-00263-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41529-022-00263-z

- Springer Nature Limited