Abstract

The initial microstructure of a wide range of structural materials is conditioned by thermo-mechanical treatments such as hot-working, tempering, or solution annealing. At the elevated temperatures associated with these treatments the dislocation microstructure evolves, usually decreasing in density through a process known as static recovery. Despite its technological relevance, static recovery is not fully characterized from a theoretical standpoint, with even the controlling mechanisms subject to debate. In this study, a climb-enabled discrete dislocation dynamics (DDD) capability is leveraged to explore the kinetics of static recovery in pure Fe when controlled by dislocation climb. Quantitative data from these simulations is used to develop a revised static recovery law, and provides the parameters appropriate for predictive microstructure models in Fe. This law differs from previous analytical derivations invoking climb of dislocations, following the logarithmic trends typical of experimental observations where prior work did not. Direct comparison between the recovery law derived from DDD to experimental recovery data in alpha Fe shows strong agreement across a range of temperatures, and suggests that climb is the controlling mechanism for static recovery in pure metals.

Similar content being viewed by others

Introduction

The plastic response of a structural metal is strongly influenced by microstructural defects, and dislocations in particular. Deformation is often mediated by slip, such that the density of dislocations, alongside their mobility and interactions with obstacles largely controls yield strength, ductility, and creep resistance1. The thermo-mechanical processing history of a metal governs many aspects of the microstructure of engineering alloys including dislocation and obstacle densities, and can be tuned to optimize performance. From the theoretical perspective, significant effort has been devoted to understanding the generation and annihilation of dislocations during loading at relatively high strain rates and low temperatures, (e.g. cold-work). Though a complete understanding of the dislocation patterns which emerge in these conditions remains elusive, models for the evolution of dislocation density and hardening are strikingly reliable2,3,4. These constitutive laws for dynamic recovery enable crystal plasticity -based predictions of alloy and component performance in service conditions5. However, significantly less attention has been given in recent years to static recovery – which is driven by thermal activation and occurs even in the absence of external loading – despite its presumptive importance in high temperature applications such as creep loading6,7,8,9 as well as a variety of important processing and fabrication techniques such as tempering, hot-working, and additive manufacturing10,11,12,13,14,15.

Early (and more recent) investigations of static recovery induced strain hardening through cold-work, and then examined the recovery of such hardening following an anneal16,17,18,19,20. This gives access to some indication of the magnitude and kinetics of dislocation recovery, with a strong indication that while the process was thermally activated the effective barrier was density dependent21. The mechanism which controls static recovery is less clear, with cross-slip, jog dragging, solute dragging, non-conservative climb, and pipe diffusion all considered as possibilities. Over time, a number of recovery laws analogous to those for dynamic recovery have been proposed, both from experimental observations and theoretical considerations19,21. Each theory-based law is formulated on the basis of a different controlling mechanism, some of which match experimentally observed trends, while others do not. Despite this, there remains no clear evidence of which mechanism is dominant. To further complicate matters, these laws are typically derived in idealized geometries involving infinite straight dislocations which do not necessarily represent realistic networks. At present, it is difficult to select an appropriate form of recovery law, with no clear predictive means of tuning it to a particular materials system for use in engineering scale applications.

This study revisits the static annealing experiments from a theoretical perspective with the use of discrete dislocation dynamics (DDD), applied to high purity iron. As with the constitutive and recovery laws, applications of DDD tend to focus on monotonic loading, strain hardening, and yield22,23,24,25,26,27,28,29,30,31. We introduce a DDD capability to describe the climb of generalized dislocation geometries (including mixed character segments and junctions) through bulk vacancy transport in a manner which accounts for heterogeneity in the dislocation arrangement. This isolates the kinetics of static recovery within a complex dislocation network when climb is the rate controlling mechanism. To this end, virtual microstructures of varying initial density are subjected to static annealing while measuring the decline in dislocation density as recovery processes activate. Because climb is the only activated mechanism, the kinetics and density dependence extracted from these virtual annealing experiments can shed light on the importance of climb in the recovery process, and which of the extant constitutive models best describes the observed responses.

The dislocation dynamics approach developed for this study can quantify climb for complex dislocation arrangements. Further, to assess the effect of configuration explicitly, it is applied to several possible dislocation structures ranging from homogeneous to heterogeneous, and including or excluding geometrically necessary dislocations (GND). Early attempts to address climb in DDD were restricted to fewer than three dimensions or segments of pure edge character and were not compatible with a nodal framework that allows mixed character segments32,33,34,35,36. DDD simulations which include climb have typically been restricted to simple configurations such as isolated loops or single dislocations rather than networks, even the more sophisticated recent approaches37. The kinematic algorithm for climb proposed in the present study operates within a nodal framework and strictly maintains the glide planes of each segment, providing an ability to represent climb for junctions in addition to mixed character segments. The framework also incorporates climb kinetics based on a complete solution to the vacancy transport problem which respects the configuration of the network and point defect interactions with the strain field, allowing accurate descriptions of climb in highly heterogeneous networks38,39.

In what follows, we outline this approach to investigating static recovery and discuss the results. First, we introduce and describe the stages of the virtual experiment beginning with the generation of initial networks with varying characteristics, and followed by the annealing stage itself. Then, we give a qualitative description and quantitative analysis of the recovery process during the annealing stage. Though dependent on conditions, reductions in density of up to 70% can be achieved in the present framework at a reasonable computational cost. Next, we compare the recovery trends from DDD to the previously proposed recovery laws and demonstrate that climb-based recovery clearly falls into the experimentally observed logarithmic family of equations - in contrast to prior analytical considerations. Accordingly, we pursue an alternative approach to deriving the analytical estimate for recovery due to climb, which reduces to one of the existing models at high density and another at low density, resolving a standing contradiction in the literature. Finally, the static recovery laws formulated in this work and parameterized by the dislocation dynamics simulations are compared directly to the existing experimental data in Fe, showing good agreement and demonstrating that climb is likely the dominant mechanism in static recovery, at least for pure metals.

Results and discussion

Initial dislocation networks

Dislocation networks are generated from quasi-random dislocation seeds subjected to a series of heavy loads followed by a period of relaxation to reach a static configuration. The seed dislocations are large loops of either a circular glide or hexagonal prismatic nature of varied radii with a mean near the box size. The orientation of the crystal with respect to the loading direction is chosen randomly. After the seed dislocations are placed, the system is subjected to three uniaxial loads in series, with each load normal to the previous load. During loading, the seed dislocations activate and interact, leading to a tangled network, which can include junctions and dislocation content in initially unseeded slip systems. Once all three loading stages are complete, the resulting structure is relaxed under zero external stress to reach an equilibrated network. Due to the stochastic nature of the initial seeds and slip system activation during the loading process, densities for the networks as formed are somewhat variable. Network density can be targeted approximately but not precisely controlled. This procedure generates relatively homogeneously distributed networks with segments on a variety of slip systems with a distribution of edge screw and mixed character, which will constitute the standard microstructures in this study.

The rate of recovery could be influenced by configurational aspects of the dislocation network not represented in these networks. In particular, high-density structures in metals which have been heavily cold-worked or have undergone a Martensitic transformation tend to display two particular configuration features not captured here. First, the spatial arrangement of these networks tends to be highly heterogeneous, featuring cell/wall structures in which the density is localized to particular regions (sometimes referred to as patterning). Second is the presence of geometrically necessary dislocations.

To examine the effects of these configurational changes, two variations on the aforementioned microstructure generation formula were introduced to emulate these differences in structure. In the first, a planar region of low dislocation mobility was introduced during loading along each box dimension at the center of the volume in order to concentrate dislocations in these regions and artificially emulate pattern formation. Normal mobility was restored during relaxation, but a heterogenous density is retained, with dislocations concentrated in these zones.

In the second case, a periodic array of dislocations mimicking a low angle grain boundary was added (along the same planes) instead of modifying the mobility. This leaves a geometrically necessary component in the resulting polarized dislocation network, although the initial boundaries are not recognizable in the microstructure after loading and relaxation. All three types of networks are illustrated in Fig. 1.

Standard networks are roughly homogeneous and have no geometrically necessary content (on the scale of the full box). Heterogeneous networks have dislocations concentrated near the box midplanes. Polarized networks are seeded with geometrically necessary dislocations. Standard networks were generated in a variety of box sizes, targeting multiple densities.

In order to access a variety of dislocation densities, a range of simulation volume sizes were used for the standard structures. These were cubes of roughly 250 nm to access high densities near 1015 m−2, 500 nm to target densities closer to 1014 m−2, and 1.5 microns for densities on the order 1013 m−2. The alternative structures were formed in the intermediate-sized box, and tend to be higher in density than their standard counterparts, by a factor of 2–3. This gives 5 categories of microstructures considered in the study, along with 2 additional large-scale simulations with intermediate density in the largest box. A summary of the microstructures generated for this study is given in Table 1, including the box size L, dislocation density ρ, and number of instances N for each. A dimensionless measure of the net dislocation content ρL2 is also given.

Recovery by climb

Each generated structure was subjected to a static anneal under zero applied stress, with vacancy transport kinetics reflecting temperatures in the range 300 to 500 C. This annealing is enabled by allowing the generation and absorption of vacancies at each dislocation segment, such that the dislocations can climb. The annealing simulation includes a full field solution to the vacancy population throughout the simulation volume (described in more detail in the methods section). In the regime of high temperatures or low dislocation densities, the transport of vacancies between segments is mediated primarily by bulk diffusion, and this is fully captured by evolving the vacancy population self-consistently with flux. An example of the vacancy density normalized to thermal equilibrium is shown in Fig. 2 for a slice near the edge of the volume with dislocations running through it. Some dislocations induce a local depletion of vacancies, others create a supersaturation, while others still have little effect at all depending on the climb force operating on the relevant segments. Climb velocities follow from the local vacancy density. The mean density in volumes of this size can vary significantly depending on the dislocation orientations with respect to one another, with the example shown reflecting a supersaturation of defects in the box. Corresponding changes in the osmotic effect which arises from vacancy absorption are embedded naturally in the solution.

Networks which were stable and near equilibrium without climb begin evolving during the anneal when climb is activated. Consequently, the density of dislocations in the network initially drops rapidly, primarily due to dipole annihilation. The networks formed by the loading and relaxation process are often stabilized by the formation of dipoles at various spacings, which (along with other features such as junctions) prevent further relaxation. Such dipoles consist of a pair of dislocations with Burgers vectors that are partly or fully opposed on parallel slip planes. These dislocations are attracted to one another, but cannot annihilate by glide. Once annealing begins and climb is activated, the dislocations climb toward each other until reaching a shared slip plane, at which point the dipole annihilates.

After each dipole annihilation event, the structure often relaxes significantly by glide, leading to further reduction in the dislocation density and significant reorganization of the dislocation network. This is shown qualitatively in Fig. 3, which illustrates the recovery of a standard initial network. Because the glide processes are many orders of magnitude faster than the climb processes for all the temperatures considered in this study, the density reduction in an individual structure exhibits discrete bursts when significant glide is unlocked by an annihilation event. Between the discrete events, recovery occurs more steadily by incremental climb and any associated glide enabled by such climb.

The quantitative dislocation recovery observed in eight standard structures at 500 C is shown in Fig. 4. The initially rapid rate of dislocation recovery tends to decline as the population of nearby dipoles becomes exhausted and dislocations become more widely separated. Accordingly, the slope of the recovery curves tends to flatten out with time. In logarithmically scaled time, the decline appears roughly linear past a point of onset, at least within the recovery regime examined here. This is broadly consistent with experimental observations of strain hardening recovery due to annealing40, which will subsequently be addressed in greater detail.

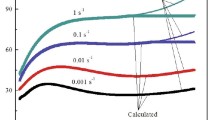

The recovery kinetics change with temperature, which was assessed by simulating select structures at a range of temperatures down to 300 C. In colder environments recovery occurs over longer timescales after a later onset. However, for an individual structure, the slope of the recovery curve in log-time is nearly temperature independent. Given the vacancy transport mediated nature of the climb mechanism, one expects recovery rates to scale directly with the magnitude of self-diffusion. Accordingly, a simple Arrhenius rescaling of time

collapses the recovery pattern into a largely coincident trajectory as shown in Fig. 5. Here, QSD is the activation energy for self-diffusion taken directly as the sum of formation and migration energies as supplied to the DDD model. There is a slight deviation, with recovery at lower temperatures slightly outpacing the expectations based on an Arrhenius dependance alone, particularly at early times. The effective activation energy for recovery is therefore lower than that of self-diffusion, though only slightly. A much more pronounced effect will become apparent when examining initial density and network configuration.

Initial density and configuration

The rate of recovery depends on the initial density of the structure in addition to temperature. The simulations already show a trend of decreasing recovery rate with time, and we have suggested this is due to declining density as recovery proceeds. To demonstrate clearly that density indeed plays a role – rather than just time – we consider a series of recovery simulations initiated from lower density seed microstructures in larger simulation volumes. As shown in Fig. 4, significant statistical variation between structures can occur for the net dislocation content at which most of the simulations were conducted. Therefore, to facilitate comparison between the sets of simulations, densities have been averaged over all simulations of a given type (which are summarized in Table 1). A clear reduction in recovery kinetics is observed for the networks of lower initial density evident in the comparison of three sets of standard structures spanning nearly two orders in initial density in Fig. 6a. To demonstrate that averaging across structures is appropriate, we have also run a limited set of order 1014 m−2 density networks in the largest volume, which are also shown in Fig. 6c, and agree closely with the averaged simulations.

a The effect of initial density in standard networks with higher densities resulting in more rapid recovery, b The effect of network structure with polarized networks experiencing slower recovery while the effect of heterogeneity is ambiguous, and c the minimal effect of simulation volume with the average of many small simulations behaving similarly to a single larger simulation. Error bars indicate twice the standard error of the mean.

Whether the configuration of the initial structure influences recovery is a more subtle matter and motivates the generation of the heterogenous and polarized networks. Due to the nature of the generation processes, these networks tend to be of significantly higher density as formed compared to their standard counterparts. As such, fewer of each were examined to construct a representative sample. The recovery of each of these types of networks is also shown in Fig. 6b. It is clear that recovery kinetics of polarized networks (bearing geometrically necessary dislocations) are slowed compared to non-polarized counterparts. Whether the faster recovery in the heterogeneous networks is due to configuration or simply higher overall density is a more complex question. Addressing this requires a recovery law applicable to the various cases, one which will now be formulated from the kinetics observed in these ddd simulations.

Static recovery laws

The purpose of a recovery law is to describe how dislocation density in a material (on average) evolves deterministically. Dislocation density is typically described by an equation of the form

for a material subjected to a strain rate \(\dot \varepsilon\). The first two terms represent dislocation storage and dynamic recovery respectively and have been well studied in the context of strain hardening. The third term represents static recovery, which has received significantly less attention and is more poorly understood, but is the relevant contributor here. Over time, a number of models have been proposed to describe the temperature and density dependence of the static recovery rate r, reviewed most recently by Nes19.

Of these, the earliest are based not on the dislocation density itself, but on the recovery of strain hardening observed in anneals of cold-worked metals21. The increase in yield strength induced by cold work ∆σ in these experiments was observed to decay from the initial value ∆σ0 during the anneal following a logarithmic trend

where the parameters α0 and β0 which vary from case to case. This expression holds only so long as a substantial fraction of the initial hardening remains, breaking down as full recovery is approached, and even becoming negative at later times. While a good description of the observed hardening recovery, this gives little direct indication of what the form the term r ought to take in Eq. (2).

Analytically, recovery laws have been derived from simplified dislocation morphologies with the solution for climb controlled recovery kinetics following the form

when mediated by bulk diffusion41. If mediated by pipe diffusion instead, the solution is similar, but becomes cubic in dislocation density. The general solution for pure static recovery follows

and (assuming the strain hardening results entirely from dislocations) \({\Delta}\sigma \propto \sqrt \rho\), such that

The analysis by Nes19 indicated that recovery would follow Eq. (3) when solute pinning or jog dragging on screw segments was the dominant recovery mechanism, while climb would result in Eq. (6) with the power −1/2 if by bulk diffusion, but with the power −1/4 if by pipe diffusion. Alternative mechanism-based models have been developed for jog dragging, solute dragging, and cross-slip, but will not be discussed at length here. Finally, an alternative recovery law was postulated more recently by Estrin42, with the from

This does not give a closed form solution for hardening recovery, but can be evolved numerically and has been adopted in crystal plasticity models for hot-work.

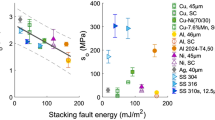

The mid-density standard simulations (see Table 1 for a description) are compared to each of these recovery laws in Fig. 7. In each case, the α and β parameters have been optimized with least-squares regression. Clearly, the logarithmic and hyperbolic expressions both fit the simulated recovery well, while the recovery laws intended to describe climb controlled kinetics do not. This is somewhat striking given that climb is the active mechanism here and that – according to conventional derivations – logarithmic decay should not be expected for this mechanism. Accordingly, we shall revisit the analytical approach to describing climb, propose that a common key assumption is incorrect, and attempt in what follows to re-formulate the recovery law for climb based processes.

For the power-law climb expression, Eq. (6), both powers of ½ (for bulk diffusion) and ¼ (for pipe diffusion) are shown.

Climb velocity at high density

The observed recovery trends in these DDD quite clearly do not follow prior expectations for climb based recovery. Climb velocities are dependent on the climb force acting on a dislocation, which is in turn inversely proportional to dislocation spacing. As dislocations climb closer to annihilation, their climb velocity accelerates, and generically can be written

with r the distance between the dislocations and κ a dimensionless constant expected to be near 1 that depends on orientation. The exact proportionality depends on configuration, and is given in full details in Supplementrary Eqs. (9–11) in the Supplementary Material. In the derivation of the quadratic recovery law with the form of Eq. (4), the exponential contribution to climb velocity is linearized. However, for usual values of elastic constants and recovery temperatures, the quantity \(\mu b^4/kT\) will range from 10 to 50 nm. Accordingly, any dislocations spaced more closely than this in the DDD simulations will climb far more rapidly than predicted by Eq. (4). At densities in excess of 1014 m−2, this will be the case for the majority of the network. This causes the quadratic law to significantly underestimate early recovery. As density drops and the more closely spaced parts of the structure annihilate, climb velocities slow toward the linearized rates.

If the exponential in velocity is not linearized, a very different form of the recovery law for climb emerges. Any closed form analytical expression is unlikely to fully capture the complexity addressed by DDD simulations. As with prior approaches, we derive analytical forms by approximating the structure as a series of dipoles which climb toward each other and reduce the density by annihilation. Consider two cases in which dislocations recover by annihilation resulting from climb. In the first, dislocations are introduced as dipoles at a separation distance inversely proportional to the dislocation density as \(R_0 \propto \rho ^{ - 1/2}\). In the second scenario, the initial dipole population is instead distributed randomly such that some dipoles are initially closer than others and will annihilate more rapidly. The latter better describes the present simulations (and recovery of cold-work) where the initial sets of dipoles may indeed be quite close. The former may be better suited to describing a scenario where dislocation generation and recovery are in equilibrium. The corresponding expressions (retaining the exponential form of climb velocity) are,

for \(R_0 \propto \rho ^{ - 1/2}\) and

for the random arrangement, both of which are derived in the Supplementary Material in Supplementary Eqs. (14) and (25).

Here, κ1 and κ2 are constants expected to be of order unity. Typically, the exponential term is linearized on the basis that its argument is small. Note that if Eq. (9) is linearized, it reduces to Eq. (4) which is generally proposed for the climb mechanism. Again though, this is only valid for low (<1014 m−2) dislocation densities, and is certainly not valid at early times for the random distribution. Without linearizing, either law produces a logarithmic-type recovery behavior resembling Eqs. (3) or (7) at densities approaching 1015 m−2 representative of cold worked metals.

Fitting the second expression to the standard structures at both densities suggests κ1 and κ2 are approximately 6.1 and 0.58 respectively. The agreement between this expression and the dislocation dynamics recovery for each of the five microstructure categories in this study are shown in Fig. 8. Finally, it becomes evident that heterogeneous arrangement does not significantly accelerate recovery. Indeed, if there is any effect it is to slightly slow down the process, at least for the degree of local concentration represented in this initial exploration. At this point though, there is insufficient evidence for extrapolation to cells or subgrain boundaries, as the increase in density within the concentrated zones in these simulations is only approximately a factor of 2 from the remainder of the simulated volume. Further, it is appropriate to note the absence of pipe diffusion in these simulations, which may become dominant in regions of high local density.

Curves above the dashed line indicate that recovery proceeds more rapidly than predicted, while curves below it indicate slower recovery. a The standard networks are well-fit, but the heterogeneous cases recover slightly more slowly. b For the polarized case, recovery is overpredicted for the total density, but underpredicted if only the statistically stored content is considered. Using a modified expression, Eq. (10), which does not allow for annihilation between GNDs provides a more accurate description of the kinetics with the same parameters κ1 and κ2.

Microstructures with GNDs, on the other hand, show significantly slower recovery than the other networks. This distinction is hardly surprising. These dislocations cannot simply annihilate with each other. Instead, they must move to a different region of the microstructure to be annihilated, a process reflected by sub-grain growth in the real material. The periodic constraints of this system cannot accommodate such a process, and consequently GNDs are not expected to recover in the simulations. The density of GNDs can be found from the Nye tensor of the simulation volume as a whole, and for these structures accounts for more than half of the initial network. However, Eq. (10) still performs poorly when applied to the statistically stored population on its own, as also shown in Fig. 8. Due to the relatively high GND content, nearly 2/3 of statistically stored dislocations are recovered, even though this represents less than 20% of the total density. There is no clear distinction a priori which of the dislocations are the geometrically necessary ones, and the distribution of spacings for annihilating pairs still reflects the total density. These pairs, only once annihilated, constitute a reduction in the statistically stored content, and when the derivation is modified to reflect this, one finds

for a GND content ρGND. This matches DDD recovery well, but should be understood to operate separately from sub-grain growth and/or recrystallization, which can provide additional recovery beyond the collapse of statistically stored networks.

Implications for pipe diffusion

Climb based recovery could also be mediated by a pipe diffusion mechanism for vacancy transport, rather than bulk diffusion as treated in this study. This is particularly true for the high dislocation densities associated with heavily cold worked material. Notably, the existing recovery laws for this mechanism rely on a similar linearization of the exponential in climb velocity41, and accordingly have a power-law form, similar to Eq. (4). This will still mischaracterize climb forces and velocities at high densities and close spacings regardless of the diffusional mode mediating mass transport. For this reason, we expect a similar logarithmic behavior for climb controlled recovery, whether mediated by bulk diffusion or pipe diffusion. The activation energy for pipe diffusion two thirds to three quarters of that for bulk diffusion, and the ratio of climb velocity between the two is well approximated as

for pipe diffusivity Dp and volume diffusivity Dv. The derivation for the pipe diffusion climb velocity is provided in full in the Supplemental Material. On this basis, a generalized form of Eq. (10) incorporating both modes using an effective diffusivity

encompasses both mechanisms. We note again that once exponentials are linearized, these recovery laws collapse to the quadratic and cubic power laws historically assigned to bulk and pipe mediated climb, respectively. The relative activity of these contributions is explored more thoroughly in the Supplementary Material.

The climb-controlled recovery kinetics predicted here compare reasonably well with the observed behavior for high purity iron when accounting for both modes of mass transport. One of the most complete set of recovery experiments in alpha Fe was collected by Michelak and Paxton in the range 300–500 C for 5–15% cold-worked material16. Using the values of \(\kappa\) extracted from the DDD simulations and the experimental diffusivities for high purity Fe with less than 1 ppm C43,44, the hardening recovery predicted by Eq. (10) is shown against the experiments in Fig. 9. The best fit was obtained using an initial density of 7 x 1014 m−2 which is comparable to the expected density in the cold worked state. Both the effect of temperature and the time evolution of recovery are generally well captured, but we note two caveats. First, the recovery kinetics for pipe diffusion mediated climb have not been directly confirmed in the DDD, and may differ in magnitude from Eq. (10). Second, the activity of both pipe and bulk diffusion in Fe is strongly sensitive to impurity content, with the former decreasing by several orders of magnitude at these temperatures with the addition of only 15 ppm C45. A similar but opposite effect is observed for bulk diffusion, where interstitial impurities lead to significantly faster self-diffusion46, which is thought to be a consequence of strong binding interactions between these impurities and vacancies47. While climb seems to describe the kinetics of recovery well for the pure metal, the broader context would indicate that recovery rates should vary substantially in steels, following from changes in chemical composition and the related changes in self-diffusion kinetics.

Climb controlled recovery

In this work we have investigated the kinetics of static recovery assuming climb as the rate-controlling mechanism, and found favorable comparison with experimental observations in contrast to prior theoretical work. This was made possible by an advanced DDD capability which couples a full-field solution to the point defect distribution in a material to a climb kinematics which can account for jogs, junctions, and mixed character segments. Recovery in these simulations follows the experimentally observed logarithmic trend rather than the quadratic from common to prior analytical derivations. This is the consequence of an exponential increase in climb velocities for dislocations approaching annihilation which has been neglected in prior work. We have formulated a revised law for climb controlled recovery, which we expect to apply to both bulk and pipe diffusion-mediated mass transport kinetics. The recovery law as fit to DDD is broadly consistent with the experimentally observed recovery kinetics when using the measured diffusivities of Fe in the ferromagnetic temperature regime. Further, this expression reduces to prior power-law formulas for climb control in the low-density limit, while at higher densities it resembles a mechanism-agnostic hyperbolic form broadly deployed in crystal plasticity models. In total this work provides a unified and predictive law for describing climb controlled static recovery, fully-parameterizes it for Fe, and provides a method which can obtain similar parameterizations for other elements.

Methods

Climb with coupled vacancy transport

Computational modeling of climb in this study relies on DDD coupled to a point defect transport framework which treats the transmission of vacancies between dislocations as a reaction-diffusion problem. The dislocation dynamics component relies on a conventional nodal framework to describe the kinetics and kinematics of dislocation glide, leveraging the FFT-based approach to determining the force acting on each segment48,49,50. This is supplemented by the point defect transport model, which determines the kinetics of climb. Finally, the kinematics of dislocation climb are treated by introducing jogs between segments, allowing segments of both edge and mixed character to climb without disturbing the slip plane of each segment. In this section, we will describe the fundamentals aspects of this climb implementation, with additional details available in the Supplementary Material.

Climb velocities are determined from the vacancy flux within the material. Vacancy populations are evolved according to the continuity equation

where c is the vacancy concentration, J is the flux, Dv is the vacancy diffusivity, and sn and \(c_n^0\) are the absorber strength and core concentration corresponding to segment n. Absorber strengths are self-consistently distributed to the finite difference grid according to dislocation segment proximity38. The vacancy diffusivity is defined by a migration energy Em migration entropy Sm and prefactor D0

The continuity equation is discretized and solved on the same grid used for determining the mechanical fields. Absorber strengths vary in space, and correspond to dislocation positions with specific values for each voxel determined by the localized absorber method38. The flux accounts for defect-strain interactions, and is given by

where ε is the elastic strain and p is the elastic dipole tensor of the vacancy. The second term in Eq. (14) represents absorption or emission of vacancies from each segment, such that the total (inward) current at a given segment is

when summed over all voxels j which contain absorbers for that segment.

The mechanical forces acting on each segment determine the equilibrium concentration at the core, given as

for a dislocation segment which spans the vector t from one end to the other. The climb force is

such that the sense of the climb direction points toward the missing half plane (for an edge dislocation). Vacancies formed under the climb force are opposed by vacancies absorbed from the bulk in Eq. (17) – often referred to as the osmotic force – and the climb velocity becomes

for each segment. The parameters used in these equations for Fe are given in Table 2.

At each climb step, the climb forces are computed, and Eq. (14) is updated to determine the vacancy distribution. Next, Eq. (20) is evaluated for each segment to determine the climb velocity. Each segment is displaced onto a parallel glide plane according to its climb velocity. Prior to this process, however, neighboring segments which would be displaced by similar amounts (within a few lattice units) are grouped into a single segment with an aggregate total current and corresponding identical climb velocities. Neighboring segments which will climb by different amounts become connected by a jog. Jogs are placed on the slip plane nearest normal to the climbing segments which contains the Burgers vector. In subsequent glide steps, these jog nodes will be able to glide on the intersection of the slip and jog planes. The mechanics of these processes are illustrated in Fig. 10. In the nodal framework, few segments are of pure edge or pure screw character, and almost all are varying degrees of mixed character. Following Eq. (20), mixed character segments are allowed to climb, and a cutoff character angle of 5 degrees is used to avoid singular climb distances only for dislocations very near the screw orientation.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Code availability

The point of contact for obtaining the dislocation dynamics code used in this study is Laurent Capolungo. It is available through requests sent to laurent@lanl.gov.

References

Anderson, P. M., Hirth, J. P. & Lothe, J. Theory of Dislocations. (Cambridge University Press, 2017).

Mecking, H. N., Zarubova, B. & Kocks, U. F. A “Universal” Temperature Scale for Plastic Flow. Acta Metall. 34, 527–535 (1986).

Mecking, H. & Kocks, U. F. Kinetics of flow and strain-hardening. Acta Metall. 29, 1865–1875 (1981).

Kocks, U. F. & Mecking, H. Physics and phenomenology of strain hardening: the FCC case. Prog. Mater. Sci. 48, 171–273 (2003).

Kuhlmann-Wilsdorf, D. The theory of dislocation-based crystal plasticity. Philos. Mag. A 79, 955–1008 (1999).

Matlock, D. K., Harrigan, W. C. & Nix, W. D. On the importance of including recovery in phenomenological theories of plastic flow in metals. Acta Metall. 20, 661–668 (1972).

Brandes, M. & Mills, M. J. Static recovery in titanium alloys at lower temperatures. Mater. Sci. Eng. A 387–389, 570–575 (2004).

Ghassemi-Armaki, H., Chen, R. P., Maruyama, K., Yoshizawa, M. & Igarashi, M. Static recovery of tempered lath martensite microstructures during long-term aging in 9–12% Cr heat resistant steels. Mater. Lett. 63, 2423–2425 (2009).

Ghassemi Armaki, H., Chen, R., Maruyama, K. & Igarashi, M. Premature creep failure in strength enhanced high Cr ferritic steels caused by static recovery of tempered martensite lath structures. Mater. Sci. Eng. A 527, 6581–6588 (2010).

Zurob, H. S., Hutchinson, C. R., Brechet, Y. & Purdy, G. Modeling recrystallization of microalloyed austenite: effect of coupling recovery, precipitation and recrystallization. Acta Mater. 50, 3077–3094 (2002).

Stüwe, H. P., Padilha, A. F. & Siciliano, F. Competition between recovery and recrystallization. Mater. Sci. Eng. A 333, 361–367 (2002).

Sandström, R. & Lagneborg, R. A model for hot working occurring by recrystallization. Acta Metall. 23, 387–398 (1975).

Krauss, G. Tempering of Lath Martensite in Low and Medium Carbon Steels: Assessment and Challenges. Steel Res. Int. 88, 1700038 (2017).

Sawada, K., Taneike, M., Kimura, K. & Abe, F. In situ observation of recovery of lath structure in 9% chromium creep resistant steel. Mater. Sci. Tech. 19, 739–742 (2013).

Barraclough, D. R. & Sellars, C. M. Static recrystallization and restoration after hot deformation of Type 304 stainless steel. Met. Sci. 13, 257–268 (2013).

Michalak, J. & Paxton, H. Some recovery characteristics of zone-melted iron. T. Metall. Soc. AIME 221, 850–857 (1961).

Yoshie, A., Fujita, T., Fujioka, M., Okamoto, K. & Morikawa, H. Formulation of the Decrease in Dislocation Density of Deformed Austenite Due to Static Recovery and Recrystallization. ISIJ Int. 36, 474–480 (1996).

Kuo, C.-M. & Lin, C.-S. Static recovery activation energy of pure copper at room temperature. Scr. Mater. 57, 667–670 (2007).

Nes, E. Recovery revisited. Acta Metall. Mater. 43, 2189–2207 (1995).

Belyakov, A., Tsuzaki, K., Kimura, Y. & Mishima, Y. Annealing behavior of a ferritic stainless steel subjected to large-strain cold working. J. Mater. Res. 22, 3042–3051 (2011).

Kuhlmann, D., Masing, G. & Raffelsieper, J. Zur Theorie der Erholung. Int. J. Mater. Res. 40, 241–246 (1949).

Cai, W., Arsenlis, A., Weinberger, C. & Bulatov, V. A non-singular continuum theory of dislocations. J. Mech. Phys. Solids 54, 561–587 (2006).

Devincre, B., Kubin, L. P., Lemarchand, C. & Madec, R. Mesoscopic simulations of plastic deformation. Mater. Sci. Eng. A 309-310, 211–219 (2001).

Madec, R., Devincre, B., Kubin, L., Hoc, T. & Rodney, D. The role of collinear interaction in dislocation-induced hardening. Science 301, 1879–1882 (2003).

Kubin, L. P., Madec, R. & Devincre, B. Dislocation Intersections and Reactions in FCC and BCC Crystals. MRS Proceedings 779, W1.6 (2011).

Bulatov, V. V. et al. Dislocation multi-junctions and strain hardening. Nature 440, 1174–1178 (2006).

Arsenlis, A. et al. Enabling strain hardening simulations with dislocation dynamics. Model. Simul. Mater. Sci. Eng. 15, 553–595 (2007).

Weygand, D., Friedman, L. H., van der Giessen, E. & Needleman, A. Discrete dislocation modeling in three-dimensional confined volumes. Mater. Sci. Eng.: A 309–310, 420–424 (2001).

Koslowski, M., Cuitiño, A. M. & Ortiz, M. A phase-field theory of dislocation dynamics, strain hardening and hysteresis in ductile single crystals. J. Mech. Phys. Solids 50, 2597–2635 (2002).

Hunter, A., Saied, F., Le, C. & Koslowski, M. Large-Scale 3D Phase Field Dislocation Dynamics Simulations On High-Performance Architectures. Int. J. High. Perform. C. 25, 223–235 (2010).

Po, G. et al. Recent Progress in Discrete Dislocation Dynamics and Its Applications to Micro Plasticity. Jom 66, 2108–2120 (2014).

Bakó, B., Clouet, E., Dupuy, L. M. & Blétry, M. Dislocation dynamics simulations with climb: kinetics of dislocation loop coarsening controlled by bulk diffusion. Philos. Mag. 91, 3173–3191 (2011).

Mordehai, D., Clouet, E., Fivel, M. & Verdier, M. Introducing dislocation climb by bulk diffusion in discrete dislocation dynamics. Philos. Mag. 88, 899–925 (2008).

Keralavarma, S. M., Cagin, T., Arsenlis, A. & Benzerga, A. A. Power-law creep from discrete dislocation dynamics. Phys. Rev. Lett. 109, 265504 (2012).

Danas, K. & Deshpande, V. S. Plane-strain discrete dislocation plasticity with climb-assisted glide motion of dislocations. Model. Simul. Mater. Sc. 21, 045008 (2013).

Ayas, C., van Dommelen, J. A. W. & Deshpande, V. S. Climb-enabled discrete dislocation plasticity. J. Mech. Phys. Solids 62, 113–136 (2014).

McElfresh, C., Cui, Y., Dudarev, S. L., Po, G. & Marian, J. Discrete stochastic model of point defect-dislocation interaction for simulating dislocation climb. Int. J. Plasticity 136, 102848 (2021).

Kohnert, A. A. & Capolungo, L. A novel approach to quantifying the kinetics of point defect absorption at dislocations. J. Mech. Phys. Solids 122, 98–115 (2019).

Kohnert, A. A. & Capolungo, L. Sink strength and dislocation bias of three-dimensional microstructures. Phys. Rev. Mater. 3, 053608 (2019).

Keralavarma, S. M. & Curtin, W. A. Strain hardening in 2D discrete dislocation dynamics simulations: a new ‘2.5D’ algorithm. J. Mech. Phys. Solids 95, 132–146 (2016).

Sandström, R. On recovery of dislocations in subgrains and subgrain coalescence. Acta Metall. 25, 897–904 (1977).

Estrin, Y. Dislocation theory based constitutive modelling: foundations and applications. J. Mater. Process. Tech. 80–81, 33–39 (1998).

Shima, Y. et al. Self-Diffusion along Dislocations in Ultra High Purity Iron. Mater. Trans. 43, 173–177 (2002).

Iijima, Y., Kimura, K. & Hirano, K. Self-diffusion and isotope effect in α-iron. Acta Metall. 36, 2811–2820 (1988).

Mehrer, H. & Lübbehusen, M. Self-Diffusion along dislocations and in the Lattice of alpha-Iron. Defect Diffus. Forum 66-69, 591–604 (1991).

Irmer, V. & Feller-Kniepmeier, M. On the influence of impurity atoms on self-diffusion in α-iron single crystals. Philos. Mag. 25, 1345–1359 (1972).

Domain, C., Becquart, C. S. & Foct, J. Ab initiostudy of foreign interstitial atom (C, N) interactions with intrinsic point defects inα-Fe. Phys. Rev. B 69, 144112 (2004).

Bertin, N. & Capolungo, L. A FFT-based formulation for discrete dislocation dynamics in heterogeneous media. J. Comput. Phys. 355, 366–384 (2018).

A. Lebensohn, R. N-site modeling of a 3D viscoplastic polycrystal using Fast Fourier Transform. Acta Mater. 49, 2723–2737 (2001).

Kohnert, A. A. & Capolungo, L. Spectral discrete dislocation dynamics with anisotropic short range interactions. Comput. Mater. Sci. 189, 110243 (2021).

De Schepper, L. et al. Positron annihilation on pure and carbon-dopedα-iron in thermal equilibrium. Phys. Rev. B 27, 5257–5269 (1983).

Mendelev, M. I. et al. Development of new interatomic potentials appropriate for crystalline and liquid iron. Philos. Mag. 83, 3977–3994 (2003).

Domain, C. & Becquart, C. S. Ab initiocalculations of defects in Fe and dilute Fe-Cu alloys. Phy. Rev. B 65, 024103 (2001).

Fu, C.-C., Torre, J. D., Willaime, F., Bocquet, J.-L. & Barbu, A. Multiscale modelling of defect kinetics in irradiated iron. Nat. Mater. 4, 68–74 (2004).

Buffington, F. S., Hirano, K. & Cohen, M. Self diffusion in iron. Acta Metall. 9, 434–439 (1961).

James, D. W. & Leak, G. M. Self-diffusion and diffusion of cobalt in alpha and delta-iron. Philos. Mag. 14, 701–713 (1966).

Hayward, E., Deo, C., Uberuaga, B. P. & Tomé, C. N. The interaction of a screw dislocation with point defects in bcc iron. Philos. Mag. 92, 2759–2778 (2012).

Rayne, J. A. & Chandrasekhar, B. S. Elastic Constants of Iron from 4.2 to 300°K. Phys. Rev. 122, 1714–1716 (1961).

Speich, G. R., Schwoeble, A. J. & Leslie, W. C. Elastic constants of binary iron-base alloys. Metall. Trans. 3, 2031–2037 (1972).

Acknowledgements

This work was funded by the United States Department of Energy (DOE) office of Nuclear Energy as part of the Nuclear Energy Advanced Modeling and Simulation (NEAMS) program.

Author information

Authors and Affiliations

Contributions

A.A.K. carried out the simulations and developed the software. A.A.K. and L.C. designed the simulations, analyzed the data, and wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kohnert, A.A., Capolungo, L. The kinetics of static recovery by dislocation climb. npj Comput Mater 8, 104 (2022). https://doi.org/10.1038/s41524-022-00790-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41524-022-00790-y

- Springer Nature Limited

This article is cited by

-

Role of interfaces on the mechanical response of accumulative roll bonded nanometallic laminates investigated via dislocation dynamics simulations

Journal of Materials Science: Materials Theory (2024)

-

Microstructural Evolution of Tantalum During Deformation and Subsequent Annealing

Metallurgical and Materials Transactions A (2024)