Abstract

Ru single-atom catalysts have great potential to replace toxic mercuric chloride in acetylene hydrochlorination. However, long-term catalytic stability remains a grand challenge due to the aggregation of Ru atoms caused by over-chlorination. Herein, we synthesize an asymmetric Ru-In atomic pair with vinyl chloride monomer yield (>99.5%) and stability (>600 h) at a gas hourly space velocity of 180 h−1, far surpassing those of the Ru single-atom counterparts. A combination of experimental and theoretical techniques reveals that there is a strong d-p orbital interaction between Ru and In atoms, which not only enables the selective adsorption of acetylene and hydrogen chloride at different atomic sites but also optimizes the electron configuration of Ru. As a result, the intrinsic energy barrier for vinyl chloride generation is lowered, and the thermodynamics of the chlorination process at the Ru site is switched from exothermal to endothermal due to the change of orbital couplings. This work provides a strategy to prevent the deactivation and depletion of active Ru centers during acetylene hydrochlorination.

Similar content being viewed by others

Introduction

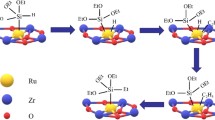

Acetylene (C2H2) hydrochlorination is a critical industrial process for the production of vinyl chloride monomer (VCM), which accounts for 35% of global poly(vinyl chloride) (PVC) output. The conventional catalysts, activated carbon-supported mercuric chloride (HgCl2/AC), have faced strong restrictions due to the Minamata Convention on Mercury, thus demanding green, Hg-free alternatives such as noble metal catalysts (e.g., Au, Pd, Ru, etc.)1,2,3,4,5. In recent years, ruthenium single-atom catalysts (Ru SACs) have emerged as promising candidates due to their excellent chlorine affinity and flexible control of active site architectures6,7,8,9,10. However, Ru SACs always suffer from easy deactivation due to metal aggregation induced by over-chlorination and simultaneous coke deposition (Fig. 1a)11,12,13,14,15. In addition, the steric hindrance of the transition state during the reaction at the atomic site substantially impedes the further improvement of activity16,17,18,19. Therefore, the rational design of Ru SACs with high activity and stable performance towards acetylene hydrochlorination remains a grand challenge.

Recently, the synthesis efforts have been expanded to neighboring sites of single-atom metal that give rise to the bifunctional site at the atomic level and unlock excellent performance for acetylene hydrochlorination20,21,22,23,24. Inspired by these previous studies, the fabrication of dual-atom catalysts offers an effective strategy to enhance the reactivity and stability as a result of optimizing the activation behavior of acetylene and hydrogen chloride (HCl) through orbital coupling between two adjacent metal atoms (e.g., d–p hybridization)25,26,27,28,29,30. In addition, the p block element indium (In) is known to have abundant empty 5p orbitals and exhibit a high degree of electrophilicity31,32,33,34. In this regard, the assembly of a single In site next to atomic Ru (i.e., In–Ru DAC, Fig. 1b) is expected to manipulate the electron configuration of Ru and deliver a desired environment to balance the trade-off between reactivity and stability, resulting in highly stable acetylene hydrochlorination35,36,37.

Here, we synthesized an asymmetric Ru–In dual-atom catalyst (denoted as Ru–N–In/NC), in which Ru and In atoms are confined by the nitrogen atoms doped in carbon (NC) through metal-N bonding coordination. Accordingly, the derived Ru–N–In/NC catalyst has achieved >99.5% activity and >600 h stability for the acetylene hydrochlorination. Experiments and density functional theory (DFT) calculations jointly reveal the continuous generation of high-valence Ru species and independent adsorption sites for C2H2 and HCl that are responsible for the enhanced performances compared to RuN4/NC (Ru is located at the center of symmetrical planar with four N-coordinated structures). Indium atoms promote stable catalysis by decreasing the Cl coordination number to prevent over-chlorination and coke deposition on atomic Ru sites. Eventually, acetylene hydrochlorination proceeds favorably over the Ru–N–In/NC structure via the Langmuir–Hinshelwood mechanism with an unconventional rate-determining step (RDS) of *CH2=CH formation, as compared to the addition of *Cl on the RuN4/NC.

Results

Synthesis and characterization of the asymmetric Ru–N–In single-atom pairs

The Ru–N–In/NC catalyst was synthesized via an atomic interface regulation strategy as illustrated in Supplementary Fig. 138. Typically, nitrogen-doped carbon, ruthenium acetylacetonate (Ru(acac)3), and MIL-68(In) were ground thoroughly to give a uniform mixture, which was then subjected to calcination under an Ar atmosphere. The single-metal counterparts of RuN4/NC and InN4/NC were prepared using the same procedures but without MIL-68(In) or Ru(acac)3, respectively. Herein, the nitrogen-doped carbon supports for anchoring metals were obtained through polyaniline (PAN) pyrolysis at 800 °C (Supplementary Figs. 2–4). Inductively coupled plasma optical emission spectrometry (ICP-OES) determined that the contents of Ru and In were ~0.98 and 0.19 wt%, respectively, which were close to the nominal loadings (Supplementary Table 1).

The transmission electron microscopy (TEM) image presents that the Ru–N–In/NC moiety possessed a hexagonal-like shape composed of randomly arranged nanosheets (Fig. 2a), similar to the morphology of NC (Supplementary Fig. 5), RuN4/NC (Supplementary Fig. 6), and InN4/NC (Supplementary Fig. 7). The selected area electron diffraction (SAED) pattern suggests the absence of metallic nanoparticles and low crystallinity of the carbon matrix with abundant carbon defects39. The C/N ratio derived from CHNS analysis was 6.52 for Ru–N–In/NC, lower than that of NC (6.73), demonstrating that Ru–N–In/NC had more carbon vacancies and unsaturated nitrogen sites (Supplementary Fig. 10)40. Energy dispersive spectroscopy (EDS) mappings confirmed that Ru, In, and N were uniformly distributed on the carbon matrix (Fig. 2b). Powder X-ray diffraction (XRD) patterns show all the samples had two diffraction peaks of (002) and (100) facets (Fig. 2c)41. The aberration-corrected high-angle annular dark-field scanning TEM (AC-HAADF-STEM) image exhibits that Ru and In atoms were well-dispersed as atomic pairs throughout the whole matrix, in which dimeric white bright spots (marked by yellow circles/boxes) were identified as Ru-N-In/NC moieties (Fig. 2d). The average distance of the two neighboring metal sites of Ru and In was determined as ~0.37 nm (Fig. 2e and Supplementary Figs. 6 and 7). The atomically dispersed Ru or In on RuN4/NC or InN4/NC was also confirmed (Supplementary Figs. 8 and 9). Subsequently, we compared the thermodynamic formation energies for six single/dimer-atom catalysts including RuN4/NC, InN4/NC, Ru2/NC, In2/NC, Ru–N–In/NC, etc., which revealed that the asymmetric Rn–N–In dual-atom structure had the lowest free energy of –2.793 eV (Supplementary Fig. 11). Additionally, N2 adsorption–desorption curves indicate that Ru-N-In/NC had a high surface area of 690.13 m2/g (Supplementary Fig. 12 and Supplementary Table 2). Fourier-transform infrared spectroscopy (FTIR) (Supplementary Fig. 13) and X-ray photoelectron spectroscopy (XPS) (Supplementary Figs. 14–16) also further proved the formation of Ru–In coordination.

a and b TEM images of the Ru–N–In/NC moiety and the corresponding EDS mappings for Ru, In, and N, respectively. c Powder XRD patterns of Ru–N–In/NC, RuN4/NC, InN4/NC, and NC. d AC-HAADF-STEM image of the Ru–N–In/NC sample, in which the single-atom Ru–In pairs are highlighted by the yellow circles/boxes. e Atomic scale identified the distance (nm) of isolated Ru and In dual single-atom sites in the selected area with yellow rectangles 1, 2, and 3 in figure (d).

The Ru oxidation state in Ru–N–In/NC was resolved by X-ray absorption near edge spectroscopy (XANES) (Fig. 3a). The Ru K edge spectrum exhibits a pre-edge transition at 22112 eV, which falls between the peaks associated with RuCl3 (22110 eV) and RuO2 (22114 eV). This indicated an intermediate oxidation state between +3 and +4 for Ru in Ru–N–In/NC. The coordination structure of Ru single atom was further revealed by the extended X-ray absorption fine structure (EXAFS) analysis. Figure 3b compares Fourier-transformed EXAFS spectra for Ru–N–In/NC, RuN4/NC, RuO2, and Ru foil. Ru–N–In/NC exhibits first-shell scattering at 1.48 Å in R space (prior to phase correction), which is proximate to the value of 1.52 Å, found for RuO2. This was distinct from the case for Ru foil, the first shell scattering of which is located at 2.30 Å. From these observations, we assigned the primary feature at 1.48 Å to be Ru–N bonding42. The atomic dispersion of Ru was also evidenced by the wavelet transform (WT) plot, with the intensity at ≈4.5 and 9.5 Å−1 arising from Ru–O and Ru–Ru scattering, respectively (Fig. 3g). The quantitative structural parameter analysis based on the fitted EXAFS spectra suggested that each Ru atom coordinates with three N atoms in the first shell within the inter-plane of the tri-striazine framework, with an average bond length of 1.99 Å (Fig. 3c and Supplementary Tables 3 and 4). The atomic dispersion of Ru over the control RuN4/NC was also investigated, where each Ru atom was coordinated with four N atoms (Supplementary Figs. 17–20 and Supplementary Tables 3).

Ru K-edge XAFS analysis of Ru–N–In/NC and RuN4/NC: a Normalized XANES, b Fourier-transform XAFS spectra, and c XAFS curves fitting in R space. In K-edge XAFS analysis of Ru–N–In/NC: d Normalized XANES, e Fourier transform XAFS spectra, and f EXAFS curves fitting in R space. g Wavelet transform contour plots of Ru–N–In/NC at Ru K-edge and In K-edge.

The coordination environments and local structures of In centers were simultaneously determined by the In K-edge XANES curves of Ru–N–In/NC, In foil, and In2O3 (Fig. 3d). The absorption edge of Ru–N–In/NC was centered at a higher energy than that of In2O3, indicating that In atoms exist at a higher valence state than in In2O3, which is in agreement with the result of In 3d XPS (Supplementary Fig. 14). Evidenced by the Fourier-transformed EXAFS spectra, unlike the In–In (≈2.96 Å) and In–O (≈1.67 Å) peaks observed in In foil and In2O3, Ru–N–In/NC exhibits a dominant peak of first-shell scattering (assigned to In–N scattering) located at ≈1.56 Å (phase-uncorrected distance) (Fig. 3e). Figure 3f presents the fitting results of the extended In K-edge, which reveals that each In atom is coordinated with four N atoms with an average In-N bond length of ≈2.15 Å (Supplementary Figs. 21–24 and Supplementary Tables 3 and 4). Moreover, the WT plots of In K-edge-weighted EXAFS indicate the atomically dispersed In species on NC supports (Fig. 3g). In addition, combining the results of DFT and X-ray absorption spectra (XAS), we further consider Ru–N–Ru/In and In–N–In/Ru as the comprehensive models and fit the raw XAS data (Fig. 3c and f). The optimal results in Supplementary Table 4 demonstrate that Ru and In are dispersed as atomic pairs on the NC supports, with a higher possibility of the presence of Ru–N–In heterostructure due to the lowest free formation energy of –2.793 eV compared to other counterparts (Supplementary Fig. 11).

The partial density of states (PDOS) results were compared for Ru–N–In/NC and RuN4/NC to obtain the orbital hybridization information induced by the electronic structures of asymmetric coordination. As illustrated in Supplementary Fig. 25, the energy of the In–(p) band matches well with that of the Ru–(d) band relative to the Fermi level, indicating that a strong d–p orbital hybridization interaction occurred between Ru and In atoms. Such a d–p hybridization interaction leads to lower orbital energy caused by enhanced electron delocalization and electron redistribution. In addition, charge density analysis provided more evidence for the Ru centers in Ru–N–In/NC moiety that exhibited significant electronic delocalization accompanied by the asymmetric electronic redistribution (Supplementary Fig. 26). Compared with RuN4/NC (–0.92 eV), the reduced Bader charge of the Ru in Ru–N–In/NC (–0.98 eV) indicated that partial electrons from the Ru centers were extracted after In introduction. The reduced electron density is also proved by the up-shifted binding energy (~0.3 eV) of Ru 3p in Ru–N–In/NC compared to that in RuN4/NC according to the XPS characterization (Supplementary Fig. 15).

From the above discussion, the distinct atomic structures of N-bridged Ru, In dual-atom Ru–N–In/NC catalyst have been clearly unveiled. We hypothesize that the electronic chemical configuration derived by d(Ru)–p(In) hybridization as compared to RuN4/NC would lend them exquisite catalytic performance for acetylene hydrochlorination.

Enhanced catalytic performance for acetylene hydrochlorination

The catalytic performances of the Ru–N–In/NC catalysts were evaluated in a continuous flow fixed-bed microreactor (Supplementary Fig. 27). The optimal reaction temperature, Ru/In ratio, gas hourly space velocity (GHSV), and carrier N-content were determined as 180 °C, 5, 180 h−1, and 5.86 wt%, respectively (Supplementary Figs. 28–32). Compared with the lower acetylene conversions of RuN4/NC (~76.35%), InN4/NC (~18.15%), and NC (~15.69%), Ru–N–In/NC showed an excellent initial activity of ~99.51% with negligible deactivation (Fig. 4a). Based on Fig. 4a, it can be concluded that Ru was the main active center. The introduction of In atoms apparently played a crucial role in stabilizing Ru, as evidenced by the deactivation rate of RuN4/NC (~4.78%) compared to no discernible drop of acetylene conversion found for Ru–N–In/NC. Notably, the VCM selectivity for these catalysts was more than 99% except for InN4/NC (Supplementary Fig. 33). The main by-product, which may originate from the oxidation of HCl or further hydrochlorination of vinyl chloride, was identified as dichloroethane (1,1-dichloroethane and 1,2-dichloroethane) through a gas chromatograph (Supplementary Fig. 34)6,43. To investigate the intrinsic reactivity of the aforementioned catalysts, the kinetics study was evaluated by considering the Weisz–Prater criterion and the Mears criterion to avoid the interference of diffusion (Supplementary Texts 1 and 2)44. The lower apparent activation energy (Ea) (46.89 kJ/mol) (Supplementary Fig. 35) and Ru loss ratio (0.2%) (Supplementary Table 1) of Ru–N–In/NC compared to 65.02 and 79.31 kJ/mol for RuN4/NC and InN4/NC contribute to its higher catalytic activity. Further, the reaction orders of HCl and C2H2 were derived from kinetic studies, and a higher reaction order for HCl (0.67–0.92) was obtained in comparison with C2H2 (0.65–0.83) (Supplementary Fig. 36).

a C2H2 conversions of Ru–N–In/NC, RuN4/NC, InN4/NC and NC [Reaction conditions: T = 180 °C, P = ambient pressure, GHSV(C2H2) = 180 h−1, V(HCl)/V(C2H2) = 1.15]. The error bars indicate the standard deviations of three experimental measurements. b Comparison of TOF (molC2H2/molmetal/h) of Ru–N–In/NC with other Ru-based, non-noble metal and non-metal catalysts6,7,59,60,61,62,63,64,65,66,67. Note that all the obtained data are the same as our reaction conditions. The data are calculated at 180 °C, ~5% C2H2 conversion to eliminate the influence of internal and external diffusion. Each point was determined by an isolated test to eliminate the interference of catalyst deactivation. c Long-term catalytic performances of Ru–N–In/NC and RuN4/NC, and corresponding AC HAADF-STEM images for the used samples. [Reaction conditions: T = 180 °C, P = ambient pressure, Vcat = 1.2 mL, V(HCl)/V(C2H2) = 1.15, GHSV(C2H2) = 180 h−1.] d Comparison of long-term stability (TOS and deactivation rate) for Ru–N–In/NC with other recently reported catalysts.

Subsequently, we compared the turnover frequency (TOF, molC2H2/molmetal/h) of Ru–N–In/NC with the recently reported catalysts (Supplementary Table 5). Intriguingly, the activity of Ru–N–In/NC was not only far exceeded by those of other Ru-based catalysts (Fig. 4b), but also higher than that of several Au- and Pt-based samples (Supplementary Fig. 37). Moreover, the successful synthesis and application strategy of Ru–N–In/NC is generally applicable to other noble metals (i.e., AuIn/NC, PdIn/NC, and PtIn/NC), which exhibit promising reactivities for acetylene hydrochlorination. Herein, the Ru–N–In/NC still has better activity compared to other catalysts (Supplementary Fig. 38). In addition, the activity of Ru–N–In/NC also outperforms that of RuIn/AC (activated carbon (AC) is the common support for commercial catalysts) (Supplementary Fig. 39) and commercial HgCl2/AC moieties (Supplementary Fig. 40).

The long-term stability of Ru–N–In/NC and RuN4/NC was subsequently evaluated at the GHSV of 180 h-1, where Ru–N–In/NC can maintain stable catalysis with an admirable VCM productivity of ~0.98 kgvcm/kgcatal./h for more than 600 h (Fig. 4c). Such stable catalysis for Ru–N–In/NC in terms of time on stream (TOS, 600 h) and deactivation rate (0.001%/h) in the present study was apparently superior to other recently reported catalysis systems (Fig. 4d). However, the completed deactivation was observed for RuN4/NC within 120 h (Fig. 4c and Supplementary Fig. 41). From the perspective of practical application, the concomitant CO2 (~250 ppm) was pulsed to evaluate the tolerance of Ru–N–In/NC, in which the VCM productivity was attenuated to ~0.76 kgvcm/kgcatal./h due to the competitive adsorption between CO2 and the reaction gases, however, the stability was still kept at 600 h (Supplementary Fig. 42)45. We also synthesized and tested the stability of RuIn/AC, which resulted in decreased activity (~0.81 kgvcm/kgcatal./h) and poor stability (450 h) (Supplementary Fig. 43). The results of XRD (Supplementary Fig. 44) and XPS (Supplementary Fig. 45) indicated that the structure of post-hydrochlorination Ru-N-In/NC was perfectly intact. TEM (Supplementary Fig. 46) and AC-HAADF-STEM (Fig. 4c) images show that the used sample retained the original morphology of randomly stacked nanosheets and, most importantly, the atomically dispersed Ru–In pairs.

Mechanisms of acetylene hydrochlorination on asymmetric Ru–N–In/NC

Prior to the mechanism investigations, the adsorption of C2H2 or HCl on asymmetric Ru–N–In/NC was studied. Temperature-programmed-desorption (TPD) experiments, in which all the desorption peaks are located at ~205 °C (Fig. 5a), were carried out to determine the adsorption sites for acetylene molecules. Compared with RuN4/NC (2329.7), the higher desorption peak area for InN4/NC (6653.7) proved that In atoms were more favorable for capturing C2H2 (Supplementary Table 6). As shown in Fig. 5b and Supplementary Fig. 47, In-situ diffuse reflectance infrared Fourier transform spectroscopy (DRIFTS) for C2H2 adsorption also offers a similar conclusion, in which the νas(C2H2) of 3258 cm−1 band underwent a downward shift with reference to the gas-phase value at 3287 cm−1, indicating that the C2H2 molecule was subjected to strong chemisorption of In–CHCH due to its significant bond polarization32,46. The –C ≡ C– bond cleavage into –C = C– bond of C2H2 upon adsorption on In species, forms p-π-bonded HC = CH species47. The integrated crystal orbital Hamilton population (ICOHP) was carried out to analyze the adsorption of C2H2 on Ru–N–In/NC and RuN4/NC (Supplementary Fig. 48)48,49. The up ICOHP in Ru–N–In/NC decreases from –1.58 to –2.24 compared with RuN4/NC, and the down ICOHP decreases from –1.76 to –2.26, demonstrating the stronger adsorption strength of the C2H2 molecules on Ru–N–In/NC. Furthermore, the C2H2 adsorption energies (Eads (C2H2)) on Ru–N–In/NC, RuN4/NC, and InN4/NC were calculated as –0.94, –0.78 and –1.18 eV, which aligned with the trend found in TPD (Supplementary Figs. 49 and 50). The modest C2H2 adsorption strength allowed the optimal interaction of C2H2 with Ru–N–In/NC (R2 = 0.87), which is required to trigger the reaction (Supplementary Fig. 51) compared to the single atom counterparts.

a C2H2-TPD curves of the Ru–N–In/NC, RuN4/NC, and InN4/NC samples. b In-situ DRIFTS of C2H2 adsorption profiles over the Ru–N–In/NC surfaces. c HCl-TPD curves of the Ru–N–In/NC, RuN4/NC, and InN4/NC. d Comparison of adsorption energy for HCl molecule on Ru and In centers. e The adsorption energy of C2H2/HCl versus TOF of the Ru–N–In/NC, RuN4/NC, and InN4/NC. The error bars indicate the standard deviations of three experimental measurements. f d-band center as a descriptor versus the TOF of the Ru–N–In/NC, RuN4/NC, and InN4/NC, in which the projected density of states analysis of Ru–N–In/NC was inserted. The error bars indicate the standard deviations of three experimental measurements. g DFT calculations of the acetylene hydrochlorination reaction pathways over the Ru–N–In/NC and RuN4/NC moieties. Cyan, orange, green, blue, gray, and white spheres represent Ru, In, Cl, N, C, and H atoms, respectively.

The HCl-TPD curves show that the desorption temperature of the three samples is located at ~170 °C. A remarkable decline of the desorption peak area for Ru–N–In/NC (4467.3) was observed compared to RuN4/NC (5474.3), but still higher than that of InN4/NC (2638.7), indicating that the addition of In atoms weakened the adsorption of HCl on the Ru site in the case of Ru–N–In/NC (Fig. 5c and Supplementary Table 6). Further, we compared the adsorption energy of Ru and In over Ru–N–In/NC. Lower adsorption energy (–0.63 eV) over Ru sites was obtained, in which HCl was adsorbed via the interaction of Ru···Cl–H between Cl (Lewis base) and Ru (Lewis acid) (Fig. 5d and Supplementary Fig. 52). In contrast, stronger HCl adsorption over RuN4/NC (Eads (HCl) = –0.83 eV) was observed, demonstrating a significant over-chlorination potential for Ru centers (Supplementary Fig. 53). In summary, the dimeric Ru-In geometry with proper distance (~0.37 nm) enables the independent adsorption configuration for C2H2 and HCl and mediates the steric hindrance for that, accounting for the enhanced activities compared to RuN4/NC.

Subsequently, we investigated the structure-activity relationship for the Ru–N–In/NC dual-atom catalyst. Generally, the catalyst with higher adsorption energy for the reactants has higher catalytic activity. However, as depicted in Fig. 5e, Ru–N–In/NC owns the medium adsorption strengths for reactants, giving rise to the highest level of reactivity50. Next, an attempt was undertaken to correlate the d-band center with TOF, which exhibited a remarkable linear relationship (R2 = 0.91) (Fig. 5f and Supplementary Fig. 54). Hence, it could be understood that the strong d(Ru)–p(In) interaction results in the up-shift of d-band center of Ru to Fermi level, forming active sites with unique electron configurations for the appropriate adsorption strengths of reactants on the atomic Ru and In sites that improve the intrinsic activity of Ru–N–In/NC51.

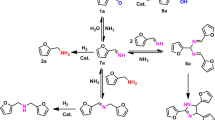

Figure 5g schemes the Gibbs free energy diagrams of acetylene hydrochlorination over the RuN4/NC and Ru–N–In/NC catalysts based on the first principle, and this process follows the Langmuir-Hinshelwood co-adsorption mechanism. Differently, C2H2 and HCl are simultaneously adsorbed on the Ru atom of RuN4/NC, whereas C2H2 and HCl molecules are separately adsorbed on the In and Ru atoms of Ru–N–In/NC, eventually forming the co-adsorbed (C2H2 + HCl)ads state. Subsequently, the HCl molecule begins to migrate, and the H–Cl bond is continuously elongated and broken, causing the *H atom to be endothermically added to *C2H2 to form *CH2 = CH. Due to the diminished steric hindrance for the Ru–N–In/NC in comparison with RuN4/NC, this process (energy barrier = 0.54 eV) serves as the new rate-determined step (RDS) for Ru–N–In/NC moiety. In the following step, the Cl* atom approaches another C atom of *C2H2, and then coordinates to *CH2 = CH to generate *CH2CHCl over Ru centers. For the RuN4/NC moiety, this endothermal process can be regarded as the RDS, while the Ru–N–In/NC decreases the energy barrier of *Cl addition from 0.61 to 0.21 eV. Overall, the cooperation of In atoms changes the RDS of acetylene hydrochlorination by regulating the steric hindrance effect of atomic active sites, skipping the conventional barrier limitation of *Cl addition for the RuN4/NC surfaces. Eventually, the reaction proceeds at a lower free energy on Ru-N-In/NC with the pathway of (C2H2 + HCl)ads → *C2H2 + *HCl → *CH2 = CH → *CH2CHCl → CH2CHCl.

Intrinsic understanding of the high stability of asymmetric Ru–N–In/NC

To unlock the intrinsic mechanism of the promising stability of Ru–N–In/NC, we carefully investigated the chlorination processes of Ru–N–In/NC and RuN4/NC. At the beginning, the dissociation energy of Ru was calculated as 1.86 and 1.27 eV for Ru–N–In/NC and RuN4/NC, respectively, suggesting a higher binding strength between single atom Ru and the substrate in the case of a dual-atom catalyst (Fig. 6a). Then, in-situ DRIFTS NH3 adsorption characterization was carried out to further determine Lewis acidity. The peak of 1591 cm−1 attributed to the NH3 adsorption on Lewis acid sites, in which the intensity of this peak for Ru–N–In/NC was remarkably faded, demonstrating that the Lewis acidity of Ru–N–In/NC was weakened compared to RuN4/NC (Supplementary Fig. 55), which could potentially prevent over-chlorination on the atomic Ru site. Further, scanning electron microscopy (SEM) and EDS images of the used Ru–N–In/NC and RuN4/NC samples indicate that the enrichment of Cl* on the catalyst surface is noticeably reduced from 14.41 to 4.08 wt% (Supplementary Fig. 56).

a Ru dissociation energy of Ru–N–In/NC and RuN4/NC moieties. Gray, blue, green, orange, and pink balls represent C, N, Cl, Ru, and In atoms, respectively. b The normalized Ru K-edge XAFS plots of the post-hydrochlorination samples of Ru–N–In/NC-3h, RuN4/NC-3h, and RuN4/NC-1h, in which the Ru foil, RuCl3, and RuO2 spectra serve as references. c Projected density of states of Ru p orbitals and Cl* d orbitals after Cl* adsorption over the interface of RuN4/NC and Ru–N–In/NC. σ and σ* represent the bonding and antibonding between \({d}_{z}^{2}\) orbital of Ru and p orbital of Cl, π1 and π1* represent the bonding and antibonding between dyz/dxz orbital of Ru and p orbital of Cl, π2 represents the bonding between the dx2–y2 orbital of Ru and p orbital of Cl. d The formation energy of various Ru chlorinated species and the corresponding illustration of the evolution pathway of Ru species over the Ru–N–In/NC and RuN4/NC structures. Gray, pink, purple, yellow, and green balls represent C, N, Ru, In, and Cl atoms, respectively. e Coke deposition of the post-hydrochlorination Ru-based catalysts, determined by the weight loss differences. The error bars indicate the standard deviations of three experimental measurements.

Next, we utilized Ru K-edge XANES to track the chemical and geometric states of Ru after chlorination for three hours for Ru–N–In/NC and RuN4/NC. The pre-edge transition of Ru–N–In/NC-3h is between RuCl3 and RuO2 references, suggesting that the Ru valence states were almost the same (between +3 and +4) before and after the reaction. In contrast, the white-line intensity of chlorinated RuN4/NC decreased with the increasing exposure time, indicating that the Ru chemical state gradually reduced (Fig. 6b). The FT k3-weighted χ(k)-function and structural parameters analysis based on the fitting of EXAFS spectra showed that the coordination number of Ru–Cl over Ru–N–In/NC-3h was kept ~1, while the coordination number of Ru–Cl on the post-hydrochlorination RuN4/NC presented an increasing trend, from ~1.3 (RuN4/NC-1h) to ~2.6 (RuN4/NC-3h) (Supplementary Table 7), verifying that the asymmetric Ru–N–In/NC configuration inherently blocked the over-chlorination of Ru. AC-HAADF-STEM analysis of RuN4/NC-3h indicated that the Ru centers aggregated from single atoms to nanoparticles with sizes up to ~4 nm, whereas the single-atom pairs were still retained on Ru–N–In/NC-3h catalyst (Supplementary Fig. 57), and even on Ru–N–In/NC-600h catalyst (Fig. 4c). Further, the XPS spectra of Cl 2p for the post-hydrochlorination samples show an apparent increase in the surface Cl content than that of the fresh sample for RuN4/NC-3h (Supplementary Fig. 58 and Supplementary Table 8).

To obtain insights into bonding information for Ru–Cl interactions, we conducted PDOS analysis for Ru d orbitals before and after Cl* adsorption. Generally, the Hδ+ and Clδ− species in HCl can be seen as Brønsted acid and Lewis base, respectively. Thus, the Ru atom (Lewis acid) can accept the Clδ− atom (Lewis base) of HCl to form Ru–Clδ− and promote the scission of the H–Cl bond52. As illustrated in Fig. 6c and Supplementary Fig. 59, upon the adsorption of Cl*, the interaction between the p orbital of Cl and the \({d}_{z}^{2}\) orbital of Ru gives the σ bonds on both Ru–N–In/NC and RuN4/NC. However, the π bonds are derived from the coupling between the p orbital of Cl and the dx2–y2 orbital of Ru for Ru–N–In/NC, while the involved orbitals are changed to p(Cl) and \({d}_{{yz}}/{d}_{{xz}}\) for RuN4/NC (Fig. 6c and Supplementary Fig. 60). Such distinct hybridization manner is attributed to the asymmetric geometry and unique electron configuration of atomic Ru enabled by the strong d(Ru)–p(In) interaction for Ru–N–In/NC53,54,55.

To reveal the evolution pathways of the chlorination process on the atomic Ru of Ru-N-In/NC and RuN4/NC, the formation energies of chlorinated species and the related PDOS analysis were carried out. For RuN4/NC, the gradual addition of *Cl to Ru centers was observed, giving a stable three Cl-coordination configuration (denoted as [RuN4/NC]Cl3) eventually. Most importantly, the entire chlorination process from RuN4/NC to [RuN4/NC]Cl3 is highly exothermic (Fig. 6d). That is because once the original symmetrical confinement of RuN4/NC was broken with the adsorption of the first Cl*, the subsequent chlorination process became more energy favorable. In contrast, although the evolution of [Ru–N–In/NC]Cl was easily obtained, the addition of second Cl* turned to be highly endothermic, as evidenced by the emergence of several obvious antibondings, such as the σ* bond (p orbital of Cl and \({d}_{z}^{2}\) orbital of Ru) and π* bond (p orbital of Cl and dx2–y2 orbital of Ru) shown in the PDOS plots of the [Ru–N–In/NC]Cl2 atomic interface (Supplementary Fig. 61). Therefore, the over-chlorinated structures such as [Ru–N–In/NC]Cl2 and [Ru–N–In/NC]Cl3 (Eform > 0 eV) are unstable (Fig. 6d). Overall, the strong d(Ru)–p(In) interaction orbital couplings in Ru–N–In/NC promote the thermodynamic transition of the chlorination process from exothermal to endothermal compared to RuN4/NC, intrinsically avoiding the over-chlorination of Ru and ensuring its excellent stability. Furthermore, the progressive chlorination of Ru–N–In/NC, particularly in proximity to Ru atoms, results in a reduced electron density at the metal sites, as concluded from a shift to higher binding energies in the XPS spectra of Ru 3p (Supplementary Fig. 62). Unfortunately, the active Ru species of RuN4/NC in comparison with Ru–N–In/NC was completely deactivated to Ru0 under the reactive atmosphere (C2H2 + HCl), as demonstrated by Ru 3p XPS (Supplementary Figs. 63–65).

Coke accumulation is an important indicator for measuring the stability of catalysts, thus, thermogravimetry (TG) was applied to determine coke deposition through the weight loss differences56,57. Fortunately, slight coke deposits (ca. 0.18%) were observed on the surface of Ru–N–In/NC, while the ample coke coverage (ca. 5.23%) was accumulated over the RuN4/NC surface (Fig. 6e). Thus, the possible explanation for the observed changes from “coking-prone” carbon to “coking-resistant” carbon upon indium introduction is that Ru–N–In/NC not only effectively adsorbed acetylene but also was favorable for the desorption of VCM13. Furthermore, Ru–N–In/NC can restrain excessive Cl* deposition and addition on the catalyst surface, thus alleviating the aggregation of Ru active sites and preventing the coupling of C–C bonds to form coke precursors. However, for RuN4/NC, excessive Cl* adsorption induced the aggregation of Ru, leading to the shift in the predominating deactivation mode, from agglomeration to coke deposition15. In addition, the leaching experiment and extraction operation interpreted that the Ru–N–In/NC catalyst also had superior recyclability and reusability (Supplementary Figs. 66 and 67). In conclusion, the successful design of Ru–N–In/NC catalyst with multiple excellent properties opens up the possibility of practical application of single-atom Ru catalysts.

Discussion

In summary, we developed an asymmetric Ru–N–In/NC dual single-atom catalyst by breaking symmetrical RuN4/NC geometry to efficiently address the over-chlorination issue of Ru for highly active and stable acetylene hydrochlorination. The experiments and theoretical analysis jointly revealed that the enhanced catalytic performances were caused by the optimized electron arrangement and local density-of-states distribution of the Ru-In synergistic centers. Accordingly, Ru–N–In/NC exhibited exceptional C2H2 conversions (>99.5%) and long-term stability (>600 h), which was evidently far superior to that of the symmetrical RuN4/NC counterpart, state-of-the-art metal-based moieties, and commercial HgCl2 catalysts. The enhanced performances result from the electronic delocalization and electron transfer induced by d-p hybridization between Ru and In atoms. The orbital couplings promote the thermodynamic transition of Cl* intermediates interacting with Ru from endothermal to exothermal, lowering the energy barrier for Cl* addition. Eventually, the selective adsorption of C2H2 and HCl on different sites achieves the transformation from “coking-prone” carbon to “coking-resistant” carbon, suppressing coke accumulation. The presented findings provide insight into the rational design of Ru SACs with excellent acetylene hydrochlorination performance.

Methods

Catalyst preparation

Preparation of NC

The N-doped carbon supports were prepared through a two-step synthesis, including the oxidative polymerization of aniline and a subsequent carbonization step9. 50 mmol of aniline was dissolved in 40 mL of deionized water with a pH of 0.4 and cooled to 4 °C. Then, the mixture was added to the pre-cooled (NH4)2S2O8 solution (5 mol/L, 4 °C) under vigorous stirring. To form higher molecular weight PAN, the polymer slurry was continuously stirred for 24 h at room temperature to complete the polymerization process, subsequently filtered, and washed with deionized water and ethanol. The formed PAN was dried in static air at 120 °C for 12 h and finally carbonized at 800 °C (5 °C/min) in an N2 atmosphere for 1 h to yield NC.

Preparation of MIL-68(In)

MIL-68(In) was employed as the precursor of In source58. Briefly, 0.450 g of 1,4-dicarboxybenzene and 0.350 g of In(NO3)3·5H2O were dissolved in 135 mL of N,N-Dimethylformamide (DMF). The mixture was ultrasound for 10 min and then heated at 120 °C for 40 min under constant stirring. The resulting solid product was collected through centrifugation and washed in a mixture of DMF and CH3OH (30 mL, v/v = 3:1) five times, before being dried at 60 °C for 12 h under vacuum to get white MIL-68(In).

Preparation of Ru–N–In/NC

The catalysts were prepared through an incipient wetness impregnation method (Ru loading of 1.0 wt%). Briefly, 5.0 g of NC and 0.1026 g of Ru(acac)3 were added with 50 mL of deionized water and 25 mL of ethanol. The mixture was sonicated for 30 min, and heated at 90 °C under stirring to evaporate the water. The obtained mixture was dried under vacuum at 60 °C for 12 h. The dried powder was then mixed with a certain amount (adjust the adding amount according to the load of In element) MIL-68(In) and ground for 30 min to form a homogeneous mixture. Then, the mixture was calcinated at 900 °C for 3 h at a heating rate of 5 °C/min under an Ar atmosphere. The obtained sample was denoted as Ru–N–In/NC. The synthesis of RuN4/NC and InN4/NC followed a similar procedure as that of Ru–N–In/NC, except that MIL-68(In) and Ru(acac)3 were not used for the synthesis of RuN4/NC and InN4/NC, respectively.

Preparation of RuIn/AC

The first step of preparing the RuIn/AC catalyst is to clean the commercial activated carbon to obtain pure AC supports7. Briefly, the commercial activated carbon (CAC) was cleaned with 36% HCl to remove ash and impurity ions on the surface, followed by washing with ultrapure water to neutral pH and desiccating at 150 °C for 24 h. Then, the washed CAC was immersed into the ammonium persulfate solution (5 mol/L) in 1.0 M of H2SO4 at room temperature for 24 h. After oxidation treatment, CAC was washed with distilled water until pH neutral then maintained at 60 °C in the thermostat water bath for 12 h and desiccated at 120 °C for 12 h to obtain AC. Then, 1.0 g of AC was added to the mixed solution (10 mL of deionized water and 5 mL of ethanol) containing 20.6 mg of Ru(acac)3 and 5.6 mg of In(NO3)3·5H2O. The mixture was sonicated for 30 min, and heated at 90 °C under stirring to evaporate the water. The resulting mixture was calcinated at 900 °C for 3 h at a heating rate of 5 °C/min under an Ar atmosphere to obtain the RuIn/AC catalyst.

Catalyst characterization

Powder XRD patterns were acquired using a powder X-ray diffractometer (PANalytical, Netherlands) with Cu-Kα radiation (λ = 1.54060 Å). Laser Raman spectra were obtained on a LabRAM HR800 Evolutions (Horiba, Japan) spectrometer. Fourier transform infrared (FTIR) spectroscopy was recorded using a Nicolet 6700 FT-IR spectrometer, and the spectra were recorded at every certain time by accumulating 64 scans with a resolution of 4 cm-1. The chemical composition and relative contents of the catalyst samples were acquired by XPS equipped with Al-Kα radiation (Thermo Fischer, ESCALAB 250Xi). ICP-OES was carried out on an Agilent ICP-OES 5110 instrument. Brunaur–Emmett–Teller surface areas were acquired with a surface area analyzer (Quantachrome NOVA 2200E). TG analysis was carried out from 50 to 800 °C by using a Mettler Toledo in an air atmosphere with a heating rate of 10 °C/min. TPD experiments were measured from 30 to 600 °C with a 10 °C/min heating rate by Quantachrome Instruments (AMI-90) in a He atmosphere. The H2-TPR experiment was performed on an automatic adsorption instrument (AutoChem II 2920). The catalyst morphology was characterized by TEM, and EDS images were also obtained. HR-TEM and AC-HAADF-STEM were performed on a double-corrected microscope JEM-ARM200F (GrandARM, JEOL).

In-situ FT-IR spectra of acetylene adsorption were conducted on a Nicolet 6700 FT-IR spectrometer using a liquid N2-cooled mercury cadmium telluride (MCT-A) detector. In-situ FT-IR spectra of NH3 adsorption were recorded on a Nicolet 6700 spectrometer in the range of 600–2000 cm−1 with a resolution of 4 cm−1 and 64 scans. XANES and EXAFS measurements of Ru and In were collected at the beamline BL14W1 of the Shanghai Synchrotron Radiation Facility (SSRF) in a fluorescence mode at room temperature. Data reduction, data analysis, and EXAFS fitting were performed and analyzed with the Athena and Artemis programs of the Demeter data analysis packages that utilize the FEFF6 program to fit the EXAFS data. Note that the above characterization procedures are shown in detail in the Supplementary Materials.

Catalytic performance tests

Catalytic performance evaluations were carried out in a fixed-bed microreactor (i.d. 8.0 mm) with accurately controlled temperature and gas flow. Prior to testing, a certain amount of catalyst was loaded into the reactor, and nitrogen was imported into the reactor to remove the air and water from the catalytic system. The catalyst was heated in a He flow to the desired temperature and allowed to stabilize for at least 30 min before the reaction mixture. Then, the purified HCl was introduced into the reactor to activate the catalyst at a temperature of 180 °C for 30 min with a flow rate of 10 mL/min. Subsequently, C2H2 and HCl (V(HCl)/V(C2H2) = 1.15) were fed through filters with GHSV(C2H2) of 180 h−1 at 180 °C. The effluent gas was passed into NaOH solution and a dryer, followed by analysis with a gas chromatograph (PANNA A60, China) equipped with a flame ionization detector (FID) and a KB-624 column (30 m × 0.32 mm × 1.8 μm)6,9.

The catalytic performances were evaluated in terms of acetylene conversion (CA), VCM selectivity (SVCM), and turnover frequency (TOF, h−1), which were defined and expressed as the following equations, respectively.

where TA0, TA, and TVC represent the volume fraction of acetylene in the feed gas, the volume fraction of acetylene in the product gas, and the volume fraction of vinyl chloride in product gas, respectively. n(C2H2)inlet and n(C2H2)outlet are defined as the molar flows of C2H2 at the inlet and outlet of the reactor, respectively. The molmetal is the total mole number of metals on the evaluated catalysts. The h represents time on stream.

DFT calculations

DFT calculations were conducted in this study to determine the optimum configurations, obtain the adsorption energy values, as well as verify the catalytic pathways and transition states. The calculations were performed using the Vienna Ab initio Simulation Package (VASP) with projector-augmented wave core potentials and the PBE-D3 functional. The detailed simulation processes are exhibited in the Supplementary Materials.

Data availability

All source data supporting the findings of this study are available within the paper and the Supplementary Information files or available from the corresponding author upon request. Source data are provided with this paper.

References

Akl, D. F. et al. Reaction-induced formation of stable mononuclear Cu(I)Cl species on carbon for low-footprint vinyl chloride production. Adv. Mater. 35, 2211464 (2023).

Hutchings, G. J. & Grady, D. T. Hydrochlorination of acetylene: the effect of mercuric chloride concentration on catalyst life. Appl. Catal. 17, 155–160 (1985).

Ye, L. et al. Self-regeneration of Au/CeO2 based catalysts with enhanced activity and ultra-stability for acetylene hydrochlorination. Nat. Commun. 10, 914 (2019).

Oliver-Meseguer, J. et al. Partial reduction and selective transfer of hydrogen chloride on catalytic gold nanoparticles. Angew. Chem. Int. Ed. 56, 6435–6439 (2017).

Hutchings, G. J. Vapor phase hydrochlorination of acetylene: correlation of catalytic activity of supported metal chloride catalysts. J. Catal. 96, 292–295 (1985).

Fan, Y. et al. Metal-organic frameworks encaged Ru single atoms for rapid acetylene harvest and activation in hydrochlorination. ACS Appl. Mater. Interfaces 15, 24701–24712 (2023).

Fan, Y. et al. Tunable redox cycle and enhanced π-complexation in acetylene hydrochlorination over RuCu catalysts. ACS Catal. 12, 7579–7588 (2022).

Conte, M. et al. Hydrochlorination of acetylene using a supported gold catalyst: a study of the reaction mechanism. J. Catal. 250, 231–239 (2007).

Kaiser, S. et al. Preserved in a shell: high-performance graphene-confined ruthenium nanoparticles in acetylene hydrochlorination. Angew. Chem. Int. Ed. 58, 12297–12304 (2019).

Zhang, H. et al. Ru–Co(III)–Cu(II)/SAC catalyst for acetylene hydrochlorination. Appl. Catal. B: Environ. 189, 56–64 (2016).

Kaiser, S. et al. Performance descriptors of nanostructured metal catalysts for acetylene hydrochlorination. Nat. Nanotechnol. 17, 606–612 (2022).

Giulimondi, V. et al. Evidence of bifunctionality of carbons and metal atoms in catalyzed acetylene hydrochlorination. Nat. Commun. 14, 5557 (2023).

Kaiser, S. K. et al. Design of carbon supports for metal-catalyzed acetylene hydrochlorination. Nat. Commun. 12, 4016 (2021).

Kaiser, S. K. et al. Controlling the speciation and reactivity of carbon-supported gold nanostructures for catalysed acetylene hydrochlorination. Chem. Sci. 10, 359–369 (2019).

Kaiser, S. K. et al. Nanostructuring unlocks high performance of platinum single-atom catalysts for stable vinyl chloride production. Nat. Catal. 3, 376–385 (2020).

Wang, X. et al. Progress of p-block element-regulated catalysts for acetylene hydrochlorination. Coord. Chem. Rev. 500, 215541 (2024).

Sun, X. et al. Facile synthesis of precious-metal single-site catalysts using organic solvents. Nat. Chem. 12, 560–567 (2020).

Kaiser, S. K. et al. Single-atom catalysts across the periodic table. Chem. Rev. 120, 11703–11809 (2020).

Lim, T. et al. Atomically dispersed Pt–N4 sites as efficient and selective electrocatalysts for the chlorine evolution reaction. Nat. Commun. 11, 412 (2020).

Cho, J. et al. Importance of broken geometric symmetry of single-atom Pt sites for efficient electrocatalysis. Nat. Commun. 14, 3233 (2023).

Kaiser, S. K. et al. Sustainable synthesis of bimetallic single atom gold-based catalysts with enhanced durability in acetylene hydrochlorination. Small 17, 2004599 (2021).

Qi, H. et al. Highly selective and robust single-atom catalyst Ru1/NC for reductive amination of aldehydes/ketones. Nat. Commun. 12, 3295–3305 (2021).

Malta, G. et al. Identification of single-site gold catalysis in acetylene hydrochlorination. Science 355, 1399–1403 (2017).

Yang, Y. et al. O-, N-atoms-coordinated mn cofactors within a graphene framework as bioinspired oxygen reduction reaction electrocatalysts. Adv. Mater. 30, e1801732 (2018).

Chen, Y. et al. Inter-metal interaction of dual-atom catalysts in heterogeneous catalysis. Angew. Chem. Int. Ed. 62, e2023064 (2023).

Li, R. et al. Polystyrene waste thermochemical hydrogenation to ethylbenzene by a N-bridged Co, Ni dual-atom catalyst. J. Am. Chem. Soc. 145, 16218–16227 (2023).

Shang, H. et al. Engineering unsymmetrically coordinated Cu–S1N3 single atom sites with enhanced oxygen reduction activity. Nat. Commun. 11, 3049 (2020).

Huang, F. et al. Low-temperature acetylene semi-hydrogenation over the Pd1–Cu1 dual-atom catalyst. J. Am. Chem. Soc. 144, 18485–18493 (2022).

Yan, L. et al. Atomically precise electrocatalysts for oxygen reduction reaction. Chem. 9, 280–342 (2023).

Zhao, S. et al. Manipulating electron redistribution induced by asymmetric coordination for electrocatalytic water oxidation at a high current density. Sci. Bull. 68, 1389–1398 (2023).

Sestelo, J. P. et al. Indium(III) as π-acid catalyst for the electrophilic activation of carbon–carbon unsaturated systems. Org. Biomol. Chem. 16, 5733–5747 (2018).

Albani, D. et al. Semihydrogenation of acetylene on indium oxide: proposed single-ensemble catalysis. Angew. Chem. Int. Ed. 56, 10755–10760 (2017).

Surendra, K. et al. A powerful new construction of complex chiral polycycles by an Indium(III)-catalyzed cationic cascade. J. Am. Chem. Soc. 133, 9724–9726 (2011).

Surendra, K. & Corey, E. J. Diiodoindium(III) cation, InI2+, a potent yneophile. generation and application to cationic cyclization by selective π-activation of C≡C. J. Am. Chem. Soc. 136, 10918–10920 (2014).

Yao, Y. et al. Engineering the electronic structure of single atom Ru sites via compressive strain boosts acidic water oxidation electrocatalysis. Nat. Catal. 2, 304–313 (2019).

Li, X. et al. CoN1O2 single-atom catalyst for efficient peroxymonosulfate activation and selective cobalt(IV)=O generation. Angew. Chem. Int. Ed. 62, e2023032 (2023).

Yue, Y. et al. Tailoring asymmetric Cu–O–P coupling site by carbothermal shock method for efficient vinyl chloride synthesis over carbon supported Cu catalysts. ACS Catal. 13, 9777–9791 (2023).

Ou, H. et al. Carbon nitride photocatalysts with integrated oxidation and reduction atomic active centers for improved CO2 conversion. Angew. Chem. Int. Ed. 61, e202206579 (2022).

Zhu, C. Z. et al. Hierarchically porous M–N–C (M = Co and Fe) Single-atom electrocatalysts with robust MNx active moieties enable enhanced ORR performance. Adv. Energy Mater. 8, 1801956 (2018).

Shi, H. et al. Atomically dispersed indium–copper dual-metal active sites promoting C–C coupling for CO2 photoreduction to ethanol. Angew. Chem. Int. Ed. 61, e202208904 (2022).

Wang, X. et al. A metal-free polymeric photocatalyst for hydrogen production from water under visible light. Nat. Mater. 8, 76–80 (2009).

Xie, P. et al. Oxo dicopper anchored on carbon nitride for selective oxidation of methane. Nat. Commun. 13, 1375 (2022).

Giulimondi, V. et al. Redispersion strategy for high-loading carbon-supported metal catalysts with controlled nuclearity. J. Mater. Chem. A 10, 5953–5961 (2022).

Wang, B. et al. Hydrochlorination of acetylene on single-atom Pd/N-doped carbon catalysts: importance of pyridinic-N synergism. Appl. Catal. B: Environ. 272, 118944 (2020).

Jiang, Z. et al. Modulating the electronic metal-support interactions in single-atom Pt1-CuO catalyst for boosting acetone oxidation. Angew. Chem. Int. Ed. 61, e202200763 (2022).

Song, Q. et al. Electrostatic force-driven lattice water bridging to stabilize a partially charged indium MOF for efficient separation of C2H2/CO2 mixtures. J. Mater. Chem. A 10, 9363–9369 (2022).

Cao, Y. et al. Selective hydrogenation of acetylene over Pd–In/Al2O3 catalyst: promotional effect of indium and composition-dependent performance. ACS Catal. 7, 7835–7846 (2017).

Wang, B. et al. A site distance effect induced by reactant molecule matchup in single-atom catalysts for fenton-like reactions. Angew. Chem. Int. Ed. 61, e2022072 (2022).

Gong, Z. et al. Modulating metal-nitrogen coupling in anti-perovskite nitride via cation doping for efficient reduction of nitrate to ammonia. Angew. Chem. Int. Ed. 62, e2023087 (2023).

Li, P. et al. p–d Orbital hybridization induced by p-block metal-doped Cu promotes the formation of C2+ products in ampere-level CO2 electroreduction. J. Am. Chem. Soc. 145, 4675–4682 (2023).

Tiwari, J. N. et al. Multicomponent electrocatalyst with ultralow Pt loading and high hydrogen evolution activity. Nat. Energy 3, 773–782 (2018).

Peng, J. et al. Manipulating micro-electric field and coordination-saturated site configuration boosted activity and safety of frustrated single-atom Cu/O Lewis pair for acetylene hydrochlorination. Nano Res. 16, 6178–6186 (2023).

Hu, L. et al. Metal-triazolate-framework-derived FeN4Cl1 single-atom catalysts with hierarchical porosity for the oxygen reduction reaction. Angew. Chem. Int. Ed. 60, 27324–27329 (2021).

Zhao, K. et al. Insight into the mechanism of axial ligands regulating the catalytic activity of Fe–N4 sites for oxygen reduction reaction. Adv. Energy Mater. 12, 2103588 (2022).

Yang, Y. et al. Regulating the coordination environment of Ru single-atom catalysts and unravelling the reaction path of acetylene hydrochlorination. Green Energy Environ. 8, 1141–1153 (2023).

Chen, Z. et al. Advances in single-atom-catalyzed acetylene hydrochlorination. ACS Catal. 14, 965–980 (2024).

Cao, R. et al. Catalytic oxidation of polystyrene to aromatic oxygenates over a graphitic carbon nitride catalyst. Nat. Commun. 13, 4809 (2022).

Li, J. et al. Core–shell ZIF-8@MIL-68(In) derived ZnO nanoparticles-embedded In2O3 hollow tubular with oxygen vacancy for photocatalytic degradation of antibiotic pollutant. J. Hazard. Mater. 414, 125395 (2021).

Shang, S. et al. Highly efficient Ru@IL/AC to substitute mercuric catalyst for acetylene hydrochlorination. ACS Catal. 7, 3510–3520 (2017).

Li, J. et al. Enhanced catalytic performance of activated carbon-supported Ru-based catalysts for acetylene hydrochlorination by azole ligands. Appl. Catal. A 592, 117431 (2020).

Man, B. et al. Oxidation modification of Ru-based catalyst for acetylene hydrochlorination. RSC Adv. 7, 23742–23750 (2017).

Li, Y. et al. Improvement of imidazolium-based ionic liquids on the activity of ruthenium catalyst for acetylene hydrochlorination. Mol. Catal. 443, 220–227 (2017).

Li, X. et al. Synthesis of vinyl chloride monomer over carbon-supported tris-(triphenylphosphine) ruthenium dichloride catalysts. Catalysts 8, 276 (2018).

Li, X. et al. Activated carbon-supported tetrapropylammonium perruthenate catalysts for acetylene hydrochlorination. Catalysts 7, 311 (2017).

Gu, J. et al. Hydrochlorination of acetylene catalyzed by an activated carbon-supported ammonium hexachlororuthenate complex. Catalysts 7, 17 (2017).

Xu, J. et al. Ultra-low Ru-promoted CuCl2 as highly active catalyst for the hydrochlorination of acetylene. RSC Adv. 5, 38159 (2015).

Wang, B. et al. Controllable synthesis of vacancy-defect Cu site and its catalysis for the manufacture of vinyl chloride monomer. ACS Catal. 11, 11016–11028 (2021).

Acknowledgements

This work was financially supported by the National Key R&D Program of China (2022YFC3901100, 2022YFC3703800), National Natural Science Foundation of China (22176121, 52070129), Natural Science Foundation of Zhejiang Province (LR22B060002), and National Natural Science Foundation of China (22278365).

Author information

Authors and Affiliations

Contributions

Y.F., H.X., Y.Y., and P.X. conceived the idea and designed the research; Y.F., G.G., and L.M. prepared materials and performed characterizations; M.W. and W.H. assembled the test system; Y.F., H.X., Z.Q., and P.X. analyzed and interpreted the results; and Y.F., H.X., Y.Y., B.D., N.Y., and P.X. contributed to the writing and revising of the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Fan, Y., Xu, H., Gao, G. et al. Asymmetric Ru-In atomic pairs promote highly active and stable acetylene hydrochlorination. Nat Commun 15, 6035 (2024). https://doi.org/10.1038/s41467-024-50221-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-50221-3

- Springer Nature Limited