Abstract

Highly sensitive, low-power, and chip-scale H2 gas sensors are of great interest to both academia and industry. Field-effect transistors (FETs) functionalized with Pd nanoparticles (PdNPs) have recently emerged as promising candidates for such H2 sensors. However, their sensitivity is limited by weak capacitive coupling between PdNPs and the FET channel. Herein we report a nanoscale FET gas sensor, where electrons can tunnel between the channel and PdNPs and thus equilibrate them. Gas reaction with PdNPs perturbs the equilibrium, and therefore triggers electron transfer between the channel and PdNPs via trapping or de-trapping with the PdNPs to form a new balance. This direct communication between the gas reaction and the channel enables the most efficient signal transduction. Record-high responses to 1–1000 ppm H2 at room temperature with detection limit in the low ppb regime and ultra-low power consumption of \(\sim\)300 nW are demonstrated. The same mechanism could potentially be used for ultrasensitive detection of other gases. Our results present a supersensitive FET gas sensor based on electron trapping effect in nanoparticles.

Similar content being viewed by others

Introduction

Hydrogen gas (H2) is one of the most promising candidates for clean and renewable energy sources, replacing fossil fuels towards a future hydrogen society1,2,3,4,5. However, any small leakage of H2 during its production, transportation, storage, and usage can be dangerous, due to its ultra-small molecule size, colorless and odorless nature, low ignition temperature, and wide explosive concentration range6. Hydrogen safety demands highly sensitive H2 sensors with short response time to detect hydrogen leakage at concentrations far below its explosion limit7,8,9,10. Additionally, low-power consumption11,12,13 and miniaturized device size14,15 are desirable for remote and distributed H2 sensors.

Palladium nanoparticles (PdNPs) decorated field-effect transistors (FETs) have emerged as a promising device candidate for H2 sensing16,17,18,19,20,21,22. The channel current of an FET-based H2 sensor is modulated by the work function change induced by H2 reaction with PdNPs, which proceeds via H2 dissociation and subsequent absorption of H atoms in Pd23. These devices have gained considerable attention owing to the current amplification in the FET, integration compatibility with CMOS circuitry, device miniaturization, and mass production possibility24. Besides, the large surface-to-volume ratio of dispersed PdNPs can enhance the sensitivity and enable room-temperature sensing capability25,26. However, in these devices, any solid gate covering the PdNPs will inevitably block their accessibility to H2. Therefore, an alternative gate, normally a back (substrate) gate is needed to turn on a buried channel and set the working point of the FET. Consequently, the PdNPs are electrically floating, thus decoupled from the gate-channel loop. This leads to indirect capacitive coupling between the PdNPs and the FET channel, thus yielding weak signal transduction. Different novel FET device designs, e.g., ultra-thin planar channel15,27 and nanowire channel with intimately attached side-gates configuration28, were recently demonstrated to enhance such capacitive coupling by reducing the distance of the sensing layers from the channel. However, the intrinsic problem of indirect capacitive coupling induced by the floating PdNPs sensing layer has not been addressed to date.

In this work, we address the fundamental issue of indirect capacitive coupling of PdNP-FET H2 sensors by using a nanoscale FET sensor design to enable a signal transduction mechanism based on electron trapping effect in PdNPs. In this design, an oxide passivated silicon nanowire (SiNW) channel is gated by two side-gates via nanoscale air gaps (NAGs)—SiNW-NAG FET. The NAGs allow PdNPs to be deposited at the closest possible location to the conducting channel forming on the SiNW sidewalls. An ultra-thin passivation oxide (2 nm) enables electrons to tunnel between the channel and the PdNPs and equilibrate them. The PdNPs work as both H2 sensing material and electron traps. When exposed to H2 gas, H2 can access and react with the PdNPs with fast kinetics. The PdNP-H2 reaction will change the potential energy of the PdNPs thus perturbing the equilibrium between the channel and the PdNPs. As a result, electrons will transfer between the channel and the PdNPs via trapping or de-trapping with the PdNPs to reach a new balance, leading to a steady change in the channel current. The direct electron tunneling communication between the channel and PdNPs enables the most efficient signal transduction. Based on this mechanism, record-high responses to 1–1000 ppm H2 are demonstrated, showing 4.86 × 106% channel resistance change to 1000 ppm H2 at room temperature. A sensitivity of 3600%/ppm and lower limit of detection (LOD) of 4.4 ppb can be deduced. Due to the small size of the SiNW channel, a power consumption of \(\sim\)300 nW is sufficient to drive the sensor. Selectivity against three different types of gases, CO (neutral), NO2 (electrophilic), and NH3 (nucleophilic) are also verified. The demonstrated signal transduction mechanism could potentially be used for detecting other gases using different sensing NPs.

Results

SiNW-NAG FET structure

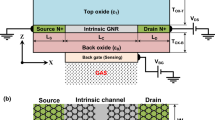

A three-dimensional (3D) schematic of the SiNW-NAG FET sensor design is shown in Fig. 1a. The device was fabricated on a (100) silicon-on-insulator (SOI) wafer with 145 nm thick buried SiO2 (BOX) layer using standard Si process technology. The source (S) and drain (D) regions of the FET were heavily p-doped (brown), while the SiNW channel consists of a 600 nm long lightly doped p-type region (gray). SiO2 passivation layers, with different thicknesses, were deposited surrounding the SiNW via the atomic layer deposition (ALD) process. Side-gates of NiSi were formed in proximity to the SiNW sidewalls, leaving 50 nm wide air gaps in between as dielectric layers. PdNPs were deposited on the top and sidewalls of the SiO2-passivated SiNW by depositing a thin layer (<1 nm) of Pd using electron beam evaporation, which yields agglomerated PdNPs similar to previous work29. To deposit the PdNPs on the SiNW sidewalls, double angled depositions were made with the tilted substrate. A detailed description of the fabrication process can be found in the Methods Section and step-by-step process schematics in Supplementary Section 1. Back-gate SiNW FETs, without any side-gates and with PdNPs only on the top of the SiNW, were fabricated in parallel.

a Three-dimensional schematic of the SiNW-NAG FET device for H2 detection. The SiNW channel is p-type and gated by the side-gates via nanoscale air gaps (NAGs). The H2 sensing layer palladium nanoparticles (PdNPs) were deposited within a coupling loop between the side-gates and the main channel. b Three-dimensional scanning electron microscope (SEM) image of the SiNW-NAG FET (top; scale bar, 400 nm) and cross-sectional transmission electron microscope (TEM) image (bottom-left; scale bar, 20 nm) and color-coded energy dispersive X-ray spectroscopy (EDS) images (bottom-right) of the PdNP-decorated SiNW channel. The SEM image is colorized; the brown, green, lightly grey, and heavily grey areas represent the heavily doped source/drain, NiSi side-gates, lightly doped channel, and substrate, respectively. The PdNPs cover both the top surface and sidewalls of the SiNW with a 4 nm thick SiO2 passivation layer in between. The green area in the EDS images indicates the corresponding element distribution. c Analysis of the capacitive coupling of the H2 signal in the conventional back-gate SiNW FET (left) and the SiNW-NAG FET (right). The simulated cross-sectional distribution of holes was obtained at drain voltage VD = 1 V and fixed working point of drain-to-source current IDS = 300 nA by proper gate voltage setting. The red loops in both devices indicate the gas reaction coupled capacitor loops, which generate the current responses in the SiNW. The black one in the back-gate SiNW FET (left) refers to the H2-insensitive loops. Real-time H2 sensing results measured at room temperature of (d) the back-gate SiNW FET and (e) the SiNW-NAG FET. Both devices are passivated with 4 nm SiO2. IDS sampling was performed in a series of H2 pulses at concentrations ranging from 100 to 1000 ppm.

Scanning electron microscope (SEM) images of the SiNW-NAG FET device with 4 nm thick passivation SiO2 are shown in Fig. 1b (top) and Supplementary Section 2, respectively. The cross-sectional transmission electron microscope (TEM) image and its element analysis of the PdNP-decorated SiNW (see Fig. 1b, bottom) confirm the SiNW dimension (height: 25 nm, width: 35 nm), the uniform SiO2 passivation layer and the deposition of PdNPs. The voltage applied to the side-gates (VG_s) can effectively modulate the channel conductance via NAG capacitance (CNAG), as evidenced by the simulated potential distribution in Supplementary Section 3 and the measured typical transfer and output characteristics in Supplementary Section 4.

Side and back-gate capacitive coupling

Hydrogen dissociates and populates interstitial lattice sites when it adsorbs on Pd and diffuses into the bulk to form Pd hydride. H (donor) hybridizes with Pd (acceptor) and modifies the electronic properties of Pd (the H1s-Pd4d bonding), leading to a detectable shift of its work function. The formation and dissociation of palladium hydride are reversible processes. The work function of Pd is sensitive to changes in hydrogen across a wide range of concentrations, which allows for precise measurement of hydrogen concentration. To investigate the Pd-based H2 transistor sensors, semiconductor device simulator provides a powerful tool30,31. For simulation and modeling purposes, the sensing mechanism of a Pd sensor is typically described by the formation of a dipole layer as the interface becomes polarized18,28,32 (see inset Fig. 1c). The first advantage of the SiNW-NAG FET structure in signal transduction is illustrated in the equivalent circuits in Fig. 1c. In a conventional back-gate FET (see Fig. 1c left), the work function change in PdNPs (ΔΦPdNP) caused by their reaction with H2 is weakly coupled to the top channel in the SiNW via small stray capacitance (Cstray; CSi is the capacitance of Si channel and Cstray ≪ CSi), as shown in the red loop in Fig. 1c left. Only a small portion of ΔΦPdNP is coupled to the top channel, leading to an insignificant variation of carrier density in the top channel. In addition, the main channel is formed at the bottom side of the SiNW by the back-gate via a strong coupling loop over the BOX layer (see the black loop; CBOX is the capacitance of the BOX layer, and VS and VG_b are the voltages applied on the source and back-gate, respectively). Since the main channel, having many more conducting carriers than the top channel is not significantly affected by ΔΦPdNP, the overall current change induced by PdNP-H2 reaction will therefore be diluted by the main channel. As a direct contrast, in the SiNW-NAG FET, ΔΦPdNP is modified within the SiNW-NAG-gate coupling loop which generates the main conducting channel on the SiNW sidewalls (Fig. 1c right). ΔΦPdNP is therefore directly coupled to the main conducting channel via CNAG. Since CNAG is much larger than Cstray, a much larger portion of ΔΦPdNP is coupled to the main channel thus producing significantly enhanced modulation of its conductance.

Previous studies have demonstrated that the coupling between the sensing material and the FET channel could be enhanced by using an ultra-thin channel15,27. However, the indirect coupling remains in the back-gate FET device structure. SiNW channel with intimately attached side-gates in a FET gas sensor has been reported as an alternative device design to enhance the signal transduction. Nevertheless, in this device design, the sensing PdNPs are out of the channel-gate loop28. Consequently, direct ΔΦPdNP coupling to the channel could not be achieved either. Such indirect coupling results in a limited signal transduction efficiency and thereby a minor sensitivity.

The H2 sensing measurement results further prove the enhanced sensitivity of the SiNW-NAG FET device over the control device with the traditional back-gate structure. Both devices were passivated with 4 nm thick SiO2 layers. The measurements were done at room temperature with no external heating. The drain voltage was fixed at VD = 1 V and the drain-to-source current (IDS) baseline was stabilized at \(\sim\)300 nA with fixed gate voltage setting, leading to a standby power consumption of \(\sim\)300 nW. Figure 1d, e shows the comparison of the real-time monitoring of IDS of the traditional back-gate FET sensor and the SiNW-NAG FET sensor, respectively. Both devices exhibit reversible current responses when exposed to the pulses of varied H2 concentration. The response amplitude is defined as the percent change in channel resistance ΔR/R0, which is shown in Supplementary Section 5. The H2 sensitivity is 1.71%/ppm (ΔR/R0 per ppm) for the SiNW-NAG FET sensor, which is significantly larger than the back-gate FET (0.035%/ppm). The simulation results also show a higher response of the SiNW-NAG FET device (see Supplementary Section 6). In addition, the LOD of the SiNW-NAG FET sensor with 4 nm passivation SiO2 is extrapolated to be 2.7 ppm, much lower than the back-gate counterpart (48 ppm) (see Supplementary Section 5 for more details).

Electron trapping effect in PdNPs

When the thickness of the passivation SiO2 layer is reduced to 2 nm, the subthreshold slope (SS) of the SiNW-NAG FET exhibits significant degradation, as shown in Fig. 2a. This indicates an increased density of traps in proximity to the SiNW surface with the thin SiO2 layer, which is accessible to electrons in the channel33. To nail down the origin of the traps, we fabricated and characterized a PdNP-free SiNW-NAG FET device with 2 nm SiO2 layer (see Fig. 2b). It exhibits a significantly sharper SS compared to the PdNP-decorated counterpart. This indicates that the PdNPs act as the electron traps in the 2 nm SiO2 layer passivated SiNW-NAG FET. Electrons in the channel can tunnel through the 2 nm SiO2 layer and get trapped in the PdNPs. Such tunneling process is suppressed with the 4 nm SiO2 layer, which explains the SS dependence shown in Fig. 2a. On the other hand, the dynamic electron trapping/de-trapping processes with the PdNPs are expected to generate extra low-frequency noise (LFN)34. Indeed, the device with the thinner oxide exhibits higher LFN (see Supplementary Section 7), which double confirms the electron trapping effect in the PdNPs.

a Transfer curves of the silicon nanowire gated via nanoscale air gaps field-effect transistors (SiNW-NAG FETs) with 2 and 4 nm thick SiO2 passivation layers. b Transfer curves of the 2 nm SiO2 layer passivated SiNW-NAG FET with and without PdNP decoration. All curves in (a) and (b) were measured in air. c Schematic and equivalent circuit of the SiNW-NAG FET with 2 nm SiO2 passivation layer in air. The PdNPs work as electron traps. The trapping/de-trapping processes are enabled via the electron tunneling through the thin SiO2 layer. EC, EV, EF, and VS are the bottom of conduction band energy, top of valence band energy, Fermi level, and source voltage, respectively. d Transfer curves of the 2 nm SiO2 layer passivated SiNW-NAG FET in air and 10 ppm H2. e Extracted density-of-state of the PdNPs from (d) as a function of channel current in air and 10 ppm H2. f Schematic and the equivalent circuit of the SiNW-NAG FET with 2 nm SiO2 passivation layer in H2 ambience. Once the PdNP energy is raised above EF due to the reaction with H2, the electrons trapped in the corresponding PdNPs are released back to the SiNW channel and recombine the holes in it. NPdNP and ΔΦPdNP are the density-of-states and work function change of PdNPs.

Due to the small size of the PdNPs (2–3 nm in diameter, as measured by TEM, see Fig. 1b), a strong Coulomb blockade exists. Each PdNP can only trap one electron and generate a single energy state (EPdNP) since the entry of the 2nd electron is not energetically favorable35. Considering the size distribution of the PdNPs and the monotonic size-dependence of nanoparticle’s work function36, the energy states of the PdNPs are distributed in energy space, as illustrated in Fig. 2c. With the 2 nm thick SiO2 layer, electrons can tunnel between the SiNW channel and the energy states of PdNPs and equilibrate them. Therefore, each PdNP with energy lower than Fermi level (EF) in the channel will trap an electron from the channel, leaving the remaining PdNPs empty. The trapping effect in the PdNPs contributes an equivalent capacitor (CPdNP), which is in parallel to the Si channel capacitor CSi (see Supplementary Section 8 for the detailed process to develop the equivalent circuit). CPdNP on 2 nm SiO2 layer is estimated to be 20 times of CSi based on the significant SS change induced by the presence of the PdNPs (see Supplementary Section 9 for detailed analysis).

As shown in Fig. 2d, exposure to H2 shifts the transfer curves of the SiNW-NAG FET with 2 nm SiO2 towards lower gate voltage and sharpens SS. These effects could be explained by a simple H2-mediated energy shift of the PdNP trap distribution. SS depends on the density-of-states of the PdNPs (NPdNP) close to EF; states below EF are already filled with electrons, while electrons do not have enough energy to access the PdNP states far above EF. Thus, NPdNP can be extracted from SS (see Fig. 2e)33, which increases at lower IDS (higher EF in the p-type channel) in both air and H2. Such non-uniform distribution of NPdNP can be explained by the size-dependence of PdNP’s work function. It is known that the evaporator-deposited metal nanoparticles exhibit a Gaussian size distribution37. Since nanoparticle’s work function exhibits a monotonic size dependence, a Gaussian-shape energy distribution of the PdNPs can be expected (see Fig. 2f). The increased NPdNP at lower IDS indicates that EF falls in the lower half region of the PdNP density profile. Moreover, Fig. 2e shows a decreased NPdNP when exposed to H2, which can be attributed to the globally raised PdNP density profile in energy space, owing to the PdNP-H2 reaction induced work function change. The reduced NPdNP in H2 is double confirmed with the lower noise measured in H2 ambience (see Supplementary Section 7) since the noise generated by the dynamic electron trapping/de-trapping processes with the PdNPs is also determined by NPdNP that the channel electrons can access. It is noticeable in Fig. 2e that NPdNP at IDS = 10−9 and 10−10 A in 10 ppm H2 can be obtained from that in air via roughly two orders of magnitude IDS shifting (which is equivalent to \(\sim\)120 mV change in EF, since the carrier density in the channel follows Boltzmann relationship with EF), suggesting that the PdNP density profile is raised by \(\sim\)120 mV upon exposure to 10 ppm H2.

Super-sensitivity enabled by the electron trapping effect

Hydrogen absorption in PdNPs will raise EPdNP, thus perturbing the equilibrium between the channel and PdNPs. This will force PdNPs to detrap electrons to the channel until a new balance is reached. Specifically, once EPdNP exceeds EF, the electrons trapped in the corresponding PdNPs are expected to spill and flow back to the SiNW channel and recombine with the holes to generate a current response, as illustrated in Fig. 2f. Owing to the large capacitance of CPdNP, the number of the released electrons and the resultant current response could be significant. The electron trapping/de-trapping processes in the SiNW-NAG FET sensor generate direct communication between the PdNP-H2 reaction and the main conducting channel, thus enabling the most efficient signal transduction. The weak capacitive coupling and the signal dilution issues in the back-gate FET gas sensors are therefore avoided.

The H2 sensitivity based on the electron trapping mechanism was tested using the SiNW-NAG FET with 2 nm SiO2 passivation layer at room temperature. Figure 3a shows the real-time IDS monitoring upon exposure to varied H2 concentrations ranging from 1 to 1000 ppm. The resistance change ΔR/R0 is extracted and plotted in Fig. 3b. The device shows ultrahigh room-temperature responses, which are exemplified with ΔR/R0 = 4.86 × 106% at 1000 ppm H2 and ΔR/R0 = 4.02 × 102% at 1 ppm H2. The reproducibility of the device is demonstrated in Supplementary Section 10. Also shown in Fig. 3b, ΔR/R0 with 2 nm SiO2 layer is roughly three orders of magnitude higher than that with 4 nm SiO2 layer in the 100–1000 ppm H2 range. A greatly enhanced sensitivity (3600%/ppm with 2 nm SiO2, see Supplementary Section 5) is also demonstrated compared with the 4 nm SiO2 layer passivated device (1.71%/ppm). This confirms the overwhelming sensitivity enabled by the electron trapping effect in the PdNPs. In the device with 4 nm SiO2, the thick SiO2 layer blocks the electron tunneling process, so only a small portion of the work function change is coupled to the channel via capacitive coupling (ΔEF ≪ ΔEPdNP). In contrast, for the 2 nm SiO2 passivated device, electron trapping/de-trapping processes via tunneling through the thin SiO2 layer enable direct communication between the channel and the PdNPs. Consequently, EF in the SiNW closely adapts to EPdNP, leading to ΔEF close to ΔEPdNP, which is much higher than ΔEF achieved via capacitive coupling. The quantitative analysis of ΔEF with the thin SiO2 passivation layer is available in Supplementary Section 11. Higher ΔEF induced by the electron trapping effect results in a significantly enhanced current response. It is notable that the LOD of 2 nm SiO2 passivated SiNW-NAG FET sensor is extrapolated to be 4.4 ppb (see Supplementary Section 5), which is more than two orders of magnitude lower than that with 4 nm SiO2 (2.7 ppm), and significantly lower than the previously reported FET18 and optical9 H2 sensors. It should be emphasized that this signal transduction mechanism demonstrated for H2 sensing in this work could also be used for other target gases, provided the work function of the sensing NPs can be changed upon exposure to the target gas. For instance, Au NPs for ozone38 and SnO2 NPs for NO239.

a Real-time H2 sensing results at varied concentration at room temperature. b Percent change in resistance ΔR/R0 of the SiNW-NAG FET devices with 2 and 4 nm thick SiO2 passivation layer as a function of H2 concentration. ΔR/R0 with 2 and 4 nm SiO2 layers is extracted from (a) and Fig. 1e, respectively. c Calculated energy variation of palladium nanoparticle ΔEPdNP as a function of H2 concentration from (b). d Benchmark of ΔR/R0 of the 2 nm SiO2 layer passivated SiNW-NAG FET with the corresponding reported data of FET H2 sensors: Si nanomesh17, electrostatically formed SiNW18, carbon nanotube21, attached sidegate SiNW28, sub-5 nm Si channel27, and graphene52. All devices were functionalized with Pd or its alloys and the measurements were performed at room temperature.

Since ΔEF in the channel approximates to ΔEPdNP, it is reasonable to estimate the latter using ΔEF, which can be extracted from the responses in Fig. 3b using the Boltzmann relationship. The H2-induced ΔEPdNP extracted via the electron trapping mechanism (see Fig. 3c) is comparable with the reported data40. Specifically, ΔEPdNP at 10 ppm H2 is estimated to be 131 mV, which is consistent with the analysis of Fig. 2e. The ultrahigh responses demonstrated with the signal transduction mechanism are benchmarked with recently reported FET-based H2 sensors that were functionalized with Pd or its alloys and measured at room temperature, which is compiled in Fig. 3d. The responses demonstrated in our work are the highest among these devices in the H2 concentration range from 1 ppm to 1000 ppm.

Kinetics and selectivity

Apart from the sensitivity discussed above, fast response and recovery and good selectivity are also critical for a high-performance gas sensor. As shown in Fig. 4a, the response time of the SiNW-NAG FET sensors with 4 and 2 nm thick SiO2 layer, defined as the time for realizing 90% current response (t90), is extracted from the real-time current traces in Figs. 1e and 3a, respectively. t90 is almost the same for both sensors based on the electron trapping mechanism (2 nm SiO2) and the conventional capacitive coupling mechanism (4 nm SiO2). This confirms that the response to H2 is not slowed down with the electron trapping mechanism, which indicates that the electron tunneling process through the 2 nm SiO2 layer is much faster than the PdNP-H2 reaction. The longer response time at lower H2 concentration can be attributed to the low sticking probability of H2 on Pd which limits the H2 reaction41. In addition, the recovery time, which is the time for recovering 50% of current response (t50), is not prolonged with the tunneling process either (see Fig. 4b). The response and recovery processes could be further accelerated by integrating a micro-heater in proximity to the H2 sensor15 or suspending the SiNW for enhanced Joule heating in the SiNW42,43.

a Response time t90 and (b) recovery time t50 of the silicon nanowire gated via nanoscale air gaps field-effect transistor (SiNW-NAG FET) devices with 2 and 4 nm SiO2 layers. t90 and t50 with 2 and 4 nm SiO2 layer are extracted from Figs. 3a and 1e, respectively. c Current responses to 50 ppm H2, 50 ppm CO, 10 ppm NO2, and 50 ppm NH3 in synthetic air of the SiNW-NAG FET device with 2 nm SiO2 layer.

The SiNW-NAG FET device can readily discriminate H2 from interfering electrophilic, neutral molecules, and nucleophilic molecules. Here, CO (neutral), NO2 (electrophilic), and NH3 (nucleophilic) gas molecules were selected as interfering gases to demonstrate the selectivity. The responses with 2 nm SiO2 layer to 50 ppm CO, 10 ppm NO2, and 50 ppm NH3 diluted in synthetic air are presented in Fig. 4c, which are significantly lower than the response to 50 ppm H2. The insensitivity towards CO is due to the absence of charge transfer of the neutral CO molecule. The sensor response towards NO2 even results in an opposite current response and is likely due to NO2 adsorption on the channel walls. NH3 exposure under our conditions (synthetic gas at low catalyst temperature) is known to lead to NH3 dissociation and PdNx formation with small amounts of N2 and H2O products, and very few NOx species44. A dipole layer can then be created by NH3 exposure (similar to H2), yielding a work function change, albeit much smaller than for H2, and hence an almost 100 times smaller signal (Fig. 4c). Finally, we note that the SiNW-NAG FET device structure with the electron trapping based signal transduction mechanism is compatible with most of the mitigation approaches developed to enhance sensors’ immunity to cross-interferences, such as alloying the NPs45 or using a filtering film46,47.

The high performance of our SiNW-NAG FET H2 sensor is promising in various applications. For instance, it could be used for H2 safety monitoring in buildings and process industry owing to the low energy consumption, high sensitivity, low cost, and easy integration48. Besides these characteristics, the selectivity against CO makes our sensor a good candidate for H2 leakage detection in H2-powered vehicles, considering the possible interference with CO released from other combustion engines49. To realize real-world applications, long-term stability needs to be ensured, e.g., by covering the PdNPs with a polymer layer46, as well as admissible working temperatures and humidity conditions.

Discussion

In summary, we demonstrate supersensitive nanotransistor-based gas sensing enabled by the electron trapping effect in nanoparticles. The sensor device is a SiNW FET fabricated using a CMOS-compatible process. The SiNW channel passivated with a thin SiO2 layer is gated by two side-gates via NAGs. The NAGs allow the sensing NPs to be deposited on the sidewalls of the SiNW so that the conducting channels are generated at the closest possible location to the NPs. Target gas can access the NPs via the air gaps with no physical barrier. When the SiO2 layer is thin enough, electrons in the main channel can tunnel between the main channel and the sensing NPs and equilibrate them. The gas reaction with the NPs will perturb the equilibrium, thus forcing electron transfer between the channel and the NPs via electron trapping/de-trapping processes, which generate the current signal. The electron trapping effect in the NPs provides direct communication between gas reaction and the main conducting channel thus enabling the most efficient signal transduction. We demonstrate a record-high H2 sensitivity of 3600%/ppm and ultra-low LOD of 4.4 ppb in this type of side-gate FET H2 gas sensor device at room temperature and with ultra-low power consumption of around 300 nW. The SiNW-NAG FET device could potentially be used for detecting other gases.

Methods

Device fabrication

The SiNW FET sensors were fabricated in 100-mm SOITEC SOI wafers with standard Si process technology50. The SOI wafers are composed of a 55 nm thick lightly doped p-type Si layer on the top of a 145 nm thick buried oxide layer. The top Si layer was thinned down from 55 to 30 nm by thermal oxidation and subsequent oxide etching in HF acid. BF2 implantation was used to form the heavily p-doped (p+) side-gate (G), source (S), and drain (D) regions, while the channel region was protected by electron-beam resist UVN during the implantation. The dopants in S/D were activated by rapid thermal processing at 1000 °C for 10 s in the N2 atmosphere. The SiNW channel with S/D contacts and the side-gates were defined by electron-beam lithography (EBL) with 2% hydrogen silsesquioxane (HSQ) resist, followed by reactive ion etching (RIE). Subsequently, a layer of SiO2 was deposited on the device via ALD with a pre-cleaning step in piranha solution for 15 min for chemical oxide growth. A 20 nm thick nickel silicide layer was formed on both G and S/D regions via 30 s rapid thermal annealing at 400 °C. PdNPs were deposited on the SiO2-passivated SiNW through electron beam evaporation process with 0.1 Å/s rate and 5 Å thickness. The substrate was tilted at 60° and double deposition was used to enable the PdNP deposition on both sidewalls of the SiNW. A back-gate SiNW FET with device, the side gates were not defined at EBL step and only the top surface of the SiNW was functionalized with the PdNPs (deposition without substrate tilt). The thickness of the Pd layer was kept constant for both devices.

Electrical measurements

All electrical measurements were performed in Linkam LTS420E-P chamber at room temperature. Transfer (IDS versus VG) and output (IDS versus VD) characteristics and real-time current sampling (IDS versus t) were measured using an HP4155A semiconductor parameter analyzer. The PSD of IDS was characterized using a Keysight E4727A advanced low-frequency noise analyzer. For each measurement, VDS was biased at 1 V. The varied gas concentration in the gas sensor measurements was done by diluting the analyte in synthetic air (O2:N2 = 1:4) and the total gas flow was fixed at 500 sccm. The sources of H2, CO, NO2, and NH3 were all research-grade gases from Air Liquid diluted in N2 with the following concentrations: 5% H2, 100 ppm CO, 100 ppm NO2, and 100 ppm NH3, respectively. The gases were subsequently diluted to desired target analyte concentrations by mixing with synthetic air by means of mass flow regulators.

Device simulation

The commercially available Sentaurus TCAD device simulator (version: S-2021.06-SP1) is used for the FET simulation51. Mobility models include doping dependence, high-field saturation, and transverse field dependence. The intrinsic carrier concentration is determined with the silicon bandgap narrowing model OldSlotBoom. Shockley–Read–Hall model with a doping-dependent lifetime is used for simulating recombination process.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

The data that support the findings of this study are available within the paper and its supplementary information files. Source data are provided with this paper.

Code availability

The custom codes used for the device simulations are available from the corresponding author upon request.

References

Hydrogen on the rise. Nat. Energy 1, 16127 (2016).

Davis, S. J. et al. Net-zero emissions energy systems. Science 360, eaas9793 (2018).

Cullen, D. A. et al. New roads and challenges for fuel cells in heavy-duty transportation. Nat. Energy 6, 462–474 (2021).

Mazloomi, K. & Gomes, C. Hydrogen as an energy carrier: prospects and challenges. Renew. Sustain. Energy Rev. 16, 3024–3033 (2012).

Abe, J. O., Popoola, A. P. I., Ajenifuja, E. & Popoola, O. M. Hydrogen energy, economy and storage: review and recommendation. Int. J. Hydrog. Energy 44, 15072–15086 (2019).

Yang, F. et al. Review on hydrogen safety issues: incident statistics, hydrogen diffusion, and detonation process. Int. J. Hydrog. Energy 46, 31467–31488 (2021).

Hübert, T., Boon-Brett, L., Black, G. & Banach, U. Hydrogen sensors-a review. Sens. Actuators B Chem. 157, 329–352 (2011).

Ndaya, C. C., Javahiraly, N. & Brioude, A. Recent advances in palladium nanoparticles-based hydrogen sensors for leak detection. Sensors 19, 4478 (2019).

Nugroho, F. A. A. et al. Metal-polymer hybrid nanomaterials for plasmonic ultrafast hydrogen detection. Nat. Mater. 18, 489–495 (2019).

Li, X., Lu, Y., Hemminger, J. C. & Penner, R. M. Catalytically activated palladium@platinum nanowires for accelerated hydrogen gas detection. ACS Nano 9, 3215–3225 (2015).

Zhang, J. et al. Nanostructured materials for room-temperature gas sensors. Adv. Mater. 28, 795–831 (2016).

Arya, S. K., Krishnan, S., Silva, H., Jean, S. & Bhansali, S. Advances in materials for room temperature hydrogen sensors. Analyst 137, 2743–2756 (2012).

Offermans, P. et al. Ultralow-power hydrogen sensing with single palladium nanowires. Appl. Phys. Lett. 94, 223110 (2009).

Lundstrom, I., Shivaraman, S., Svensson, C. & Lundkvist, L. A hydrogen-sensitive MOS field-effect transistor. Appl. Phys. Lett. 26, 55–57 (1975).

Fahad, H. M. et al. Room temperature multiplexed gas sensing using chemical-sensitive 3.5-nm-thin silicon transistors. Sci. Adv. 3, e1602557 (2017).

Choi, B. et al. A bottom-gate silicon nanowire field-effect transistor with functionalized palladium nanoparticles for hydrogen gas sensors. Solid-State Electron. 114, 76–79 (2015).

Min, G. et al. Palladium-decorated silicon nanomesh fabricated by nanosphere lithography for high performance, room temperature hydrogen sensing. Small 14, 1703691 (2018).

Mukherjee, A. et al. Ultrasensitive hydrogen detection by electrostatically formed silicon nanowire decorated by palladium nanoparticles. Sens. Actuators B Chem. 346, 130509 (2021).

Kong, J., Chapline, M. G. & Dai, H. Functionalized carbon nanotubes for molecular hydrogen sensors. Adv. Mater. 13, 1384–1386 (2001).

Kuru, C. et al. MoS2 nanosheet-Pd nanoparticle composite for highly sensitive room temperature detection of hydrogen. Adv. Sci. 2, 1500004 (2015).

Xiao, M. et al. Batch fabrication of ultrasensitive carbon nanotube hydrogen sensors with sub-ppm detection limit. ACS Sens. 3, 749–756 (2018).

Agarwal, P. et al. Chemically induced surface potential modulation at Pd|Al2O3|graphene field effect transistors: implications for enhanced H2 sensing. ACS Appl. Nano Mater. 5, 10941–10950 (2022).

Christofides, C. & Mandelis, A. Solid‐state sensors for trace hydrogen gas detection. J. Appl. Phys. 68, R1–R30 (1990).

Sharma, B. et al. Recent advances on H2 sensor technologies based on MOX and FET devices: a review. Sens. Actuators B Chem. 262, 758–770 (2018).

Adams, B. D. & Chen, A. The role of palladium in a hydrogen economy. Mater. Today 14, 282–289 (2011).

Darmadi, I., Nugroho, F. A. A. & Langhammer, C. High-performance nanostructured palladium-based hydrogen sensors-current limitations and strategies for their mitigation. ACS Sens 5, 3306–3327 (2020).

Fahad, H. M., Gupta, N., Han, R., Desai, S. B. & Javey, A. Highly sensitive bulk silicon chemical sensors with sub‑5 nm thin charge inversion layers. ACS Nano 12, 2948–2954 (2018).

Ahn, J.-H., Yun, J., Choi, Y.-K. & Park, I. Palladium nanoparticle decorated silicon nanowire field-effect transistor with side-gates for hydrogen gas detection. Appl. Phys. Lett. 104, 013508 (2014).

Nah, J. et al. Quantum size effects on the chemical sensing performance of two-dimensional semiconductors. J. Phys. Chem. C. 116, 9750–9754 (2012).

Varghese, A., Eblabla, A. & Elgaid, K. Modeling and simulation of ultrahigh sensitive AlGaN/AlN/GaN HEMT-based hydrogen gas detector with low detection limit. IEEE Sensors J. 21, 15361–15368 (2021).

Bansal, G., Tiwari, A., Majumdar, B., Mukhopadhyay, S. C. & Kanungo, S. Catalytic metal-gated nano-sheet field effect transistor and nano-sheet tunnel field effect transistor based hydrogen gas sensor—a design perspective. Adv. Theory Simul. 7, 2301031 (2024).

Lundstrom, K. I., Shivaraman, M. S. & Svensson, C. M. A hydrogen-sensitive Pd-gate MOS transistor. J. Appl. Phys. 46, 3876–3881 (1975).

Sze, S. M. & Ng, K. K. Physics of semiconductor devices 3rd edn, (John Wiley & Sons, 2006).

Hung, K. K., Ko, P. K., Hu, C. & Cheng, Y. C. A unified model for the flicker noise in metal-oxide-semiconductor field-effect transistors. IEEE Trans. Electron. Devices 37, 654–665 (1990).

Davidovic, D. & Tinkham, M. Coulomb blockade and discrete energy levels in Au nanoparticles. Appl. Phys. Lett. 73, 3959 (1998).

Zheng, H., Zhou, Y. & Gangopadhyay, S. Size-dependent work function and single electron memory behavior of pentacene non-volatile memory with embedded sub-nanometer platinum nanoparticles. J. Appl. Phys. 117, 024504 (2015).

Yun, M., Ramalingam, B. & Gangopadhyay, S. Room temperature observation of size dependent single electron tunneling in a sub-2 nm size tunable Pt nanoparticle embedded metal–oxide–semiconductor structure. Nanotechnology 22, 465201 (2011).

Doll, T., Lechner, J., Eisele, I., Schierbaum, K.-D. & Göpel, W. Ozone detection in the ppb range with work function sensors operating at room temperature. Sens. Actuators B Chem. 34, 1–3 (1996).

Karthigeyan, A. et al. Low temperature NO2 sensitivity of nano-particulate SnO2 film for work function sensors. Sens. Actuators B Chem. 78, 1–3 (2001).

Ruths, P. F., Ashok, S., Fonash, S. J. & Ruths, J. M. A study of Pd/Si MIS Schottky barrier diode hydrogen detector. IEEE Trans. Electron Devices 28, 1003–1009 (1981).

Johansson, M., Lytken, O. & Chorkendorff, I. The sticking probability of hydrogen on Ni, Pd and Pt at a hydrogen pressure of 1 bar. Top. Catal. 46, 175–187 (2007).

Yun, J., Ahn, J.-H., Moon, D.-I., Choi, Y.-K. & Park, I. Joule-heated and suspended silicon nanowire based sensor for low-power and stable hydrogen detection. ACS Appl. Mater. Interfaces 11, 42349–42357 (2019).

Seo, J., Lim, Y. & Shin, H. Self-heating hydrogen gas sensor based on an array of single suspended carbon nanowires functionalized with palladium nanoparticles. Sens. Actuators B Chem. 247, 564–572 (2017).

Dann, E. K. et al. Structural selectivity of supported Pd nanoparticles for catalytic NH3 oxidation resolved using combined operando spectroscopy. Nat. Catal. 2, 157–163 (2019).

Song, L., Ahn, J., Kim, D. H., Shin, H. & Kim, I. D. Porous Pd-Sn alloy nanotube-based chemiresistor for highly stable and sensitive H2 detection. ACS Appl. Mater. Interfaces 14, 28378–28388 (2022).

Girma, H. G. et al. Room-temperature hydrogen sensor with high sensitivity and selectivity using chemically immobilized monolayer single-walled carbon nanotubes. Adv. Funct. Mater. 33, 2213381 (2023).

Meng, X., Zhang, Q., Zhang, S. & He, Z. The enhanced H2 selectivity of SnO2 gas sensors with the deposited SiO2 filters on surface of the sensors. Sensors 19, 2478 (2019).

Song, Z. et al. Wireless self-powered high-performance integrated nanostructured-gas-sensor network for future smart homes. ACS Nano 15, 7659–7667 (2021).

Lavanya, N. et al. Development of a selective hydrogen leak sensor based on chemically doped SnO2 for automotive applications. Int. J. Hydrog. Energy 42, 10645–10655 (2017).

Hu, Q., Chen, S., Solomon, P. & Zhang, Z. Ion sensing with single charge resolution using sub–10-nm electrical double layer–gated silicon nanowire transistors. Sci. Adv. 7, eabj6711 (2021).

Sentaurus Device User Guide, Version M-2016.12, Synopsys Inc. Mountain View, CA, USA, (2016).

Johnson, J. L., Behnam, A., Pearton, S. J. & Ural, A. Hydrogen sensing using Pd-functionalized multi-layer graphene nanoribbon networks. Adv. Mater. 22, 4877–4880 (2010).

Acknowledgements

This work was supported by Swedish Strategic Research Foundation FFL15-0174 (Z.Z.), Swedish Research Council VR2014-05588 and VR2019-04690 (Z.Z.), Wallenberg Academy Fellow KAW2015-0127 and its extension KAW2020-0190 programs (Z.Z.), H2020-MSCA-RISE program through “Canleish” 101007653 (L.Ö.), and Olle Engkvist Foundation 196-0077 (Z.Z.). Dr. Tesfalem Welearegay is acknowledged for his help on the selectivity tests.

Funding

Open access funding provided by Uppsala University.

Author information

Authors and Affiliations

Contributions

Z.Z. conceived the idea and initiated the project. Q.H. and Z.Z. designed the experiments. Q.H. performed device fabrication and characterization, gas sensing measurements, simulation, data analysis, and modeling under the supervision of Z.Z. L.Ö. guided the gas sensor tests and analysis. Q.H. wrote the manuscript. P.S., L.Ö., and Z.Z. analyzed the data and revised the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Sayan Kanungo and Bharat Sharma for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hu, Q., Solomon, P., Österlund, L. et al. Nanotransistor-based gas sensing with record-high sensitivity enabled by electron trapping effect in nanoparticles. Nat Commun 15, 5259 (2024). https://doi.org/10.1038/s41467-024-49658-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-49658-3

- Springer Nature Limited