Abstract

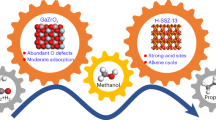

Direct conversion of CO2 to a single specific hydrocarbon with high selectivity is extremely attractive but very challenging. Herein, by employing an InZrOx-Beta composite catalyst in the CO2 hydrogenation, a high selectivity of 53.4% to butane is achieved in hydrocarbons (CO free) under 315 °C and 3.0 MPa, at a CO2 conversion of 20.4%. Various characterizations and DFT calculation reveal that the generation of methanol-related intermediates by CO2 hydrogenation is closely related to the surface oxygen vacancies of InZrOx, which can be tuned through modulating the preparation methods. In contrast, the three-dimensional 12-ring channels of H-Beta conduces to forming higher methylbenzenes and methylnaphthalenes containing isopropyl side-chain, which favors the transformation of methanol-related intermediates to butane through alkyl side-chain elimination and subsequent methylation and hydrogenation. Moreover, the catalytic stability of InZrOx-Beta in the CO2 hydrogenation is considerably improved by a surface silica protection strategy which can effectively inhibit the indium migration.

Similar content being viewed by others

Introduction

The hydrogenation of CO2 to hydrocarbons using green hydrogen is now considered a practical process in tackling the globe warming caused by excessive emission of greenhouse gases1,2,3 as well as in recycling CO2 as a carbon feedstock to produce value-added chemicals4,5,6,7,8. In this regard, the conversion of CO2 into bulk chemicals including light olefins9,10,11,12 and aromatics13,14,15,16 has attracted special attention. Two routes are now proposed for the CO2 hydrogenation, viz., the modified Fischer-Tropsch synthesis (FTS) one using Fe- or Co-based catalysts17,18,19,20,21 and the methanol-mediated one over a composite catalyst consisting of metal oxides and zeotypes (OX-ZEO)11,22. As the FTS route keeps to the Anderson-Schultz-Flory (ASF) rule for the product distribution, a wide spectrum of hydrocarbons are produced. In contrast, the selectivity to the target olefin and aromatic products can be considerably improved by using the OX-ZEO composite catalyst via the methanol-mediated route which dispenses with the ASF rule16,23.

Great progress has been made in the hydrogenation of CO2 to C2–C3 alkenes/alkanes in recent years. Through the regulation of surface electronic structure of metal oxides and acidic properties of zeotypes, a high selectivity to ethene (ca. 70%)24, propene + butene (ca. 65%)25, or propane (ca. 70%)26 was achieved for the CO2 hydrogenation. Nonetheless, it is very challenging to achieve a high selectivity to a defined hydrocarbon (in particular a relatively long chain one) through the CO2 hydrogenation, due to the chemical inertia of CO2 and the complexity of C–C coupling reactions. For example, the selective hydrogenation of CO2 into C4+ hydrocarbons is rarely reported27, although the C4+ hydrocarbons are highly valuable as clean fuel and solvents. In this regard, butane is widely used as fuel (liquefied gas), refrigerant, spray, and feedstock in chemical synthesis. Traditionally, butane is obtained from petroleum cracking28. The direct conversion of CO2 to butane under mild reaction conditions may provide a new strategy for the renewable production of C4+ chemicals. Unfortunately, current reported catalyst in general gave a rather low selectivity to butane (<30%)29. In addition, to improve the practicability of CO2 hydrogenation to demanded hydrocarbons, the formation of CH4 (from CO2 methanation) and CO (from reverse water-gas shift, RWGS) should also be suppressed to the utmost.

For the CO2 hydrogenation over a bifunctional OX-ZEO catalyst, first, the oxide moiety should be highly effective in building methanol-related intermediate. In2O3 is a promising catalyst component for the CO2 hydrogenation to methanol, showing high activity at a high temperature of 280–330 °C30,31,32. To suppress the formation of CH4 and CO, various dopants were used to regulate the crystal structure and surface electronic properties of In2O333,34,35,36; among them, doping Zr into In2O3 proved to be rather effective. Frei and co-workers observed that Zr was able to increase the concentration of surface oxygen vacancies of In2O3, which could then promote the adsorption and activation of CO2 and raise the selectivity to methanol37. Chen and co-workers found that the interfacial interaction between In2O3 and ZrO2 was favorable to the formation of methanol38. Similarly, a high methanol space time yield (STY) was observed over InZrOx in the CO2 hydrogenation39,40.

Next, the zeotype moiety must work in close cooperation with the oxide moiety to achieve a high yield of specific hydrocarbon. The zeotype moiety is responsible for the successive transformation of the methanol-related intermediates generated on the oxide moiety into hydrocarbons on the acid sites in the confined interspace41,42. Naturally, the distribution of products on the OX-ZEO catalysts is closely related to the topology framework and acidity of the zeotype moiety. Various composite catalysts like InZrOx/SSZ-1326, In2O3/SAPO-3435, and In2O3/ZSM-543 were used in the CO2 hydrogenation, which were selective to alkanes (C20–C40), light olefins (C2=–C4=), and liquid fuels, respectively. It implies that higher alkanes/alkenes like butane may request the zeotype moiety a relative large pore channel such as Beta, which can accommodate large reaction intermediates and allow the quick diffusion of large molecular products. In addition, the facile synthesis of Beta zeolite with a wide range of Si/Al ratio makes it attractive as a catalyst component in the conversion of methanol44. It is then expected that a bifunctional catalyst composed of Zr-doped In2O3 and H-Beta may give a high yield of C4 hydrocarbons for the CO2 hydrogenation. However, we have seldom noticed such reports in this regard, despite that the In-based catalysts have been widely used in the CO2 hydrogenation to alcohols and light alkene and alkane mixtures. In addition, Wang and co-workers reported recently that the indium species in the oxide moiety would continuously run off during the reaction process, resulting in a rapid poisoning of the acid sites on the zeotype moiety45, which may also inhibit the application of In2O3 in the bifunctional catalyst in practice for the CO2 hydrogenation to hydrocarbons.

Herein, a bifunctional composite catalyst consisting of InZrOx oxide and H-Beta zeolite was designed and employed in the hydrogenation of CO2; a high selectivity of 53.4% to butane in all hydrocarbons (CO free) is achieved under 315 °C, 3.0 MPa, and a space velocity of 1200 mL g−1 h−1 (H2/CO2 = 3), at a CO2 conversion of 20.4% and a selectivity of only about 2% to CH4. Combining with various characterization measures and density-functional theory (DFT) calculation, it is revealed that the high selectivity to butane originates from the hydrocarbon pool (HCP) in the H-Beta zeolite filled with bulkier methylbenzenes and methylnaphthalenes, via an alkyl side-chain intermediate. Moreover, a surface silica protection strategy was developed, which can effectively inhibit the phase separation of InZrOx oxide and the migration of In species into the H-Beta zeolite and then considerably improve the catalytic stability of InZrOx-Beta in the CO2 hydrogenation. These results pave a way for the design of stable In-based catalyst in the CO2 hydrogenation to a specific hydrocarbon product.

Results

Textural and structural properties of InZrOx

Supplementary Table 1 and Supplementary Fig. 1 give the textural properties of the InZrOx oxides prepared by different methods determined by N2 sorption. Apparently, the surface area of three InZrOx oxides decreases in the order of InZrOx(CP) (73 m2 g−1) > InZrOx(SG) (59 m2 g−1) > InZrOx(HT) (41 m2 g−1); in addition, InZrOx(CP) also displays much larger mesopore volume (0.31 cm3 g−1) than InZrOx(SG) (0.07 cm3 g−1) and InZrOx(HT) (0.15 cm3 g−1).

Figure 1 shows the XRD patterns and TEM images of the InZrOx oxides prepared by different methods. In the HRTEM images, the (211) and (222) crystal facets, with a lattice spacing of 0.405–0.410 and 0.290–0.291 nm, respectively, are resolved for three InZrOx oxides (Fig. 1a–c)10. Five diffraction peaks at 21.5°, 30.6°, 35.5°, 51.0°, and 60.7° are observed for all three InZrOx oxides (Fig. 1d), corresponding to the (211), (222), (400), (440) and (622) crystal facets of cubic In2O3, respectively (JCPDS PDF#06-0416)42. Furthermore, the TEM images shown in Supplementary Fig. 2 illustrated that all three InZrOx oxides are aggregates of spherical nano particles (NPs), with a mean size of 9.76 nm for InZrOx(CP) (prepared by co-precipitation), 9.19 nm for InZrOx(SG) (by sol-gel method), and 25.18 nm for InZrOx(HT) (by hydrothermal method). The STEM-EDX elemental mapping results indicate that the In, Zr, and O elements are uniformly dispersed with each other in the InZrOx oxides (Fig. 1e–i and Supplementary Figs. 3, 4).

The surface electronic state of various InZrOx oxides was analyzed by XPS, as shown in Supplementary Fig. 5. The peaks at 444.4 and 451.8 eV in the In 3d XPS spectra correspond to 3d5/2 and 3d3/2 of In3+, respectively, while those at 182.4 and 184.8 eV in the Zr 3d XPS spectra are assigned to 3d5/2 and 3d3/2 of Zr4+, respectively. The O 1s XPS spectra reveal three oxygen species in the InZrOx oxides (Fig. 2a)46; the peaks at 532.6, 531.4, and 529.9 eV are ascribed to the surface hydroxyl groups (–OH), oxygen around the vacancies (Odefect), and lattice oxygen (Olattice), respectively. The deconvolution results indicate that the fraction of surface oxygen around the vacancies (representing the abundance of oxygen vacancies) for three InZrOx oxides decreases in the order of InZrOx(CP) (36.15%) > InZrOx(SG) (32.39%) > InZrOx(HT) (27.65%). In addition, the same sequence of three oxides by the surface oxygen vacancy concentration is manifested by the in situ O 1s XPS results (Supplementary Fig. 6), viz., InZrOx(CP) (43.47%) > InZrOx(SG) (36.75%) > InZrOx(HT) (31.76%). The in situ O 1s XPS gives higher surface oxygen vacancy concentrations than the ex situ one, which is ascribed to the fact that more surface oxygen defects are formed due to the elimination of certain surface oxygen atoms by reduction in the in situ H2-containing atmosphere, in agreement with previous works24,47.

a O 1s XPS spectra of various InZrOx oxides, in which the abundance of surface oxygen vacancies (Odefect, calculated as Idefect/(Ilattice + Idefect) are labeled (Idefect and Ilattice represent peak area of defect and lattice oxygen, respectively)42. b H2-TPR profiles of various InZrOx oxides (The shadow insert is the enlargement of H2-TPR profiles in the temperature range of 100–250 °C). c Cell volumes of various fresh InZrOx oxides compared to that of H2-reduced ones. d CO2-TPD profiles of various InZrOx oxides.

Figure 2b shows the H2-TPR profiles of various InZrOx oxides. The high temperature peak (centered around 650 °C) is attributed to the reduction of bulk In2O3, whereas the low temperature one (150–250 °C) is due to the annihilation of surface oxygen from In2O347. Apparently, InZrOx(CP) displays a more intense H2 consumption peak (19 μmol g−1) attributed to the removal of surface oxygen at a lower temperature (160 °C), in comparison with InZrOx(SG) (18 μmol g−1, at 180 °C) and InZrOx(HT) (16 μmol g−1, at 220 °C), indicating that InZrOx(CP) has more surface defects (oxygen vacancies), agreeing well with above O 1s XPS results. The Rietveld refinement of the in situ XRD patterns (Supplementary Fig. 7) indicates that the cell volume of InZrOx decreases after H2 reduction, due to the release of surface oxygen atoms47. Interestingly, as shown in Fig. 2c, InZrOx(CP) also displays the highest cell shrinkage ratio than InZrOx(SG) and InZrOx(HT), according well with the more surface defects of InZrOx(CP). Moreover, since the onset temperature for the reduction of bulk In2O3 to metallic indium species is only around 315 °C, it is conceivable that certain metallic indium species may be generated on the surface of InZrOx oxide during the reduction and subsequent reaction processes. These metallic indium species may easily migrate to the zeolite moiety and then poison the acid sites of zeolite component45,47; this will be discussed in detail in the following section.

Figure 2d displays the CO2-TPD profiles of various InZrOx oxides. The peak below 150 °C represents the physical adsorption of CO2, whereas that at above 300 °C is ascribed to the chemical adsorption of CO2 on the surface oxygen defects42. As expected, InZrOx(CP) exhibits larger CO2 desorption amount at above 300 °C, followed by InZrOx(SG) and InZrOx(HT). It further evinces that CO2 adsorption is enhanced on InZrOx(CP) (prepared by co-precipitation) with abundant oxygen vacancies.

Properties of H-Beta zeolites

As illustrated in Supplementary Fig. 8a, b, the H-Beta, H-SSZ-13 and USY zeolites used in this work have a typical BEA, CHA and FAU topological framework, respectively, with high crystallinity. N2 sorption results (Supplementary Fig. 8c and Supplementary Table 2) indicate that various H-Beta zeolites with different Si/Al ratios (20–100) are similar in their textural properties. The SEM images shown in Supplementary Fig. 9 display that the H-Beta zeolites has a particle size of around 1 μm. In contrast, the NH3-TPD results given in Supplementary Table 2 and Supplementary Fig. 8d indicate that both the weak acid and strong acid contents of H-Beta decrease with the increase of the Si/Al ratio.

Catalytic performance of InZrOx-Beta in the CO2 hydrogenation

The InZrOx oxides alone were first tested for the hydrogenation of CO2 under 315 °C, 3.0 MPa, and with a space velocity (SV) of 2400 mL g−1 h−1 and H2/CO2 ratio of 3 in the feed. As shown in Supplementary Fig. 10, InZrOx(CP) prepared by co-precipitation exhibits a higher CO2 conversion (18.7%) and a higher methanol space time yield (STY) (0.012 mol kg−1 h−1) than InZrOx(SG) prepared by sol-gel method (17.3% and 0.011 mol kg−1 h−1, respectively) and InZrOx(HT) by hydrothermal method (11.2% and 0.003 mol kg−1 h−1, respectively).

Next, the catalytic performance of granule-mixed bifunctional InZrOx-Beta catalyst (0.3 g InZrOx + 0.3 g H-Beta) was evaluated in the hydrogenation of CO2 under 315 °C, 3.0 MPa, a SV of 1200 mL g−1 h−1, and an H2/CO2 ratio of 3 in the feed. As shown in Fig. 3a, over InZrOx-Beta(40), butane is the dominant hydrocarbon product. In particular, InZrOx(CP)-Beta(40) exhibits a selectivity of 53.4% to butane in the hydrocarbon products, at a CO2 conversion of 20.4% and a selectivity of 54.9% to CO. In contrast, over InZrOx(SG)-Beta(40), the selectivity to butane in the hydrocarbon products, CO2 conversion, and selectivity to CO are 52.9%, 18.7%, and 53.0%, respectively, whereas over InZrOx(HT)-Beta(40), the CO2 conversion decreases to 12.6%, whilst the selectivity to butane decreases to 34.7%, accompanied by the formation of more C2–C3 components. It seems that InZrOx(CP) with abundant oxygen vacancies exhibits high activity in the CO2 hydrogenation to methanol; when composed with H-Beta(40), the InZrOx(CP)-Beta(40) composite catalyst also displays excellent performance in the tandem transformation of CO2 to butane.

a–c CO2 conversion and product distribution for the CO2 hydrogenation over various InZrOx-Beta(40) composite catalysts (a); over InZrOx(CP) composed with different zeolites (b); over InZrOx(CP) composed with H-Beta of different Si/Al ratios (c). Reaction conditions: 315 °C, 3.0 MPa, SV = 1200 mL g−1 h−1, and H2/CO2 = 3.

Besides the oxide moiety, the yield and spectrum of hydrocarbon products for the CO2 hydrogenation are also closely related to the topology framework and acidic properties of the zeotype moiety in the bifunctional composite catalyst. As shown in Fig. 3b, butane appears as the main hydrocarbon product over InZrOx(CP)-Beta, whereas more C2–C3 and C5+ hydrocarbons are generated over InZrOx(CP)-SSZ-13 and InZrOx(CP)-USY with smaller windows and larger cavities. It indicates that the 3D 12-ring channels of H-Beta is pertinent for the transformation of methanol-related intermediates (generated from CO2 hydrogenation over the oxide moiety) into butane.

Moreover, the product distribution for the CO2 hydrogenation over InZrOx(CP)-Beta is associated with the acid density of the H-Beta zeolite moiety. As shown in Fig. 3c, with an increase of the Si/Al ratio of H-Beta from 20 to 100, the selectivity to C2–C3 components decreases, whereas the fraction of C5+ components in the product increases, whilst the selectivity to C4 hydrocarbons (dominated by butane) achieves the maximum value at a Si/Al ratio of 40. A higher Si/Al ratio (viz., less acid sites in H-Beta) may weaken the capability of alkenes hydrogenation and then yield more alkenes. In particular, InZrOx(CP)-Beta(100) displays even an incomplete conversion of methanol due to its rather low acid density. In contrast, excessive acid sites in H-Beta zeolite (e.g. Beta(20), with a very low Si/Al ratio) conduce to the cracking of long-chain hydrocarbons and then generate more small alkenes/alkanes48. Therefore, the selectivity to butane shows a volcanic curve with the Si/Al ratio of H-Beta and gets to the maximum value of 53.4% over InZrOx(CP)-Beta(40). Notably, isobutane accounts for 86.5% of two butane isomers.

As water is a co-product in the hydrogenation of CO2, which acts also vividly in the competitive reverse water-gas (RWGS) reaction5,6, the possible role of water in the reaction process was further evaluated by adding different proportions of water into the H2 and CO2 feed. As shown in Supplementary Fig. 11a, when water is introduced into the reaction system after about 16 h, the CO2 conversion decreases from 19.1 to 8.9%, along with the attenuation of the selectivity to CO from 54.7 to 34.0%. Such a phenomenon becomes more evident when the proportion of water in the feed increases from 7.5 to 15.1% (Supplementary Fig. 11b), where the CO2 conversion and selectivity to CO decreases considerably to 7.3% and 26.1%, respectively. This can be explained by the fact that more water in the reaction mixture can effectively counteract the RWGS reaction (CO2 + H2 = CO + H2O), leading to the decline of the CO2 conversion and the selectivity to CO5,6,9. In addition, water molecules may also compete for the active adsorption sites with the reactants, which may also abate the conversion of CO2 to hydrocarbons.

It is noteworthy that the conversion of CO2 and selectivity to CO are both spontaneously rejuvenated, when the co-feeding water is cut off (Supplementary Fig. 11c). However, the CO2 conversion cannot be fully recovered to the original value, implying that co-feeding water has certain impact on the catalytic activity of the InZrOx oxide. The XRD patterns and TEM images of the spent catalysts shown in Supplementary Fig. 12 indicate that after the CO2 hydrogenation with co-feeding water, the particle size of InZrOx oxide increases considerably, along with the decrease of surface area and pore volume (Supplementary Fig. 13a and Supplementary Table 3). This leads to a decrease in the surface oxygen vacancies concentration, which can weaken the CO2 adsorption capacity, as indicated by the O 1s XPS and CO2-TPD results (Supplementary Fig. 13b, c), although the In, Zr and O elements are still uniformly dispersed with each other in the InZrOx oxide (Supplementary Fig. 14). Nevertheless, the selectivity to butane changes very little during the reaction. This is ascribed to the fact that the crystal structure, morphology, and particle size of H-Beta zeolite, which determine the manner for the formation of hydrocarbons from the methanol-related intermediates, are well maintained during the CO2 hydrogenation with co-feeding different contents of water (Supplementary Fig. 15).

Optimization of reaction conditions

The reaction temperature has a great influence on the product yield and spectrum for the hydrogenation of CO2 over InZrOx(CP)-Beta(40). As shown in Fig. 4a, with the increase of temperature from 285 to 350 °C, as expected, the CO2 conversion increases from 11.4% to 28.8%, despite that more CO are produced due to the promotion of the reverse water-gas shift (RWGS) reaction at a higher temperature5,6. Meanwhile, the selectivity to butane and C5+ decreases gradually with the increase of temperature, accompanied by the formation of more C1–C3 products due to the aggravated cracking of long-chain hydrocarbons, as also observed by Ding and co-workers49.

a–e CO2 conversion and product distribution for CO2 hydrogenation over the InZrOx(CP)-Beta(40) composite catalyst at different temperatures (a), pressures (b), oxide/zeolite mass ratios (c), space velocities (d), and different composing manners of two moieties (e). Basic reaction conditions: 315 °C, 3.0 MPa, space velocity of 1200 mL g−1 h−1, and H2/CO2 ratio of 3 in the feed.

In contrast, an increase of the reaction pressure from 0.1 to 3.0 MPa (at 315 °C) elevates the CO2 conversion from 16.6 to 20.4%, but decreases the selectivity to CO from 65.4 to 54.9%, as shown in Fig. 4b. Meanwhile, the selectivity to butane is raised from 39.1 to 53.4%, accompanied by a gradual decline of the selectivity to alkenes, as a higher hydrogen pressure conduces to the hydrogenation of alkenes. However, a further increase of pressure to 4.0 MPa leads to the formation of more C1–C3 alkanes, at the expense of butane and C5+ hydrocarbons.

The effect of the oxide/zeolite mass ratio in the InZrOx(CP)-Beta(40) composite on the CO2 hydrogenation was also considered, as demonstrated in Fig. 4c. With a decrease of the oxide/zeolite mass ratio from 2 to 1/2, the CO2 conversion and selectivity to CO decrease from 21.7% and 57.5% to 18.5% and 49.6%, respectively, while the highest selectivity to butane (53.4%) is achieved at an oxide/zeolite mass ratio of 1.

The space velocity and H2/CO2 ratio in the feed also have certain influence on the CO2 hydrogenation. A decrease of the space velocity from 2400 to 800 mL g−1 h−1 makes the CO2 conversion increase from 14.9 to 23.4%, despite that the formation of CO is also promoted (Fig. 4d), whilst the selectivity to butane gets the maximum value of 53.4% at a space velocity of 1200 mL g−1 h−1. In addition, elevating the H2/CO2 ratio from 3 to 6 in the feed raises the CO2 conversion from 20.4 to 25.6% and decreases the selectivity to CO slightly from 54.9 to 51.2%, while it has little influence on the selectivity to butane, as shown in Supplementary Fig. 16.

In addition, the manner used to compose the InZrOx-Beta bifunctional catalysts also displays a significant influence on the CO2 hydrogenation. As shown in Fig. 4e, a decrease in the contact distance between InZrOx(CP) and H-Beta(40) from dual-bed filling to granule stacking makes the CO2 conversion and selectivity to butane slightly increase from 19.1% and 53.1% to 20.4% and 53.4%, respectively. However, the composite catalyst prepared by powder mixing of the two moieties just produces large amounts of methane (40.2%) and methanol (24.2%), due to the rapid deactivation of H-Beta zeolite. Similar phenomenon was also observed by Wang and co-workers45; that is, the In species may easily migrate from the metal oxide moiety to the zeotype moiety when the two moieties are in very close contact, resulting in the rapid passivation of the acid sites in the zeotype moiety that are responsible for the successive transformation of methanol-related intermediates to hydrocarbons.

On all accounts, the bifunctional InZrOx(CP)-Beta(40) composite catalyst composed by granule stacking with equal mass of oxide and zeolite exhibits excellent performance in the selective hydrogenation of CO2 to butane. Under 315 °C, 3.0 MPa, a space velocity of 1200 mL g−1 h−1, and an H2/CO2 ratio of 3 in the feed, a high selectivity of 53.4% to butane in all hydrocarbons is achieved, at a CO2 conversion of 20.4% and a selectivity of only about 2% to CH4.

Reaction mechanism of the CO2 hydrogenation to butane

To reveal the reaction mechanism, in situ DRIFTs were first performed for the CO2 hydrogenation to methanol over the InZrOx(CP), InZrOx(SG), and InZrOx(HT) oxides, as shown in Fig. 5a–d and Supplementary Fig. 17. After introducing H2 and CO2 for reaction over InZrOx(CP) for 1 min, the vibration bands attributed to the carbonate (CO32−/HCO3−) species appear at 1506, 1650, and 1700 cm−1 50,51,52, belonging to the signals of activated CO2 (Fig. 5a, b). Besides, the characteristic peaks assigned to the formate (HCOO*) species at 1382, 1555, 2857, and 2964 cm−1 are quickly observed15,53. Meanwhile, the peaks at around 1077, 1458, and 2927 cm−1 ascribed to the methoxy (H3CO*) species are simultaneously detected15,53,54. With the proceeding of the reaction process, the peak intensity of HCOO* and H3CO* species decreases gradually, as they are hydrogenated to methanol. Such phenomena confirm that formate and methoxy are crucial intermediates for methanol formation in the CO2 hydrogenation over InZrOx(CP), in line with the previous reports15,53. In comparison with InZrOx(CP), InZrOx(SG) and InZrOx(HT) also show the characteristic peaks of the formate and methoxy species, but in a much lower intensity (Fig. 5c, d and Supplementary Fig. 17), corresponding to their less oxygen vacancies and poorer catalytic performance in the CO2 hydrogenation.

a–d In situ DRIFT spectra of InZrOx(CP) (a, b) and InZrOx(HT) (c, d) in CO2 hydrogenation. The spectra were collected every 1 min up to 10 min after pretreating the sample under Ar atmosphere (30 mL min−1) for 0.5 h at 200 °C and 0.1 MPa and purging with the H2 and CO2 mixture (40 mL min−1, H2/CO2 = 3).

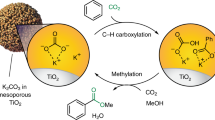

The methanol-related intermediates generated on the InZrOx oxide are further transformed into hydrocarbons on the acid sites of the H-Beta zeolite, which can be consolidated by the control experiments for methanol conversion (viz., methanol to hydrocarbons, MTH) in the H2 atmosphere over the H-Beta(40) zeolite. As shown in Fig. 6a, butane is the dominant product in MTH; in addition, the selectivity to butane (58.0%) here in MTH over H-Beta(40) is highly comparable to that in the CO2 hydrogenation over InZrOx-Beta(40) (53.4%).

a Methanol conversion and product distribution for MTH in H2 atmosphere over H-Beta(40) zeolite with a methanol WHSV of 0.05 h−1. b GC-MS chromatograms of residual species in H-Beta(40) after the MTH reaction in H2 atmosphere with a methanol WHSV of 0.05 h−1 (The shadow inserts are the enlargement of GC-MS chromatograms at specified retention times). c 13C content of the confined organic species in H-Beta(40), obtained from 12C/13C methanol switching experiment.

After the MTH reaction, the residual species in the H-Beta zeolite were extracted and detected by GC-MS55. As demonstrated in Fig. 6b, higher polymethylbenzens (polyMBs, e.g., pentaMB and hexaMB) are found to be the dominant hydrocarbon pool (HCP) species generated in the methanol conversion process over the H-Beta zeolite, which could quickly grow up into aromatics containing isopropyl side-chain via continuous methylation reactions. It is known that these polyMBs are responsible for the propene formation via the side-chain aromatic-based cycle56,57. After the elimination of isopropyl side-chain, the generated propene can be further converted to butane through methylation and subsequent hydrogenation reactions. In fact, certain polyMBs and polymethylnaphthalenes (polyMNs) with isopropyl side-chain (e.g. 1-isopropyl-2,3,4,5-tetramethylbenzene (isopropyl-MB) and 8-isopropyl-2,5-dimethyl-1,2,3,4-tetrahydronaphthalene (isopropyl-MN)) are simultaneously detected by GC-MS (Fig. 6b). Meanwhile, in the 12C/13C-methanol isotope switching experiments, these higher polyMBs and even polyMNs were labeled by a high content of 13C (e.g. 61.1% of hexaMB and 58.9% of isopropyl-MN), according well with their high activity in MTH (Fig. 6c).

Furthermore, as expected, these polyMBs and polyMNs as the HCP species are also detected on the spent InZrOx(CP)-Beta(40) catalyst after the CO2 hydrogenation test, as shown in Supplementary Fig. 18. In contrast, the content of polyMBs and polyMNs containing isopropyl side-chain on the spent InZrOx(HT)-Beta(40) catalyst is rather lower than that on the spent InZrOx(CP)-Beta(40) catalyst (Supplementary Fig. 19), corresponding to the rather lower activity of InZrOx(HT) in the CO2 hydrogenation to methanol; that is, as less methanol-related intermediates are formed on the InZrOx(HT) moiety with poorer activity in the CO2 hydrogenation, the formation and growth of higher polyMBs as the HCP species for MTH are also greatly restricted in the H-Beta moiety, leading to the lower yield of butane over the InZrOx(HT)-Beta composite catalyst (Fig. 3a).

The reaction kinetics for butane formation was further investigated by DFT calculation. As shown in Fig. 7 and Supplementary Fig. 20, isopropyl-MB and isopropyl-MN are first protonated to the corresponding carbocations, with a free energy barrier of 79 and 69 kJ mol−1, respectively. The elimination of isopropyl group from these two carbocations to form the propoxy species on the acid sites requires a low free energy barrier of 69 and 47 kJ mol−1, with a high rate constant of 8.76 × 106 and 8.45 × 108 s−1, respectively, similar to those reported previously56. Propene is then obtained from the deprotonation of propoxy with a free energy barrier of 70 kJ mol−1 and a rate constant of 8.20 × 106 s−1. Further conversion of propene to butoxy and then to iso-butane via methylation, isomerization, and hydrogenation reactions needs to overcome a free energy barrier of 124, 48, and 47 kJ mol−1, respectively.

a Reaction scheme of butane formation via the side-chain route of aromatic-based cycle. b Free energy profiles for butane formation from 8-isopropyl-2,5-dimethyl-1,2,3,4-tetrahydronaphthalene (orange/blue line) or 1-isopropyl-2,3,4,5-tetramethylbenzene (green/blue line) at 315 °C over H-Beta zeolite, where the overall free energy height (ΔG≠) and overall reaction free energy (ΔG) in kJ mol−1 are labeled. c Optimized transition states of various reaction steps, including protonation (P), elimination (E), deprotonation (D), methylation (M), isomerization (I), and hydrogenation (H); atom coloring: cyan (Si), red (O), white (H), pink (Al).

In addition, as given by the calculated free energy surface, the overall free energy height for the butane formation over H-Beta is only 115 kJ mol−1, with an overall reaction free energy of −104 kJ mol−1. All these evince that butane can be generated easily from the methanol-related intermediates via the side-chain route of aromatic-based cycle in the H-Beta zeolite.

On all accounts, the CO2 hydrogenation over a bifunctional catalyst relies on both the oxide and the zeotype moieties. For the InZrOx-Beta composite, the InZrOx moiety is responsible for the conversion of CO2 to the methanol-related intermediates (similar to methanol synthesis), whereas the H-Beta moiety is accountable to the subsequent transformation of methanol-related intermediates into hydrocarbons (similar to methanol to hydrocarbons (MTH), via the hydrocarbon pool mechanism). As a result, the conversion of CO2 is mainly related to the InZrOx moiety; InZrOx(CP) prepared by co-precipitation has abundant oxygen vacancies and great capacity for the CO2 hydrogenation to methanol. In contrast, the product distribution is mainly associated with the framework topology and acidity properties of the zeotype moiety. The H-Beta zeolite of 3D 12-ring channels with moderate acidity (Si/Al = 40) is appropriate for the construction of HCP containing abundant higher polyMBs and polyMNs as well as the production of butane via the aromatic-based cycle of HCP mechanism through the isopropyl side-chain elimination and subsequent methylation and hydrogenation reactions. In addition, the granule-mixing manner used to compose the InZrOx-Beta bifunctional catalyst can realize a pertinent contact between two moieties and then achieve a prominent coupling of two reaction steps (viz., CO2 hydrogenation to methanol and MTH).

Surface silica modification to restrict the in migration

The degeneration of either the metal oxide moiety or the zeotype moiety can deactivate the whole bifunctional OX-ZEO catalyst system in the hydrogenation of CO2 to hydrocarbons58,59. The degeneration of metal oxide often causes a rapid decrease in the CO2 conversion, as the adsorption and activation of CO2 are mainly performed on the surface of metal oxide37,43. As for the acidic zeolite, it catalyzes the subsequent transformation of the methanol-related intermediates previously generated on the oxide moiety into hydrocarbons; the rapid increase in the selectivity to unconverted methanol is an important sign for the deactivation of the zeolite component45,60,61. For the In-based bifunctional catalyst, the indium species may facilely migrate from the oxide moiety into the zeotype moiety in the H2-containing atmosphere, which can passivate the acid sites in the zeotype moiety and then rapidly deactivate the whole composite catalyst used in the CO2 hydrogenation by lowering capacity of the acidic zeolite component in the transformation of methanol-related intermediates to hydrocarbons45.

As shown in Fig. 8a, methanol and dimethyl ether (DME) are clearly detected for the CO2 hydrogenation over InZrOx(CP)-Beta(40) after reaction for 42 h on stream; thereafter, the selectivity to methanol and DME increases quickly, accompanied by a considerable decrease of the selectivity to butane, suggesting the rapid degeneration of the Beta zeolite. Meanwhile, more CO is generated, due to the shrinking of the methanol conversion capacity of the H-Beta zeolite that may relatively promote the competitive RWGS reaction5. After the reaction test, certain amounts of the In element are detected in the H-Beta moiety (Supplementary Table 4), indicating the serious phase segregation of InZrOx(CP) during the CO2 hydrogenation reaction. In fact, the migration of indium species turns to be a fatal defect for the application of the In-based bifunctional catalyst in practice for the hydrogenation of CO2 to hydrocarbons; it is pressing but also rather challenging to effectively inhibit the migration of the In species.

a–c CO2 conversion and product distribution for CO2 hydrogenation to butane over InZrOx(CP)-Beta(40) (a), InZrOx(SCP-4)-Beta(40) (b), and InZrOx(SCP-8)-Beta(40) (c). Reaction conditions: 315 °C, 3.0 MPa, 1200 mL g−1 h−1 and H2/CO2 = 6. The catalyst lifetime is defined as the time on stream when the selectivity to methanol and DME reaches 2% for CO2 hydrogenation over the bifunctional catalyst.

To improve the structural stability of the In-based catalyst in the CO2 hydrogenation, a surface silica protection strategy was adopted in current work; that is, certain amount of SiO2 (4 wt.% for InZrOx(SCP-4) and 8 wt.% for InZrOx(SCP-8)) was deposited on the InZrOx(CP) oxide through impregnation with tetraethylorthosilicate (TEOS) solution and subsequent calcination at 500 °C (Supplementary Fig 21a). The XRD patterns shown in Fig. 9a indicate that the surface silica modification has little impact on the crystal structure of InZrOx(CP). In addition, no diffraction peaks of SiO2 are detected, suggesting that SiO2 is highly dispersed on the InZrOx surface and/or present in amorphous phase. The EDX elemental mapping results show that the silica species are evenly distributed on the surface of InZrOx(CP), despite that they cannot be clearly distinguished by XRD, HR-TEM and Aberration-corrected HAADF-STEM (Fig. 9a and Supplementary Figs. 22–24), which consolidates the high dispersion of silica in the SiO2-modified InZrOx oxide. The SiO2-modified InZrOx(SCP-4) and InZrOx(SCP-8) oxides also show larger surface area than InZrOx(CP), as revealed by the N2 sorption results (Supplementary Fig. 25 and Supplementary Table 5). Besides, the SiO2-modified InZrOx(SCP-4) and InZrOx(SCP-8) oxides have the average particle size of 6.10 and 4.70 nm, respectively, much smaller than that of the unmodified InZrOx (9.76 nm) (Supplementary Fig. 26), suggesting that the silica modification can also inhibit the agglomeration of InZrOx upon calcination at high temperature.

a XRD patterns of fresh InZrOx(CP), InZrOx(SCP-4) and InZrOx(SCP-8). b–d In 3d (b), Zr 3d (c) and Si 2p (d) XPS spectra of fresh InZrOx(CP), InZrOx(SCP-4) and InZrOx(SCP-8). e H2-TPR profiles of fresh InZrOx(CP), InZrOx(SCP-4) and InZrOx(SCP-8). f XRD patterns of H-Beta(40) zeolite separated from the spent InZrOx(CP)-Beta(40), InZrOx(SCP-4)-Beta(40) and InZrOx(SCP-8)-Beta(40) composite catalysts (The shadow insert is the enlargement of XRD patterns in the 2θ range of 29–32°). g–i TEM images of the spent H-Beta(40) zeolite separated from InZrOx(CP)-Beta(40) (g), InZrOx(SCP-4)-Beta(40) (h) and InZrOx(SCP-8)-Beta(40) (i) composite catalysts.

Moreover, the XPS spectra shown in Fig. 9b–d illustrate that the In 3d and Zr 3d signals of silica-modified InZrOx(SCP-4) and InZrOx(SCP-8) shift towards higher binding energies, whereas the Si 2p signal moves to lower value, compared to the corresponding signals of the unmodified InZrOx(CP) counterpart. This is indicative of a strong interaction between the InZrOx(CP) and silica species, which is confirmed by the H2-TPR results; the reduction of both defect In2O3 sites and bulk In2O3 in InZrOx(SCP-4) and InZrOx(SCP-8) requires higher temperature than that in the unmodified InZrOx(CP) counterpart (Fig. 9e). The strong interaction between the InZrOx and silica species is further corroborated by the calculated projected density of states (PDOS) and charge difference density (CDD) results. As shown in Supplementary Fig. 27, strong electron donation and back-donation are observed between the surface silica species and InZrOx oxide in the CDD plot, substantiating an intense interaction of the Si 2p orbitals with the In 3d orbitals around Fermi level. Such strong interaction makes the reduction and migration of indium species in the silica-modified InZrOx(SCP-4) and InZrOx(SCP-8) oxides more difficult than that in the unmodified InZrOx(CP) counterpart.

A schematic diagram is then plotted in Supplementary Fig. 21b to illustrate the mechanism of enhancing structural and catalytic stability of the InZrOx-Beta composite by the surface silica protection strategy. For the un-protected InZrOx oxide, indium species may be easily reduced to metallic In species in the reductive atmosphere, which facilely migrate to the H-Beta component and then passivate the acid sites, leading to the rapid deactivation of the composite catalyst. In contrast, after the surface silica modification, the strong interaction between the SiO2 and InZrOx species can suppress the reduction of In2O3 to metallic indium species and then effectively hinder the metallic indium species from migration into the H-Beta component. Consequently, the structural and catalytic stability of the InZrOx-Beta composite during the reduction and CO2 hydrogenation processes can be greatly improved by the surface silica protection strategy.

The catalytic performance of InZrOx(SCP-4)-Beta(40) and InZrOx(SCP-8)-Beta(40) in the CO2 hydrogenation was then compared with that of the InZrOx(CP)-Beta(40) counterpart. As shown in Fig. 8b and Supplementary Fig. 28a, the reaction time when the selectivity to unconverted methanol reaches 2% is considerably prolonged from about 42 h of InZrOx(CP)-Beta(40) to 97 h of InZrOx(SCP-4)-Beta(40) under the same conditions, indicating the higher catalytic stability of latter InZrOx(SCP-4)-Beta(40). Meanwhile, the acidic properties of the H-Beta zeolite component separated from various spent InZrOx-Beta composite catalysts after reaction for the same time were evaluated, as demonstrated in Supplementary Fig. 29 and Supplementary Table 6. Apparently, after reaction for 24 and 42 h, the total acid content and strong acid content of H-Beta zeolite separated from the spent InZrOx(SCP-4)-Beta(40) catalyst are both much higher than that separated from the InZrOx(CP)-Beta(40) counterpart. This further confirms that the surface silica protection strategy to alleviate the rapid passivation of the acid sites in H-Beta is rather effective in improving the stability of the bifunctional InZrOx-Beta composite catalyst in the CO2 hydrogenation to hydrocarbons.

In addition, the selectivity to CO over InZrOx(SCP-4)-Beta(40) is reduced to 34.5% from the value of 51.2% over InZrOx(CP)-Beta(40), being much lower than those reported for the In-based bifunctional catalysts in the CO2 hydrogenation in the literature at a similar CO2 conversion (Supplementary Table 7). Through a further increase of the SiO2 loading to 8 wt.%, the catalytic lifetime (e.g. the reaction time when the selectivity to unconverted methanol reaches 2%) of InZrOx(SCP-8)-Beta(40) is further prolonged to above 140 h, along with a lower selectivity to CO (33.1%), as shown in Fig. 8c.

Notably, although the selectivity to butane keeps at around 53% over both the SiO2-modified and unmodified InZrOx-Beta catalysts during the steady stage, the selectivity to butane for the CO2 hydrogenation over the InZrOx(SCP-4)-Beta(40) and InZrOx(SCP-8)-Beta(40) composite catalysts still decreases gradually after a long time on stream (ca. 70–100 h). It indicates that the surface silica modification method may not completely and eternally solve the problem of indium species migration. Nevertheless, the onset time for the decrease in the selectivity to butane is extended from 40 h of InZrOx(CP)-Beta(40) to ca. 70 h of InZrOx(SCP-4)-Beta(40) and ca. 100 h of InZrOx(SCP-8)-Beta(40), as demonstrated in Supplementary Fig. 28b. This also suggests that an increase of the SiO2 loading is favorable for lowering the impact of indium migration on the butane formation. However, the deposited SiO2 may also cover a fraction of the surface oxygen vacancies, which leads to a decrease of CO2 adsorption capacity on the SiO2-modified InZrOx oxides (Supplementary Fig. 30). As shown by the O 1s XPS spectra in Supplementary Fig. 31, InZrOx(SCP-4) and InZrOx(SCP-8) have a lower concentration of surface oxygen vacancies but abundant OH groups originated from the surface Si–OH of SiO2, in comparison with the InZrOx(CP) counterpart. Consequently, the CO2 conversion is also decreased from 25.6% over InZrOx(CP)-Beta(40) to 19.7% over InZrOx(SCP-4)-Beta(40), and further to 16.6% over InZrOx(SCP-8)-Beta(40). Accordingly, the loading of SiO2 for the surface protection of the InZrOx oxide should be restricted to a certain value (ca. 4–8 wt.%) to elevate the catalytic stability of catalyst and meanwhile avoid a substantial decrease of the CO2 conversion.

After the reaction test, the granules of InZrOx(CP) oxide and H-Beta zeolite in the InZrOx(CP)-Beta composite were separated from each other and then characterized by various measures. According to the TG analysis results (Supplementary Fig. 32), all three samples show a very low coking rate (ca. 0.0003–0.0005 h−1), indicating that the coke deposition here should not be the major cause of catalyst deactivation. Unlike the conversion of methanol to hydrocarbons (MTH) over a zeolite catalyst in the N2 or Ar atmosphere, for the hydrogenation of CO2 to hydrocarbons, the presence of H2 and H2O in high pressure can effectively eliminate the coke precursors and thus greatly hinder the formation and accumulation of coke species. However, in the XRD patterns shown in Fig. 9f, one obvious diffraction peak at ca. 30.6° ascribed to the (222) crystal facet of In2O3 is distinctly detected on the H-Beta zeolite separated from the spent InZrOx(CP)-Beta(40) catalyst, which is further verified by the identification of InZrOx nano-particles in the TEM image on the surface of separated H-Beta zeolite (Fig. 9g). In contrast, such In species are nearly undetectable on the H-Beta zeolite separated from the spent InZrOx(SCP-4)-Beta and InZrOx(SCP-8)-Beta catalysts (Fig. 9h/i), suggesting that the phase segregation of InZrOx and the migration of indium species are effectively slowed down on the SiO2-modified InZrOx(SCP-4) and InZrOx(SCP-8) oxides during the CO2 hydrogenation reaction.

In addition, after reaction for 100 h over InZrOx(SCP-4) and 140 h over InZrOx(SCP-8), the diffraction peaks in the XRD patterns and the binding energies in the In 3d, Zr 3d and Si 2p XPS spectra of the spent InZrOx(SCP-4) and InZrOx(SCP-8) oxides are highly comparable to those of the corresponding fresh ones (Supplementary Fig. 33). Meanwhile, the lattice spacing of 0.290–0.291 nm, assigned to the (222) crystal facet of In2O3, is clearly visible on the Aberration-corrected HAADF-STEM images and HR-TEM images of the spent InZrOx(SCP-4) and InZrOx(SCP-8) oxides (Supplementary Fig. 34), along with the uniform distribution of In, Zr, O and Si elements over these two samples (Supplementary Figs. 35, 36). The TEM images suggests that the spent InZrOx(SCP-4) and InZrOx(SCP-8) samples have a particle size of 7.57 and 5.16 nm, respectively, only slightly larger than the values of 6.10 and 4.70 nm for the fresh InZrOx(SCP-4) and InZrOx(SCP-8) counterparts, respectively (Supplementary Fig. 37). All these results reveal that the surface silica protection strategy used in current work is rather effective in suppressing the phase segregation of InZrOx oxide moiety and avoiding the rapid poisoning of the acid sites in the zeolite moiety induced by the In migration, which can thus significantly improve the structural and catalytic stability of the In-based oxide-zeolite composite catalyst in the CO2 hydrogenation.

As expected, such a strategy can also be extended to the SiO2-modified In2O3-Beta catalyst. As shown in Supplementary Fig. 38a, the In2O3(SCP-4)-Beta(40) catalyst shows a long catalytic lifetime (ca. 65 h) and high selectivity to butane (ca. 53% in hydrocarbons) in the CO2 hydrogenation. In contrast, over the unmodified In2O3(CP)-Beta(40) counterpart, the selectivity to butane is quickly decreased to 30%, along with the generation of much more unconverted methanol (25%) after reaction for ca. 65 h (Supplementary Fig. 38b). Undoubtedly, the improved stability of the In2O3(SCP-4)-Beta(40) catalyst also originates from the inhibition of the indium species from reduction and migration by the surface silica protection, which can alleviate the rapid deactivation of the zeolite moiety in the hydrogenation of CO2 to hydrocarbons (Supplementary Fig. 38c–e).

It is noteworthy that although the strong interaction between the surface SiO2 species and InZrOx oxide can inhibit the indium species from easy reduction and migration and then improve the stability of the InZrOx-Beta composite catalyst in the CO2 hydrogenation, it does not relocate the indium species on the composite catalyst. In other words, the silica species are only highly dispersed on the surface of InZrOx oxide and do not cause any significant structural distortion and/or rearrangement of the InZrOx oxide upon the reduction and reaction process over the time. To confirm this point, the crystal structure and surface electronic states of the silica-modified InZrOx(SCP-4) after reaction for different periods of time are analyzed. Apparently, the diffraction peaks in the XRD patterns, the lattice spacing in the HRTEM images and the binding energies in the In 3d, Zr 3d and Si 2p XPS spectra of the spent InZrOx(SCP-4)-24h and InZrOx(SCP-4)-42h samples are all highly comparable to those of the fresh counterpart (Supplementary Fig. 39j–l and Supplementary Fig. 40a). In addition, the TEM images display that the particle size of InZrOx(SCP-4) is only slightly increased from 6.10 nm of fresh InZrOx(SCP-4) to 6.89 nm of InZrOx(SCP-4)-24h and to 7.30 nm of InZrOx(SCP-4)-42h (Supplementary Fig. 39a–i). Meanwhile, the surface In/Zr and In/Si ratios of InZrOx(SCP-4) also show little change upon the CO2 hydrogenation reaction test (Supplementary Fig. 40b–e). That is, the major function of the introduced surface silica species is the inhibition of the indium species from reduction and migration in the reductive atmosphere containing hydrogen, whereas without causing any significant structural distortion and atomic rearrangement of the InZrOx oxide as well as the InZrOx-Beta composite catalyst upon the preparation and reaction process over the time.

Discussion

A composite bifunctional catalyst consisting of InZrOx oxide and H-Beta zeolite was designed, which exhibits excellent performance in the selective hydrogenation of CO2 to butane. Under 315 °C, 3.0 MPa, and a space velocity of 1200 mL g−1 h−1, a high selectivity of 53.4% to butane in all hydrocarbons (CO free) is achieved at a CO2 conversion of 20.4% and a selectivity of only about 2% to CH4.

Various characterization measures and DFT calculation were used to explore the reaction mechanism and structure-performance relationship. The results reveal that the conversion of CO2 to butane keeps to the tandem methanol-mediated mechanism and the catalytic performance of the InZrOx-Beta composite is related to both the InZrOx oxide moiety and the H-Beta zeolite moiety. The generation of methanol-related intermediates by CO2 hydrogenation is closely related to the surface oxygen vacancies of InZrOx, which can be finely tuned through modulating the preparation methods. In contrast, the three-dimensional 12-ring channels of H-Beta zeolite conduces to forming a hydrocarbon pool (HCP) filled with higher methylbenzenes and methylnaphthalenes, which favors the successive transformation of methanol-related intermediates to butane via the aromatic-based cycle, through the alkyl side-chain elimination and subsequent methylation and hydrogenation.

In addition, to tackle the passivation of the acid sites in H-Beta by the migration of indium species of InZrOx in the reductive atmosphere containing H2, a surface silica protection strategy was developed, which can effectively inhibit the phase separation of InZrOx oxide and the indium migration, and then considerably improve the catalytic stability of InZrOx/Beta in the hydrogenation of CO2 to hydrocarbons. The insight shown in this work may pave a way for the design of stable In-based catalyst in the CO2 hydrogenation to get a specific hydrocarbon product.

Methods

Catalyst preparation

As described in detail in the Supplementary Information, three InZrOx oxides with an In/Zr molar ratio of 4 were prepared, viz., InZrOx(CP) by co-precipitation, InZrOx(SG) by sol-gel processing, and InZrOx(HT) by hydrothermal method. In addition, InZrOx(CP) was further modified by depositing 4 and 8 wt.% SiO2 on the surface, to obtain the SiO2-modified InZrOx(SCP-4) and InZrOx(SCP-8) oxides, respectively. Meanwhile, a series of H-Beta zeolites with a Si/Al molar ratio (n) of 20, 30, 40, 60, and 100 were synthesized by the hydrothermal method and denoted as Beta(n). Moreover, H-USY (Si/Al = 5.5) and H-SSZ-13 (Si/Al = 9), purchased from Nankai University Catalyst Co., were used for comparison.

Three manners were used to compose the InZrOx-Beta bifunctional catalysts, viz., dual-bed, granule-mixing, and powder-grinding. By the dual-bed manner, 0.3 g of granule InZrOx (20–40 mesh) was used as the upper layer and 0.3 g of granule H-Beta (20–40 mesh) as the lower layer. By granule-mixing, 0.3 g of InZrOx and 0.3 g of H-Beta (both in 20–40 mesh) was mixed in granules. By powder-mixing, 0.3 g of powder InZrOx and 0.3 g of powder H-Beta were grinded together for 5 min and the powdery mixture was then granulated into particles of 20–40 mesh.

Catalyst characterization

Various catalyst samples were characterized by N2 sorption, X-ray diffraction (XRD), X-ray photoelectron spectra (XPS), field emission-scanning electron microscopy (FE-SEM), transmission electron microscopy (TEM), high-resolution TEM (HRTEM), Aberration-corrected high-angle annular dark-field scanning TEM (Aberration-corrected HAADF-STEM), temperature-programmed reduction with H2 (H2-TPR), temperature-programmed desorption of NH3 (NH3-TPD) and CO2 (CO2-TPD), thermogravimetric analysis (TGA), inductively coupled plasma-atomic emission spectrometer (ICP-AES), in situ diffuse reflectance infrared Fourier transform (DRIFT) spectroscopy, gas chromatography-mass spectrometry (GC-MS), and 12C/13C methanol switching experiment, as described in detail in the Supplementary Information.

Catalytic reaction tests

The CO2 hydrogenation reaction was carried out in a stainless steel tubular fixed-bed reactor, as described in detail in the Supplementary Information. Briefly, for the CO2 hydrogenation to methanol, 0.3 g of InZrOx was used and the reaction was conducted under 315 °C, 3.0 MPa, and with a space velocity (SV) of 2400 mL g−1 h−1 and H2/CO2 ratio of 3 in the feed. For the CO2 hydrogenation to butane, unless specially claimed, 0.6 g of granule-mixed bifunctional InZrOx-Beta catalyst (0.3 g InZrOx + 0.3 g H-Beta) was used and the reaction was performed under 315 °C, 3.0 MPa, a SV of 1200 mL g−1 h−1, and H2/CO2 ratio of 3 in the feed. For the InZrOx(CP)-Beta composite catalyst prepared by granular mixing, two components of InZrOx(CP) and H-Beta in the spent InZrOx(CP)-Beta catalyst after the reaction test were distinctly different in color, as displayed in Supplementary Fig. 41; therefore, two components can be easily separated by hand according to the granule color, for further characterization. For comparison, the reaction of methanol-to-olefins (MTO) was conducted in a U-type quartz tube loading with 300 mg of H-Beta and with H2 as the carrier gas, under 315 °C, atmospheric pressure and a methanol weighted hourly space velocity (WHSV) of 0.05 h−1.

DFT calculation

DFT calculation was conducted with the Gaussian 09.E01 package, as described in detail in the Supplementary Information.

Data availability

The source data that support the findings of this study including the article and its Supplementary Information are provided with this paper and are also available in the ScienceDB repository at https://doi.org/10.57760/sciencedb.07972 or available from the author upon reasonable request. Source data are provided with this paper.

References

Aresta, M., Dibenedetto, A. & Angelini, A. Catalysis for the valorization of exhaust carbon: from CO2 to chemicals, materials, and fuels technological use of CO2. Chem. Rev. 114, 1709–1742 (2014).

Dorner, R. W., Hardy, D. R., Williams, F. W. & Willauer, H. D. Heterogeneous catalytic CO2 conversion to value-added hydrocarbons. Energy Environ. Sci. 3, 884–890 (2010).

Porosoff, M. D., Yan, B. & Chen, J. G. Catalytic reduction of CO2 by H2 for synthesis of CO, methanol and hydrocarbons: challenges and opportunities. Energy Environ. Sci. 9, 62–73 (2016).

Wang, W., Wang, S., Ma, X. & Gong, J. Recent advances in catalytic hydrogenation of carbon dioxide. Chem. Soc. Rev. 40, 3703–3727 (2011).

Guo, S. et al. Feasibility, limit, and suitable reaction conditions for the production of alcohols and hydrocarbons from CO and CO2 through hydrogenation, a thermodynamic consideration. Ind. Eng. Chem. Res. 61, 17027–17038 (2022).

Guo, S. et al. Conversion of the CO and CO2 mixture to alcohols and hydrocarbons by hydrogenation under the influence of the water-gas shift reaction, a thermodynamic consideration. J. Fuel Chem. Technol. 51, 482–491 (2023).

Centi, G., Quadrelli, E. A. & Perathoner, S. Catalysis for CO2 conversion: a key technology for rapid introduction of renewable energy in the value chain of chemical industries. Energy Environ. Sci. 6, 1711–1731 (2013).

Jiao, F. & Bao, X. Selective conversion of syngas to light olefins. Science 351, 1065–1068 (2016).

Liu, X. et al. Tandem catalysis for hydrogenation of CO and CO2 to lower olefins with bifunctional catalysts composed of spinel oxide and SAPO-34. ACS Catal. 10, 8303–8314 (2020).

Dang, S. et al. Role of zirconium in direct CO2 hydrogenation to lower olefins on oxide/zeolite bifunctional catalysts. J. Catal. 364, 382–393 (2018).

Li, Z. et al. Highly selective conversion of carbon dioxide to lower olefins. ACS Catal. 7, 8544–8548 (2017).

Ronda-Lloret, M., Rothenberg, G. & Shiju, N. R. A critical look at direct catalytic hydrogenation of carbon dioxide to olefins. ChemSusChem 12, 3896–3914 (2019).

Cui, X. et al. Selective production of aromatics directly from carbon dioxide hydrogenation. ACS Catal. 9, 3866–3876 (2019).

Zuo, J. et al. Selective methylation of toluene using CO2 and H2 to para-xylene. Sci. Adv. 6, eaba5433 (2020).

Ni, Y. et al. Selective conversion of CO2 and H2 into aromatics. Nat. Commun. 9, 3457 (2018).

Wang, Y. et al. Rationally designing bifunctional catalysts as an efficient strategy to boost CO2 hydrogenation producing value-added aromatics. ACS Catal. 9, 895–901 (2018).

You, Z., Deng, W., Zhang, Q. & Wang, Y. Hydrogenation of carbon dioxide to light olefins over non-supported iron catalyst. Chin. J. Catal. 34, 956–963 (2013).

Xu, Y. et al. Selective production of aromatics from CO2. Catal. Sci. Technol. 9, 593–610 (2019).

Wei, J. et al. Precisely regulating brønsted acid sites to promote the synthesis of light aromatics via CO2 hydrogenation. Appl. Catal. B 283, 119648 (2021).

Tu, W. et al. Chemical and structural properties of Na decorated Fe5C2-ZnO catalysts during hydrogenation of CO2 to linear α-olefins. Appl. Catal. B 298, 120567 (2021).

Zhang, S. et al. Morphological modulation of Co2C by surface-adsorbed species for highly effective low-temperature CO2 reduction. ACS Catal. 12, 8544–8557 (2022).

Li, Z. et al. Highly selective conversion of carbon dioxide to aromatics over tandem catalysts. Joule 3, 570–583 (2019).

Chen, H. et al. Carbon-confined magnesium hydride nano-lamellae for catalytic hydrogenation of carbon dioxide to lower olefins. J. Catal. 379, 121–128 (2019).

Wang, S. et al. Highly effective conversion of CO2 into light olefins abundant in ethene. Chem 8, 1376–1394 (2022).

Wang, S. et al. Selective conversion of CO2 into propene and butene. Chem 6, 3344–3363 (2020).

Liu, Z., Ni, Y., Sun, T., Zhu, W. & Liu, Z. Conversion of CO2 and H2 into propane over InZrO and SSZ-13 composite catalyst. J. Energy Chem. 54, 111–117 (2021).

Li, Z. et al. Ambient-pressure hydrogenation of CO2 into long-chain olefins. Nat. Commun. 13, 2396–2405 (2022).

Asami, K., Zhang, Q., Li, X., Asaoka, S. & Fujimoto, K. Semi-indirect synthesis of LPG from syngas: conversion of DME into LPG. Catal. Today 106, 247–251 (2005).

Fujiwara, M., Satake, T., Shiokawa, K. & Sakurai, H. CO2 hydrogenation for C2+ hydrocarbon synthesis over composite catalyst using surface modified HB zeolite. Appl. Catal. B 179, 37–43 (2015).

Li, S., Guo, L. & Ishihara, T. Hydrogenation of CO2 to methanol over Cu/AlCeO catalyst. Catal. Today 339, 352–361 (2020).

Wei, Y. et al. Catalytic roles of In2O3 in ZrO2-based binary oxides for CO2 hydrogenation to methanol. Mol. Catal. 525, 112354 (2022).

Martin, O. et al. Indium oxide as a superior catalyst for methanol synthesis by CO2 hydrogenation. Angew. Chem. Int. Ed. 55, 6261–6265 (2016).

Dang, S. et al. Selective transformation of CO2 and H2 into lower olefins over In2O3-ZnZrOx/SAPO-34 bifunctional catalysts. ChemSusChem 12, 3582–3591 (2019).

Jiang, X. et al. A combined experimental and DFT study of H2O effect on In2O3/ZrO2 catalyst for CO2 hydrogenation to methanol. J. Catal. 383, 283–296 (2020).

Numpilai, T., Wattanakit, C., Chareonpanich, M., Limtrakul, J. & Witoon, T. Optimization of synthesis condition for CO2 hydrogenation to light olefins over In2O3 admixed with SAPO-34. Energy Convers. Manag. 180, 511–523 (2019).

Gao, P. et al. Direct production of lower olefins from CO2 conversion via bifunctional catalysis. ACS Catal. 8, 571–578 (2017).

Frei, M. S. et al. Role of zirconia in indium oxide-catalyzed CO2 hydrogenation to methanol. ACS Catal. 10, 1133–1145 (2019).

Chen, T. et al. Unraveling highly tunable selectivity in CO2 hydrogenation over bimetallic In-Zr oxide catalysts. ACS Catal. 9, 8785–8797 (2019).

Wang, J., Zhang, A., Jiang, X., Song, C. & Guo, X. Highly selective conversion of CO2 to lower hydrocarbons (C2-C4) over bifunctional catalysts composed of In2O3-ZrO2 and zeolite. J. CO2 Util. 27, 81–88 (2018).

Wang, W., Chen, Y. & Zhang, M. Facet effect of In2O3 for methanol synthesis by CO2 hydrogenation: A mechanistic and kinetic study. Surf. Interfaces 25, 101244 (2021).

Yang, L. et al. Stabilizing the framework of SAPO-34 zeolite toward long-term methanol-to-olefins conversion. Nat. Commun. 12, 4661–4671 (2021).

Wang, S. et al. Enhancement of light olefin production in CO2 hydrogenation over In2O3-based oxide and SAPO-34 composite. J. Catal. 391, 459–470 (2020).

Gao, P. et al. Direct conversion of CO2 into liquid fuels with high selectivity over a bifunctional catalyst. Nat. Chem. 9, 1019–1024 (2017).

Simonetti, D. A., Ahn, J. H. & Iglesia, E. Mechanistic details of acid-catalyzed reactions and their role in the selective synthesis of triptane and isobutane from dimethyl ether. J. Catal. 277, 173–195 (2011).

Wang, Y. et al. Visualizing element migration over bifunctional metal-zeolite catalysts and its impact on catalysis. Angew. Chem. Int. Ed. 60, 17735–17743 (2021).

Qi, Y. et al. Photoinduced defect engineering: enhanced photothermal catalytic performance of 2D black In2O3−x nanosheets with bifunctional oxygen vacancies. Adv. Mater. 32, 1903915 (2020).

Zhang, W. et al. Effective conversion of CO2 into light olefins along with generation of low amounts of CO. J. Catal. 413, 923–933 (2022).

Shi, Y. et al. Hierarchically structured Pt/K-Beta zeolites for the catalytic conversion of n-heptane to aromatics. Microporous Mesoporous Mater. 324, 111308 (2021).

Ding, H., Zhou, Q., Li, J., Zhu, K. & Fan, W. Self-assembly of silicoaluminophosphate nanocrystals in biphasic media with a water-insoluble structure-directing agent. Catal. Sci. Technol. 11, 5135–5146 (2021).

Zhou, C. et al. Highly active ZnO-ZrO2 aerogels integrated with H-ZSM-5 for aromatics synthesis from carbon dioxide. ACS Catal. 10, 302–310 (2019).

Bai, S. et al. Highly active and selective hydrogenation of CO2 to ethanol by ordered Pd-Cu nanoparticles. J. Am. Chem. Soc. 139, 6827–6830 (2017).

Khan, M. U. et al. Pt3Co octapods as superior catalysts of CO2 hydrogenation. Angew. Chem. Int. Ed. 55, 9548–9552 (2016).

Luo, Y. et al. Conversion of syngas into light olefins over bifunctional ZnCeZrO/SAPO-34 catalysts: regulation of the surface oxygen vacancy concentration and its relation to the catalytic performance. Catal. Sci. Technol. 11, 338–348 (2021).

Kattel, S., Yan, B., Yang, Y., Chen, J. G. & Liu, P. Optimizing binding energies of key intermediates for CO2 hydrogenation to methanol over oxide-supported copper. J. Am. Chem. Soc. 138, 12440–12450 (2016).

Wang, C. et al. π-Interactions between cyclic carbocations and aromatics cause zeolite deactivation in methanol-to-hydrocarbon conversion. Angew. Chem. Int. Ed. 59, 7198–7202 (2020).

Plessow, P. N., Enss, A. E., Huber, P. & Studt, F. A new mechanistic proposal for the aromatic cycle of the MTO process based on a computational investigation for H-SSZ-13. Catal. Sci. Technol. 12, 3516–3523 (2022).

Lesthaeghe, D., Horre, A., Waroquier, M., Marin, G. B. & Van Speybroeck, V. Theoretical insights on methylbenzene side-chain growth in ZSM-5 zeolites for methanol-to-olefin conversion. Chem. Eur. J. 15, 10803–10808 (2009).

Zhou, W. et al. New horizon in C1 chemistry: breaking the selectivity limitation in transformation of syngas and hydrogenation of CO2 into hydrocarbon chemicals and fuels. Chem. Soc. Rev. 48, 3193–3228 (2019).

Bao, J., Yang, G., Yoneyama, Y. & Tsubaki, N. Significant advances in C1 catalysis: highly efficient catalysts and catalytic reactions. ACS Catal. 9, 3026–3053 (2019).

Su, J. et al. Syngas to light olefins conversion with high olefin/paraffin ratio using ZnCrOx/AlPO-18 bifunctional catalysts. Nat. Commun. 10, 1297 (2019).

Ding, Y. et al. Effects of proximity-dependent metal migration on bifunctional composites catalyzed syngas to olefins. ACS Catal. 11, 9729–9737 (2021).

Acknowledgements

The authors sincerely thank to the financial supports of the National Key R&D Program of China (2020YFA0210900; 2018YFB0604802), National Natural Science Foundation of China (U1910203; U1862101; 21991090; 21991092; 22272195; U22A20431), Natural Science Foundation of Shanxi Province of China (202203021224009), Innovation foundation of Institute of Coal Chemistry, Chinese Academy of Sciences (SCJC-DT-2023-06), Youth Innovation Promotion Association CAS (2021172) and Excellent doctoral student award and subsidy program of Shanxi Province (BK2018001).

Author information

Authors and Affiliations

Contributions

H.W. and S.F. conducted experiments on catalyst preparation, evaluation, characterization and theoretical calculation; H.W. wrote the paper; S.G. carried out partial catalyst characterization experiments; M.D., H.Z., and W.F. provided some idea and part of the experimental guidance; S.W., Z.Q., and J.W. guided the whole experiments and revised the article; H.W. and S.F. contributed equally to this work. All the authors contributed to the discussions on the experimental and theoretical calculation results.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Hermenegildo Garcia and the other, anonymous, reviewer for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, H., Fan, S., Guo, S. et al. Selective conversion of CO2 to isobutane-enriched C4 alkanes over InZrOx-Beta composite catalyst. Nat Commun 14, 2627 (2023). https://doi.org/10.1038/s41467-023-38336-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-023-38336-5

- Springer Nature Limited

This article is cited by

-

Phase Behavior of Isobutane + CO2 and Isobutane + H2 at Temperatures Between 190 and 400 K and at Pressures Up to 20 MPa

International Journal of Thermophysics (2024)