Abstract

Facile formation of carbon-heteroatom bonds is a long-standing objective in synthetic organic chemistry. However, direct cross-coupling with readily accessible alkenyl acetates via inert C‒O bond-cleavage for the carbon-heteroatom bond construction remains challenging. Here we report a practical preparation of stereoselective tri- and tetrasubstituted alkenyl silanes and stannanes by performing cobalt-catalyzed C‒O silylation and stannylation of alkenyl acetates using silylzinc pivalate and stannylzinc chloride as the nucleophiles. This protocol features a complete control of chemoselectivity, stereoselectivity, as well as excellent functional group compatibility. The resulting alkenyl silanes and stannanes show high reactivities in arylation and alkenylation by Hiyama and Stille reactions. The synthetic utility is further illustrated by the facile late-stage modifications of natural products and drug-like molecules. Mechanistic studies suggest that the reaction might involve a chelation-assisted oxidative insertion of cobalt species to C‒O bond. We anticipate that our findings should prove instrumental for potential applications of this technology to organic syntheses and drug discoveries in medicinal chemistry.

Similar content being viewed by others

Introduction

Transition metal-catalyzed cross-coupling reactions have been recognized as a powerful toolbox for the construction of C–C and C–X (X = heteroatoms) bonds, which play a vital role in the synthesis of pharmaceuticals, agrochemicals, and feedstock commodity chemicals1,2,3,4,5. For practical applications and easy availability in synthesis, oxygen-based electrophiles have been recognized as halide-free alternatives for coupling with organometallic reagents6,7,8,9,10. Among them, alkenyl esters represent an attractive candidate for non-aromatic functionality due to their versatile occurrence in biomass-derived chemicals and convenient preparation. However, most of the advances in cross-couplings were accomplished with activated esters, such as triflate, tosylate, sulfamate, carbamate, phosphate, and carbonate. Hence, numerous contributions have been made to further expand the library of electrophiles11,12,13,14,15,16. Alkenyl acetates17,18,19, as a class of (pseudo)halide electrophile bearing a small and nonhazardous leaving group, have received considerable recent attention20. While unactivated enol acetates in coupling reactions remain a significant challenge due to the selective cleavage issue between vinyl Csp2–O and acetyl–O bonds (445 vs 335 kJ/mol)21. As such, using mild nucleophilic reagents as the coupling partners or/and devising highly active catalytic systems, which operate under kinetic control rather than a thermodynamic pathway, are the key for achieving cross-couplings via selective vinyl Csp2‒O bond cleavage (Fig. 1a).

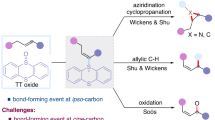

Since Shi22 and Garg23 independently pioneered the feasibility of nickel-catalyzed Negishi- and Suzuki-coupling reactions by using alkenyl pivalates as the electrophiles, alkenyl acetates have been extensively exploited for transition metal-catalyzed C–C bond formation cross-coupling reactions with B, Zn, Mg-based organometallics using Ni24, Fe21, Co25, Cr26, Rh27, and Pd catalysis28,29,30. Moreover, Ackermann31 disclosed the chelation-assisted cobalt-catalyzed Csp2–H alkenylations of indoles with alkenyl acetates, which underwent a remarkably mild C–O bond cleavage as compared to the ruthenium catalysis32. Gosmini33,34,35 and Shu36 also reported the applications of vinyl acetates in Co- and Ni-catalyzed reductive arylation and alkylation. Despite these major advances, major challenges in the area of C–O functionalization with alkenyl acetates still need to be overcome: (i) in contrast to the common alkenyl C–C bond formation, rather rare examples of alkenyl C–heteroatom bond formation were developed;37 (ii) most of the progresses have been made with cyclic, non- or mono-substituted alkenyl acetates as the coupling partners, rather poor Z/E-selectivity is observed when employing acyclic tri- or tetrasubstituted alkenyl acetates as the coupling partners. Hence, the methods aimed at C–heteroatom bond formation and stereo-controllable C–O cross-coupling are highly desirable (Fig. 1b).

Towards the mechanism of C–O bond activation, two plausible pathways have been given: initial transmetalation between organometallics and transition metal catalyst forms the C–[TM] species, which undergoes (i) oxidative insertion of C–O bond to the [TM]-center, along with following reductive elimination; or (ii) 1,2-carbometalation of enol carboxylates, in tandem with isomerization (II and III) and trans-, or syn-elimination. Therefore, avoiding the latter pathway, selective oxidative insertion to form a single diastereomer intermediate (I) is the key for achieving stereoselective C–O functionalization (Fig. 1c)20. We hypothesized that the challenging issue would be solved by introducing a removable directing group into the polysubstituted alkenyl acetates, thereby preferentially realizing chelation-assisted oxidative insertion of transition metal species to C–O bond, rather than 1,2-nucleophilic addition process. In this context, acyclic tri- and tetrasubstituted alkenyl acetates bearing a modulable carbonyl group are attractive alternative candidates: OAc imparts better mass efficiency than other leaving groups, carbonyl groups are valuable functional groups and versatile precursors for alcohols, amines, and other important functionalities in organic synthesis. Organozinc reagents are important intermediates which display high reactivity and excellent chemoselectivity in organic synthesis38,39,40,41,42,43,44. Hence, we developed the bench-stable and easy-to-handle silyl and stannylzinc reagents45,46, and applied to 3d cobalt-catalyzed cross-couplings47,48,49,50,51,52,53 with polyfunctionalized alkenyl acetates to build synthetically useful C–Si54,55,56 and C–Sn57,58,59,60 bonds (Fig. 1d). In this work, Me2PhSi‒ZnOPiv•Li2(Cl)(OPiv) and (nBu)3Sn‒ZnCl•LiCl show superior reactivity over the other commonly available Si- and Sn-based organometallic reagents. Moreover, notable features of our strategy are excellent functional group tolerance, and complete control of regio- and stereoselectivity, thus providing expedient access to the stereodefined alkenyl silanes and stannanes, which can be further utilized for the synthesis of stereochemically defined acyclic tri- and all-carbon tetrasubstituted alkenes.

Results

Optimization studies

We initiated our studies by preparing different Si‒Met (1) and Sn‒Met (2) reagents (Met = Li, Mg, Zn, and Al) through transmetalation of corresponding Si‒Li and Sn‒Li reagents with MgBr2, ZnX2, and Zn(OPiv)2, or AlCl3. Thereafter, we tested their reactivity for the cobalt-catalyzed silylation and stannylation of alkenyl acetates via C‒O bond activation (Fig. 2). To our delight, CoBr2 in the presence of 2,2’-bipyridyl enables silylation of 3a using Me2PhSi‒ZnOPiv•Li2(Cl)(OPiv) (1a) as the nucleophile [PhMe2Si‒ZnOPiv•2Li(OPiv)(Cl) was abbreviated as Me2PhSi‒ZnOPiv for the sake of clarity], which displayed unique reactivity in carbonsilylation of alkenes by nickel catalysis45, the desired product 4 was obtained in 72% yield. Interestingly, the typical halides-supported Si‒Zn reagents 1b–1d, as well as Si‒Mg reagent 1e failed to undergo the C‒O silylation process under the identical cobalt catalysis. These findings are consistent with the previous nickel-catalyzed carbosilylation of alkenes, which demonstrated the crucial importance of OPiv-coordination for improving the reactivity of Si‒Zn reagents. Furthermore. cross-coupling product was not observed in the treatment of Sn‒Li (2d), Sn‒Zn (2b), or Sn‒Al (2 f) with indenyl acetate (3b) in the presence of CoBr2/2,2′-bipyridine (10 mol%) in MeCN at 0 °C. Whereas a two-step sequence including cobalt-catalyzed stannylation and nucleophilic addition/elimination occurred when employing Sn‒Mg (2e) as the nucleophile, affording the bis-stannylated product 5 in 24% yield. The envisioned alkenyl stannane 7 was obtained using Sn‒Zn 2a or 2c as the nucleophiles, and thus (nBu3)Sn‒ZnCl•LiCl yielding the desired product 7 in 20% yield, along with 24% of the destannylative product 6.

These results encouraged us to further optimize the reaction conditions for cobalt-catalyzed C–Si and C–Sn bonds formation using Me2PhSi‒ZnOPiv•Li2(Cl)(OPiv) (1a) and (nBu)3Sn‒ZnCl•LiCl (2a) as the nucleophilic partners (Table 1). Firstly, optimization studies identified THF as the ideal reaction medium and bipyridine (L1) or 5,5′-dimethylbipyridine (L4) as the ligands of choice for the cobalt-catalyzed C–O silylation, leading to the desired alkenyl silane 4 in 81% yield (Table 1a, entries 1‒8). Lowering the temperature or employing other cobalt complexes as the catalyst gave moderate yields (entries 9–12). However, examination with a metal source such as nickel, iron, or chromium salts provided only a negligible conversion, as was also observed in the absence of a catalyst (entries 13–14). After extensive optimization of ligands, such as bis(pyridine)s (L1‒L7), tridentate 2,6-bis(N-pyrazolyl)pyridine (L8) phosphines (L9‒L11), and bipyridine (L1) gave the optimal conversion of 7 (Table 1b, entries 1‒11). Meanwhile, MeCN was identified as the ideal medium of choice (entry 12). Switching from CoBr2 to NiCl2, FeCl2, or CrCl2 failed to improve the transformation (entry 13). A significant breakthrough was made when performed the reaction at −20 °C, affording 7 in 53% yield, while no reaction was observed at −30 °C (entry 14). Notably, shortening the reaction time to 15 min led to a further yield increase to 66% yield (entries 15‒16), which highlighted the robustness of the cobalt catalyst and unique reactivity of (nBu)3Sn‒ZnCl•LiCl reagent (2a).

Substrate scope studies

With the optimized cobalt catalyst in hand, the generality of our protocol was subsequently explored in a range of C‒O bond-silylation reactions with various polyfunctionalized alkenyl acetates 5 and solid silylzinc pivalate PhMe2Si‒ZnOPiv (1a) (Fig. 3). We were pleased to find that cyclic and various all-carbon tetrasubstituted acyclic alkenyl acetates smoothly proceeded cobalt-catalyzed C‒O bond-silylation with 1a under the otherwise identical reaction conditions. The solid PhMe2Si‒ZnOPiv (1a) exhibited good reactivity under remarkably mild reaction conditions at 23 °C, thereby delivering the corresponding tetrasubstituted alkenyl silanes 9‒30 in 50‒86% yields. Importantly, the cobalt catalysis displayed excellent functional group compatibility, such as fluoro, chloro, bromo, ester, nitrile, acetate, piperidine, and alkenyl substituents, were well tolerated under the mild reaction conditions. Notably, the catalytic system showed excellent chemoselectivity to realize C‒O bond activation, rather than C‒Hal (Cl and Br) cross-couplings. Moreover, the C‒O bond cleavage of all-carbon tetrasubstituted acyclic alkenyl acetates 5 smoothly underwent a silylation process in a highly stereoretentive fashion, the corresponding (Z)-alkenyl silanes 9‒31 were obtained with excellent stereoselectivity. A similar result was also observed when employing (Z)-alkenyl acetate bearing a lactone fragment as the electrophile, furnishing the (Z)-stereoisomer 32 as the sole product in 81% yield, which could be further reduced to the ring-opening diol 33 in a stereoretentive fashion. In sharp contrast, the lactam substrate failed to deliver the silylated product. The trisubstituted acyclic acetates failed to generate the desired product because a significant amount of the corresponding hydrodesilylated product 34 was formed, which is likely owing to the poor stability of the alkenyl silane under the reaction conditions.

Reaction conditions for silylation: alkenyl acetates (0.25 mmol, 1.0 equiv), Me2PhSi‒ZnOPiv 1a (0.50 mmol, 2.0 equiv), CoBr2 (10 mol %), bpy (L1, 11 mol %), THF (1.5 mL), 23 °C. [a] DIBAH (2.0 equiv), THF, −78 °C. [b] CoBr2(5,5′-dmbpy) (10 mol%) as the catalyst. [c] LiAlH4 (1.5 equiv), Et2O, 0 °C. DIBAH diisobutylaluminum hydride.

On the basis of the remarkably high stereoselectivity and efficacy of the C‒O bond-silylations, we subsequently succeeded in examing analogous stannylations of various alkenyl acetates with (nBu3)Sn‒ZnCl•LiCl (2a). Indeed, a variety of cyclic enol acetates, including indenyl acetate, naphthalenyl acetate, chromenyl acetate, as well as cyclopentenyl and cycloheptenyl acetates, were smoothly stannylated with 2a, delivering the alkenyl stannanes 7, 35‒39 in 47‒85% yields. Moreover, the desired C‒O bond stannylation can be successfully scaled up to the gram scale with a slightly reduced yield (38) (Fig. 4a).

a Scope of C–O stannylation with cyclic and trisubstituted alkenyl acetates. b Scope of C–O stannylation with tetrasubstituted alkenyl acetates. Reaction conditions for stannylation: alkenyl acetates (0.25 mmol, 1.0 equiv), 2a (0.325 mmol, 1.3 equiv), CoBr2 (10 mol%), bpy (L1, 11 mol%), MeCN (1.5 mL), −20 °C. [a] CoBr2 and L1 (15 mol%). [b] 0 °C. [c] 23 °C. [d] LiAlH4 (1.5 equiv), Et2O, 0 °C.

Furthermore, we turned our attention to examining the stereoselective transformation of our cobalt catalysis. It is worth noting that the (Z)-alkenyl acetates underwent cobalt-catalyzed stannylation in a stereoretentive fashion, generating the (Z)-stereoisomer as the sole product. As expected, various trisubstituted acrylates bearing electron-rich as well as electron-deficient substituents on the aryl side were identified as viable substrates for direct stannylations under remarkably mild reaction conditions, furnishing the (Z)-diastereomers 40‒51 in 49‒78% yields through excellent chemo- and stereoselective C‒O bond activation. Moreover, a variety of valuable functional groups such as trifluoromethyl, ester, nitrile, and terminal alkene were well tolerated under otherwise identical reaction conditions. A similar result was also observed when employing (Z)-acetoxyheptenyl carboxylate as the electrophilic partner, giving the desired product 52 in 76% yield (Fig. 4b).

Toward the stereoselective preparation of more challenging unsymmetrical all-carbon tetrasubstituted alkenyl stannanes, a series of stereodefined all-carbon tetrasubstituted alkenyl acetates were investigated. To our delight, a range of all-carbon tetrasubstituted alkenyl acetates bearing different functional groups smoothly underwent the cobalt-catalyzed C‒O bond stannylation to afford the desired products 53‒68 in 47‒84% yields with complete control of stereoselectivity. It is worth noting that tertiary amide, lactam, as well as lactone were found to be effective chelation groups for the envisioned stereoselective C‒O bond-stannylation reaction, thereby providing (Z)-selective 69‒72 as the sole products (Fig. 4b).

In order to further illustrate the potential applications of our protocol in the late-stage modifications of natural products and pharmaceutically active molecules. The alkenyl acetates derivatives of cholesterol, lithocholic acid, and citronellol were proven to be viable substrates for cobalt-catalyzed C‒O silylation with PhMe2Si‒ZnOPiv (1a), delivering the corresponding alkenyl silanes 73‒76 in moderate yields with high (Z)-selectivity. Moreover, the enol acetates derivatives of citronellol, ibuprofen, probenecid, celecoxib, and indomethacin were well stannylated with (nBu)3Sn‒ZnCl•LiCl, leading to the (Z)-diastereomers 77‒81 in 47‒71% yields, thus displaying the potential utility of this technology to drug discovery in medicinal chemistry (Fig. 5).

Reaction conditions for silylation: alkenyl acetates (0.25 mmol, 1.0 equiv), Me2PhSi‒ZnOPiv 1a (0.50 mmol, 2.0 equiv), CoBr2 (10 mol%), bpy (L1, 11 mol%), THF (1.5 mL), 23 °C. Reaction conditions for stannylation: alkenyl acetates (0.25 mmol, 1.0 equiv), 2a (0.325 mmol, 1.3 equiv), CoBr2 (10 mol%), bpy (L1, 11 mol%), MeCN (1.5 mL), −20 °C. [a] CoBr2(5,5′-dmbpy) (10 mol%) as the catalyst. [b] CoBr2 and L1 (15 mol%). [c] 0 °C. [d] 23 °C.

Mechanistic studies

Inspired by the high reactivity of the PhMe2Si‒ZnOPiv (1a) and (nBu)3Sn‒ZnCl•LiCl (2a) for cobalt-catalyzed stereoselective C‒O bond silyl- and stannylation of alkenyl acetates, we sought to unravel the reaction mechanism. To this end, a series of control experiments with radical scavengers 82 were performed, and both silylated and stannylated products were isolated with slightly reduced yields (Fig. 6a). We next set the parallel reactions with stereodefined (Z)- and (E)-alkenyl acetates, substrate (Z)-83 afforded the stereoretentive product 84 in 86% yield, whereas the resulting products were detected by GC analysis with an E/Z ratio of 5.4:1 when employing (E)-83 as the electrophile. Moreover, a (E)-alkenyl acetate (85) bearing a conjugated amide only delivered the desired product 86 in a negligible conversion (Fig. 6b). These findings suggested that the chelation-assisted oxidative insertion of cobalt into the C‒O bond of (Z)-alkenyl acetates is preferred to (E)-alkenyl acetates. Intermolecular competition experiments with (Z)-and E-alkenyl acetates revealed (Z)-83 to be inherently more reactive (Fig. 6c). Switching from (Z)-87 to the more hindered substrate of (Z)-88 led to a significantly decreased yield of the corresponding product 89 and 90 (0 and 31%) (Fig. 6d). In addition, the substrate bearing a conjugated N,N-dimethyl amide (Z)-91 only gave the desired stannane 93 in 43% yield with complete control of geometry. Moreover, an enol acetate 94 bearing a conjugated nitrile was also examined under standard conditions. However, only a trace amount of silylated product 95 and a low yield of stannylated product 96 were formed. As expected, no desired C‒O bond functionalization was observed when using the substrate without a conjugated ester group as the electrophilic coupling partner (see Supplementary Fig. 1e). These findings suggested that the ester group is crucial to the stereoselective C–O bond activation due to its chelation-assistance and conjugation effect to active the α,β-unsaturated alkenyl acetate system (Fig. 6e).

Based on our mechanistic studies and previous insights26,29, a plausible mechanism for the cobalt-catalyzed stannylation of alkenyl acetates is proposed, as shown in Fig. 7. The Co(II) precatalyst is initially reduced to form an active LnCoI-species by the [Si/Sn]‒ZnX (1a or 2a). Alkenyl acetate 3 then coordinates to the in situ formed LnCoI-species (A) with the assistance of ester chelation. The chelation effect can facilitate the oxidative addition of CoILn into C–O bond, thus forming Co(alkenyl)(OAc) complex B as a single diastereomer. Subsequent coordination and transmetalation with [Si/Sn]‒ZnX (1a or 2a) affords the intermediate D. Final reductive elimination of D releases the desired alkenyl silanes and stannanes in a stereoretentive fashion and regenerates the catalytically active cobalt species A to close the catalytic cycle.

Finally, the synthetic utility of the resulting alkenyl silanes and stannanes was further described in the palladium-catalyzed Hiyama and Stille coupling reactions (Fig. 8). Remarkably, aryl halides bearing chloro, and sensitive ketone, aldehyde substituents were well coupled with various alkenyl silanes and stannanes under mild reaction conditions, delivering the arylated products 97–100 in moderate to excellent yields with complete control of stereoselectivity, the conformation of 100 was confirmed by X-ray crystal analysis. 1,3-Dienes are key important structural motifs of natural products with activities of relevance to biology chemistry61,62. Such building blocks could be expediently constructed by palladium-catalyzed stereoselective alkenyl‒alkenyl coupling reactions; the desired 1,3-dienes 101‒105 were afforded in a stereoselective fashion. Beyond that, the potential applications of our protocol to the late-stage modifications of drug-like molecules, such as probenecid, duloxetine, and fluoxetine derivatives, were further demonstrated by a facile Stille-alkenylation under room temperature to afford the desired products 106‒108 in 56‒72% yields, thus proving instrumental technology for the synthesis of highly complex molecules in drug discovery. Moreover, these alkenyl silanes can be further converted to the corresponding silalactones 109‒110 through selective Si–C bond electrophilic cleavage. Interestingly, the selectivity was largely dominated by the reaction temperature.

[a] Reaction conditions: electrophiles (Ar–I; 2.0 equiv), alkenyl silanes (1.0 equiv), Pd2(dba)3 (2.5 mol%), NaOH (2.0 equiv), THF, 60 °C, 16 h. [b] Reaction conditions: electrophiles (E–I/Br; 1.2 equiv), alkenyl stannanes (1.0 equiv), Pd(PPh3)4 (5 mol%), CuI (50 mol%), DMF, 23 °C, 16 h. [c] I2 (1.5 equiv), CCl4, 90 or 70 °C.

Discussion

In conclusion, we have demonstrated the utility of Si‒Zn and Sn‒Zn reagents for the efficient cobalt-catalyzed cross-coupling of alkenyl acetates through chelation-assisted C‒O bond cleavage under mild reaction conditions, thus providing a practical and efficient strategy for the preparation of various tri- and tetrasubstituted alkenyl silanes and stannanes in a stereoretentive fashion. Indeed, the solid silylzinc pivalate and stannylzinc chloride showed excellent reactivity and chemoselectivity toward diverse alkenyl acetates, as well as an ample substrate scope and high functional group compatibility. Preliminary mechanism studies suggested that the stereoselectivity presumably is caused by the chelation-assisted oxidative addition of cobalt to the C–O bond of alkenyl acetates. Finally, we have also illustrated the synthetical versatility of the polyfunctionalized alkenyl silanes and stannanes by the facile transformations of Hiyama and Stille reactions with complete control of stereoselectivity, such as arylation and alkenylation. Further development of the related applications with Si‒Zn and Sn‒Zn reagents are currently ongoing in our laboratory and will be reported in due course.

Methods

Cobalt-catalyzed stereoselective C–O silylation and stannylation of alkenyl acetates

To an oven-dried 25 mL screw-cap tube equipped with a stir bar was vacuumed and backfilled with N2 for three times. A suspension of CoBr2 (10 mol%), 2,2′-bipyridyl (11 mol%) in THF or MeCN (0.5 mL) was charged and stirred at 0 °C for 5 min, then the alkenyl acetate (0.25 mmol, 1.0 equiv), and PhMe2Si‒ZnOPiv•Li2(Cl)(OPiv) (1a, 0.5 mmol, 2.0 equiv, 1.0 mL THF) or (nBu3)Sn‒ZnCl•LiCl (2a, 0.325 mmol, 1.3 equiv, 1.0 mL MeCN) were sequentially added to the catalyst suspension. The reaction mixture was stirred at the identified temperature (silylation: 23 °C; stannylation: −20, or 0, or 23 °C) under an atmosphere of N2. At ambient temperature, the solvent was evaporated under reduced pressure and the remaining residue was purified by column chromatography on silica gel to yield the desired products.

Data availability

The experimental procedures and compound characterization, and related data generated in this study are provided in the Supplementary Information/Source Data file. The X-ray crystallographic data of 100 used in this study are available in the joint Cambridge Crystallographic Data Centre and Fachinformationszentrum Karlsruhe Access Structures service www.ccdc.cam.ac.uk/structures.

References

Beller, M. & Bolm, C. (ed.) Transition Metals for Organic Synthesis (Wiley, 2004).

de Meijere, A. Bräse, S. & Oestreich, M. (ed.) Metal-Catalyzed Cross-Coupling Reactions and More (Wiley, 2014).

Seechurn, C. C. C. J., Kitching, M. O., Colacot, T. J. & Snieckus, V. Palladium-catalyzed cross-coupling: a historical contextual perspective to the 2010 Nobel Prize. Angew. Chem. Int. Ed. 51, 5062–5085 (2012).

Haas, D., Hammann, J. M., Greiner, R. & Knochel, P. Recent developments in negishi cross-coupling reactions. ACS Catal. 6, 1540–1552 (2016).

Hassan, J., Sévignon, M., Gozzi, C., Schulz, E. & Lemaire, M. Aryl-aryl bond formation one century after the discovery of the Ullmann reaction. Chem. Rev. 102, 1359–1470 (2002).

Nassar, Y., Rodier, F., Ferey, V. & Cossy, J. Cross-coupling of ketone enolates with Grignard and zinc reagents with first-row transition metal catalysts. ACS Catal. 11, 5736–5761 (2021).

Qiu, Z. & Li, C.-J. Transformations of less-activated phenols and phenol derivatives via C–O cleavage. Chem. Rev. 120, 10454–10515 (2020).

Zeng, H. et al. An adventure in sustainable cross-coupling of phenols and derivatives via carbon–oxygen bond cleavage. ACS Catal. 7, 510–519 (2017).

Cornella, J., Zarate, C. & Martin, R. Metal-catalyzed activation of ethers via C–O bond cleavage: a new strategy for molecular diversity. Chem. Soc. Rev. 43, 8081–8097 (2014).

Rosen, B. M. et al. Nickel-catalyzed cross-couplings involving carbon−oxygen bonds. Chem. Rev. 111, 1346–1416 (2011).

Li, B.-J. et al. Cross-coupling of alkenyl/aryl carboxylates with Grignard reagent via Fe-catalyzed C−O bond activation. J. Am. Chem. Soc. 131, 14656–14657 (2009).

Sun, C.-L. & Fürstner, A. Formal ring-opening/cross-coupling reactions of 2-pyrones: iron-catalyzed entry into stereo-defined dienyl carboxylates. Angew. Chem. Int. Ed. 52, 13071–13075 (2013).

Guo, L., Hsiao, C.-C., Yue, H., Liu, X. & Rueping, M. Nickel-catalyzed Csp2–Csp3 cross-coupling via C–O bond activation. ACS Catal. 6, 4438–4442 (2016).

Pan, W. J. & Wang, Z. X. Nickel-catalyzed cross-coupling of β-carbonyl alkenyl pivalates with arylzinc chlorides. Org. Biomol. Chem. 16, 1029–1036 (2018).

Chen, Z. & So, C. M. Palladium-phenylpyrazolylphosphine-catalyzed cross-coupling of alkenyl pivalates. Asian J. Org. Chem. 10, 776–779 (2021).

Hu, B. et al. Rhenium-catalyzed arylation–acyl cyclization between enol lactones and organomagnesium halides: facile synthesis of indenones. Angew. Chem. Int. Ed. 60, 15497–15502 (2021).

Panek, J. S. (ed.) Science of Synthesis: Houben-Weyl Method of Molecular Transformations (Thieme, 2006).

Yu, J.-Y., Shimizu, R. & Kuwano, R. Selective cine substitution of 1-arylethenyl acetates with arylboron reagents and a diene/rhodium catalyst. Angew. Chem. Int. Ed. 49, 6396–6399 (2010).

Hering, T., Hari, D. P. & König, B. Visible-light-mediated α-arylation of enol acetates using aryl diazonium salts. J. Org. Chem. 77, 10347–10352 (2012).

Hu, Y., Hu, B., Liu, X., Ren, Z. & Li, J. Recent developments in catalytic cross-couplings with unsaturated carboxylates. Org. Biomol. Chem. 19, 7754–7767 (2021).

Gartner, D., Stein, A. L., Grupe, S., Arp, J. & Jacobi von Wangelin, A. Iron-catalyzed cross-coupling of alkenyl acetates. Angew. Chem. Int. Ed. 54, 10545–10549 (2015).

Li, B.-J. et al. Cross-coupling of aryl/alkenyl pivalates with organozinc reagents through nickel-catalyzed C‒O bond activation under mild reaction conditions. Angew. Chem. Int. Ed. 47, 10124–10127 (2008).

Quasdorf, K. W., Tian, X. & Garg, N. K. Cross-coupling reactions of aryl pivalates with boronic acids. J. Am. Chem. Soc. 130, 14422–14423 (2008).

Sun, C.-L. et al. Construction of polysubstituted olefins through Ni-catalyzed direct activation of alkenyl C·O of substituted alkenyl acetates. Chem. Eur. J. 16, 5844–5847 (2010).

Li, J. & Knochel, P. Cobalt-catalyzed cross-couplings between alkenyl acetates and aryl or alkenyl zinc pivalates. Angew. Chem. Int. Ed. 57, 11436–11440 (2018).

Li, J., Ren, Q., Cheng, X., Karaghiosoff, K. & Knochel, P. Chromium(II)-catalyzed diastereoselctive and chemoselective Csp2‒Csp3 cross-couplings using organomagnesium reagents. J. Am. Chem. Soc. 141, 18127–18135 (2019).

Yu, J. Y. & Kuwano, R. Rhodium-catalyzed cross-coupling of organoboron compounds with vinyl acetate. Angew. Chem. Int. Ed. 48, 7217–7220 (2009).

Lindh, J., Sävmarker, J., Nilsson, P., Sjöberg, P. J. R. & Larhed, M. Synthesis of styrenes by palladium(II)-catalyzed vinylation of arylboronic acids and aryltrifluoroborates by using vinyl acetate. Chem. Eur. J. 15, 4630–4636 (2009).

Becica, J., Heath, O. R. J., Zheng, C. H. M. & Leitch, D. C. Palladium-catalyzed cross-coupling of alkenyl carboxylates. Angew. Chem. Int. Ed. 59, 17277–17281 (2020).

Becica, J., Gaube, G., Sabbers, W. A. & Leitch, D. C. Oxidative addition of activated aryl-carboxylates to Pd(0): divergent reactivity dependant on temperature and structure. Dalton Trans. 49, 16067–16071 (2020).

Moselage, M., Sauermann, N., Richter, S. C. & Ackermann, L. C−H alkenylations with alkenyl acetates, phosphates, carbonates, and carbamates by cobalt catalysis at 23 ̊C. Angew. Chem. Int. Ed. 54, 6352–6355 (2015).

Matsuura, Y. et al. The Ru(cod)(cot)-catalyzed alkenylation of aromatic C‒H bonds with alkenyl acetates. J. Am. Chem. Soc. 129, 9858–9859 (2007).

Polleux, L., Labbé, E., Buriez, O. & Périchon, J. CoI- and Co0-bipyridine complexes obtained by reduction of CoBr2bpy: electrochemical behaviour and investigation of their reactions with aromatic halides and vinylic acetates. Chem. Eur. J. 11, 4678–4686 (2005).

Amatore, M., Gosmini, C. & Périchon, J. Cobalt-catalyzed electrochemical vinylation of aryl halides using vinylic acetates. Eur. J. Org. Chem. 2005, 989–992 (2005).

Gomes, P., Gosmini, C. & Périchon, J. Cobalt-catalyzed electrochemical vinylation of aryl halides using vinylic acetates. Tetrahedron 59, 2999–3002 (2003).

He, R.-D. et al. Reductive alkylation of alkenyl acetates with alkyl bromides by nickel catalysis. Angew. Chem. Int. Ed. 61, e202114556 (2022).

Gaube, G., Fernandez, N. P. & Leitch, D. C. An evaluation of palladium-based catalysts for the base-free borylation of alkenyl carboxylates. N. J. Chem. 45, 20095–20098 (2021).

Liu, X., Wang, J. & Li, J. Versatile opiv-supported organozinc reagents for transition metal-catalyzed cross-couplings. Synlett https://doi.org/10.1055/a-1872-0179 (2022).

Wei, B. & Knochel, P. Recent adcances in cross-couplings of functionalized organozinc reagents. Synthesis 54, 246–254 (2022).

Eckert, P., Sharif, S. & Organ, M. G. Salt to taste: the critical roles played by inorganic salts in organozinc formation and in the Negishi reaction. Angew. Chem. Int. Ed. 60, 12224–12241 (2021).

Manolikakes, S. M., Ellwart, M., Stathakis, C. I. & Knochel, P. Air-stable solid aryl and heteroaryl organozinc pivalates: syntheses and applications in organic synthesis. Chem. Eur. J. 20, 12289–12297 (2014).

Greshock, T. J. et al. Synthesis of complex druglike molecules by the use of highly functionalized bench-stable organozinc reagents. Angew. Chem. Int. Ed. 55, 13714–13718 (2016).

Kim, J. H., Ko, Y. O., Bouffard, J. & Lee, S.-G. Advances in tandem reactions with organozinc reagents. Chem. Soc. Rev. 44, 2489–2507 (2015).

Knochel, P. & Singer, R. D. Preparation and reactions of polyfunctional organozinc reagents in organic synthesis. Chem. Rev. 93, 2117–2188 (1993).

Wang, J. et al. Salt-stabilized silylzinc pivalates for nickel-catalyzed carbosilylation of alkenes. Angew. Chem. Int. Ed. 61, e202202379 (2022).

Wang, D.-Y., Wang, C. & Uchiyama, M. Stannyl-lithium: a facile and efficient synthesis facilitating further application. J. Am. Chem. Soc. 137, 10488–10491 (2015).

Bera, S. S. & Szostak, M. Cobalt–H-heterocyclic carbene complexes in catalysis. ACS Catal. 12, 3111–3137 (2022).

Guérinot, A. & Cossy, J. Cobalt-catalyzed cross-couplings between alkyl halides and Grignard reagents. Acc. Chem. Res. 53, 1351–1363 (2020).

Kyne, S. H. et al. Iron and cobalt catalysis: new perspectives in synthetic radical chemistry. Chem. Soc. Rev. 49, 8501–8542 (2020).

Lutter, F. H. et al. Cobalt-catalyzed cross-couplings and electrophilic aminations using organozinc pivalates. ChemCatChem 11, 5188–5197 (2019).

Moselage, M., Li, J. & Ackermann, L. Cobalt-catalyzed C‒H activation. ACS Catal. 6, 498–525 (2016).

Cahiez, G. & Moyeux, A. Cobalt-catalyzed cross-coupling reactions. Chem. Rev. 110, 1435–1462 (2010).

Gosmini, C., Begouin, J.-M. & Moncomble, A. Cobalt-catalyzed cross-coupling reactions. Chem. Commun. 44, 3221–3233 (2008).

Brook, M. A. (ed.) Silicon in Organic, Organometallic, and Poly-mer Chemistry (Wiley, 2000)

Denmark, S. E. & Liu, J. H.-C. Silicon-based cross-coupling reactions in the total synthesis of natural products. Angew. Chem. Int. Ed. 49, 2978–2986 (2010).

Nakao, Y. & Hiyama, T. Silicon-based cross-coupling reaction: an enviromentally benign version. Chem. Soc. Rev. 40, 4893–4901 (2011).

Wang, D.-Y. et al. Stille coupling via C‒N bond cleavage. Nat. Commun. 7, 12937–12945 (2016).

Cordovilla, C., Bartolomé, C., Martínez-Ilarduya, J. M. & Espinet, P. The Stille reaction, 38 years later. ACS Catal. 5, 3040–3053 (2015).

Carsten, B., He, F., Son, H. J., Xu, T. & Yu, L. Stille polycondensation for synthesis of functional materials. Chem. Rev. 111, 1493–1528 (2011).

Ragan, J. A. et al. Cross-coupling methods for the large-scale preparation of an imidazole−thienopyridine: synthesis of [2-(3-methyl-3H-imidazol-4-yl)- thieno[3,2-b]pyridin-7-yl]-(2-methyl-1H-indol-5-yl)-amine. Org. Process Res. Dev. 7, 676–683 (2003).

Mehta, G. & Rao, H. S. P. in The Chemistry of Dienes and Polyenes (ed. Rappoport, Z.) Ch. 9 (Wiley, 1997).

De Paolis, M., Chataigner, I. & Maddaluno, J. Recent advances in stereoselective synthesis of 1,3-dienes. Top. Curr. Chem. 327, 87–146 (2012).

Acknowledgements

We thank the Natural Science Foundation of Jiangsu Province (BK20221355), the start-up grant (NH10900422) of Soochow University, the sponsored program by the Jiangsu Province for the Cultivation of Innovation and the Fundamental Research Funds for the Central Universities (WHU 2042022kf1038 and 2042021KF1020) for financial support.

Author information

Authors and Affiliations

Contributions

Jie. L. conceived and directed the project; Jie. L. and X.Q. wrote the paper; Y.H. and B.H. designed and performed the experiments; X.Q. and J.P. participated in the design and discussion of the mechanism; J.W., J.J., J. Lin, and X.L. prepared the starting materials; all the authors were involved in the interpretation of the results presented in the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks David Leitch and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hu, Y., Peng, J., Hu, B. et al. Stereoselective C–O silylation and stannylation of alkenyl acetates. Nat Commun 14, 1454 (2023). https://doi.org/10.1038/s41467-023-37192-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-023-37192-7

- Springer Nature Limited