Abstract

This review addresses the synthesis of various polymers carrying bulky and rigid adamantyl substituents in their side chains. Synthetic methods for these polymers include typical polymer reactions of introducing adamantyl groups into existing polymers and the polymerization of monomers bearing pendant adamantyl groups. In particular, with regard to the latter synthetic method, the addition polymerization of adamantyl-containing vinyl monomers such as α-olefins, acetylenes, (meth)acrylates, (meth)acrylamides, vinyl ethers, 1,3-dienes, and styrenes is described. A variety of vinyl monomers are capable of undergoing living anionic polymerization to afford polymers with predictable molecular weights and narrow molecular weight distributions (M w/M n = 1.1). In several cases, the introduced adamantyl groups afford steric hindrance to prevent side reactions and control the addition modes of the polymerization. In general, the resulting adamantyl-substituted polymers show extremely high glass transition temperatures and high thermal stability derived from the stiff adamantyl substituents compared with the corresponding parent polymers.

Similar content being viewed by others

Introduction

Adamantane (tricyclo[3.3.1.13,7]decane) is a highly symmetrical alicyclic hydrocarbon composed of ten sp3 carbons and 16 hydrogens (Fig. 1), and it possesses a small strain energy derived from the fixed chair-form conformations of the fused cyclohexane rings [1, 2]. The tetrahedral (T d) symmetry and spherical structure of the adamantane molecule leads to easy sublimation due to the low intermolecular forces. Adamantane is bulky, rigid, and hydrophobic and shows characteristic features such as transparency in the UV region and good chemical and thermal stability. Since various functional groups can be introduced onto the tertiary bridgehead carbons under suitable reaction conditions, a family of adamantane derivatives can be synthesized [3, 4].

Based on these attractive features, a number of polymers containing bulky adamantyl skeletons in the main chain and side chain have been synthesized via step-growth and chain-growth polymerizations. As a first example, Reinhardt reported that a polymer was produced by the Wurtz-type coupling polymerization of 3,3′-dibromo-1,1′-biadamantane using sodium metal in p-xylene (Scheme 1) [5, 6]. Although the resulting polymer was insoluble in any solvent, its chemical structure was supposed to be a poly(1,3-adamantane) obtained by the coupling between the bridgehead sp3 carbons. Since this pioneering synthetic study of poly(1,3-adamantane), several main-chain adamantane-containing polyamides and polyimides have been produced by condensation polymerization [7,8,9,10]. For instance, an all-aliphatic polyimide was obtained by the reaction of 1,3-diaminoadamantane or 3,3′-diamino-1,1′-biadamantane and an aliphatic dianhydride (Scheme 2). The resulting polyimides showed UV transparency as well as excellent thermal stability. A semialicyclic poly(benzoxazole) containing adamantane-1,3-diyl linkages was also prepared by the condensation of 1,3-adamantanedicarbonyl chloride and 4,4′-(hexafluoroisopropylidene)bis(o-aminophenol) (Scheme 3) [11]. On the other hand, an adamantane-containing poly(thiocarbonate) was formed by the ring-opening polymerization of the cyclic thiocarbonate monomer [12].

1,3-Dehydroadamantane (1a), a [3.3.1]propellane derivative, is a highly distorted molecule that exhibits high reactivity, similar to other small-ring propellanes [13,14,15]. In fact, 1a easily reacts with radical or acidic reagents to afford the corresponding 1,3-disubstituted adamantanes in high yields (Scheme 4). Pincock and coworkers reported that thermal polymerization of 1a rapidly occurred to yield a white powder when 1a was heated in bulk at 130–160 °C [14]. Although the resultant polymeric product was insoluble in all organic solvents due to the rigidity of the polymer backbone, the resulting compound was supposed to be a poly(1,3-adamantane), poly(1a), according to elemental analysis and IR measurements. In addition to the thermal polymerization, 1a underwent ring-opening polymerization to give a similar insoluble polymer under cationic and radical conditions.

To clarify the chemical structure and molecular weight, Ishizone and coworkers newly synthesized a series of 1,3-dehydrodamantane derivatives bearing butyl, butoxy, phenyl, and trimethylsilylmethyl groups (1b–1d, Scheme 5) [16, 17]. The cationic ring-opening polymerization of these monomers with trifluoromethanesulfonic acid (TfOH) or radical polymerization with α,α′-azobisisobutyronitrile (AIBN) proceeded to give the corresponding polymers [18,19,20]. Although unsubstituted poly(1a) showed extremely low solubility, the introduction of butyl, butoxy, phenyl, and trimethylsilylmethyl groups on the poly(1,3-adamantane) framework effectively endowed the resulting polymers with excellent solubility. This enables characterization of the chemical structures and the molecular weights of the polymers in detail by NMR and size exclusion chromatography (SEC) measurements. It is also noteworthy that the resultant (1,3-adamantane)s presented remarkable thermal stability derived from the stiff adamantane rings. As expected from the high reactivity toward various chemical reagents, spontaneous copolymerizations of 1a with electron-deficient vinyl monomers such as acrylonitrile and methyl acrylate also proceeded without any initiator or catalyst to form alternating copolymers containing adamantane-1,3-diyl linkages in the main chain (Scheme 6) [21]. The obtained copolymers showed higher thermal stability than polyacrylonitrile and poly(methyl acrylate), reflecting the property of the introduced adamantane-1,3-diyl linkage in the copolymers. Thus, various main chain adamantane-containing polymers have been synthesized and characterized to develop new high-performance polymeric materials.

It is well known that the functional groups in the side chain strongly affect the main properties of polymers. As a pendant group, the spherical adamantane ring in the polymer side chain was captured by the cavity of β-cyclodextrin to form an inclusion compound [22]. This particular interaction of the adamantane moiety was utilized for the preparation of polymer micelles and polymer gels. In this review, we focus on the synthesis of adamantane side chain-bearing polymers. The main synthetic method includes the polymerization of monomers bearing the adamantyl pendant groups, in addition to the polymer modification by the introduction of adamantyl groups. The adamantyl-bearing monomers are α-olefins, alkynes, (meth)acrylates, acrylamides, vinyl ethers, 1,3-butadienes, and styrenes, capable of addition polymerization. Although these target monomers possess bulky adamantyl substituents near the polymerizable carbon–carbon multiple bonds, each polymerization smoothly occurs to give the corresponding polymer in quantitative yield. In several cases, even living polymerizations are attained to produce well-defined polymers under suitable reaction conditions. The living character of the polymerizations certainly enables us to synthesize tailored block copolymers and chain-end functionalized polymers. As expected from the unique features of the adamantane molecule, the resulting adamantane-containing polymers present attractive thermal and optical properties.

Synthesis of polymers carrying adamantyl substituents by polymer reaction

As mentioned in the Introduction, there are two representative pathways to produce the polymers possessing adamantyl groups in their side chain. One is polymerization of a monomer possessing an adamantyl group and the other is chemical modification of the parent reactive polymers, such as polystyrene and poly(acrylic acid), with adamantyl compounds, such as 1-bromoadamantane, 1-adamantanol, and 1-aminoadamantane. The former pathway usually requires the synthesis of the particular adamantyl-substituted monomer since those monomers are fairly unique and not commercially available. The latter pathway is rather simple and versatile for the synthesis of adamantyl-substituted polymers, while the contents of the substituents are usually difficult to control in the polymer reactions.

Allcock and his coworkers attempted to modify a chloro-substituted polyphosphazene by treatment with adamantane compounds such as 1-aminoadamantane and sodium salts of 1-adamantanol and 1-adamantanemethanol (Scheme 7) [23, 24]. The nucleophilic substitution on the P–Cl linkages with the bulky adamantane compounds proceeded to afford the corresponding modified polyphosphazenes, and the contents of the adamantyl substituents were ~50%. The typical glass transition temperature (T g) of the polyphosphazene is much lower than room temperature and ~–100 °C, but the resulting polymers bearing various adamantyl groups showed T g values of ~180 °C. Thus, the observed T g values markedly increased from the original one because of the effect of the introduced adamantyl groups.

Polymerization of α-olefin and acetylenes

The simplest adamantyl containing vinyl monomer is 1-vinyladamantane (2). This simple mono-substituted alkene underwent cationic polymerization with aluminum tribromide (AlBr3) at 25 or –80 °C in CH2Cl2 to give polymers showing high thermal stability (Scheme 8), while no polymerization proceeded with AIBN or benzoyl peroxide (BPO) [25]. In thermal gravimetric analysis (TGA) measurements, the resulting poly(2) started to decompose at ~300 °C just after melting. IR and 1H NMR analyses revealed that the vinyl group in the polymeric products completely disappeared, supporting the hypothesis that the expected vinyl addition polymerization of 2 proceeded exclusively. However, the limited solubility of the polymer hindered detailed characterization of the chemical structures, including stereoregularity and molecular weights.

As another example of side-chain-type hydrocarbon polymers, Mathias and coworkers reported the synthesis of the homopolymer of 3-(1-adamantyl)propene (1-allyladamantane, 3) and its copolymer with α-olefins via metallocene-catalyzed polymerization using rac-ethylenebis(1-indenyl)zirconium dichloride in the presence of methylaluminoxane in toluene (Scheme 9) [26]. However, since the resulting poly(3) and the copolymers showed very poor solubility, the characterization of the polymeric products was limited to solid-state NMR. It was noted that the bulky 1-adamantylmethyl group certainly influenced the T g values of the copolymers in comparison with the corresponding homopolymers. In fact, the homopolymer of 3 exhibited a significantly high T g value at 235 °C, much higher than those of polyethylene (T g = –125 °C) and polypropylene (T g = 0 °C), suggesting the effect of the adamantyl substituent.

1-Adamantylacetylene (1-ethynyladamantane, 4) can be quantitatively polymerized by transition metal catalysts such as MoCl5 and WCl6 in toluene at 30 °C to afford an insoluble conjugated polyacetylene derivative (Scheme 10) [27]. Higashimura and coworkers reported that the stability of the polyacetylenes against oxidation was increased by introducing the bulky adamantyl group into the repeating units, in addition to enhancing the thermal stability. It is noteworthy that hydrocarbon monomers carrying the adamantyl groups, 2 (vinyl) and 4 (acetylene), smoothly gave the corresponding polymers under suitable reaction conditions even though the bulky substituents are located near the polymerizable moieties. Three other p-(1-adamantyl)phenylacetylene derivatives were polymerized using MoCl5 or TaCl5-based catalysts to give soluble polyacetylenes (Fig. 2) [28]. The oxygen permeability of the free-standing polymer film was investigated to clarify the effect of the bulkiness and rigidity of the substituents.

Polymerization of (meth)acrylates

Attempts to synthesize a variety of alkyl and aromatic (meth)acrylates have been reported under various conditions. The adamantyl substituted monomers 1-adamantyl (5a) and 3,5-dimentyl-1-adamantyl methacrylate (5b) were polymerized with a radical initiator such as AIBN in benzene (Scheme 11) [29, 30]. The free radical polymerization of 5a smoothly proceeded, and the resulting poly(5a) did not show a T g before thermal degradation at ~280 °C, suggesting its excellent thermal properties. Although the anionic polymerization of 5a was also attempted by Otsu and coworkers with sec-butyllithium (s-BuLi) in THF at –78 °C, detailed information on the control of the molecular weight was not provided [29]. It is proposed that thermally stable poly[(meth)acrylates] including poly(5a) without aromatic moieties are new candidate photoresist materials due to the possible transparency near the ultraviolet region as well as in the visible light region. Other thermally stable polymethacrylates, including poly(1-adamantylmethyl methacrylate) (T g = 201 °C) and poly(p-(1-adamantyl)phenyl methacrylate) (T g = 253 °C), were obtained by radical polymerization (Fig. 3) [31, 32].

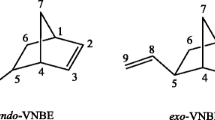

The basic hydrolysis of 1-adamantyl ester is usually difficult because of the bulkiness of the substituents. In the case of bulky tertiary alkyl esters such as tert-butyl esters, cleavage between the tertiary carbon of the alkyl groups and oxygen of the COOR moiety readily occurs under acidic conditions to give a stable tertiary carbocation and a COOH moiety. Although the 1-adamantyl ester is a similar tertiary alkyl ester, such acidic cleavage is fairly difficult for the following reasons. The possible bridgehead tertiary adamantyl carbocation is rather unstable, and the formation of a distorted alkene, adamantene, via the β-elimination of the adamantyl cation is strongly prohibited because of steric factors (Scheme 12) [33, 34]. On the other hand, another tertiary adamantyl ester, 2-methyl-2-adamantyl ester, can be easily decomposed to form an exo-methylene compound, 2-methyleneadamantane, under acidic conditions. Therefore, since a poly(methacrylic acid) is readily obtained by treating poly(2-alkyl-2-adamantyl methacrylate)s with strong acid, these 2-alkyl-2-adamantyl esters are useful as a positive-type resist [35, 36]. During the acidic development process, the 2-alkyl-2-adamantyl ester with rather low solubility changed to a poly(methacrylic acid) that was highly soluble in the alkaline solution.

(Meth)acrylates, typical α,β-unsaturated carbonyl compounds, readily accept nucleophilic conjugate addition, i.e., 1,4-addition. From the viewpoint of polymer chemistry, this conjugate addition of (meth)acrylates is an initiation or propagation step in anionic polymerization. In fact, (meth)acrylate monomers show significantly higher anionic polymerizability than styrene, 1,3-dienes, and vinylpyridines since the electron-withdrawing carbonyl groups activate the carbon–carbon double bonds toward nucleophilic addition [36,37,38,39,40].

Ishizone and coworkers synthesized 3-methacryloyloxy-1,1′-biadamantane, 6, the methacrylate of the adamantane dimer, and polymerized it with 1,1-diphenyl-3-methylpentyllithium (DMPLi, a 1:1 adduct of s-BuLi and 1,1-diphenylethylene) or diphenylmethylpotassium (Ph2CHK) (Scheme 13) [41]. The polymerization of 6 quantitatively proceeded in THF at –50 °C to give polymers possessing the molecular weights predicted based on the molar ratios between the monomer and initiators and narrow molecular weight distributions (M w/M n < 1.2), as shown in Table 1. Binary initiator systems such as DMPLi and LiCl or Ph2CHK and Et2Zn can also effectively induce the living polymerization of 6, similar to previous reports on methyl methacrylate [42, 43]. A series of well-defined block copolymers can be obtained by the sequential anionic copolymerization of 6 and various comonomers, such as alkyl methacrylates, styrene, and isoprene. The resulting poly(6) bearing a bulky 1,1′-biadamantane moiety started to decompose near 370 °C in the TGA analysis, and the 10% weight loss temperature was observed at 405 °C. To our knowledge, its T g at 236 °C is the highest reported value for a poly(alkyl methacrylate).

The anionic polymerization of acrylate monomers is not as straightforward as those of their methacrylate counterparts since inherent side reactions such as intramolecular ester carbonyl attack (back-biting reaction) to the antepenultimate unit and α-proton abstraction with the growing less-hindered enolate anions occasionally occur during the course of the polymerization. In fact, living anionic polymerizations of acrylates have been achieved only in limited cases [44]. Binary initiator systems such as Ph2CHK/Et2Zn, Ph2CHK/Et3B, and DMPLi/LiCl are effective in controlling the molecular weights and their distributions of the polymer of tert-butyl acrylate (tBA) [45, 46]. Recently, Mays and coworkers succeeded in the living anionic polymerization of 1-adamantyl acrylate (7) in THF at –78 °C (Fig. 4) [47]. In the presence of an excess amount of Lewis acidic Et2Zn, the polymerization of 7 proceeded via initiation with Ph2CHK in a living fashion, similar to the case of tBA reported by Ishizone and coworkers [45]. The resulting poly(7) showed a T g at 133 °C, much higher than those of poly(methyl acrylate) (T g = 8 °C) and poly(tBA) (T g = 11 °C). Similar to the poly(adamantyl methacrylates), the poly(adamantyl acrylates) exhibited a drastic effect of the introduced adamantyl group on their thermal properties.

Polymerization of (meth)acrylamides

Most polyacrylamides, including poly(N-alkylacrylamide)s, are known as hydrophilic or water-soluble polymers due to their polar –CONH– moieties. For example, poly(N-isopropylacrylamide) (poly(NIPAM)) is a typical water-soluble polymer, and its aqueous solution usually shows a reversible cloud point at ~32 °C upon heating and cooling. Ritter and his coworkers performed the radical copolymerization of N-isopropylacrylamide (NIPAM) and an acrylamide derivative bearing a hydrophobic adamantyl group in its side chain in water with potassium persulfate to prepare copolymers (Scheme 14) [22]. They also prepared the corresponding copolymer of NIPAM and a corresponding cyclohexyl-substituted acrylamide. The cyclohexyl derivative showed a cloud point at ~31 °C, which was very similar to the value of the parent poly(NIPAM). On the other hand, the cloud point of the corresponding adamantyl derivative unexpectedly increased to 95 °C.

N-Adamantylacrylamide (8) and N-adamantylmethacrylamide (9) possessing a bulky hydrophobic substituent were polymerized with free radical initiators (Fig. 5) [48,49,50]. The adamantyl group was introduced on the nitrogen of the amide moiety to reduce the hydrophilicity of the polymer. The resulting poly(8) formed a Langmuir–Blodgett membrane because the hydrophobic adamantyl groups segregated at the air surface and the polar CONH moieties were located in the water phase [48, 49]. Thus, the adamantyl group introduced in the side chain endow poly(8) with a local amphiphilic property. Morishima and coworkers reported that a random copolymer of 9 and hydrophilic monomers such as sodium 2-(acrylamido)-2-methylpropanesulfonate did not aggregate intermolecularly but instead formed a stable unimolecular micelle in water under dilute conditions [50]. They explained that intramolecular aggregation between the alicyclic adamantane moieties mediated by hydrophobic interactions plays an important role in the formation of unimolecular micelles, similar to proteins possessing fixed inherent conformations in aqueous media.

Polymerization of vinyl ethers

If one considers the adamantane molecule as a substituent, there are two isomers, namely, 1- and 2-adamantyl substituents. The substitution position of the former type is a bridgehead CH carbon, and that of the latter is a CH2 carbon of the adamantane ring. This example allows comparison of the effect of the substituted position of the adamantane ring on the polymerizability of the isomers.

Hashimoto and coworkers investigated the cationic polymerization of 1-adamantyl vinyl ether (10) and 2-adamantyl vinyl ether (11) with an adduct of isobutyl vinyl ether and acetic acid in the presence of Et1.5AlCl1.5/CH3COOEt in toluene at 0 °C (Scheme 15) [51]. In each case, the molecular weight of the resulting polymer increased with the conversion of monomers, as also seen for vinyl ether monomers. The M w/M n values were always ~1.3, indicating the relatively narrow molecular weight distribution of the polymers. Even in the presence of bulky adamantyl substituents, the polymerization of 10 and 11 smoothly proceeded to 100% conversion. It was reported that the T g values of poly(10) and poly(11) were 231 and 181 °C, respectively. Interestingly, the substituted position of the adamantyl groups apparently affected the thermal properties of the polymers. In other words, the isomer of the substituents clearly affected the T g values of the polymers but did not affect their polymerization behaviors.

Polymerization of 1,3-butadiene derivative

It is well known that conjugated 1,3-dienes such as 1,3-butadiene and isoprene are representative monomers capable of living anionic polymerization, as are styrenes and alkyl (meth)acrylates [37,38,39,40]. For poly(1,3-diene), the control of microstructures is of great interest because they strongly affect the thermal and mechanical properties of those polymers as rubber materials. Notably, the microstructures of anionically produced polydienes are strongly influenced by the conditions, such as solvent, counterion, and polymerization temperature. For instance, the polymerization of isoprene with alkyllithium initiators such as n-butyllithium (n-BuLi) in nonpolar hydrocarbons usually affords polymers with high 1,4-microstructure contents. On the other hand, the microstructures of polyisoprene dramatically changed to a mixture of 1,4-, 1,2-, and 3,4-addition modes when the polymerization was carried out in polar solvents such as THF. In addition, the substituents strongly affect the microstructures of a series of poly(2-alkyl-1,3-butadiene)s [52, 53]. The 1,4-microstructural contents of the polymers obtained with n-BuLi in a polar solvent of diethyl ether increased with the bulkiness of the 2-substituted alkyl groups. The observed 1,4-contents for polymers of 2-ethyl-, 2-propyl-, 2-(n-butyl)-, and 2-isopropyl-1,3-butadiene were 58%, 57%, 56%, and 81%, respectively, while that of polyisoprene, the 2-methyl counterpart, was only 19% under identical polymerization conditions.

As an adamantyl-substituted 1,3-diene monomer, 2-(1-adamantyl)-1,3-butadiene (12) was newly synthesized from 1-adamantanecarboxylic acid, as shown in Scheme 16 [54, 55]. Since the adamantyl group is directly connected to the 1,3-diene framework, intense substituent effects are expected on the polymerization behaviors and thermal properties of the resulting polymer. The anionic polymerization of 12 was attempted with s-BuLi in cyclohexane at 40 °C, with s-BuLi in THF at –30 °C, and with potassium naphthalenide (K-Naph) in THF at –78 °C. In each polymerization system, the polymerization of 12 quantitatively proceeded to afford polymers possessing the predicted molecular weights and narrow molecular weight distributions. The living polymerizability of 12 allows us to synthesize novel block copolymers with styrene or isoprene by sequential anionic copolymerization, as well as the homopolymer.

On the other hand, the microstructure of poly(12) was affected by the anionic initiators and solvents. The contents of the 1,4-repeating unit in poly(12)s obtained with s-BuLi in cyclohexane, with s-BuLi in THF, and with K-Naph in THF were 96%, 88%, and 55%, respectively. Unlike the polymerization behavior of 1,3-butadiene and isoprene in polar solvent, the introduction of the bulky adamantyl ring to the 1,3-diene framework drastically increased the 1,4-addition modes in the poly(12) obtained, even in THF. The 1,4-rich poly(12) obtained by using s-BuLi in cyclohexane was completely converted into a novel saturated alternating copolymer, poly(ethylene-alt-1-vinyladamantane) (P(E-alt-VAd)), by hydrogenation with p-toluenesulfonyl hydrazide (TsNHNH2). The bulky adamantyl ring did not hinder the hydrogenation of the C = C linkage of the 1,4-repeating unit in the polymer main chain. It is noteworthy that poly(12) with an M n value over 5000 was hardly soluble in common organic solvents, while hydrogenated P(E-alt-VAd) was readily soluble in a wide variety of organic solvents, such as benzene, chloroform, and THF. The flexible saturated main chain after hydrogenation endows the polymer with higher solubility by eliminating the planar rigid C = C double bonds.

The resulting poly(12) and P(E-alt-VAd) started to decompose at 280 and 380 °C in the TGA analyses, and the 10% weight loss temperatures (T 10) were observed at 345 and 425 °C, respectively. After hydrogenation, the thermal stability of the polymer significantly increased. Poly(12) before and after hydrogenation presented T g values of 100 and 125 °C on the DSC thermograms. These T g values are markedly higher than those of 1,4-polyisoprene (–70 °C) and the corresponding hydrogenated alternating copolymer poly(ethylene-alt-propylene), (–66 °C).

Polymerization of styrene derivatives

In the case of styrene derivatives, various molecular designs are possible in the framework. The T g values of para-alkyl-substituted polystyrenes can be readily tuned lower or higher by changing the substituent on the para-position of the aromatic ring. Linear alkyl substituents decrease the T g of polystyrenes with increasing side chain length, while bulky substituents such as tert-butyl (130 °C) or phenyl (161 °C) groups tend to cause higher T g values.

Among the substituents, the adamantyl skeleton was shown to drastically enhance the T g values and retard thermal degradation. As a styrene derivative, N-(1-adamantyl)-4-vinylbenzylamine (13) was synthesized via the reaction of 4-vinylbenzyl chloride and 1-aminoadamantane and polymerized under radical conditions (Fig. 6) [56]. The radical copolymerization of 13 and styrene was also attempted. The T g values of the homopolymer of 13 and its random copolymer with styrene (styrene content: 55 mol%) were 165 and 147 °C, respectively.

As a simpler styrene derivative, 4-(1-adamantyl)styrene (14) was synthesized from 1-bromoadamantane in four reaction steps, as shown in Scheme 17 [57]. In the case of 14, the 1-adamantyl group was directly connected to the para-position of the styrene framework. This hydrocarbon monomer 14 smoothly underwent anionic polymerization in THF at –78 °C by initiation with s-BuLi or K-Naph. The polymer yields were quantitative, and the resulting polymers showed unimodal narrow molecular weight distributions (M w/M n < 1.1) in the SEC measurements. The observed molecular weights of poly(14) were in good accordance with the values calculated based on the molar ratios between 14 and the initiators, indicating quantitative initiator efficiency. A series of well-defined block copolymers of 14 and styrene or isoprene were also produced by sequential anionic copolymerization. The resulting poly(14) was soluble in benzene, chloroform, and THF and showed T 10 and T g values at 406 and 234 °C, respectively. The T g values of random copolymers of 14 and styrene could be controlled from 100 to 230 °C by changing the feed molar ratio of the comonomers.

The anionic polymerization of 14 with s-BuLi was also possible in a nonpolar hydrocarbon solvent such as cyclohexane to afford a polymer with well-defined chain structures [58]. The three-step sequential copolymerization of 14 (A monomer) and isoprene (B monomer) in cyclohexane initiated with s-BuLi enables the tailored synthesis of an ABA-type triblock copolymer, poly(14)-b-polyisoprene-b-poly(14), as shown in Scheme 18. The microstructure of the polyisoprene segment in the block copolymer was predominantly controlled in a 1,4-addition mode under the polymerization condition. The unsaturated C = C bonds of the 1,4-polyisoprene unit were completely hydrogenated with TsNHNH2 to afford a saturated alternating copolymer unit, poly(ethylene-alt-propylene) (poly(E-alt-P)). After hydrogenation of the block copolymer, the hydrogenated ABA-type triblock copolymer poly(14)-b-poly(E-alt-P)-b-poly(14) presented two T g values at 215 and –50 °C. The former T g corresponds to the glass transition behavior of the poly(14) hard block, and the latter is derived from the poly(E-alt-P) soft block. The microphase-separated structure of the hydrogenated block copolymer was observed by transmission electron microscopy (TEM), as expected. This microphase-separated triblock copolymer carrying bulky adamantyl groups in the hard end blocks showed high tensile strength (22–24 MPa), high elongation at break (590–660%), and high upper service temperature (175–210 °C) by dynamic mechanical analysis, stress relaxation testing, and tensile testing. Thus, the living nature of the polymerization enabled the production of a novel tailored thermoplastic elastomer showing a high service temperature via the sequential copolymerization of 14 and isoprene and subsequent hydrogenation.

The living anionic polymerizations of the hydrocarbon monomers 3-(4-vinylphenyl)-1,1′-biadamantane (15) [57] and 4-(1-adamantyl)-α-methylstyrene (16) [59] were also realized in THF with s-BuLi and K-Naph at –78 °C. The α-methylstyrene derivative 16 showed typical reversible polymerization behavior due to the low ceiling temperature. The quantitative conversion of 16 was achieved at –78 °C under anionic conditions, but the propagating carbanion of poly(16) underwent complete depolymerization at room temperature.

Other adamantyl-substituted styrenes, N-(1-adamantyl)-N-4-vinylbenzylideneamine (17) and N-(2-adamantyl)-N-4-vinylbenzylideneamine (18), were newly synthesized and anionically polymerized with various initiators, such as oligo(α-methylstyryl)dipotassium, K-Naph, Ph2CHK, and diphenylmethyllithium (Ph2CHLi), in THF at –78 °C for 1 h [60]. In each case, well-defined poly(17) or poly(18) with a predictable molecular weight and a narrow molecular weight distribution was obtained in 100% yield. This strongly indicates that the bulky 1-adamantyl and 2-adamantyl groups can effectively protect the electrophilic CH = N linkage from undesirable side reactions, similar to the previous polymerization results for cyclohexyl-, tert-butyl-, 2,6-dimethylphenyl-, and 2,6-diethylphenyl-substituted iminostyrenes [61, 62]. A reactive poly(4-formylstyrene) with well-regulated chain structures was quantitatively formed by acidic hydrolysis of the N-adamantylimino groups of poly(17) (Scheme 19). The isomeric poly(17) and poly(18) showed similar solubility and thermal degradation behavior regardless of the chemical structures. On the other hand, poly(17) and poly(18) presented significantly high T g values at 257 and 209 °C, depending on the substituted position on the adamantyl skeletons. The observed tendency of the T g values of the isomeric polymers is very similar to that of the poly(adamantyl vinyl ether)s described above [51]. The 1-substituted derivative showed higher T g values than the corresponding 2-substituted isomer.

Although acyl groups are versatile and attractive functional groups in organic synthesis, the direct anionic polymerization of styrene derivatives carrying acyl (COR) groups should be very difficult due to their high electrophilicity and the high acidity of the α-hydrogens (pKa = 25) [63]. In fact, no polymerization of 4-acetylstyrene bearing a COCH3 group occurred with s-BuLi or Ph2CHK in THF at –78 °C. With the latter initiator, the orange color of Ph2CHK disappeared immediately, indicating that rapid side reactions such as an electrophilic carbonyl attack or an α-hydrogen abstraction occurred prior to polymerization.

Therefore, 1-adamantyl 4-vinylphenyl ketone (19), a styrene derivative carrying an electrophilic C = O group and a bulky adamantyl group, was purposefully synthesized and anionically polymerized (Scheme 20) [64]. This particular 4-acylstyrene derivative possesses no acidic α-hydrogen, and the steric effect of the adamantyl group will play an important role in protecting the electrophilic C = O bond from nucleophilic attack by the anionic species. In fact, the polymerization of 19 quantitatively proceeded with Ph2CHK, diphenylmethylcesium (Ph2CHCs), or triphenylmethylpotassium (Ph3CK) in THF at –78 °C within 24 h to form polymers with predictable molecular weights and narrow molecular weight distributions (M w/M n < 1.1). The electron-withdrawing C = O group remarkably increased the anionic polymerizability of 19 and allowed quantitative initiation efficiencies of low nucleophilic initiators including Ph2CHK and Ph3CK, similar to the cases of 17 and 18 possessing CH = N-R groups. In contrast, no polymerization of 19 occurred with s-BuLi at –78 °C, and a polymer with an ill-controlled molecular weight was obtained with Ph2CHLi in only 10% yield even after 24 h. These contrasting results clearly indicate that suitable choices of bulky π-conjugated anionic initiators and a larger countercation (such as potassium or cesium) of the initiators are essential to achieve anionic polymerization of the ketone-type styrene monomer. The stability of the propagating carbanion derived from 19 was also demonstrated via the quantitative efficiency of the postpolymerization after complete consumption. The plausible side reactions of the carbonyl group were completely suppressed by stabilization of the propagating benzylic carbanion due to the electron-withdrawing effect of the acyl group, in addition to the steric effect of the neighboring adamantyl substituent. Thus, 19 is the first successful example of the living anionic polymerization of a ketone-type styrene monomer. Interestingly, the reaction of poly(19) with a Grignard reagent such as methylmagnesium iodide quantitatively proceeded in THF/diethyl ether at room temperature, indicating that the adamantyl ketone moieties in the isolated poly(19) maintained their electrophilicity (Scheme 21).

The polystyrene derivatives bearing adamantyl groups poly(14)-poly(19) presented high T g values between 193 and 274 °C, as shown in Fig. 7. Since all the polymers were prepared via living anionic polymerization of the corresponding monomers, they had well-defined chain structures, as described above. Compared with polystyrene (T g = 100 °C) and poly(α-methylstyrene) (T g = 160 °C), all the polymers showed higher T g values, indicating the effect of the bulky stiff adamantyl substituent. In particular, the T g of poly(16), the poly(α-methylstyrene) derivative, reached 274 °C. Compared with poly(14) with the directly substituted adamantyl group, ketone-type poly(19) and imine-type poly(17) had lower and higher T g values, respectively. This observation indicates that the linkages between the adamantyl substituents and the polystyrene frameworks also play very important roles in determining the T g values.

Conclusions

In this review, we focused on the synthesis of polymers possessing bulky and stiff adamantyl groups in the side chain. To achieve this goal, various adamantyl-substituted monomers were synthesized and polymerized under various polymerization conditions, in addition to chemical modification of the reactive polymer. In particular, the living anionic polymerizations of acrylates, methacrylates, 1,3-butadienes, and styrenes carrying adamantyl or 1,1′-biadamantyl groups afforded thermally stable polymers of well-defined chain structures with predictable molecular weights and narrow molecular weight distributions (M w/M n = 1.1). In each case, the polymerization of the vinyl monomers smoothly proceeded, and the complete consumption of monomer was attained. Significant retardation of polymerization and decreased polymerizability of the monomers were not observed regardless of the bulky substituents on the monomers. The living nature of the anionic polymerization systems and the high T g values of the resulting adamantyl-substituted polymers will open a novel synthetic pathway for various new thermoplastic elastomers with high service temperatures. Although the solubility of the adamantyl-substituted polymers was often restricted, these polymers were expected to show high transparency and low dielectric constants, as well as significant heat- and weather-resistant properties. Thus, progress in the precise synthesis of a variety of adamantyl-containing polymers will lead to the development of novel thermally stable functional polymeric materials.

References

Fort RC Jr., Schleyer PvR. Adamantane: consequences of the diamondoid structure. Chem Rev. 1964;64:277–300.

Schwertfeger H, Fokin AA, Schreiner PR. Diamonds are a chemist’s best friend: diamondoid chemistry beyond adamantane. Angew Chem Int Ed. 2008;47:1022–36.

Schreiner PR, Lauenstein O, Butova ED, Gunchenko PA, Kolomitsin IV, Wittkopp A, Feder G, Fokin AA. Selective radical reactions in multiphase systems: phase-transfer halogenations of alkanes. Chem Eur J. 2001;7:4996–5003.

Fokin AA, Schreiner PR. Metal-free, selective alkane functionalizations. Adv Synth Catal. 2003;345:1035–52.

Reinhardt HF. Polyadamantane. Polym Lett. 1964;2:567–8.

Ishizone T, Tajima H, Matsuoka S, Nakahama S. Synthesis of tetramers of 1,3-adamantane derivatives. Tetrahedron Lett. 2001;42:8645–7.

Chern Y, Chung W. Preparation and properties of polyamides and polyimides drived from 1,3-diaminoadamantane. J Polym Sci: Part A: Polym Chem. 1996;34:117–24.

Chern Y, Shiue H. Low dielectric constants of soluble polyimides based on adamantane. Macromolecules. 1997;30:4646–51.

Chern Y, Shiue H, Kao SC. Synthesis and characterization of new polyamides containing adamantyl and diamantyl moieties in the main chain. J Polym Sci: Part A: Polym Chem. 1998;36:785–92.

Seino H, Mochizuki A, Ueda M. Synthesis of aliphatic polyimides containing adamantyl units. J Polym Sci: Part A: Polym Chem. 1999;37:3584–90.

Fukukawa K, Shibasaki Y, Ueda M. A photosensitive semi-alicyclic poly(benzoxazole) with high transparency and low dielectric constant. Macromolecules. 2004;37:8256–61.

Kameshima H, Nemoto N, Sanda F, Endo T. Cationic ring-opening polymerization of five-membered cyclic thiocarbonate bearing and adamantane moiety via selective ring-opening direction. Macromolecules. 2002;35:5769–73.

Pincock RE, Torupka EJ. Tetracyclo[3.3.1.13,7.01,3]decane. Highly react 1,3-dehydro derivative of adamantanee. J Am Chem Soc. 1969;91:4593–4593.

Pincock RE, Schmidt J, Scott WB, Torupka EJ. Synthesis and reactions of strained hydrocarbons possessing inverted carbon atoms. Tetracyclo[3.3.1.13.7.01.3]decanes. Can J Chem. 1972;50:3958–64.

Scott WB, Pincock RE. Compounds containing inverted carbon atoms. Synthesis and reactions of some 5-substituted 1,3-dehydroadamantanes. J Am Chem Soc. 1973;95:2040–1.

Inomata S, Harada Y, Nakamura Y, Nakamura T, Ishizone T. Synthesis of 1,3-dehydroadamantanes possessing alkyl, phenyl, and alkoxy substituents by intramolecular Wurtz-type coupling reaction of 1,3-dibromoadamantanes. Synthesis. 2013;45:3332–40.

Inomata S, Harada Y, Matsuoka S, Ishizone T. Synthesis and ring-opening reaction of novel 1,3-dehydroadamantanes possessing phenyl and alkoxyl substituents. Tetrahedron. 2013;69:3238–48.

Ishizone T, Matsuoka S, Sakai S, Harada W, Tajima H. Synthesis of poly(1,3-adamantane)s by cationic ring-opening polymerization of 1,3-dehydroadamantanes. Macromolecules. 2004;37:7069–71.

Inomata S, Matsuoka S, Sakai S, Tajima H, Ishizone T. Ring-opening polymerizations of 1,3-dehydroadamantanes: synthesis of novel thermally stable poly(1,3-adamantane)s. Macromolecules. 2012;45:4184–95.

Inomata S, Harada Y, Nakamura Y, Uehara Y, Ishizone T. Catainonic ring-opening polymerization of novel 1,3-dehydroadamantanes with various alkyl substituents: synthesis of thermally stable poly(1,3-adamantane)s. J Polym Sci Part A: Polym Chem. 2013;51:4111–24.

Matsuoka S, Ogiwara N, Ishizone T. Formation of alternating copolymers via spontaneous copolymerization of 1,3-dehydroadamantane with electron-deficient vinyl monomers. J Am Chem Soc. 2006;128:8708–9.

Ritter H, Sadowski O, Tepper E. Influence of cyclodextrin molecules on the synthesis and the thermoresponsive solution behavior of n-isopropylacrylamide copolymers with adamantyl groups in the side-chains. Angew Chem Int Ed. 2003;42:3171–3.

Allcock HR, Krause WE. Polyphosphazenes with adamantyl side groups. Macromolecules. 1997;30:5683–7.

Cho YS, Allcock HR. Synthesis of adamantyl polyphosphazene–polystyrene block copolymers, and β-cyclodextrin-adamantyl side group complexation. Macromolecules. 2009;42:4484–90.

Zuanic M, Majerski Z, Janovic Z. Poly(1-vinyladamantane). J Polym Sci, Polym Lett Ed. 1981;19:387–9.

van Reenen AJ, Mathias LJ, Coetzee L. Polymerization of olefins with bulky substituents. 1. Homo- and copolyerization of 3-(1-adamantyl)propene. Polym (Guildf). 2004;45:799–804.

Okano Y, Masuda T, Higashimura T. Polymerization of tert-alkylacetylenes by Mo- and W-based catalysts. J Polym Sci: Polym Chem. 1985;23:2527–37.

Teraguchi M, Masuda T. Synthesis and properties of polyacetylenes with adamantyl groups. J Polym Sci Part A: Polym Chem. 1999;37:4546–53.

Otsu T, Matsumoto A, Horie A, Tanaka S. Synthesis of thermally stable vinyl polymers from adamantyl-containing acrylic derivatives. Chem Lett. 1991;20:1141–8.

Matsumoto A, Tanaka S, Otsu T. Synthesis and characterization of poly(1-adamantyl methacrylate): effects of the adamantyl group on radical polymerization kinetics and thermal properties of the polymer. Macromolecules. 1991;24:4017–24.

Acar HY, Jensen JJ, Thigpen K, McGowen JA, Mathias LJ. Evaluation of the spacer effect on adamantane-containing vinyl polymer T g’s. Macromolecules. 2000;33:3855–9.

Mathias LJ, Jensen J, Thigpen K, McGowen J, McCormick D, Somlai L. Copolymers of 4-adamanthylphenyl methacrylate derivatives with methyl methacrylate and styrene. Polym (Guildf). 2001;42:6527–37.

Grant D, McKervey MA, Rooney JJ, Samman NG, Step G. Adamantene and its dimer. J Chem Soc, Chem Commun. 1972;21:1186–1187.

Gano JE, Eizenberg L. Short-lived intermediates. IV. Adamantene. J Am Chem Soc. 1973;95:972–4.

Kanehashi S, Konishi S, Takeo K, Owa K, Kawakita H, Sato S, Miyakoshi T, Nagai K. Effect of OH group on the water vapor sorption property of adamantane-containing polymer membranes. J Membr Sci. 2013;427:176–85.

Ando S, Koyama Y, Miyata S, Sato S, Kanehashi S, Nagai K. Synthesis and characterization of ABA-type triblock copolymers derived from polyimide and poly(2-methyl-2-adamantyl methacrylate). Polym Int. 2014;63:1634–42.

Hsieh HL, Quirk RP. Anionic polymerization: principles and practical applications. New York, NY, USA: Marcel Dekker, Inc.; 1996.

Ishizone T, Hirao A. Synthesis of polymers: new structures and methods. In: Schlüter D, Hawker CJ & Sakamoto J, editors. Singapore: Wiley-VCH; 2012. p. 81–133.

Hirao A, Goseki R, Ishizone T. Advances in living anionic polymerization: from functional monomers, polymerization systems, to macromolecular architectures. Macromolecules. 2014;47:1883–905.

Ishizone T, Kosaka Y, Goseki R. Anionic polymerization: principles, practice, strength, consequences and applications. In: Hadjichristidis N & Hirao A, editors. Japan, Tokyo: Springer; 2015;127–89.

Ishizone T, Tajima H, Torimae H, Nakahama S. Anionic polymerization of 1-adamantyl methacrylate and 3-methacryloyloxy-1,1’-biadamantane. Macromol Chem Phys. 2002;203:2375–84.

Varshney SK, Hautekeer JP, Fayt R, Jérôme R, Teyssié Ph. Anionic polymerization of (meth)acrylic monomers. 4. Effect of lithium salts as ligands on the “living” polymerization of methyl methacrylate using monofunctional initiators. Macromolecules. 1990;23:2618–22.

Ozaki H, Hirao A, Nakahama S. Anionic polymerization of alkyl methacrylates in the presence of diethylzinc. Macromol Chem Phys. 1995;196:2099–111.

Fayt R, Forte R, Jacobs C, Jérôme R, Ouhadi T, Tessié Ph, Varshney SK. New initiator system for the living anionic polymerization of tert-alkyl acrylates. Macromolecules. 1987;23:1442–4.

Ishizone T, Yoshimura K, Hirao A, Nakahama S. Controlled anionic polymerization of tert-butyl acrylate with diphenylmethyl anions in the presence of dialkylzinc. Macromolecules. 1998;31:8706–12.

Ishizone T, Yoshimura K, Yanase E, Nakahama S. Controlled anionic polymerization of tert-butyl acrylate with diphenylmethylpotassium in the presence of triethylborane. Macromolecules. 1999;32:955–7.

Lu W, Huang C, Hong K, Kang N-G, Mays JW. Poly(1-adamantyl acrylate): living anionic polymerization, block copolymerization, and thermal properties. Macromolecules. 2016;49:9406–14.

Feng F, Aoki A, Miyashita T. A new type of cyclic alkylacrylamide polymer Langmuir–Blodgett film. Chem Lett. 1998;27:205–6.

Feng F, Mitsuishi M, Miyashita T, Okura I, Asai K, Amao Y. Preparation of polymer Langmuir–Blodgett films containing porphyrin chromophore. Langmuir. 1999;15:8673–7.

Morishima Y, Nomura S, Ikeda T, Seki M, Kamachi M. Characterization of unimolecular micelles of random copolymers of sodium 2-(acrylamido)-2-methylpropanesulfonate and methacrylamides bearing bulky hydrophobic substituents. Macromolecules. 1995;28:2874–81.

Hashimoto T, Makino Y, Urushisaki M, Sakaguci T. Living cationic polymerization of 2-adamantyl vinyl ether. J Polym Sci Part A: Polym Chem. 2008;46:1629–37.

Ohno R, Kawakami M, Tanaka Y. Synthesis and characterization of 2-alkylbutadiene polymers. I. Structural characterization of 2-ethyl-, 2-n-propyl-, 2-isopropyl-, and 2-n-butylbutadiene polymers. Polym J. 1973;4:49–55.

Ohno R, Tanaka Y, Kawakami M. Synthesis and characterization of 2-alkylbutadiene polymers. II. Stereospecific polymerization of 2-ethyl-, 2-n-propyl-, 2-isopropyl-, and 2-n-butylbutadienes. Polym J. 1973;4:56–60.

Kobayashi S, Kataoka H, Ishizone T. Synthesis of well-defined poly(ethylene-alt-1-vinyladamantane) via living anionic polymerization of 2-(1-adamantyl)-1,3-butadiene, followed by hydrogenation. Macromolecules. 2009;42:5017–26.

Kobayashi S, Kataoka H, Ishizone T, Kato T, Ono T, Kubotaka S, Arimoto K, Ogi H. Synthesis of well-defined random and block copolymers of 2-(1-adamantyl)-1,3-butadiene with isoprene via anionic polymerization. React Funct Polym. 2009;69:409–15.

Yoshida E, Tsuchiya T, Katayama K. Synthesis of polymers with adamantane amino derivatives as pendant groups. Polym J. 1999;31:32–36.

Kobayashi S, Matsuzawa T, Matsuoka S, Tajima H, Ishizone T. Living anionic polymerizations of 4-(1-adamantyl)styrene and 3-(4-vinylphenyl)-1,1′-biadamantane. Macromolecules. 2006;39:5979–86.

Kobayashi S, Kataoka H, Ishizone T, Kato T, Ono T, Kobutaka S, Ogi H. Synthesis and properties of new thermoplastic elastomers containing poly[4-(1-adamantyl)styrene] hard segments. Macromolecules. 2008;41:5502–8.

Kobayashi S, Kataoka H, Goseki R, Ishizone T. Living anionic polymerization of 4-(1-adamantyl)-α-methylstyrene. Macromol Chem Phys. 2018;219:1700450.

Kang B-G, Shoji H, Kataoka H, Kurashima R, Lee J-S, Ishizone T. Living anionic polymerization of N-(1-adamantyl)-N-4-vinylbenzylideneamine and N-(2-adamantyl)-N-4-vinylbenzylideneamine: effect of adamantyl groups on polymerization behaviors and thermal properties. Macromolecules. 2015;48:8489–96.

Ishizone T, Sueyasu N, Sugiyama K, Hirao A, Nakahama S. Anionic polymerization of monomers containing functional groups. 7. Anionic polymerizations of N-alkyl-N-(4-vinylbenzylidene)amines. Macromolecules. 1993;26:6976–84.

Ishizone T, Utaka T, Ishino Y, Hirao A, Nakahama S. Anionic polymerization of monomers containing functional groups. 10. Anionic polymerizations of N-Aryl-N-(4-vinylbenzylidene)amines. Macromolecules. 1997;30:6458–66.

Bordwell FG. Equilibrium acidities in dimethyl sulfoxide solution. Acc Chem Res. 1988;21:456–63.

Matsuoka D, Goseki R, Uchida S, Ishizone T. Living anionic polymerization of 1-adamantyl 4-vinylphenyl ketone. Macromol Chem Phys. 2017;218:1700015.

Acknowledgements

This work was supported by Grant-in Aid (No. 17K19149) from the Ministry of Education, Science, Sports, and Culture, Japan. TI appreciates the financial support from the JX Corporation and Kuraray Co., Ltd.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Ishizone, T., Goseki, R. Synthesis of polymers carrying adamantyl substituents in side chain. Polym J 50, 805–819 (2018). https://doi.org/10.1038/s41428-018-0081-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-018-0081-3

- Springer Nature Limited