Abstract

Achieving high-luminescence organic light-emitting devices (OLEDs) with narrowband emission and high color purity is important in various optoelectronic fields. Laser displays exhibit outstanding advantages in next-generation display technologies owing to their ultimate visual experience, but this remains a great challenge. Here, we develop a novel OLED based organic single crystals. By strongly coupling the organic exciton state to an optical microcavity, we obtain polariton electroluminescent (EL) emission from the polariton OLEDs (OPLEDs) with high luminance, narrow-band emission, high color purity, high polarization as well as excellent optically pumped polariton laser. Further, we evaluate the potential for electrically pumped polariton laser through theoretical analysis and provide possible solutions. This work provides a powerful strategy with a material–device combination that paves the way for electrically driven organic single-crystal-based polariton luminescent devices and possibly lasers.

Similar content being viewed by others

Introduction

In the past decades, organic light-emitting diodes (OLEDs) have made significant progress and shown great promise in display applications due to their ease of fabrication, lightweight flexibility, and high efficiency1,2,3,4. Nevertheless, most organic luminescent materials exhibit broad emission with full width at half-maximum (FWHM > 60 nm)5,6, due to the intrinsic exciton–vibration coupling and structural relaxation at the excited states7,8,9. This brings about poor color purity and inability to meet the International Telecommunication Union-Radiocommunication Recommendation BT.2020 color gamut standard in ultrahigh-definition (UHD) displays10,11. In recent years, the emerging hyperfluorescence and boron/nitrogen (B/N)-based polycyclic multiple resonance strategies have inspired OLEDs to narrow their FWHM to below 25 nm10,12,13,14. However, it remains a practical challenge in the synthesis of new molecules and in satisfying the color gamut standard of BT.2020.

The strategy of strongly coupling the organic exciton state to an optical microcavity provides an alternative solution, achieving the narrowband emission15,16,17. In such a strong coupling system, the strong hybridization between organic excitons and cavity photons leads to the formation of stable exciton–polariton (EP) quasiparticles at room temperature, benefiting from the large exciton binding energies and oscillator strengths of organic excitons18,19. Thanks to the advantageous features inherited from their constituents, EPs have emerged as an attractive platform for exploring the quantum phenomena as well as optoelectronic applications20,21,22. In particular, due to their bosonic characteristics, EPs can macroscopically condensate the polariton ground state and achieve coherent laser-like emission without population inversion at thresholds orders of magnitude below conventional photon laser23,24,25. Organic EP lasers, leveraging the high monochromaticity (FWHM of <1 nm), high luminosity, and extensive achievable color gamut, exhibit great potential for revolutionary display technologies26,27. However, the readily available organic EP-based electroluminescent (EL) devices, namely organic polariton light-emitting diode (OPLEDs), still suffer from low carrier mobilities, low external quantum efficiency (EQE), and poor stability at high current densities, resulting in the inability to reach the current densities required for EP condensation22,28. Hence, there is an urgent requirement for organic EP devices with high performances and low condensation threshold under electric pumping.

Organic single-crystals (OSCs) have shown attractive potential in EL devices due to their perfect crystallinity and excellent electrical and optical properties23,25,29,30. In this work, we demonstrate novel single-crystal OPLEDs with high luminance, narrow emission, and high polarization, as well as optically pumped polariton lasing at room temperature. The electrically pumped pure-red-color EP emission with the main band located at 627 nm and FWHM of 4.1 nm is clearly observed, exhibiting highly polarized degree of 170 and angle-independent high color purity with the Commission Internationale de l’Éclairage (CIE) chromaticity coordinates of (0.69, 0.31) due to excellent EP dispersion, which is close to the standard of BT.2020 of (0.708, 0.292). Thanks to the virtues of OSCs, including low defect density and balanced carrier transport, this OPLED displays a high luminance of over 780,000 cd m−2 and remarkable long-term stability. This device also demonstrates an excellent optically pumped polariton laser. We theoretically analyze and demonstrate that our OPLEDs are a promising way to the electrically pumped polariton laser. This work provides a powerful strategy with a material–device combination that paves the way for electrically driven OSC-based polariton luminescent devices and possibly lasers.

Results

Anisotropic strong coupling in an organic single-crystal microcavity

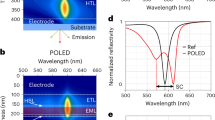

Figure 1a schematically shows the OPLED device architecture used in this work: silver (Ag, 150 nm)/molybdenum trioxide (MoO3, 5 nm)/1,4-dimethoxy-2,5-di(2,2’,5’,2”-terthiophenestyryl) benzene (TTPSB) OSC (~580 nm)/cesium fluoride (CsF, 2 nm)/calcium (Ca, 10 nm)/silver (Ag, 35 nm). Here, the upper and bottom silver films can not only serve as electrodes for charge injection but also as an optical microcavity based on the high reflectivity of silver film. The reflectivity of 150-nm Ag film is more than 99%, and that of 35-nm film reaches about 50%.

a Scheme of the TTPSB-microcrystal-based OPLED. b The molecular packing along [011] direction. The microcrystal is bounded by (\(10\bar{3}\)) and (\(\bar{1}03\)) crystal planes on the top and bottom surfaces. The transition dipole-moment of TTPSB (blue arrow) along the molecular long-axis is tilted at an angle of 8° with (\(10\bar{3}\)) crystal plane. c Angle-resolved reflectivity of the microcavity. LP1 and LP2 (red lines) are lower polariton branches caused by strong coupling between cavity modes and the 0-1 excitons at 570 nm (cyan dotted line). The CM1’ is in uncoupled cavity mode. d The absorption (blue line) and PL (red line) spectra of the TTPSB microcrystals

The synthesis and characterization of TTPSB microcrystals and TTPSB-based OPLEDs are detailed and described in the Supporting Information31. The as-assembled TTPSB microcrystals show uniform red photoluminescence (PL) and a smooth surface with a roughness of <1 nm (details in Fig. S1). As shown in Fig. 1b, TTSPB molecules are orderly stacked preferentially along the crystal [011] (defined as long axis) and [103] directions of the crystal. The transition dipole moment of TTPSB (blue arrow) is oriented parallel to the molecular long axis with an angle of 8° with (\(10\bar{3}\)) crystal plane (red plane). This near-in-plane orientation of dipole moments is conducive to the occurrence of anisotropic strong coupling and the enhancement of the outcoupling EL efficiency.

Figure 1c shows the unpolarized reflectivity as a function of the wavelength and angle of the sample, carried out by a homemade Fourier imaging spectroscopy setup covering the angle range of θ = ±60° at room temperature (details in Fig. S1). Two sets of modes with distinctive curvatures are observed, respectively, marked by an orange curve for one large curvature mode and red curves for two smaller curvature modes. Polarization-dependent angle-resolved reflectivity (Fig. S2) was performed by adding a linear polarizer in the detection optical path. These two sets of modes are attributed to two orthogonal polarizations, that is, the large-curvature mode is horizontal (H)-polarization (parallel to the long axis of the microcrystal), while the two small-curvature modes are vertical (V)-polarization (perpendicular to the long axis). The V-polarized modes can be well-fitted using a coupled harmonic oscillator Hamiltonian model (details in Supporting Information)32. The corresponding fit parameters are shown in Table S2. This result indicates that they originate from lower polariton dispersions (LP1 and LP2 in Fig. 1c), deriving from the strong coupling between two V-polarized cavity modes and organic excitons at the first excited singlet state (S1 at 573 nm), as shown in the absorption spectrum (blue line in Fig. 1d). Notably, the broad and strong absorption of TTPSB microcrystals causes the upper polariton branches to be invisible due to the nature of H-aggregation (the corresponding structural and spectroscopic analysis in Figs. S3 and S4)31.

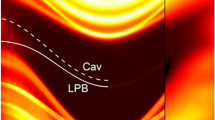

EP lasing through vibration-assisted relaxation

The behaviors of EP lasing in the above TTPSB OPELD are investigated using a focused second harmonic (λ = 400 nm, pulse width 150 fs, 1 kHz) of a Ti:sapphire regenerative amplifier. Figure 2a shows the angle-resolved PL (ARPL) spectrum measured at a low pump density of P = 8.65 μJ cm−2, which perfectly coincides with the experimental and calculated LP2 dispersion (red line). This demonstrates that the ARPL signals originate from the EP emission. In strong contrast to the fact that EPs populate the entire LP2 branch at low pump density, they condense at the bottom of the LP2 branch within the angle of around θ = ±20° when the pump density increases to P = 20.19 μJ cm−2 (1.2 Pth, Fig. 2b). As shown in Fig. 2c, the PL spectra exhibit typical lasing behaviors, with an explosive increase in intensity and FWHM narrowing above a critical threshold. The clear power-dependent blueshift of the lasing spectra is visible above the Pth (Fig. 2c). We plot the integrated intensity (red dots) and FWHM (black dots) of PL spectra as a function of pump density in Fig. 2d. The intensity dependence is separately fitted to power laws xp with p = 0.41 ± 0.04, and 6.16 ± 0.19, respectively. The threshold is determined to be Pth = 15.8 μJ cm−2 located at the intersection between the sublinear and superlinear regions. Meanwhile, the FWHM narrows from 8 nm to 2 nm. Figure 2e shows the time-resolved PL from the LP2 emission measured with a streak camera. At low pump density P = 0.2 Pth (3.16 μJ cm−2), the PL follows single exponential decay with τ = 0.36 ± 0.01 ns. Above the threshold, e.g., P = 1.4 Pth (22.12 μJ cm−2), the PL decay time collapses sharply to <30 ps, which is limited by the resolution of our apparatus. This clear EP lasing with a low threshold lays the foundation for evaluating the possibility of realizing electrically pumped EP lasers.

Angle-resolved PL spectrum measured at P < Pth (a) and P > Pth (b). c PL spectra of LP2 branch at the different pump densities. d The integrated PL intensities (red dots) and line width (black dots) of the LP2 branch as a function of pump density. e The PL decay profiles under different pump densities

Polariton EL characterization

The above TTPSB OPLED is also directly applied to EL emission. Figure 3a presents the energy diagram of this OPLED (also see details in Schemes S2 and S3). Here, MoO3 and CsF were used as the hole- and electron-injection materials for efficient carrier injection, which match well with the highest occupied molecular orbital (HOMO) level (−5.26 eV) and the lowest unoccupied molecular orbital (LUMO) level (−2.96 eV) of TTPSB (Fig. S5), respectively. We also fabricated the devices dedicated to pure electron and pure hole transport and subsequently measured their space-charge-limited current (Fig. S6). The calculated electron mobility, μe = 4.72 × 10−7 cm2 V−1 s−1 and the hole mobility, μh = 2.42 × 10−5 cm2 V−1 s−1, respectively.

a Energy diagram for multilayered components in the device. b Bright-field and c EL images of TTPSB OPLED. Scale bar: 50 μm. d ARPL spectrum and AREL spectrum (in the black box). e EL spectra at the different current densities. f CIE coordinates and g polarization angle-dependent EL characteristics of LP2 branch

We further carried out the EL measurements using a sourcemeter (Keithley 2400) equipped with the detection system in a nitrogen-filled glovebox (details in Supplementary Materials). Figure 3b presents the bright-field optical image of the chosen OPLED. The bright and pure red-color EL is observed from the top electrode (Fig. 3c). The angle-resolved EL (AREL) spectrum is collected and presented in Fig. 3d, comparing with the ARPL of the same OPLEDs. Notably, the angle range of the AREL spectrum is about ±15° limited by the numerical aperture of the microscope lens in our setup. As shown in Fig. 3d, the EL emission in the AREL spectrum agrees well with the dispersions of LP1 and LP2 in the ARPL spectrum, illustrating that the EL signals stem from the polariton emission. We integrated the AREL spectra within the ±15° range and observed a narrow full width at half maximum (FWHM) of only 4.1 nm (inset of Fig. 3e). Additionally, we collected full-angle emission spectra of the microcavity (Fig. S7) and revealed a FWHM of only 9.1 nm, significantly narrower than mainstream narrowband emitting OLED devices2,10. This suggests that no color change is noticeable in our OPLEDs in comparison with the severe angular dispersion in traditional microcavity OLEDs15. This EP emission with slight angular dispersion might benefit from the heavy exciton-like polaritons in our H-aggregate microcrystals, which leads to angle-independent narrow EP emission. Figure 3e shows the power-dependent EL spectra of this OPLED. The main peak of EP emission increases in intensity and maintains its FWHM during the process of increasing the pump current density. In our case, this narrow emission provides a high color purity as indicated by the CIE coordinates of (0.69, 0.31), as shown in Fig. 3f, which is quite close to the BT.2020 red-light standard (0.708, 0.292).

The highly polarized EP and cavity modes from TTPSB-based OPLEDs indicate its great potential for highly polarized EP EL emission. We perform the polarization angle-resolved EL measurements by inserting an angle-changeable polarizer. The EL intensity at 627 nm (LP2 branch) of OPLEDs strongly depends on the polarization angles, as evidenced by the polar-coordinate diagram (Figs. 3g and S8) from the polarized EL spectra of representative polarization angles. The EL intensity of the OPLED has a maximum value along V-polarization and a minimum value along H-polarization. The polarization ratio is calculated to be as high as 170 from PR = IV/IH33, where IV and IH are the intensities of V- and H-polarized EL at the LP2 branch, respectively.

Figure 4 summarizes the characteristics of this optimized TTPSB OPLED (the optimization process is detailed in Table S3). The maximum luminance and current efficiency of about 780,000 cd m−2 and a maximum current density of about 175 A cm−2, respectively, were achieved (Fig. 4a), which is greatly superior to the other OPLEDs reported so far15. According to the ARPL and AREL of this TTPSB OPLED, the optimized EQE is determined to be a maximum of 1.52% at 23,000 cd m−2 (Fig. 4b). We estimated the theoretical efficiency of our TTPSB OLEDs according to the equation of EQE = χ × γ × ΦS × ηout, which is widely adopted in OLED, where the χ fraction of spin statistics is 25% for fluorescence materials in the EL process, γ is the charge balance or the exciton formation efficiency (ideally 100%), ΦS for TTPSB is 17.7%, and the ηout light out-coupling factor is usually 20% for thin-film devices. Thus, the ideal efficiency of TTPSB OLEDs without microcavity is estimated to be 0.88%. Here, the experimental measured EQE of 1.52% is higher than the calculated value of 0.88%, mainly attributed to the fact that the output coupling efficiency in our case exceeds the 20% upper limit observed in thin film samples because the horizontal orientation of TTPSB molecules in the cavity affects the light outcoupling. Figure 3b displays our TTPSB OPLEDs have a low-efficiency roll-off and high stability, which might be due to the efficient avoidance of exciton quenching at high current density by short-lived polaritons. The OPLED lifetime is characterized by an initial luminance of 1000 cd m−2 and plotted as a function of time in Fig. 4c. An outstanding 95% of the initial luminance (LT95), the key indicator for verifying device stability, is 19.9 h. Moreover, after 200 h of operation, the luminance is still maintained at more than 70% of the initial luminance.

Discussion

Regrettably, we do not observe electrically pumped polariton lasers in our OPLEDs. However, the fact of the simultaneous realization of an optically pumped laser and polariton EL allows us to estimate the required polariton density for an electrically pumped laser. For the case of optical pumping, the density of pumped exciton (Nth) is deduced from the equation Nth = 0.5 Pth/[z(hc/λ)]34, where 0.5 is the transmittance of the pump laser to the top reflector, Pth is the threshold of the polariton laser, z is the thickness of the TTPAB microcrystal, h is the Planck constant, c is the velocity of light in a vacuum, and λ is excitation wavelength. The optically pumped rate (POP) of the reservoir is estimated by the equation POP = Nth/TPW, where TPW is the pulse width of the pump laser, POP ~ 4 × 1026 cm−3 s−1. The rate equation approach is used to estimate the generating polariton density in the LP branch. First, the exciton density in the reservoir nR is depicted by

where τtherm is the upper limit of relaxation time from the reservoir into the LP branch, which is approximately equal to the polariton lifetime (~40 fs, estimated by the FWHM of LP branches). The non-radiative exciton lifetime τnr is calculated to be 0.52 ns. The polariton density nLP in the LP branch is given by

where τcav is the photon lifetime (~19 fs, estimated by the FWHM of the uncoupled cavity modes). α and β are the photonic fraction and excitonic fraction of polariton, respectively. Assuming quasi-steady-state conditions \(({{\rm{d}}n}/{{\rm{d}}t}\approx 0)\), the critical polariton density is calculated as28

to be ~2 × 1013 cm−3 for optically pumped polariton laser, which is of the same order of magnitude as anthracene35.

In the case of electrical pumping, the pumped rate is determined (PEP) to be ~6 × 1026 cm−3 s−1 at the highest current density of our devices. The χ fraction of spin statistics, which is 25% for fluorescence materials, is introduced to modify the PEP. The electrically pumped polariton density in the LP is defined as

The required nLP for electrically pumped lasing is calculated to be 5 × 1012 cm−3, which is four times lower than that of optical pumping. Therefore, in order to achieve the electrically pumped polariton laser, we must improve the nLP. We think that the enhancement of the OPLED can be approached from two aspects. Firstly, the highly reflective distributed Bragg reflector (DBR) mirrors should replace the metal mirrors to increase the quality factor to over 1000, as this has been shown to improve the τtherm and reduce the threshold. Secondly, the χ fraction could be increased to 100% through the utilization of thermally activated delayed fluorescence (TADF) or phosphorescent materials that can efficiently utilize triplet excitons.

Conclusion

In summary, we demonstrate a high-luminance, narrow-emission, and high-polarized OPLED that presents excellent optically pumped polariton laser characteristics. The device exhibits a pure-red-color emission with a high luminance of over 780,000 cd m−2, high color purity of (0.69, 0.31), a highly polarized degree of 170, and remarkable long-term stability. We further evaluate the potential for electrically pumped polariton lasers through theoretical analysis and provide possible solutions. This work provides a powerful strategy with a material–device combination that paves the way for electrically-driven OSC-based polariton luminescent devices and possibly lasers.

Materials and methods

The preparation of TTPSB microcrystals

In our experiment, 1,4-dimethoxy-2,5-di(2,2’,5’,2”-terthiophenestyryl) benzene (TTPSB) microbelts were fabricated using a facile physical vapor deposition (PVD) method. A quartz boat carrying 3 mg TTPSB was then placed in the center of a quartz tube which was inserted into a horizontal tube furnace. A continuous flow of cooling water inside the cover caps was used to achieve a temperature gradient over the entire length of the tube. To prevent oxidation of TTPSB, argon (Ar) was used as an inert gas during the PVD process (flowrate: 15 sccm min−1). The pre-prepared hydrophobic substrates were placed on the downstream side of the argon flow for product collection, and the furnace was heated to the sublimation temperature of TTPSB (at a temperature region of ~320 °C), upon which it was physically deposited onto the pre-prepared hydrophobic substrates at temperature region of ~230 °C for 1 h.

The preparation of TTPSB-crystal-based microcavity

Highly n-doped (100) Si wafers (0.05–0.2 U cm) were successively cleaned with piranha solution (70/30 vol./vol. H2SO4/H2O2), deionized water, and isopropanol, respectively, and then were dried by N2 and O2 plasma for 10 min. The bottom electrode was fabricated by using a metal vacuum deposition system (Amostrom Engineering 03493) to thermally evaporate a silver film with a thickness of 150 ± 5 nm (reflectivity R ≥ 99%) on the glass substrate, the root mean square roughness (Rq) of the silver film in the 5 μm × 5 μm area is 2.23 nm, a 5 ± 0.4 nm MoO3 layer was deposited on the silver film with Rq of 0.4 nm, the deposited rates were both 0.2 Å s−1 and the base vacuum pressure is 3 × 10−6 Torr. The TTPSB crystals were transferred to the substrate for the next step of device preparation. We used a shadow mask to cover the crystals for evaporating top electrodes. Finally, cesium fluoride (CsF) with 2 ± 0.2 nm thickness was used as the modification layer between crystals and calcium (thickness of 10 ± 1 nm) to improve the electron injection, and then a 30 ± 2 nm Ag layer was deposited as top reflector.

Structural and spectroscopic characterization

As-prepared TTPSB microbelts were characterized by field emission scanning electron microscopy (FE-SEM, HITACHI S-4800) by dropping them on a silicon wafer. The X-ray diffraction (XRD, Japan Rigaku D/max-2500 rotation anode X-ray diffractometer, graphite monochromatized CuKα radiation (λ = 1.5418 Å)) operated in the 2θ range from 3° to 30°, by using the samples on a cleaned glass slide.

The fluorescence micrograph, diffused reflection absorption, and emission spectra were measured on Olympus IX71, HITACHI U-3900H, and HITACHI F-4600 spectrophotometers, respectively. The photoluminescence spectra of isolated single TTPSB microbelts in microcavity were characterized by using a homemade photoelectric integrated detection system equipped with a ×50 0.42 NA objective lens (working distance 20.5 mm) (Scheme S1). The second harmonic (λ = 400 nm, pulse width 150 femtosecond) of a 1 kHz Ti: sapphire regenerative amplifier was focused to a 50-μm diameter spot to excite the selected single TTPSB on a two-dimensional (2D) movable table. A sourcemeter (Keithley 2400) equipped with probes is applied to electrical measurement.

Calculation of EQE and irradiation power

The electrically driving light emission from OLEDs was detected by tailor-made equipment for recording emission image, spectra and current simultaneously.

Formulaically speaking, according to the following definition Eq. (1), the EQE of EL device is acquired from the number of the collection emissive photons nν divided by the number of injected carriers ne

A halogen lamp with a known irradiation power of Pc(λ), which is calibrated by the Shanghai Institute of Measurement and Testing Technology, is used as the calibration light source. A reflector with a known reflectivity of R(λ) is placed at the focal plane of the lens, and the light intensity by a CCD camera (PIXIS 100 BR) equipped spectrometer after being reflected by the reflector is Ic(λ), the response function of the light path to light of different wavelengths is H(λ) = Ic(λ)/Pc(λ) × R(λ). When testing electroluminescence samples, the obtained irradiation power at a specific wavelength is Ps(λ) = Is(λ)/H(λ), where Is(λ) is the electroluminescence intensity measured by the same detection light path and the spectrometer.

The distribution of photon number nν, is calculated by Eq. (2). Hence, the number of total photons nν from detected emissive spectra ranging from starting and ending wavelength can be calculated through mathematical integral.

where nν is the number of photons at any wavelength, in counts. λ is the wavelength of the emissive light, in nm. h is Planck constant (6.626 × 10−34 J s). c is the velocity of light in a vacuum (3.0 × 108 m s−1). The number of injected carriers ne during the test is calculated from the recombination current I at saturation region of OLED devices divided by the elementary charge e = 1.602 × 10−19 C and integral time.

Therefore, the EQE is calculated by

References

Kim, D. H. et al. High-efficiency electroluminescence and amplified spontaneous emission from a thermally activated delayed fluorescent near-infrared emitter. Nat. Photonics 12, 98–104 (2018).

Chan, C. Y. et al. Stable pure-blue hyperfluorescence organic light-emitting diodes with high-efficiency and narrow emission. Nat. Photonics 15, 203–207 (2021).

Chen, Y. et al. Approaching nearly 40% external quantum efficiency in organic light emitting diodes utilizing a green thermally activated delayed fluorescence emitter with an extended linear donor–acceptor–donor structure. Adv. Mater. 33, 2103293 (2021).

Jung, H. et al. Two-band optical gain and ultrabright electroluminescence from colloidal quantum dots at 1000 A cm−2. Nat. Commun. 13, 3734 (2022).

Liu, Y. C. et al. All-organic thermally activated delayed fluorescence materials for organic light-emitting diodes. Nat. Rev. Mater. 3, 18020 (2018).

Zhao, W. J., He, Z. K. & Tang, B. Z. Room-temperature phosphorescence from organic aggregates. Nat. Rev. Mater. 5, 869–885 (2020).

Dong, H. Y. et al. Organic microcrystal vibronic lasers with full-spectrum tunable output beyond the Franck–Condon principle. Angew. Chem. Int. Ed. 57, 3108–3112 (2018).

Hestand, N. J. & Spano, F. C. Expanded theory of H- and J-molecular aggregates: the effects of vibronic coupling and intermolecular charge transfer. Chem. Rev. 118, 7069–7163 (2018).

Zang, C. X. et al. Top-emitting thermally activated delayed fluorescence organic light-emitting devices with weak light–matter coupling. Light Sci. Appl. 10, 116 (2021).

Park, I. S. et al. Achieving ultimate narrowband and ultrapure blue organic light-emitting diodes based on polycyclo-heteraborin multi-resonance delayed-fluorescence emitters. Adv. Mater. 34, 2107951 (2022).

Fardy, M. & Yang, P. D. Materials science—Lilliputian light sticks. Nature 451, 408–409 (2008).

Zou, Y. et al. High-performance narrowband pure-red OLEDs with external quantum efficiencies up to 36.1% and ultralow efficiency roll-off. Adv. Mater. 34, 2201442 (2022).

Lv, X. L. et al. Extending the π-skeleton of multi-resonance TADF materials towards high-efficiency narrowband deep-blue emission. Angew. Chem. Int. Ed. 61, e202201588 (2022).

Qiu, Y. T. et al. Narrowing the electroluminescence spectra of multiresonance emitters for high-performance blue OLEDs by a peripheral decoration strategy. ACS Appl. Mater. Interfaces 13, 59035–59042 (2021).

Mischok, A. et al. Highly efficient polaritonic light-emitting diodes with angle-independent narrowband emission. Nat. Photonics 17, 393–400 (2023).

Huang, Y. G. et al. Mini-LED, micro-LED and OLED displays: present status and future perspectives. Light Sci. Appl. 9, 105 (2020).

Qi, L. H. et al. Monolithic full-color active-matrix micro-LED micro-display using InGaN/AlGaInP heterogeneous integration. Light Sci. Appl. 12, 258 (2023).

Weisbuch, C. et al. Observation of the coupled exciton-photon mode splitting in a semiconductor quantum microcavity. Phys. Rev. Lett. 69, 3314–3317 (1992).

Lidzey, D. G. et al. Room temperature polariton emission from strongly coupled organic semiconductor microcavities. Phys. Rev. Lett. 82, 3316–3319 (1999).

Kasprzak, J. et al. Bose–Einstein condensation of exciton polaritons. Nature 443, 409–414 (2006).

Amo, A. et al. Superfluidity of polaritons in semiconductor microcavities. Nat. Phys. 5, 805–810 (2009).

Sanvitto, D. & Kéna-Cohen, S. The road towards polaritonic devices. Nat. Mater. 15, 1061–1073 (2016).

Kéna-Cohen, S. & Forrest, S. R. Room-temperature polariton lasing in an organic single-crystal microcavity. Nat. Photonics 4, 371–375 (2010).

Lu, T. C. et al. Room temperature polariton lasing vs. photon lasing in a ZnO-based hybrid microcavity. Opt. Express 20, 5530–5537 (2012).

Ren, J. H. et al. Efficient bosonic condensation of exciton polaritons in an H-aggregate organic single-crystal microcavity. Nano Lett. 20, 7550–7557 (2020).

Chellappan, K. V., Erden, E. & Urey, H. Laser-based displays: a review. Appl. Opt. 49, F79–F98 (2010).

Zhao, J. Y. et al. Full-color laser displays based on organic printed microlaser arrays. Nat. Commun. 10, 870 (2019).

Graf, A. et al. Electrical pumping and tuning of exciton–polaritons in carbon nanotube microcavities. Nat. Mater. 16, 911–917 (2017).

Yin, F. et al. High-performance organic laser semiconductor enabling efficient light-emitting transistors and low-threshold microcavity lasers. Nano Lett. 22, 5803–5809 (2022).

Liu, D. et al. Organic laser molecule with high mobility, high photoluminescence quantum yield, and deep-blue lasing characteristics. J. Am. Chem. Soc. 142, 6332–6339 (2020).

Long, T. et al. Helical polariton lasing from topological valleys in an organic crystalline microcavity. Adv. Sci. 9, 2203588 (2022).

Kéna-Cohen, S., Davanço, M. & Forrest, S. R. Strong exciton-photon coupling in an organic single crystal microcavity. Phys. Rev. Lett. 101, 116401 (2008).

An, M. H. et al. Highly polarized emission from organic single-crystal light-emitting devices with a polarization ratio of 176. Optica 9, 121 (2022).

Wang, K. & Zhao, Y. S. Pursuing electrically pumped lasing with organic semiconductors. Chem 7, 3221–3231 (2021).

Slootsky, M., Zhang, Y. F. & Forrest, S. R. Temperature dependence of polariton lasing in a crystalline anthracene microcavity. Phys. Rev. B 86, 045312 (2012).

Acknowledgements

This work was supported by the National Key R&D Program of China (Grant Nos. 2018YFA0704805, 2018YFA0704802 and 2017YFA0204503), the National Natural Science Foundation of China (22150005, 22090022, 21833005, and 21873065), the Natural Science Foundation of Beijing, China (KZ202110028043), Beijing Advanced Innovation Center for Imaging Theory and Technology. The authors thank Dr. H.W. Yin from Ideaoptics Inc. for the support on the angle-resolved spectroscopy measurements.

Author information

Authors and Affiliations

Contributions

J.B.D., R.Y.Z., F.Y., T.L., H.H., X.C., and Q.L. designed the experiments and performed experimental measurements. C.L.G., C.B.A., B.L., H.B.F., and Q.L. wrote the manuscript with contributions from all authors. Q.L. and H.B.F. supervised the project. All authors analyzed the data and discussed the results.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Supplementary information

41377_2024_1531_MOESM1_ESM.docx

Supporting Information Organic Polaritonic Light-Emitting Diodes with High Luminance and Color Purity toward Laser Displays

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

De, J., Zhao, R., Yin, F. et al. Organic polaritonic light-emitting diodes with high luminance and color purity toward laser displays. Light Sci Appl 13, 191 (2024). https://doi.org/10.1038/s41377-024-01531-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41377-024-01531-0

- Springer Nature Limited