Abstract

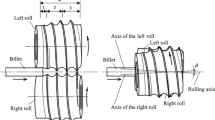

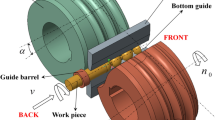

This paper presents the numerical and experimental results of a study investigating helical rolling of ball studs. First, methods for producing balls studs widely used in the automotive industry are discussed. Then, in light of the discussed manufacturing techniques, a helical rolling process for producing this type of parts is proposed. The idea of rolling stepped parts in skew rolling mills is presented and the design concept for helical tools is described. Next, numerical results of a helical rolling process for ball studs are presented. Theoretical considerations are based on the results of simulations performed by the finite element method using the FORGE NxT simulation software. The simulations involved examining metal flow, thermal parameters and force parameters in the process, as well as predicting material cohesion loss based on the distribution of the Cockcroft-Latham ductile fracture criterion. The numerical results were verified experimentally. In the experiments, the process was investigated with respect to potential failure modes. The correctness of the designed numerical models of helical rolling was assessed based on the shape of produced forgings and the distributions of force parameters. Obtained results demonstrate that helical rolling is an effective technique for producing ball studs, and the design concept for helical tools can be based on the solutions developed for wedge tools used in cross wedge rolling.

Similar content being viewed by others

References

E. Doege, J. Thalemann, F. Weber, Hot forging of precision parts, J. Mater. Process. Technol. 35 (1992) 469–481.

www.emersonforge.in. [Access online 20 March 2019].

K. Lange, Handbook of Metal Forming, McGraw-Hill, New York, USA, 1985.

www.afdex.com. [Access online 15 March 2019].

Y.S. Lee, J.H. Lee, J.U. Choi, T. Ishikawa, Experimental and analytical evaluation for elastic deformation behaviors of cold forging tool, J. Mater. Process. Technol. 127 (2002) 73–82.

J.G. Eom, Y.H. Son, S.W. Jeong, et al., Effect of strain hardening capability on plastic deformation behaviors of material during metal forming, Mater. Des. 54 (2014) 1010–1018.

J.H. Song, Y.T. Im, Expert system for the process sequence design of a ball stud, J. Mater. Process. Technol. 89–90 (1999) 72–78.

T. Bulzak, Z. Pater, J. Tomczak, Numerical and experimental analysis of a cross wedge rolling process for producing ball studs, Arch. Civ. Mech. Eng. 17 (2017) 729–737.

J. Zhou, Y. Yu, Q. Zeng, Analysis and experimental studies of internal voids in multi-wedge cross wedge rolling stepped shaft, Int. J. Adv. Manuf. Technol. 72 (2014) 1559–1566.

J. Zhao, L.Q. Lu, Z.H. Hu, Study on varying rule of mechanical parameters in forming automobile semi-axes with multi-wedge cross wedge rolling, Proc. Int. Conf. Mech. Eng. Mech. 1–2 (2007) 1723–1727.

A. Tofil, The Rolling Processes of Semifinished in a Universal Forging Mill, Lublin University of Technology Press, Lublin, 2016.

V.Z. Smirnov, V.P. Anisiforov, M.V. Vasilchikov, et al., Poperechnaya Prokatka V Mashinostroyenii, GNTIML, Moskva, 1957.

Z. Pater, J. Tomczak, Z. Pater, J. Tomczak, FEM modelling of a helical wedge rolling process for axisymmetric parts, Adv. Sci. Technol. Res. J. 12 (2018) 115–126.

S.P. Gronovskij, Novye Procesy I Stany Dla Prokatki Izdelij V Vintovych Kalibrach, Mietalurgija, Moscow, 1980 (in Russian).

Z. Pater, J. Tomczak, Helical Rolling for Balls Used in Ball Mills, Lublin University of Technology Press, Lublin, 2012.

Z. Pater, J. Tomczak, J. Bartnicki, M.R. Lovell, P.L. Menezes, Experimental and numerical analysis of helical-wedge rolling process for producing steel balls, Int. J. Mach. Tools Manuf. 67 (2013) 1–7.

M.V. Filippova, M.V. Temlyantsev, V.N. Peretyat’ko, E.E. Prudkii, Rolling of metal balls, Steel Transl. 47 (2014) 435–439.

Z. Hu, B. Wang, J. Liu, et al., Technology of Skew Rolling, Chemical Industry Press, Beijing, 2014, pp. 4–5.

Z. Pater, Cross Wedge Rolling, Lublin University of Technology Press, Lublin, 2009.

R. Pan, K.S. Zhang, Z. Jia, Analysis on processing boundary of stepped shaft during cross wedge rolling process, Adv. Mat. Res. 472–475 (2012) 775–780.

FORGE® NxT Materials Databases, TRANSVALOR, 2017.

Z. Pater, J. Tomczak, T. Bulzak, Numeral analysis of a skew rolling process for producing axle shafts, Comp. Method Mater. Sci. 16 (2016) 63–69.

Z. Pater, J. Tomczak, T. Bulzak, Numerical analysis of the skew rolling process for main shafts, Metalurgija 54 (2015) 627–630.

Z. Pater, The method of determination of plastic properties of materials by rotary crimping with flat tools, Polish patent no PL 220786, 2011.

Z. Pater, P. Walczuk, K. Lis, L. Wojcik, Preliminary analysis of a rotary compression test, Adv. Sci. Technol. Res. J. 12 (2018) 77–82.

K. Komori, Ductile fracture criteria for simulating shear by no de separation method, Theor. Appl. Fract. Mech. 43 (2005) 101–114.

J. Tomczak, Z. Pater, T. Bulzak, Skew rolling mill, Patent application (2016), no P.416274,.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tomczak, J., Pater, Z. & Bulzak, T. A helical rolling process for producing ball studs. Archiv.Civ.Mech.Eng 19, 1316–1326 (2019). https://doi.org/10.1016/j.acme.2019.07.008

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1016/j.acme.2019.07.008