Abstract

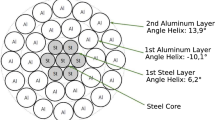

The traditional overhead conductors (OHL conductors) are made from a high strength steel core and several layers of aluminium wires. Operating conditions under variable stress derived from von Karman vortices leads to fatigue cracking of the outer layer of wires, first of the outer layer, and then the inner layers. The dynamic component of tension, dependent on the static tension of the wire, its geometric construction and rigidity (the number and diameter of the wires, the coil angle), lead to fatigue destruction of the wires. The consequence of this is the gradual degradation of the conductor as a whole, which is a decrease in the electrically active cross-section, and as a result of overheating, also in its mechanical properties. The ultimate effect is breaking of the conductor and a fault of the power line. The subject of the paper concerns fatigue strength tests of cold-drawn commercially pure aluminium wires in different temper of strain hardening. The paper attempts to describe fatigue strength, research methodology, description of a research stand. Based on study results and their analysis, conclusions were formulated concerning the differentiation of fatigue strength and EN AW-1370 wires used for overhead power conductors.

Similar content being viewed by others

References

F. Kiessling, P. Nefzger, J.F. Nicolasco, U. Kaintzyk, Overhead Power Lines. Planning, Design, Construction, Springer, 2003.

A. Nowak, Research on the influence of eolian vibrations on the operating properties of overhead power lines from AlMgSi alloys, PhD thesis, AGH Cracow, 2015.

S. Kocanda, Zmeczeniowe niszczenie metali, Wyd. Naukowo-Techniczne, Warszawa, 1978.

HAEL Mughrabi, H. Fatigue, an everlasting materials problem – still en vogue, Proc. Eng. (2) (2009) 3–26.

R.B. Kalomboa, J.M.G. Martíneza, J.L.A. Ferreiraa, C.R.M. da Silvaa, J.A. Araújoa, Comparative fatigue resistance of overhead conductors made of aluminium and aluminium alloy: tests and analysis, Proc. Eng. 133 (2015) 223–232.

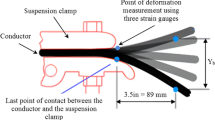

B. Ouaki, S. Goudreau, A. Cardou, M. Fiset, Fretting fatigue analysis of aluminium conductor wires near the suspension clamp: Metallurgical and fracture mechanics analysis, The Journal of Strain Analysis for Engineering Design 38 (2) (2003) 133–147.

M. Boniardi1, S. Cincera1, F. D’Errico1, C. Tagliabue, Fretting fatigue phenomena on an all aluminium alloy conductor, Key Eng. Mater. 348–349 (2007) 5–8.

J.P. Hou, Q. Wang, H.J. Yang, X.M. Wu, C.H. Li, X.W. Li, Z.F. Zhang, Microstructure evolution and strengthening mechanisms of cold-drawn commercially pure aluminum wire, Mater. Sci. Eng. A 639 (2015) 103–106.

N.A. Alang, N.A. Razak, A.K. Miskam, Effect of Surface roughness on fatigue life of notched carbon steel, Int. J. Eng. Technol. IJET-IJENS 11 (1) (2011).

K.K. Ma, H.M. Wen, T. Hu, T.D. Topping, D. Isheim, D.N. Seidman, E.J. Lavernia, J.M. Schoenung, Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy, Acta Mater. 62 (2014) 141–155.

R. Liu, Y. Tian, Z. Zhang, X. An, P. Zang, Z. Zhang, Exceptional high fatigue strength in Cu–15 at%Al alloy with moderate grain size, Scient. Rep. (2016).

J.P. Hou, Q. Wang, H.J. Yang, X.M. Wu, C.H. Li, Z.F. Zhang, X.O. Li, Fatigue and fracture behavior of a cold-drawn commercially pure aluminum wire, Materials 9 (2016) 764.

A. Mamala, W. Sc´iezor, P. Kwasniewski, J. Grzebinoga, R. Kowal, Study of the mechanical properties of strips obtained in TRC line, Arch. Metall. Mater. Pol. Acad. Sci. 61 (2B) (2016) 1101–1108, ISSN 1733-3490 (Committee of Metallurgy. Institute of Metallurgy and Materials Science).

A. Mamala, P. Kwasniewski, A. Nowak, J. Grzebinoga, W. Sciezor, R. Kowal, Effect of metallic additives to polymer matrix on properties of composite adhesives dedicated for light metal joining, Arch. Metall. Mater. Pol. Acad. Sci. 62 (4) (2017) 2287–2294, ISSN 1733-3490 (Committee of Metallurgy. Institute of Metallurgy and Materials Science).

H. Hael Mughrabi, Fatigue, an everlasting materials problem – still en vogue, Proc. Eng. (2) (2009) 3–26.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bartosz, J., Beata, S., Malgorzata, Z. et al. The researches of influence of strengthening on fatigue strength of aluminium wires for OHL conductors. Archiv.Civ.Mech.Eng 19, 862–870 (2019). https://doi.org/10.1016/j.acme.2018.10.006

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1016/j.acme.2018.10.006