Abstract

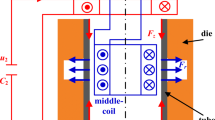

In a strip winding process, the sleeve is a hollow cylinder that is mounted between a strip coil and a mandrel to maintain uniform coil shape when the strip coil is very thin, but its deformation behavior has not been investigated before. Thus, a finite element (FE) model was presented to calculate the stress distribution in a sleeve and strip coil when 1–3 mm-thick stainless steel was wound around the sleeve. The FE model was developed by extending a previous model by adding a sleeve between the mandrel and strip, and by modifying the boundary and interaction conditions. The strip winding process was divided into an initial process and a steady-state process. During the initial process, the minimum and maximum pressure required on the belt wrapper to maintain coil shape by self-friction of the strip was calculated by the FE model when the belt wrapper is ejected at the end of the initial process. After the initial process, an analytical model of the steady-state process was established to calculate the stress distribution and was compared with the FE model to validate it. The suggested analytical model took 11 s to give the same stress distribution that the FE model took 30 d to produce.

Similar content being viewed by others

Abbreviations

- Ebelt, Eman, Esle, Estr:

-

Modulus of elasticity of belt wrapper, mandrel, sleeve, and strip, respectively

- h :

-

Strip thickness

- N :

-

Last coiling layer number

- P :

-

Contact pressure

- ri,sle:

-

Inner radius of sleeve

- r i ,belt :

-

Inner radius of belt wrapper

- r i ,man :

-

Inner radius of mandrel

- r i ,str :

-

Inner radius of strip coil

- r o,sle :

-

Outer radius of sleeve

- r o,belt :

-

Outer radius of belt wrapper

- r o,man :

-

Outer radius of mandrel

- r o,str :

-

Outer radius of strip coil

- v :

-

Coiling velocity

- νbelt, νman, νsie, νsir:

-

Poisson’s ratio of belt wrapper, mandrel, sleeve, and strip, respectively

- μ:

-

Coefficient of friction

- σr,in:

-

Radial stress on the innermost side of sleeve

- σr,out:

-

Radial stress on the outermost side of sleeve

- σo,in:

-

Hoop stress on the innermost side of sleeve

- σo,out:

-

Hoop stress on the outermost side of sleeve

- σT:

-

Winding tension

References

B. Anderssen, N. Fowkes, R. Hickson, M. McGuinness, Analysis of coil slumping., 26th MISG, Wollongong, 2009.

J. Case, A. H. Chilver, Strength of Materials and Structures: An Introduction to the Mechanics of Solids and Structures, Elsevier E-book, 2013.

I. Doghri, Mechanics of Deformable Solids: Linear and Nonlinear Analytical and Computational Aspects, Springer E-book, 2000.

R. B. Sims, J. A. Place, Brit. J. Appl. Phys. 4 (1953) No. 7, 213–216.

W. W. Park, D. K. Kim, Y. T. Im, H. C. Kwon, M. S. Chun, Met. Mater. Int. 20 (2014) No. 4, 719–726.

C. S. Jeong, The Analysis of Stress Distribution and Strain of the Strip Build-up and the Temperature Gradient in Coiling Process, Pusan National University, Pusan, 2001.

Y. J. Choi, PID Sliding Mode Control Using a Coiler Simulator in Hot Strip Mill, Pusan National University, Pusan, 2008.

Y. J. Choi, M. C. Lee, Int. J. Precis. Eng. Manuf. 10 (2009) No. 2, 53–61.

N. Pholdee, S. Bureerat, W. W. Park, D. K. Kim, Y. T. Im, H. C. Kwon, M. S. Chun, Int. J. Precis. Eng. Manuf. 16 (2015) No. 7, 1493–1499.

N. Pholdee, W. W. Park, D. K. Kim, Y. T. Im, S. Bureerat, H. C. Kwon, M. S. Chun, Eng. Optim. 47 (2015) No. 4, 521–532.

Y. Q. Wang, L. I. Li, X. C. Yan, Y. X. Luo, W. U. Liang, J. Iron Steel Res. Int. 19 (2012) No. 8, 6–11.

H. Koc, D. Knittel, M. de Mathelin, G. Abba, IEEE Trans. Control Syst. Technol. 10 (2002) No. 2, 197–208.

C. L. Chen, K. M. Chang, C. M. Chang, Appl. Math. Modell. 28 (2004) No. 10, 863–876.

E. Laroche, D. Knittel, Control Eng. Pract. 13 (2005) No. 5, 659–666.

T. Bastogne, H. Noura, P. Sibille, A. Richard, Control Eng. Pract. 6 (1998) No. 9, 1077–1088.

H. Glaoui, A. Hazzab, B. Bouchiba, I. K. Bousserhane, Int. J. Adv. Comput. Sci. Appl. 4 (2013) No. 2, 110–115.

C. Ugural, S. K. Fenster, Advanced Strength and Applied Elasticity, 4th Ed., Prentice-Hall, Inc., Upper Saddle River, New Jersey, 1994.

T. J. Chung, Applied Continuum Mechanics, Cambridge University Press, Cambridge UK, 1996.

T. Sato, Four Concentric Cylinders With Prescribed Axial Strain, Thiokol Corporation, Utah, 1974.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, Yh., Park, K., Won, Sy. et al. Stress analysis model of strip winding system with a sleeve for a coil of thin stainless steel. J. Iron Steel Res. Int. 24, 1–7 (2017). https://doi.org/10.1016/S1006-706X(17)30002-X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(17)30002-X