Abstract

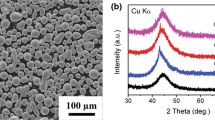

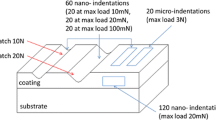

Fe-based powder with a composition of Fe42.87Cr15.98Mo16.33C15.94B8.88 (at. %) was used to fabricate coatings by high-velocity oxygen fuel spraying. The effects of the spraying parameters on the microstructure and the wear properties of the Fe-based alloy coatings were systematically studied. The results showed that the obtained Fe-based coatings with a thickness of about 400 µm consisted of a large-volume amorphous phase and some nanocrystals. With increasing the fuel and oxygen flow rates, the porosity of the obtained coatings decreased. The coating deposited under optimized parameters exhibited the lowest porosity of 2.8%. The excellent wear resistance of this coating was attributed to the properties of the amorphous matrix and the presence of nanocrystals homogeneously distributed within the matrix. The wear mechanism of the coatings was discussed on the basis of observations of the worn surfaces.

Similar content being viewed by others

References

P. Duwez, R. H. Willens, W. J. Klement, Appl. Phys. Lett. 31 (1960) 1137–1140.

G. Wang, H. B. Fan, Y. J. Huang, J. Shen, Z. H. Chen, Mater. Des. 54 (2014) 251–255.

A. Peker, W. L. Johnson, Appl. Phys. Lett. 63 (1993) 2342–2344.

J. Shen, Q. J. Chen, J. F. Sun, H. B. Fan, G. Wang, Appl. Phys. Lett. 86 (2005) 151907.

D. H. Xu, B. Lohwongwatana, G. Duan, W. L. Johnson, C. Garland, Acta Mater. 52 (2004) 2621–2624.

G. Wang, D. D. Miao, P. Xiao, Z. J. Huang, J. Funct. Mater. 11 (2014) 19001–19004.

Y. J. Huang, Y. Z. Guo, H. B. Fan, J. Shen, Mater. Lett. 89 (2012) 229–232.

L. Li, B. Kharas, H. Zhang, S. Sampath, Mater. Sci. Eng. A 456 (2007) 35–38.

K. Chokethawai, D. G. Mcartney, P. H. Shipway, J. Alloys Comp. 480 (2009) 351–359.

Y. L. An, G. L. Hou, J. Chen, X. Q. Zhao, G. Liu, H. D. Zhou, Vacuum 107 (2014) 132–140.

C. Zhang, L. Liu, K. C. Chan, Q. Chen, C. Y. Tang, Intermetallics 29 (2012) 80–85.

G. Bolelli, B. Bonferroni, J. Laurila, L. Lusvarghi, A. Milanti, K. Niemi, P. Vuoristo, Wear 276–277 (2012) 29–47.

A. L. Greer, K. L. Rutherford, I. M. Hutchings, Inter. Mater. Rev. 47 (2002) 87–112.

Z. Zhou, L. Wang, F. C. Wang, H. F. Zhang, Y. B. Liu, S. H. Xu, Surf. Coat. Technol. 204 (2009) 563–570.

S. J. Pang, T. Zhang, K. Asami, A. Inoue, Acta Mater. 50 (2002) 489–497.

T. C. Totemeier, J. Therm. Spray Technol. 14 (2005) 369–374.

Z. Zhou, L. Wang, D. Y. He, F. C. Wang, Y. B. Liu, J. Therm. Spray Technol. 19 (2010) 1287–1293.

H. Zhang, Y. T. Xie, L. P. Huang, S. S. Huang, X. B. Zheng, G. Chen, Surf. Coat. Technol. 258 (2014) 495–502.

K. Yang, J. W. Feng, X. M. Zhou, S. Y. Tao, Surf. Coat. Technol. 206 (2012) 3082–3087.

W. Tian, Y. Wang, Y. Yang, C. G. Li, Surf. Coat. Technol. 204 (2009) 642–649.

M. Yamasaki, S. Kagao, Y. Kawamura, K. Yoshimura, Appl. Phys. Lett. 84 (2004) 4653–4655.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (51205001); Key Project of Natural Science of Education Department of Anhui Province of China (KJ2014A023); Scientific Research Starting Foundation of Anhui Polytechnic University of China (2012YQQ006)

Rights and permissions

About this article

Cite this article

Wang, G., Xiao, P., Huang, Zj. et al. Microstructure and Wear Properties of Fe-based Amorphous Coatings Deposited by High-velocity Oxygen Fuel Spraying. J. Iron Steel Res. Int. 23, 699–704 (2016). https://doi.org/10.1016/S1006-706X(16)30108-X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(16)30108-X