Abstract

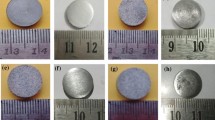

The carbonation and microstructurc characteristics of pellets containing ferrous dusts were investigated during carbonation consolidation at different reaction temperatures and CO2 partial pressures. The results indicated that green pellets had loose and network supporting structure with initial strength, and large cracks and pores existed in the pellets. The carbonation reaction was controlled by interfacial chemical reaction at the initial fast stage, which limited diffusion and thus caused the reaction rate to decrease. With increasing reaction temperature and CO2 partial pressure, the conversion rates of CaO and the number of microcrystalline CaCO3 particles increased, and the volume expansion of CaCO3 led to a decrease in the open porosity, average pore size and specific surface area of the pellets. Micro-pores were occluded, and the number of smaller pores (diameter less than 50 nm) increased, thereby resulting in the more compact and uniform structure of carbonated pellets. Simultaneously, the dense structure prevented CO2 diffusion into the product layer, affecting the increase in carbonation conversion rate.

Similar content being viewed by others

References

Y. X. Chen, W. J. Feng, Sinter. Pelletiz. 30 (2005) No. 5, 42–46.

B. Das, S. Prakash, P. S. R Reddy, V. N. Misra, Resour. Conserv. Recycl. 50 (2007) 40–57.

X. F. She, Q. G. Xue, J.J Dong, J. S. Wang, H. Zeng, H. F. Li, Y. G. Ding, H. X. Yang, C. Peng, The Chinese Journal of Process Engineering 9 (2009) Suppl. 1, 7–12.

R. Robinson, Thermochim. Acta 432 (2005) 112–123.

C. Q. Hu, T. Han, Y. Z. Zhang, Z. X. Zhang, J. Iron Steel Res. Int. 18 (2011) No. 12, 27–31.

J. Pal, S. Ghorai, M. C. Goswami, S. Ghosh, D. Ghosh, D. Bandyopadhyay, ISIJ Int. 49 (2009) 210–219.

H. T. Makkonen, J. Heino, L. Laitila, A. Hiltunen, E. Pöyliö, J. Härkki, Resour. Conserv. Recycl. 35 (2002) 77–84.

J. Pal, M. C. Goswami, B. Mahato, S. Ghosh, D. Ghosh, D. Bandyopadhyay, ISIJ Int. 49 (2009) 1325–1332.

P. Sun, J. R. Grace, C. J. Lim, E. J. Anthony, Chem. Eng. Sci. 63 (2008) 47–56.

V. Manovic, E. J. Anthony, D. Loncarevic, Chem. Eng. Sci. 64 (2009) 3236–3245.

Y. J. Li, C. S. Zhao, H. C. Chen, Journal of Southeast University (Natural Science Edition) 39 (2009) 262–268.

R. G. Wei, J. T. Chen, H. W. Chen, L. Chen, Journal of Chinese Society of Power Engineering 33 (2013) 147–152.

Y. Shi, X. J. Li, C. Q. Hu, Adv. Mater. Res. 609–603 (2013) 374–377.

G. Q. Zuo, ISIJ Int. 40 (2000) 1195–1202.

Y. Shi, W. H. Liu, C. Q. Hu, The Chinese Journal of Process Engineering 13 (2013) 83–87.

J. Pal, S. Ghorai, D. P. Singh, A. K. Upadhyay, S. Ghosh, D. Ghosh, D. Bandyopadhyay, ISIJ Int. 50 (2010) 105–114.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (51074061); Natural Science Foundation of Hebei Province of China (E2011209039)

Rights and permissions

About this article

Cite this article

Shi, Y., Liu, Sm., Hu, Cq. et al. Microstructure Variation of Pellets Containing Ferrous Dust During Carbonation Consolidation. J. Iron Steel Res. Int. 22, 128–134 (2015). https://doi.org/10.1016/S1006-706X(15)60020-6

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(15)60020-6