Abstract

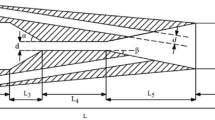

This paper reports optimization of various geometrical parameters of two types of hydrodynamic cavitation reactors (HC) such as venturi type and orifice type. Mostly orifice and venturi nozzles are used as HC reactor, a simple valve can also be used to cause cavitation which depends on geometry and area of opening. Different operating and geometrical parameters such as divergence angle, throat height/diameter to length ratio, number of holes and inlet pressure to the cavitating device were selected to study the inception, growth and dynamics of cavities. In this work, a comprehensive computational fluid dynamics simulation is performed to numerically investigate the 3-D flow behaviors within HC reactors using cavitational model with standard k-ε Turbulence model. The study of different geometries of venturi type HC reactor (like slit, circular and elliptical) shows that 1:1 of the ratio of throat height/diameter to length and 6.5° of divergence angle is an optimum geometry for best cavitational activity. In case of orifice, 1:3 of the ratio of diameter to length is best for cavitation and an increase in the total flow area increases the cavitational yield.

Similar content being viewed by others

References

SHAH Y. T., PANDIT A. B. and MOHOLKAR V. S. Cavitation reaction engineering[M]. New York, USA: Kluwer Academic/Plenum Publishers, 1999.

MAHULKAR A. V. Computational fluid dynamical analysis of cavitational reactors[D]. Doctoral Thesis, Mumbai, India: Mumbai University, 2009.

BALASUNDARAM PANDIT B. A. B. Significance of location of enzymes on their release during microbial cell disruption[J]. Biotechnology and Bioengineering, 2001, 75(5): 607–614.

TSALAGKAS D., LAGANA R. and POLJANSEK I. et al. Fabrication of bacterial cellulose thin films self-assembled from sonochemically prepared nanofibrils and its characterization[J]. Ultrasonics Sonochemistry, 2015, 28: 136–143.

PINJARI D. V., PANDIT A. B. Cavitation milling of natural cellulose to nanofibrils[J]. Ultrasonics Sonochemistry, 2010, 17(5): 845–852.

SAHARAN V. K., BADVE M. P. and PANDIT A. B. Degradation of reactive red 120 dye using hydrodynamic cavitation[J]. Chemical Engineering Journal, 2011, 178: 100–107.

BADVE M., GOGATE P. and PANDIT A. et al. Hydrodynamic cavitation as a novel approach for wastewater treatment in wood finishing industry[J]. Separation and Purification Technology, 2013, 106(6): 15–21.

BADVE M. P., GOGATE P. R. and PANDIT A. B. et al. Hydrodynamic cavitation as a novel approach for delignification of wheat straw for paper manufacturing[J]. Ultrasonics Sonochemistry, 2013, 21(1): 162–168.

SAHARAN V. K., RIZWANI M. A. and MALANI A. A. et al. Effect of geometry of hydrodynamically cavitating device on degradation of orange-G[J]. Ultrasonics Sonochemistry, 2013, 20(1): 345–353.

SIVAKUMAR M., PANDIT A. B. Wastewater treatment: A novel energy efficient hydrodynamic cavitational technique[J]. Ultrasonics Sonochemistry, 2002, 9(3): 123–131.

LI Y., ZHAO D. and YUAN Q. Research, development and application of ultrasound wave in petrochemical industry[J]. Petrochemical Technology, 2005, 34(2): 176–180.

BALASUNDARAM B., PANDIT A. B. Selective release of invertase by hydrodynamic cavitation[J]. Biochemical Engineering Journal, 2001, 8(3): 251–256.

NOWACKI R., PIORKOWSKA E. Influence of solid particles on cavitation in poly (methylene oxide) during crystallization[J]. Journal of Applied Polymer Science, 2007, 105(3): 1053–1062.

SUNDARAM J., MELLEIN B. R. and MITRAGOTRI S. An experimental and theoretical analysis of ultrasoundinduced permeabilization of cell membranes[J]. Biophysical Journal, 2003, 84(5): 3087–3101.

TANG S. Y., SIVAKUMAR M. A novel and facile liquid whistle hydrodynamic cavitation reactor to produce submicron multiple emulsions[J]. AIChE Journal, 2013, 59(1): 155–167.

SIVAKUMAR M., TANG S. Y. and TAN K. W. Cavitation technology-A greener processing technique for the generation of pharmaceutical nanoemulsions[J]. Ultrasonics Sonochemistry, 2014, 21(6): 2069–2083.

PARTHASARATHY S., TANG S. Y. and MANICKAM S. Generation and optimization of palm oil-based oil-inwater (O/W) submicron-emulsions and encapsulation of curcumin using a liquid whistle hydrodynamic cavitation reactor (LWHCR)[J]. Industrial and Engineering Chemistry Research, 2013, 52(34): 11829–11837.

GOGATE P. R., TAYAL R. K. and PANDIT A. B. Cavitation: A technology on the horizon[J]. Current Science, 2006, 91(1): 35–46.

BADVE M. P., ALPAR T. and PANDIT A. B. et al. Modeling the shear rate and pressure drop in a hydrodynamic cavitation reactor with experimental validation based on KPI decomposition studies[J]. Ultrasonics Sonochemistry, 2015, 22: 272–277.

BASHIR T. A., SONI A. G. and AHULKAR A. V. et al. The CFD driven optimisation of a modified venturi for cavitational activity[J]. Canadian Journal of Chemical Engineering, 2011, 89(6): 1366–1375.

MOHOLKAR V. S., KUMAR P. S. and PANDIT A. B. Hydrodynamic cavitation for sonochemical effects[J]. Ultrasonics Sonochemistry, 1999, 6(1–2): 53–65.

MIKIC B. B., ROHSENOW W. M. and GRIFFITH P. On bubble growth rates[J]. International Journal of Heat and Mass Transfer, 1970, 13(4): 657–666.

FLORSCHUETZ L. W., CHAO B. T. On the mechanics of vapor bubble collapse[J]. Journal of Heat Transfer, 1965, 87(2): 209–220.

KUNZ R. F., SIEBERT B. W. and COPE W. K. et al. A coupled phasic exchange algorithm for three-dimensional multi-field analysis of heated flows with mass transfer[J]. Computers and fluids, 1998, 27(7): 741–768.

CARRICA P. M., DREW D. and BONETTO F. et al. A polydisperse model for bubbly two-phase flow around a surface ship[J]. International Journal of Multiphase Flow, 1999, 25(2): 257–305.

SINGHAL A. K., ATHAVALE M. M. and LI H. et al. Mathematical basis and validation of the full cavitation model[J]. Journal of Fluids Engineering, 2002, 124(3): 617–624.

NURICK W. H. Orifice cavitation and its effect on spray mixing[J]. Journal of Fluids Engineering, 1976, 98(4): 681–687.

SCHMIDT D. P., CORRADINI M. L. The internal flow of diesel fuel injection nozzles: A review[J]. International Journal of Engine Research, 2001, 2(1): 1–22.

Author information

Authors and Affiliations

Corresponding author

Additional information

Biography: Kuldeep (1989-), Male, M. Tech. Candidate

Rights and permissions

About this article

Cite this article

Kuldeep, Saharan, V.K. Computational study of different venturi and orifice type hydrodynamic cavitating devices. J Hydrodyn 28, 293–305 (2016). https://doi.org/10.1016/S1001-6058(16)60631-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1001-6058(16)60631-5