Abstract

Carrot waste is a rich source of pro-vitamin A, β-carotene, recognized for its immunomodulatory and health-promoting properties. The present study was aimed at formulating an innovative table spread (ITS) enriched with concentrated carotenoid extract derived from carrot pomace. Prior extraction of carotenoids in flaxseed oil was optimized resulting in extract (CE) rich in carotenoids (82.66 µg/g) and alpha-linolenic acid (ALA). The effects of three ingredients i.e. CE, tri-sodium citrate (TC), and common salt (CS) on ITS formulated using 33 factorial experiment (27 treatment combinations) were determined employing three-way ANOVA of Proc GLM method of SAS 9.3 for its textural and sensory acceptability. The optimized formulation contained 15% CE, 1.0% CS and 0.3% TC. ITS displayed medium (≈51% fat) internal phase emulsion (confirmed via fluorescence microscopy) stabilized (-56.867 mV ± 0.850 zeta potential) by whey protein concentrate and possessed high thermal stability (studied through thermogravimetric analysis). The control table spread (CTS) was prepared using all ingredients except CE replaced with flaxseed oil. ITS showed significantly (p < 0.05) higher carotenoid, antioxidant (ABTS, DPPH and FRAP), yellowness index and b* value than CTS; while non-significant (p > 0.05) difference existed for proximate composition and acidity. ITS turned out to be a naturally colored functional product and excellent source of carotenoids (24.276 μg/g ± 0.076) and ALA (13.816 g/ 100 g fat).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Food and Agriculture Organization (FAO) has recommended designing more eco-friendly, sustainable and new age processes for agro-industrial produce for reducing waste throughout the production chain. Four (i.e. 2, 3, 12 and 13) out of the seventeen sustainable development goals (SDGs) directly or indirectly pertain to promoting nutrition, besides reducing waste by reprocessing the same. Abundant waste, rich in bioactive components, is generated from agro-horticultural activities. This has concerned researchers to engross towards achieving SDGs through extraction of bioactive components from plant and animal matrices by exploiting novel non-thermal approaches.

Carrots undoubtedly assume a top rank amongst the most economical and concentrated sources of carotenoids (β-carotene, lutein, zeaxanthin, or lycopene) from plant sources. Carrot processing industries generate huge waste (25–30%) in the form of carrot rejects, peels, and pomace which contain a large amount of high-value bioactive carotenoids, tocopherols, pectin and phenolic compounds known for their health-promoting effects [1]. Utilization of this rich carotenoid reservoir can not only yield a valuable functional ingredient for formulating healthy products but also reduce huge organic waste burdening environmental pollution [2, 3]. Growing interest in the use of carotenoids as natural pigment and functional ingredients has sparked the expanding carotenoid market which is estimated to grow from USD 1.5 billion in 2019 to USD 2.0 billion in 2026 [4].

Previously, our team extracted carotenoids from carrot pomace using green bio-refinery approach and flaxseed oil as ‘green’ solvent [5]. This was based on findings of our earlier research wherein extraction efficiency of carotenoids was studied using different groups of vegetable oils; and flaxseed oil turned out to be the best [6]. This made the extract (CE) an excellent source of both carotenoids and alpha-linolenic acid (ALA) as flaxseed is one of the richest vegan sources of ALA, an essential omega-3 polyunsaturated fatty acid, which may help in preventing CVDs and certain malignancies, because of its anti-inflammatory effects [7]. Further, we prepared emulsion-based delivery system of CE for its application as functional natural colorant in flavored milk [8]. The utilization of CE directly in the food system was not attempted earlier and happens to be the aim of this work. Recently, Ordóñez-Santos et al. [9] extracted carotenoids from tangerine epicarp in sunflower oil using ultrasonication process and reported its application as natural colorant in cake and bread for replacing synthetic colorant, ‘tartrazine’. Suo et al. [10] reported 7.32 times higher a* value of fresh fries fried in corn oil containing carotenoids extracted from apricot flesh. The present study was envisaged towards formulation of medium internal phase emulsion (table spreads) for expanding horizon of application of CE as intended product require no harsh heating, unlike cakes, breads and fresh fries; and is recommended to be stored under refrigerated storage. This could be helpful not only in providing appealing yellow colour to end product, but also retaining its carotenoids content.

Table spreads are water-in-oil or oil-in-water kind of emulsions that may vary from high (HIPE) to medium (MIPE) to low internal phase emulsions (LIPE) depending upon the concentration of volume fraction of droplet (internal) phase [11]. They are plastic in nature and possess tremendous advantages due to nutritional value, simplicity in application and consumer appeal. These are an interesting and effective food vehicle to be fortified with lipid-soluble compounds (CE in our case), more because of their revolutionary applications and compatibility with appetizers, snacks, regular course (bread, chapatti, rice), and traditional meals. Food spreads market is growing at a CAGR of 3.42% and is expected to be at USD 31.47 billion in 2024 and estimated to reach USD 37.23 billion by 2029. The trend towards premium quality spreads with nutritional claims and negligible use of synthetic ingredients is gaining popularity amongst the consumers [12]. Emulsifying salt, also referred to as melting/ chelating salt like trisodium citrate (TC) plays a significant role in providing structure to table spread and exert affirmative influence on its melting characteristics via aiding in emulsification of fat in protein matrix. These are believed to result in fat emulsification, stabilization of interface between fat, protein, and water, and also influence creaming in products [13]. Salt is considered to be the second most important ingredient in formulating emulsified (like, salad dressing and mayonnaise) and non-emulsified (like mint sauce and brown sauce) sauces as it deliberates stability and microbiological safety to product, besides its primary role as flavor enhancer and modifier [14].

The major challenge associated with formulating innovative functional products containing flaxseed oil as an integral ingredient lies in veiling the peculiar taste and flavor associated with it which further augments during storage. This peculiarity in sensory could be attributed to the presence of high levels of polyunsaturated fatty acid (ALA) making it prone to rancidity and generation of off-flavors at higher temperatures and in presence of oxygen. Hence, the present study was focused on formulation of texturally acceptable and organoleptically superior ITS containing carotenoids extracted in ALA-rich flaxseed oil. In order to develop a new food product, decision on optimum level of different ingredients can be achieved by changing one ingredient at a time, however, this approach is lengthy, tedious, and sometimes fails to deliver optimum combination and does not depict the combined effects of all the factors involved. To overcome this limitation, 33 factorial experiment was applied for optimizing three indispensable ingredients, namely, vegetable oil i.e. CE, common salt (CS) and TC for the preparation of ITS. Further, the optimized product was analysed for microstructure, electrostatic stability and thermal profiling and compared with control for proximate composition, carotenoid content, fatty acid profiling, anti-oxidant value and other physico-chemical parameters. To the best of our knowledge, such innovative product rich in both carotenoids (natural colorant and bio-functional component) and ALA is not formulated so far.

2 Materials

Orange carrots were procured from local market of Karnal, Haryana, India. Flaxseed oil was obtained from the local market of Tilak Bazar Chowk, Delhi, India. Whey Protein Concentrate (WPC) was procured from Milk Specialties Global. All other chemicals used were purchased from Sigma Aldrich Chemicals Pvt. Ltd, Fisher Scientific India Pvt. Ltd, HiMedia Laboratories Pvt. Ltd, or Easy Life Retailing Pvt. Ltd. Extraction of carotenoids from carrot pomace in flaxseed oil (CE) was carried out according to protocol optimized earlier in our laboratory [5].

3 Methods

3.1 Preparation of innovative table spread (ITS)

The two phases of emulsion were prepared separately. Aqueous phase was prepared by mixing predetermined quantities of all dry ingredients i.e. WPC, common salt (CS), TC, emulsifier, stabilizer, spice mix etc. in water, while the fat phase was prepared by mixing butter with CE. The combination of variables i.e. CE, CS and TC are mentioned in Table 1. Table spread was prepared by mixing aqueous phase into fat phase with the help of hand blender for 10 min to form coarse emulsion followed by process of homogenization at 175 bars. It was then pasteurized at 75ºC for 15 min, packed into PET jars after cooling at room temperature and stored at refrigerated temperature (Fig. 1). A control table spread (CTS) was prepared by replacing CE with flaxseed oil, while keeping the levels of other ingredients same as obtained for optimized innovative table spread (ITS).

3.2 Optimization of table spread (based on texture and sensory analysis)

The textural attributes of 27 treatment combinations were studied in triplicate using Texture Analyzer TAXT2i (Stable Micro System, Godalming, Surrey, UK). The product was subjected to application of force to a depth of 15 mm by a spreadability rig attached to the texture analyzer fitted with 25 kg load cell. The results were obtained in the form of work of shear (N·s), firmness (N), work of adhesion (N·s) and stickiness (N).

All the combinations of prepared table spreads were evaluated by 6 trained panellists (between 30 to 45 years of age) on the basis of 9-point hedonic scale for flavor, body and texture, color and appearance, spreadability, and overall acceptability. The samples were served in polystyrene cups along with bread and spoon for checking the spreadability. One combination was selected for preparation of optimized innovative table spread (ITS) based on the statistical analysis of textural and sensorial data as given in Sect. 3.5.

3.3 Characterization of ITS for microstructure, zeta potential and thermo gravimetric profiling

Fluorescence microscopy: A thin smear of ITS was prepared on glass slides. The slides were individually stained with 10 µl of Nile Red (0.1 g/L in propan-2-diol), aqueous solution of Nile blue (0.1 g/L) and calcofluor white and kept under refrigerator for 5 min for staining fat, protein and carbohydrates, respectively. The samples were covered with cover slip and kept under refrigerated condition for 10 min before viewing under the fluorescence light microscopy (Carl Zeiss Axiolab5). One smear of ITS was prepared on a glass slide and sequentially stained with all the dyes before viewing under 100X magnification of fluorescence microscope (Fig. 2).

Zeta potential: The zeta potential of ITS was measured by using Zetasizer Nano-ZS90 by dissolving the sample separately in Millipore water and ethanol. The samples were diluted to 0.1% (v/v) and measurements were made at 25 °C and an equilibrium time of 120 s was given.

Thermo gravimetric analysis (TGA): The thermal characterization of ITS was carried out by TGA using TGA 2 STARe system, METTLER TOLEDO, Switzerland. A fixed amount (mentioned in Fig. 3) of ITS was loaded in the crucible, and placed in furnace and experiment was run at temperature programmed from 25 to 800 °C with heating rate of 10 °C/min under nitrogen flow rate of 100 mL/ min.

3.4 Comparative evaluation of ITS and CTS

3.4.1 Proximate composition

Protein content was determined by Kjeldahl method (IDF 20 B 1993) using Pelican Kjeltec digestion equipment (2300, KjeltecAnalyzer, FOSS) followed by distillation and titration [15]. Fat [16], moisture [17] and ash [18] content of table spread was determined using standard methods.

3.4.2 Physico-chemical properties

3.4.2.1 Color value, pH and titratable acidity

Hunter Lab Color Flex (Reston, VA, USA) was used to measure color of samples. Results were expressed as L*, a*, b* values and yellowness index (YI). For measuring pH, 10 g of sample was mixed with 10 mL of distilled water and a slurry was prepared thereof. The pH of slurry was determined at 25 °C using microprocessor-controlled pH analyzer with combined glass electrode.

About 10 g of the sample was accurately weighed in a 250 mL conical flask. It was followed by addition of 30 mL warm distilled water and 1 mL of phenolphthalein indicator (0.5 g phenolphthalein was dissolved in 100 mL of 50% ethyl alcohol). The contents were properly mixed and titrated against standard 0.1N NaOH solution.

3.4.2.2 Antioxidant assays

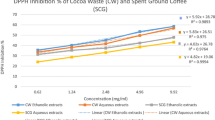

Antioxidant analyses was done using ABTS (2, 2-Azino-bis (3-ethylbenzothiazoline-6-sulphonic acid), DPPH (2, 2-Diphenyl-1-picrylhydrazyl) and FRAP (Ferric Reducing Antioxidant power) assays.

Sample preparation: Ten grams of sample was weighed and 15 mL, 100% of methanol was added to it. Centrifugation was performed for 15 min at 4000 rpm. The supernatant was collected in a test tube, while 15 mL, 80% methanol was added to the pellet followed by centrifugation for same time. The supernatant was collected and mixed with previous supernatant. Further, 15 ml methanol (60%) was added to the pellet. Centrifugation was carried out under same conditions and supernatant was collected and mixed with previous supernatant. All the collected supernatants were mixed gently and termed as sample extract.

For ABTS antioxidant activity, 100 μl of sample extract and 2900 μl ABTS working solution were mixed together. These reactants were allowed to stand in dark for reaction followed by measuring absorbance after 30 min at 734 nm [19]. The standard curve was obtained by adopting same procedure as that of sample, but using Trolox as standard solution (μg/mL). The results of the sample were expressed as Trolox equivalent antioxidant capacity (TEAC; µg/g).

For DPPH antioxidant analysis, 50 μl sample and 3.95 mL of methanol were mixed. To this, 1 mL of 0.2 mM DPPH solution (prepared by adding 0.0394 g DPPH mixed in 50 mL methanol) was added for reaction to take place. After 30 min of incubation in dark at room temperature, the absorbance was measured at 517 nm using methanol as blank [20]. The standard curve was prepared using Trolox (μg/mL) and results were expressed in terms of TEAC Trolox equivalent antioxidant capacity (µg/g) sample.

The FRAP antioxidant activity was analyzed according to the method given by Benzie and Strain [21] with little modifications. 2850 µL of FRAP reagent (prepared by mixing 30 mL of acetate buffer, 3.0 mL of the TPTZ solution and 3.0 mL of ferric chloride solution) was mixed with 150 μl of the sample. The prepared FRAP reagent was warmed to 37 °C before use and absorbance was then measured at 593 nm after exactly 30 min of incubation. Standard curve was prepared using Trolox (μg/mL) as standard.

3.4.2.3 Oxidative stability

Free fatty acid [22], peroxide [22] and p-anisidine (AV) value [23] of fat spread was determined by using AOCS official methods (1998), while TBA value [24] was determined as per standard method given by King [24]. For this, to 3 g of extracted fat, 15 ml distilled water, 1 ml trichloroaceitic acid and 2 ml of 95% ethanol was added. The sample mixture was filtered after 5 min followed by taking 4 ml of the clear filterate and addition of 1 ml of TBA (prepared by dissolving 1.4 g TBA in 100 ml, 95% ethanol) in it. The optical density was observed at 532 nm after the sample was incubated in water bath at 60 °C for 60 min.

3.4.2.4 Total carotenoid content (TCC)

The TCC was analysed based on the protocol standardized by Luterotti and Kljak [25].

3.4.2.5 Fatty acid determination

Extraction of fat Ten grams of sample was taken into Mojonnier flask. 100 mg pyrogallic acid, and 2.0 mL triglycerides internal standard solution was added into it along with few boiling granules. 2.0 mL of ethanol was added and mixed gently followed by addition of 4.0 mL distilled water and 2.0 mL NH4OH. After digestion at 70–80 °C, solution was kept basic with addition of ammonium hydroxide. Extraction of fat was done using diethyl ether and petroleum ether followed by evaporation of solvents.

Methylation To the extracted fat, 2.0 mL of BF3 was added and vial was sealed using screw cap top containing Teflon/silicon septum. The vial was then heated to 100 °C for 45 min with gentle shaking at an interval of every 10 min followed by cooling to room temperature. Five mL distilled water, 1.0 mL hexane and 1.0 g Na2SO4 were added to vial with shaking for 1 min. The layers were allowed to separate and top layer containing fatty acid methyl esters (FAMEs; including FAME of triglyceride internal standard solution) was carefully transferred to another vial containing 1.0 g Na2SO4.

Gas chromatography (GC) Relative retention times and response factors of individual FAME was obtained by GC analysis of standard solution of individual and mixed FAMEs. One μl of mixed FAMEs standard solution was injected. Mixed FAMEs standard solution was used to optimize chromatographic responses before injecting test solutions. The retention time for each FAME was calculated in individual FAME standard solutions. This retention time was used to identify FAMEs in mixed FAME standard solution.

where,

Ps1 = peak area of individual fatty acid in mixed FAMEs standard solution.

Psc110 = peak area of C110 fatty acid in mixed FAMEs standard solution.

Wc110 = weight of internal standard in mixed FAMEs standard solution.

W1 = weight of individual FAMEs in mixed FAMEs standard solution.

One μL sample of FAME was injected into Gas chromatography column coupled with Flame ionization detector (FID), with injection temperature of 230 °C and FID temperature of 240 °C. The oven temperature was programmed as follows:

The carrier gas (nitrogen) was set at the flow rate of 1 mL/ min (4psi). The pressure for air and hydrogen was kept between 4 and 6psi. The sample was run and digital chart of peaks were obtained and analyzed.

3.5 Statistical analysis

All the analyses were carried out in triplicate. Results are expressed as mean ± standard deviation (SD). 33 factorial experiments were employed for selecting levels of CE, CS and TC (Table 1). The data obtained from texture profile and sensory analyses were analyzed by three-way ANOVA using the Proc GLM method of SAS 9.3. The comparison of ITS and CTS were made using t test.

4 Results and discussion

Three important ingredients, namely CE (functional natural colorant), TC (emulsifier and structure provider) and CS (natural taste enhancer) were optimized using 33 factorial experiment resulting in 27 treatment combinations and analyzed in triplicate for textural properties like firmness, adhesiveness, etc.; and sensorial properties so as to have an ideal blend of objective (textural study) and subjective (sensorial study) characteristics for selection of final combination. However, the other ingredients like WPC, emulsifier, stabilizer, etc. were kept constant based on the preliminary trails. Optimization for obtaining the best combination of variable ingredients was carried out by studying the effect of ingredients solely and also their interaction (Table 1).

4.1 Optimization based on textural attributes

Heptaesthesis is mechanical behaviour of material and reveals information pertaining to perceived texture. Textural parameters are key complex physical properties that are a result of structural constitution of food. These quality traits determine suitability of ingredients for production and subsequent consumption of final product prepared from them. The effect of interaction of different levels of CE, TC, and CS on textural parameters namely firmness, work of shear, stickiness, and work of adhesion were studied and discussed hereunder.

4.1.1 Firmness

The force that increases up to the point of maximum penetration depth in force-distance curve is referred to as firmness (N). The maximum firmness (~ 24 N) was obtained at 20, 1.5, and 0.50% or 25, 1, and 0.30% of CE, CS, and TC, respectively, while minimum firmness (4.08 N) was obtained at the corresponding values of 15, 1.25 and 0.30% (Table 1). The levels of CE, CS, and TC individually and in combination showed a significant effect (p < 0.05) on firmness of ITS (Table 2). Tiwari and Sachdeva [13] revealed that firmness is slightly influenced by TC, while it showed a non-significant effect on spreadability and mouthfeel of spread. Further, TC coupled with tri-sodium phosphate is not as effective as TC alone. In our study, firmness of ITS increased significantly (p < 0.05) with increasing level of CE and CS alone and in combination (Table S1). WPC, globular proteins forming compact structure, were employed in fixed quantity in all formulations. The salt induced strong attractive gelation of WPC with increasing concentration of CS could have resulted in increased firmness of ITS- a MIPE, more because pH of product was near pI of WPC. Literature suggests that in absence of salt, whey protein isolates result in flowable emulsion, while the presence of salt leads to self-supportive non-flowable gel [26]. The minimum firmness from interaction of CE and CS (6.80N) was obtained at their respective level of 15% and 1.25%, while maximum value (20.70N) was obtained at their corresponding level of 25% and 1.25% (Table S1). The interaction of CS and TC at corresponding levels of 1% and 0.5% showed minimum (11.43N) firmness and at 1.5% and 0.5%, respective levels showed maximum (17.92N) firmness (Table S2). Similarly, minimum (6.98N) and maximum (21.89N) firmness for interaction of CE and TC were obtained at 15%, 0.3%; and 25%, 0.3%, respective levels (Table S3). The decreasing trend in firmness of ITS on increasing concentration of flaxseed oil was reported by Pandule et al. [27]. This could be attributed to high unsaturated fatty acid content (89.29%) of flaxseed oil [28]. Table spreads are required to possess minimum firmness for providing good overall acceptability. Moreover, high negative correlation has been reported between firmness and spreadability [29] and hence lower firmness is required for ease in spreadability. The minimum value (4.08 N) of firmness was obtained at 15% CE, 1.25% CS, and 0.3% TC which could be selected as an optimized level based on firmness (Table 1).

4.1.2 Work of shear

Work of shear (N.s) is the amount of energy required to perform shearing process. It corresponds to area under penetration cycle (downstroke) in force-distance curve and measures resistance offered by sample while the probe penetrates in it during compression. All the levels of CE, CS, and TC individually and their interaction showed significant effect (p < 0.05) on work of shear except interaction of CE and CS (Table 1). This means that these variables affect amount of work necessary for inserting spoon or scoop into the product and its in-mouth spreadability. Table S2 indicates that mean value of work of shear decreased significantly (p < 0.05) with increasing level of CS from 1 to 1.25% and thereafter increased significantly (p < 0.05) with increasing level of CS from 1.25 to 1.5% but value of work of shear for TC increased significantly with its increasing concentration from 0.3 to 0.4%, while it remained non-significant from 0.4 to 0.5% level of TC. TC being an emulsifying salt reduces oiling off in MIPE, which could have resulted in increased work of shear with its increasing concentration. The mean value of work of shear significantly (p < 0.05) increased with increasing level of CE from 15 to 25% (Table S2, S3). The minimum (21.52N.s) and maximum value (40.79 N.s) of work of shear obtained from interaction of CS and TC were at a respective level of 1.25%, 0.3%; and 1.5%, 0.5%. The minimum work of shear (18.57 N.s) was obtained when level of CE and TC were 15% and 0.3%, respectively, while maximum value (42.04 N.s) was obtained with corresponding levels of 20% and 0.4% (Table S3). Thus, 15% CE, 1.5% CS, and 0.3% TC could be the best-optimized combination on account of minimum value for work of shear in range (3.64 to 27.26 N·s) with that reported by Raj [30] who optimized channa-based reduced-fat spread with improved functional attributes.

4.1.3 Stickiness

Stickiness is used for expressing maximum negative peak upon withdrawal of probe from sample. Weenen et al. [31] reported that stickiness is an important sensory characteristic of semi-solid food products, described as a sticky feeling that can be perceived by tongue and palate. Here, CE and CS showed a significant effect (p < 0.0001) individually and in combination, while TC showed non-significant effect (p > 0.05) individually but significant effect (p < 0.0001) on interaction with CE and CS. Also, interaction of CE, CS, and TC showed a significant effect (p < 0.0001) on stickiness of ITS (Table 2). The stickiness values should not be too low or too high, as too low stickiness exhibits liquid behaviour, while too high value may resist the separation from host leading to poor spreadability [32]. The mean value of stickiness increased significantly (p < 0.05) with increasing level of CE (15% to 25%). Also, stickiness increased with CS (1 to 1.5%) alone and in combination with CE. The minimum stickiness (-5.88N) from interaction of CE and CS was obtained at 15% and 1.25%, respectively and maximum (-20.41N) was obtained from their corresponding interaction at 25% and 1.25% (Table S1). Kumar (2015) used blends of olive oil and butterfat for the preparation of mixed chocolate spread and reported increase in stickiness with increase in content of olive oil. A similar trend is observed in our study with increasing concentration of CE in ITS. This could be attributed to the presence of flaxseed gums in CE as carotenoids were extracted in un-refined flaxseed oil [5]. Flaxseed gums besides being natural source of soluble dietary fibre, exhibit thickening, gelling and emulsifying properties. The interaction of CS and TC at 1% and 0.5% showed minimum (− 8.87N) stickiness, while maximum (− 16.62N) was obtained at their corresponding levels of 1.5% and 0.5% (Table S2). Also, minimum stickiness (− 6.28N) from interaction of CE and TC was obtained at 15% and 0.3% level, while maximum value (-21.36N) from their interaction was obtained at 25% and 0.3%, respectively (Table S3). Kumar [33] stated that optimized product with stickiness range of − 9.08 to − 2.175 N possessed good textural attributes. Therefore, results from our study suggest that 15% CE, 1.25% CS, and 0.3% TC could be selected for preparation of ITS with − 7.29 ± 0.04 N stickiness.

4.1.4 Work of adhesion

In the force-distance curve, area under penetration cycle (upstroke) representing amount of energy required to remove the probe from a sample is referred to as ‘work of adhesion’ (N·s). CE, TC and CS individually and in combination showed a significant effect (p < 0.05) on the work of adhesion, except the interaction of CE and CS which resulted in non-significant effect (Table 2). The mean value of work of adhesion increased significantly (p < 0.05) with increasing level of CS from 1 to 1.25% and thereafter increased non-significantly (p > 0.05) with increasing level of CS from 1.25% to 1.5% but value of work of adhesion due to TC increased significantly (p < 0.05) with increasing concentration of TC from 0.3 to 0.5%. The minimum (− 9.28N·s) work of adhesion obtained from interaction of CS and TC at 1% and 0.3% level, respectively and maximum value (-14.16N·s) was obtained at 1.25% CS and 0.5% TC (Table S2). The mean value of work of adhesion increased significantly (p < 0.05) with increasing level of CE from 15 to 25% and TC from 0.3 to 0.5%. Fat spreads formulated with flaxseed oil showed higher adhesiveness and firmness than those prepared with soybean oil when other ingredients were constant [28]. The minimum (− 7.23N.s) work of adhesion was obtained with 15% CE and 0.3% TC, while maximum mean value (− 16.43N.s) was obtained with corresponding levels of 20% and 0.5% (Table S3). The maximum work of adhesion (~ 18N·s) was obtained when levels of CE, CS, and TC respectively were 25, 1.25 and 0.50%, while minimum work of adhesion (~ 8 N·s) was obtained with their corresponding values of 15, 1.25 and 0.30%; 15, 1.50 and 0.30%; and 15, 1.25 and 0.40 (Table 1). Lumor et al. [34] stated that more adhesive spread is more likely to stick to utensils such as spreading knife; hence, adhesiveness or work of adhesion of the product should be lower.

4.2 Optimization based on sensory attributes

4.2.1 Color and appearance

The color and appearance (C&A) of any food product is the first and most important parameter which decides its acceptance and/or rejection. It is often said, ‘we eat by our eyes’. It can be observed from Table 1 that C&A score of ITS varied from 6.75 to 7.91. CE (at 15, 20 and 25%) and CS (at 1, 1.25 and 1.50%) individually (Table S1) and in combination (Table 1) showed a highly significant effect (p < 0.0001) on C&A of ITS. On the contrary, TC (at 0.3, 0.4, and 0.5%) individually and in combination with CE and CS; and interaction of all three ingredients showed non-significant (p > 0.05) effect (Table 2). On this basis, the lowest level of TC could be selected for preparation of optimized product (ITS). However, TC delivers multiple precedence to product as it is color retention agent, stabilizer, anticaking agent, acidity regulator and preservative, etc. It can be deduced from Table S1 that C&A score decreased significantly (p < 0.05) with increasing level of CE (from 15 to 25%) and CS (from 1 to 1.50%). The minimum average score (6.97) was obtained when concentration of CE and CS were 25% and 1.25%, respectively, while maximum average score (7.91) was obtained with a corresponding combination of 20% and 1.25% respectively, indicating that C&A score got reduced at higher level of CE (Table S1). Recently, Pandule et al. [27] found decreasing trend in C&A score when omega-3 enriched butter was prepared using flaxseed oil. El-Hadad et al. [35] reported that on using olein oil as a source of fat for preparation of fat spread, C&A were negatively correlated with increasing level of olein oil. Contrary to this, some authors concluded non-significant effect of omega-3 oils on C&A scores. El-Waseif et al. [28] and Kolanowski et al. [36] found non-significant (p > 0.05) effect on C&A score of table spread formulated using ALA rich flaxseed oil; and EPA (Eicosapantaenoic acid) and DHA (Docosahexaenoic acid) rich fish oil, respectively. However, in present study, the increasing level of CE and CS individually and in combination reduced the score for C&A. This could be attributed to deeper yellow color of the product at higher level of CE due to presence of more amount of carotenoids in it. Hence, the interaction level of CE and CS resulting in highest C&A score, while minimum level of TC due to its non-significant effect (p < 0.05) on said score could be selected; resulting in combination possessing 20% CE, 1.25% CS and 0.3% TC.

4.2.2 Flavor

Food flavor perception is a complex process including senses of smell and taste, as well as chemesthesis (the common chemical sense; also called pungency or irritation). Each sense contributes unique feature to flavor by interacting with various types of chemical stimuli or by brain interactions that regulate the responses of other senses [37]. From Table 2, it can be observed that CE and CS individually and in combination showed a highly significant (p < 0.0001) effect on the flavor. This could be due to the fact that both salt and fat stimulate appetite [38]. The researchers suggest that breakdown products of fats (i.e. fatty acids) are perceived by gustatory system and fat is often considered primary sixth taste. However, the ability of an individual to discriminate between different fat concentrations depends on its body weight, fat consumption, etc. [39].

The interaction of all three ingredients, i.e. CE, CS, and TC showed a significant (p < 0.05) effect on flavor of ITS (Table 2). The interaction of CE and CS resulted in minimum (6.78) and maximum mean score (7.59) at 20, 1.5% and 15, 1%, respectively (Table S1). It can be deduced from Table S1 that the overall mean value of sensory score for flavor decreased significantly (p < 0.05) with increasing concentration of CE and CS. Bolhuis et al. [40] studied effect of combination of fat and salt on taste preference and perception and revealed fat concentration of 20% was less pleasant, while 0, 5 and 10% didn’t differ in pleasantness. Flavor represents combination of aroma and taste [41]. The characteristic nutty aroma and slightly bitter taste of flaxseed oil may be perceived unacceptable to some individuals which could have resulted in decreasing trend in flavor scores with increasing concentration of CE. Similar pattern of results is reported by earlier workers [28]. Pandule et al. [27] reported decreased flavor score at higher levels of flaxseed oil. Butter substitution with flaxseed oil in the preparation of spreadable processed cheese showed dramatic reduction in flavor scores [42].

TC, individually and in combination with CE and CS showed non-significant (p > 0.05) effect on flavor of ITS, therefore its lowest level could be selected. However, the interaction level of CE and CS leading to maximum flavor could be selected. Thus, based on different combinations examined, CE, CS and TC at 15%, 1%, and 0.3%, respectively could be selected due to the highest sensory score for flavor (Table 3). WPC and guar gum employed for encapsulating CE (consisting of carotenoids and flaxseed oil) in ITS might have improved its stability and sensorial acceptability, besides the presence of spice mix in ITS.

4.2.3 Body and texture

Body and texture is an important characteristic that determines acceptability of any food product by the consumers. The results revealed that CE individually and in combination with CS showed highly significant (p < 0.0001) effect on body and texture, while CS individually and in combination with TC showed significant (p < 0.05) effect on body and texture of ITS (Table 2). TC besides acting as stabilizer, also acts as a flavor sharper, food preservative, colorant retention agent and acidity regulator. TC, individually and in combination with CE, showed non-significant effect (p > 0.05) on body and texture of ITS. However, the combined interaction of CE, CS and TC showed significant effect (p < 0.05) on body and texture of ITS (Table 2). The mean score of body and texture decreased significantly (p < 0.05) with increasing levels of CE (from 15 to 25%) and CS (from 1 to 1.50%) (Table 3). This could be due to a corresponding decrease in level of butter with the increase in level of flaxseed oil used in preparation of ITS. Similar decrease in body and texture score was observed by Mijena [43] when the amount of milk fat was replaced with sesame oil. The author attributed this to the rich textural attributes associated with milk fat.

The minimum (6.64) mean score was obtained when concentration of CE and CS were 20% and 1.50%, respectively, while the maximum (7.67) was obtained with corresponding combination of 20% and 1%, respectively. The minimum (6.92) mean score was obtained when concentration of CS and TC were 1.5% and 0.3% respectively, while the maximum mean score (7.61) was obtained with their respective concentration of 1% and 0.4%. This indicates important role of CS and TC in maintaining body and texture as its mean score got reduced significantly (p < 0.05) with increasing levels of CS (from 1 to 1.50%). Dostalova [44] reported that in table spread, the role of emulsifiers is to reduce the interfacial tension between the aqueous phase and oil phase thereby improving the stability of water-in-oil and oil-in-water emulsion and helping to improve body and texture of spread. Based on different combinations examined (Table 1); CE, CS and TC at 20%, 1%, and 0.3%, respectively could be selected as this yielded maximum sensory score for body and texture of ITS. Pandule et al. [27] and Ahmed et al. [42] also reported non-significant effect of flaxseed oil (CE in our case) on body and texture.

4.2.4 Spreadability

The term ‘spreadability’ is often used in connection with the solid-state of table spreads. The spreadability offered by table spread is influenced by its consistency, texture and shear, besides the material on which fat is spread (i.e. the host). It indicates the capacity of fat spreads to be applied as thin layer on the host [45]. The spreadability score of ITS varied from 6.75 to 8.00 (Table 1). CE and CS individually and in combination showed highly significant effect (p < 0.0001) on spreadability of ITS (Table 2), while TC individually and in combination with CE and CS showed non-significant (p > 0.05) effect. Thus, the lowest level of TC could be selected. The interaction of CE, CS, and TC showed significant effect (p < 0.05) (Table 2). The minimum average score (6.83) was obtained at 20% CE and 1.50% CS, while the maximum average score (7.92) was obtained with the corresponding combination of 15% and 1%. This concludes that scores of spreadability decreased significantly (p < 0.05) with the increasing level of CE (from 15 to 25%) and CS (from 1 to 1.50%). With increasing level of CE, ITS acquired more flowy character due to augmented content of unsaturated fatty acids in it. These results can be corroborated well with textural attributes like firmness. A too high or too low firmness is not desirable in table spreads as these lead to lack of spreadability in end product with higher firmness values, while lesser firmness imparts more pourable character to product. Both of these influence consumer acceptability of table spread. The results of sensory panellist manifest the instrumental results of firmness. Thus, CE at 15%, CS at 1%, and TC at 0.3% could be selected based upon three way ANOVA analysis of spreadability.

4.2.5 Overall acceptability

The overall acceptability of spread and spread like products are mainly dependent on their color and appearance, flavor, body and texture, and spreadability. It can be observed that maximum score (7.70 ± 0.46) for overall acceptability was obtained at the interaction level of 15% CE, 1% CS, and 0.30% TC, while the minimum score (6.58 ± 0.20) was obtained at 20% CE, 1.5% CS, and 0.30% TC (Table 1). CE showed a highly significant effect (p < 0.0001); CS showed significant effect (p < 0.05), while TC showed a non-significant effect (p > 0.05) on overall acceptability (Table 2). The interaction between CE and CS showed a significant effect (p < 0.0001), while the interaction between CE and TC; and TC and CS showed a non-significant effect (p > 0.05) on overall acceptability of ITS (Table 2). The minimum score of overall acceptability (6.64) due to interaction of CE and CS was obtained at 20% and 1.5%, respectively, while the maximum score (7.63) was obtained at corresponding levels of 15% and 1% (Table S1). The overall acceptability of ITS decreased significantly (p < 0.05) with the increasing level of CE (from 15 to 25%) and CS (from 1 to 1.5%) (Table S1). Hence, CE and CS showing maximum overall acceptability score could be selected, and lowest level of TC could be selected as it non-significantly affected overall acceptability score of spreadability. Thus, CE, CS, and TC at 15%, 1%, and 0.3% levels, respectively could be selected based on overall acceptability of ITS.

Table 3 gives the expected combination that could be selected based on the individual parameters studied. It can be deduced from Table 3 that 15% CE, 1% CS and 0.3% TC could be selected for the preparation of ITS as it showed optimum values for most of the parameters. The combined effect of CE, CS and TC showed a non-significant effect (p > 0.05) on the color and appearance of the table spread, therefore any level of these could be selected for preparation of ITS. There existed a non-significant difference between body and texture as affected by CE, CS and TC at 20, 1 and 0.3%; and 15, 1 and 0.3% level, respectively. Moreover, a non-significant difference (p > 0.05) existed between values for stickiness (-7.29 ± 0.04) and work of adhesion (-8.49 ± 0.26) at 15% CE, 1.25% CS and 0.3% TC with that of the respective values (-8.30 ± 1.39 and -9.07 ± 0.72) at 15% CE, 1% CS and 0.3% TC. Similarly, non-significant difference existed for the values for work of shear (23.25 ± 1.39) at 15% CE, 1.5% CS and 0.3% TC with those at 15% CE, 1% CS and 0.3% TC (25.75 ± 1.97). However, significant difference existed between the values of firmness at a level of 15% CE, 1.25% CS and 0.3% TC (4.08 ± 0.15) with that of the respective values of 15, 1 and 0.3% (9.43 ± 1.05). As discussed earlier, Kumar [33] advocated the range of firmness to be 2.87–12.47N during optimization of functional mix chocolate fat spread. Therefore, 15% CE, 1% CS and 0.3% TC level was selected for the preparation of ITS.

4.3 Characterization of innovative table spread (ITS) for microstructure, zeta potential and thermo gravimetric profiling

4.3.1 Fluorescence microscopy

Fluorescence microscopy is an advanced technique for studying internal structure of food by differentially staining its various components by fluorescent dyes. The micrographs of ITS labelled individually with different dyes are presented in Fig. 2. It can be observed from Fig. 2a that fat droplets, stained with Nile red, are evenly distributed throughout ITS matrix. The structure clearly revealed presence of stable O/W emulsion as no coalescence of fat droplets is observed. Figure 2b shows ITS stained with Nile blue which labels protein fraction. The fat droplets in Fig. 2b are indicated with arrow pointed towards black spheres/ circles as Nile red stain was not employed in these slides. Further, Fig. 2c reflects the presence of carbohydrates uniformly dispersed in water phase of emulsion. Figure 2d depicts the microstructure of ITS after staining the slide with all dyes. Earlier, Hu et al. [46] characterized Pickering HIPE using Nile red and Nile blue dyes. The results obtained in present study are in accordance with literature.

4.3.2 Zeta potential

Zeta potential, an important physical property, measures charge stability of dispersion system and is exhibited by the particle i.e. macromolecule dispersed in suspension. Zeta potential of O/W emulsion was observed both in water and ethanol. The results revealed significantly higher (p < 0.05) zeta potential of ITS in Millipore water (− 56.867 mV ± 0.850) over ethanol (− 20.8 mV ± 2.82) indicating its higher stability in aqueous system. However, the product showed physical stability towards coalescence in both the systems due to high electric charge necessary for repulsive electrostatic force amongst the particles. Mezdour and Korolczuk [47] reported similar behaviour for zeta potential of sodium caseinate in water–ethanol solutions. The solvent used for dissolving sample modulates the local electrochemical environment leading to redistribution of interface charges [48]. Further, ethanol possesses lower dielectric constant than water which might have resulted in the reduction in zeta potential in ethanol over water. Alternatively, ethanol might have weakened the adsorbed protein (WPC) layer due to competitive adsorption leading to reduction in zeta potential of ITS.

4.3.3 Thermogravimetric analysis

Thermogravimetric analysis (TGA) was employed for measuring mass of ITS as a function of temperature and/ or time as the sample was subjected to controlled temperature program under controlled atmosphere. The results revealed typical sigmoid curve wherein first part of the curve i.e. until 143 °C was similar to that obtained by Ahmad et al. [49] and Razafindralambo et al. [50]. The first sharp slope reflects 23.707% reduction in mass of ITS between 28 to 81.17 °C. This could be attributed to removal of volatiles and free water present in ITS. This is followed by a plateau (Fig. 3) till 143 °C, wherein 3.212% reduction in weight was observed. At this point, the total reduction in weight was 26.919%. It can be inferred from the curve that the food sample showed a thermal stability till 143 °C as sample did not undergo pyrolysis. It was interesting to note a sharp decrease in weight gain till 423.67 °C. The total reduction in weight till this point was 87.848%. This second part of TGA curve could be attributed to decomposition step, besides removal of the bound water. A further decrease in weight has been observed from 423.67 to 581.17 °C. The residual compounds at this temperature could be carbon black and inorganic compounds [50].

4.4 Comparative evaluation of innovative table spread (ITS) and control table spread (CTS)

4.4.1 Proximate composition

Table 4 indicated no significant (p > 0.05) difference in the proximate composition of ITS and CTS suggesting addition of CE did not affect its proximate composition. However, each of these major nutrients play a significant role in the functional properties of fat spread. Fat, besides influencing the textural properties like spreadability, firmness, plasticity and thixotropy [51] of final product, also acts as a vital carrier of fat soluble vitamins and essential fatty acids [52]. The developed product fell into the category of MIPE due to presence of ≈ 51% fat content being present as dispersed phase (Fig. 1, Table 4). Miao et al. [11] stated that the emulsions possessing internal phases between 50 and74% can be classified as MIPE. The emulsifying properties of WPC could have attributed in stabilizing MIPE as WPC was used as an ingredient during formulation of product [8]. Further, it also offers organoleptic, functional and nutritional properties in addition to contributing towards improving water holding capacity and viscosity of the aqueous phase. Moreover, milk protein imparts creamy mouthfeel to the spreads thereby increasing the consumer acceptability. Pandule et al. [27] fortified butter with two different levels of flaxseed oil-WPC emulsion and reported the proximate composition of developed product to be 85–87% fat, 0.014–0.005% protein and 12–14% moisture. The product reported is a HIPE due to high fat content. In a recent study, Hitlamani, et al. [53] formulated a virgin coconut oil based spread possessing high fiber (11.2%) and high protein (9.23%) with 67.35% fat.

4.4.2 Physico-chemical analysis

4.4.2.1 Color value, pH and acidity

L* is the measure of lightness of a product and its value ranges from 0 (black) to 100 (white). On the other hand, a* indicates redness with values spread over + 60 (red) to -60 (green). A significantly (p < 0.05) higher L* and a* value of CTS (76.02 ± 0.196; 2.546 ± 0.030) over ITS (72.80 ± 0.085; -1.680 ± 0.032) indicate whiter and more reddish tinge of CTS. On the other hand, ITS appeared to be darker with more greenish which could be attributed to presence of carotenoids in ITS. The b* value ranges from + 60 (yellow) to − 60 (blue) and indicates yellowness of product. Unlike L* and a*, b* value of CTS (22.076 ± 0.102) was significantly (p < 0.05) lower than that of ITS (34.356 ± 0.136). This could be due to the presence of CE in ITS.

The yellowness index (YI) of novel and innovative carotenoids rich developed table spread (ITS) was significantly (p < 0.05) higher than CTS. Extracted carotenoids hold tremendous potential to be utilized as functional natural colorant in a wide range of products including spreads and margarines. Ordóñez-Santos et al. [9] extracted carotenoids from mandarin epicarp and used it as natural coloring additive in bakery products (cake and bread). Cake and bread prepared from extract containing carotenoids revealed respectively, 2.52 ± 0.03 and 4.21 ± 0.24 mg β-carotene per 100 g of dry sample which could be a function of baking temperature of both i.e. 180 °C for bread and 215 °C for cake. The thermal processing might have led to degradation of carotenoids with series of processes like isomerization, oxidation and degradation associated with carotenoids. Recently, Suo et al. [10] extracted carotenoids from apricot flesh in corn oil and analysed its applicability in fries frying. The a* of fries fried by oil rich in carotenoids was 7.31 times higher than that of control. This is in accordance with our observation that carotenoid rich oil could improve color of processed products.

Table 4 revealed non-significant (p > 0.05) difference in pH (hydronium ion concentration) and acidity (total acid content) of both CTS and ITS. The values of acidity obtained are similar to those reported by earlier workers i.e. 0.09–0.73% [35] and 0.414–1.010% [54].

4.4.2.2 Antioxidant assays

Antioxidant potential of CTS and ITS were assessed by the ability of antioxidant to quench ABTS free radicals. Inhibition process of the auto-oxidation in lipids by antioxidant is linked to the ability of antioxidant to break the radical formation reaction [55]. The ABTS antioxidant activity for ITS was statistically higher as compared to CTS and was found to be 96.556 ± 0.663 and 195.190 ± 1.750 (μgTrolox eq./ml), respectively (Table 4). The ability of carotenoids to scavenge free radicals of ABTS depends on the number of conjugated double bonds as well as the functional group (carboxyl or hydroxyl group) at terminal ends [56]. This can also be correlated with lower peroxide values obtained for ITS over CTS.

The free radical of DPPH (2,2-diphenyl-1-picrylhydrazyl) is scavenged by the antioxidant present in food system resulting in reduction in its amount measured at 517 nm. ITS showed significantly (p < 0.05) higher DPPH antioxidant activity than CTS. On the basis of obtained results, it could be inferred that ITS have the strong ability to quench free radicals that could be attributed to the high reducing power of carotenoid present in ITS. On the other hand, FRAP (Ferric Reducing Antioxidant power) antioxidant activity method is based on the reduction of Fe3+ TPTZ complex (colorless complex) to Fe2+-tripyridyltriazine (blue colored complex) formed by the action of electron donating antioxidants at low pH. Baria et al. [6] reported that the number of the conjugated double bond (C = C) system in carotenoids influences the ferric reducing activity. This might have led to significantly higher (p < 0.05) FRAP antioxidant value of ITS than CTS (Table 4).

4.4.2.3 Oxidative stability analysis

Lipolysis of a fat-rich product adversely affects the consumer acceptability. Shahidi and Wanasundara [57] proposed PV measurement for evaluating the complete status of lipid oxidation in fat-based food corresponding to time because peroxides are susceptible to break down with time. This could be explained by the phenomenon of formation of primary oxidation substances i.e. peroxides during the initial stages of lipid oxidation. The peroxides undergo further oxidation and form different types of volatile and non-volatile secondary oxidation products. p-Anisidine value is a measure of secondary oxidation product, while thiobarbituric acid (TBA) determines oxidation product of fatty acids having three or more double bonds i.e. monoaldehyde (MDA), besides measuring TBA reactive components like 2-alkenes and 2, 4-alkadienals. Therefore, TBA is also called as TBARs (TBA reactive substances). All these parameters were determined in both the freshly prepared products and as expected ITS showed a non-significantly (p > 0.05) lower FFA, p-Anisidine and TBA value and significantly (p < 0.05) lower peroxide value in comparison to CTS (Table 4). This could be attributed to the presence of CE in it. Carotenoids have been advocated to enhance oxidative stability of lipid-rich foods like vegetable oils. Carotenoids extracted from pumpkin oil cake demonstrated protection against lipid oxidation (in terms of peroxide value) and oxygen barrier properties for flaxseed oil packed in active film containing carotenoids and maize zein [58].

4.4.2.4 Total carotenoid content (TCC)

Carotenoids are potent lipophilic antioxidants due to the linearly conjugated carbon bonds that provide high reduction potential [59]. The characteristic color of carotenoids, varying from yellow to red, is due to a polyene chain with several conjugated double bonds that function as a chromophore [60]. Table 4 revealed significantly (p < 0.05) higher TCC in ITS over CTS. This could be attributed to the presence of CE possessing carotenoids extracted from carrot pomace in flaxseed oil. These carotenoids from CE apart from providing characteristic yellow color to table spread increased its nutritional values as approximately 90% of carotenoids in orange carrots are β-carotene, which possess excellent pro-vitamin A activity and could play a significant role in the body [5]. Moreover, carotenoids with excellent antioxidant potential can also reduce rancidity related issues associated with fat rich products on long term storage. Thus, could be of great significance in extending shelf life of the product.

4.4.2.5 Fatty acid profile

The fatty acids of both CTS and ITS are given in Table 5. The uniqueness of both ITS and CTS are its high ALA content. ALA is an omega-3 polyunsaturated fatty acid which is essentially to be supplied through diet as it can’t be synthesized by human body. It may help in preventing CVD and certain malignancies, because of its anti-inflammatory effects [7]. The complete fatty acid profile of ITS and CTS is indicated in Table 5 and both showed non-significant difference. This is due to the presence of flaxseed oil and butter at same concentration in both the products. However, ITS contained carotenoids extracted from carrot pomace using flaxseed as a green solvent. The composition of ALA/100 g of fat was noted to be 13.623 and 13.816 g for CTS and ITS, respectively. ICMR (2005) recommended 1.3–1.6 g/ day ALA to ensure the nutritional adequacy to children (1.3 g/ day) and healthy adults (1.6 g/ day). Therefore, the consumption of one tablespoon (i.e. 10 g/ day) of these products can ensure ~ 50% and 42% nutritional adequacy for children and adults, respectively (purely on the basis of theoretical calculations).

5 Conclusion

The study successfully depicted deployment of carotenoids extracted from carrot pomace in flaxseed oil-a green solvent in formulation of an innovative table spread. The developed product was a medium internal phase emulsion stabilized by whey protein concentrate. The study utilized 33 factorial experiment and three-way ANOVA of Proc GLM method of SAS 9.3 statistical tool for understanding the effect of three indispensable ingredients, namely, vegetable oil (CE in our case), emulsifying salt (tri-sodium citrate) and common salt required for formulation of table spread. The optimization was based on evaluation of both subjective (sensory) and objective (texture profile) attributes. The optimized product showed stable medium internal phase emulsion, excellent thermal stability and antioxidant properties. Besides, CE served as an exceptional source of both carotenoids and ALA rich functional natural colorant in the novel and innovative table spread. In fact, on the basis of calculations, one tablespoonful of product could ensure ~ 50% and 42% nutritional adequacy of ALA for children and adults, respectively. In future, assays like in vivo and in vitro bioavailability studies may be carried out for widening the nutritional claims of the developed functional food.

Data availability

Data is provided within the manuscript or supplementary information files.

References

Šeregelj V, Vulić J, Ćetković G, Čanadanovć-Brunet J, Šaponjac VT, Stajčić S. Natural bioactive compounds in carrot waste for food applications and health benefits. Stud Nat Prod Chem. 2020;67:307–44.

Jayesree N, Hang PK, Priyangaa A, Krishnamurthy NP, Ramanan RN, Turki MA, Ooi CW. Valorisation of carrot peel waste by water-induced hydrocolloidal complexation for extraction of carotene and pectin. Chemosphere. 2021;272:129919.

Duval AM. Valorization of Carrot Processing Waste (Doctoral dissertation, California Polytechnic State University). 2020.

Kultys E, Kurek MA. Green extraction of carotenoids from fruit and vegetable byproducts: a review. Mol. 2022;27(2):518.

Tiwari S, Upadhyay N, Singh AK, Meena GS, Arora S. Organic solvent-free extraction of carotenoids from carrot bio-waste and its physico-chemical properties. J Food Sci Technol. 2019;56:4678–87. https://doi.org/10.1007/s13197-019-03920-5.

Baria B, Upadhyay N, Singh AK, Malhotra RK. Optimization of ‘green’ extraction of carotenoids from mango pulp using split plot design and its characterization. LWT-Food Sci Technol. 2019;104:186–94. https://doi.org/10.1016/j.lwt.2019.01.044.

Naghshi S, Aune D, Beyene J, Mobarak S, Asadi M, Sadeghi O. Dietary intake and biomarkers of alpha linolenic acid and risk of all cause, cardiovascular, and cancer mortality: Systematic review and dose-response meta-analysis of cohort studies. BMJ. 2021. https://doi.org/10.1515/DMDI.2000.17.1-4.189.

Tiwari S, Upadhyay N, Singh AK. Stability assessment of emulsion of carotenoids extracted from carrot bio-waste in flaxseed oil and its application in food model system. Food Biosci. 2022;47: 101631. https://doi.org/10.1016/j.fbio.2022.101631.

Ordóñez-Santos LE, Esparza-Estrada J, Vanegas-Mahecha P. Ultrasound-assisted extraction of total carotenoids from mandarin epicarp and application as natural colorant in bakery products. LWT Food Sci Technol. 2021;139: 110598. https://doi.org/10.1016/j.lwt.2020.110598.

Suo A, Fan G, Wu C, Li T, Cong K. Green extraction of carotenoids from apricot flesh by ultrasound assisted corn oil extraction: Optimization, identification, and application. Food Chem. 2023;420:136096. https://doi.org/10.1016/j.foodchem.2023.136096.

Miao C, Tayebi M, Hamad WY. Investigation of the formation mechanisms in high internal phase pickering emulsions stabilized by cellulose nanocrystals. Philos Trans Royal Soc A. 2018;376(2112):20170039.

https://www.mordorintelligence.com/industry-reports/global-food-spreads-market-industry. Assessed 15 Feb 2024.

Tiwari BD, Sachdeva S. Development and manufacturing techniques for development of paneer/chhana spread from buffalo milk cheddar cheese. Ind J Dairy Sci. 1991;37:21–3.

Jones AA. Ambient-stable sauces and pickles. In: Shelf-life Evaluation of Foods (Eds, Man, C M D and Jones, A A), 2nd edn, Aspen Publishers, Inc., Gaithersburg, MD, pp. 211–226. 2000.

AOAC (2000). Official methods of analysis of AOAC (17th ed.).

Bureau of Indian Standards. Determination of fat content in milk powder and similar products. Bureau of Indian Standards, IS-11721, Manak Bhavan, New Delhi: BIS. 1986.

Ranganna S. Handbook of analysis and quality control for fruit and vegetable products. Chennai: Tata McGraw-Hill Education; 1986.

ISI 18 (PART XI). ISI Hand book of food analysis, Part XI dairy products, Indian Standards Institute, Manak Bhavan, New Delhi. 1981.

Awika JM, Rooney LW, Wu X, Prior RL, Cisneros-Zealots L. Screening methods to measure antioxidant activity of sorghum (Sorghum bicolour) and sorghum products. J Agric Food Chem. 2003;51(23):6657–62.

Cuendet M, Hostettmann K, Potterat O, Dyatmiko W. Iridoidglucosides with free radical scavenging properties from Fagraeablumei. Helv Chim Acta. 1997;80(4):1144–52.

Benzie IF, Strain JJ. The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: the FRAP assay. Anal Biochem. 1996;239(1):70–6.

AOCS DF. Official methods and recommended practices of the American Oil Chemists' Society,5, 2–93. AOCS. 1998.

AOCS A. Official method. Anisidine value. pp (18–90). 1998.

King RL. Oxidation of milk fat globule membrane material. I. Thiobarbituric acid reaction as a measure of oxidized flavor in milk and model systems. J Dairy Sci. 1962;45:1165–71. https://doi.org/10.3168/jds.S0022-0302(62)89590-3.

Luterotti S, Kljak K. Spectrophotometric estimation of total carotenoids in cereal grain products. Acta Chim Slov. 2010;57:781–7.

Patel A, Longmore N, Mohanan A, Ghosh S. Salt and pH-induced attractive interactions on the rheology of food protein-stabilized nanoemulsions. ACS Omega. 2019;4(7):11791–800.

Pandule VS, Sharma M, Devaraj HC, Nath BS. Omega-3 fatty acid-fortified butter: preparation and characterisation of textural, sensory, thermal and physico-chemical properties. Int J Dairy Technol. 2021;74(1):181–91.

El-Waseif MA, Hashem HA, El-Dayem HA. Using flaxseed oil to prepare therapeutical fat spreads. Ann Agri Sci. 2013;58:5–11. https://doi.org/10.1016/j.aoas.2013.01.002.

Glibowski P, Zarzycki P, Krzepkowska M. The rheological and instrumental textural properties of selected table fats. Int J Food Prop. 2008;11(3):678–86.

Raj KA. Development of technology for reduced fat chhana based dairy spread with improved functional attributes. Doctoral thesis, National Dairy Research Institute, Karnal, Haryana, India. 2013.

Weenen H, Van Gemert LJ, Van Doorn JM, Dijksterhuis GB, De Wijk RA. Texture and mouthfeel of semisolid foods: commercial mayonnaises, dressings, custard desserts and warm sauces. J Texture Stud. 2003;34(2):159–79.

Adhikari B, Howes T, Bhandari BR, Truong V. Stickiness in foods: a review of mechanisms and test methods. Int J Food Prop. 2001;4(1):1–33. https://doi.org/10.1081/JFP-100002186.

Kumar P. Process optimization for the preparation of chocolate spread incorporating whey protein concentrate, cocoa powder, olive oil and butterfat using response surface methodology. J Food Process Presev. 2015;39(6):745–57. https://doi.org/10.1111/jfpp.12284.

Lumor SE, Pina-Rodriguez AM, Shewfelt RL, Akoh CC. Physical and sensory attributes of a trans-free spread formulated with a blend containing a structured lipid, palm mid-fraction, and cottonseed oil. J Am Oil Chem Soc. 2010;87:69–74. https://doi.org/10.1007/s11746-009-1470-8.

El-Hadad NN, Youssef MM, Abd El-Aal MH, Abou-Gharbia HH. Utilisation of red palm olein in formulating functional chocolate spread. Food Chem. 2011;124(1):285–90. https://doi.org/10.1016/j.foodchem.2010.06.034.

Kolanowski W, Franciszek S, EwaL Stanislaw B. Enrichment of spreadable fats with polyunsaturated fatty acids omega-3 using fish oil. Int J Food Sci Nutri. 2001;52(6):469–76.

Laing DG, Jinks A. Flavour perception mechanisms. Trends Food Sci Technol. 1996;7(12):387–9. https://doi.org/10.1016/S0924-2244(96)10049-2.

Leshem M. Biobehavior of the human love of salt. Neurosci Biobehav Rev. 2009;33:1–17.

Martínez-Ruiz NR, López-Díaz JA, Wall-Medrano A, Jiménez-Castro JA, Angulo O. Oral fat perception is related with body mass index, preference and consumption of high-fat foods. Physiol Behav. 2014;129:36–42.

Bolhuis DP, Newman LP, Keast RS. Effects of salt and fat combinations on taste preference and perception. Chem Senses. 2016;41(3):189–95.

Tietel Z, Plotto A, Fallik E, Lewinsohn E, Porat R. Taste and aroma of fresh and stored mandarins. J Sci Food Agri. 2011;91(1):14–23.

Ahmed SO, Awad RA, Ali MA, Rashid MR. Chemical and biological studies on spreadable processed cheese made using flaxseed oil as butter substitute. Al-Azhar J Agri Res. 2019;44(2):35–48. https://doi.org/10.21608/ajar.2019.101823.

Mijena RB. Production technology of sesame fat spread. Doctoral thesis, AAU, Anand. 2015.

Dostalova J. Low fat spreads. In: Dostalova J, editor. Encyclopedia of food science and nutrition. 2nd ed. New York: Academic Press; 2003. p. 3617–22.

Mendez DA, Fabra MJ, Martínez-Abad A, Μartínez-Sanz Μ, Gorria M, López-Rubio A. Understanding the different emulsification mechanisms of pectin: Comparison between watermelon rind and two commercial pectin sources. Food Hydrocoll. 2021;120:106957. https://doi.org/10.1016/j.foodhyd.2021.106957.

Hu YQ, Yin SW, Zhu JH, Qi JR, Guo J, Wu LY, Yang XQ. Fabrication and characterization of novel Pickering emulsions and Pickering high internal emulsions stabilized by gliadin colloidal particles. Food Hydrocoll. 2016;61:300–10. https://doi.org/10.1016/j.foodhyd.2016.05.028.

Mezdour S, Korolczuk J. Zeta potential of sodium caseinate in water-ethanol solutions. Milchwissenschaft Milk Sci Int. 2010;65(4):392–5.

Wu Y, Li Q, Deng F, Liang X, Liu H. Solvent effect on ζ potential at an aqueous/oil interface in surfactant-free emulsion. Langmuir. 2014;30(8):1926–31. https://doi.org/10.1021/la403900e.

Ahmad N, Sahrin N, Talib N, Ghani FA. Characterization of energy content in food waste by using thermogravimetric analyser (TGA) and elemental analyser (CHNS-O). J Phys Con Ser. 2019;1349(1):012140.

Razafindralambo H, Razafindralambo A, Blecker C. Thermophysical fingerprinting of probiotic-based products. Sci Rep. 2019;9(1):10011. https://doi.org/10.1038/s41598-019-46469-1.

Formo MW, Bailey AE. Bailey’s industrial oil and fat products. Hoboken: Wiley; 1997.

Rohm H, Weidinger KH. Rheological behaviour of butter at small deformations. J Texture Stud. 1993;24(2):57–172. https://doi.org/10.1111/j.1745-4603.1993.tb00041.x.

Hitlamani V, Huded P, Kumar GS, Chetana R. Development of high-fiber and high-protein virgin coconut oil-based spread and its physico-chemical, and sensory qualities. J Food Sci Technol. 2024. https://doi.org/10.1007/s13197-024-05990-6.

Kara HH, Mercan E, Gök G, Taşbaş S, Arslan M. Fatty acid profile and quality specifications of chocolate spreads. Arch Lebensmittelhyg. 2014;65(2):40–4.

Sulieman AERM, El-Makhzangy ATTYA, Ramadan MF. Antiradical performance and physicochemical characteristics of vegetable oils upon frying of French fries: a preliminary comparative study. J Food Lipids. 2006;13(3):259–76. https://doi.org/10.1111/j.1745-4522.2006.00050.x.

Rao AV, Rao LG. Carotenoids and human health. Pharmacol Res. 2007;55:207–16. https://doi.org/10.1016/j.phrs.2007.01.012.

Shahidi F, Wanasundara UN. Methods for measuring oxidative rancidity in fats and oils. In: Shahidi F, Wanasundara UN, editors. Food lipids, chemistry, nutrition, and biotechnology. 4th ed. New York: Marcel Dekker; 2002. p. 465–88.

Hromiš N, Lazić V, Popović S, Šuput D, Bulut S, Kravić S, Romanić R. The possible application of edible pumpkin oil cake film as pouches for flaxseed oil protection. Food Chem. 2022;371: 131197.

Vershinin A. Biological functions of carotenoids diversity andevolution. Biofac. 1999;10:99–104. https://doi.org/10.1002/biof.5520100203.

Ruiz-Sola MÁ, Rodríguez-Concepción M. Carotenoid biosynthesis in Arabidopsis: a colorful pathway. The Arabidopsis book/Am. Soc Plant Biol. 2012. https://doi.org/10.1199/tab.0158.

Funding

This work was done under the institute funded project number IXX12952 titled, ‘Preparation and Characterization of Micro/nano delivery systems for “green” carotenoids’.

Author information

Authors and Affiliations

Contributions

N.U.: Conceptualization, bench work, manuscript writing and editing, revising the manuscript and overall supervision KK: Bench work, manuscript writing and statistical analysis; S.T.: Manuscript writing and revising the manuscript; S.K.M.: writing draft of manuscript; R.M.: statistical analysis, data curation; A.K.S.: Manuscript editing, Laboratory facility C.K.: Manuscript editing and revision.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

The study did not require formal ethical approval as per the norms/ guidelines of institute of study i.e. ICAR-National Dairy Research Institute, Karnal. All the panellist in this study were adults and participated purely on a voluntary basis.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Upadhyay, N., Kamble, K., Tiwari, S. et al. Novel avenue of carotenoids & omega-3 rich carrot waste extract in innovative table spread: optimization (based on texture and sensory) and characterization. Discov Food 4, 67 (2024). https://doi.org/10.1007/s44187-024-00141-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44187-024-00141-4