Abstract

There is a growing need for plant-based yogurts analogue that meet consumer demands in terms of texture and sensory qualities. Stabilizers are crucial in plant-based yogurt's physical properties which help develop a thicker and creamier texture, mimicking dairy yogurt. Thus, the study aims to evaluate the effect of pectin, corn starch, and locust bean gum (LBG) at different ratios on the physical, chemical, microbiological, and sensory properties of chickpea yogurts analogue (CYA). The concentration of stabilizer significantly influenced (p < 0.05) the proximate compositions, physicochemical and textural properties, and cell viability. CYA with 0.5% pectin showed the highest fat (4.75 ± 0.07) and protein content (2.39 ± 0.07), which were significantly different from other formulations. A significant increase (p < 0.05) was observed in yogurt viscosity with the addition of corn starch and LBG at 1.0%. Firmness and consistency were improved in samples supplemented with 1.0% corn starch. The sensory evaluation indicated that adding LBG at the ratio of 0.5% generated better preference among panelists in terms of the appearance, color, and texture aspects. Meanwhile, commercial CYA showed significantly higher overall acceptability (p < 0.05) than other samples. The stabilizer’s behavior significantly impacts the features of CYA, and which with 0.5% LBG received high consumer acceptance, indicating good potential for CYA to be on the same shelf with other commercial yogurts analogue in the market.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Yogurt is one of the dairy products that is well-known for its nutritional values that improve the digestibility and bioavailability of some nutrients due to the acidification process and serves as a medium for fortification [1]. Due to the current trend where consumers are shifting to plant-based foods, the demand for plant-based yogurt analogues has also escalated. The term analogue refers to the resemblance of yogurt made from plant sources to traditional yogurt, particularly its appearance. This aligns with the current public trend of adopting a healthy and sustainable diet [2], along with the ethical issue that relates to the confining and slaughtering of animals [3].

Typically, the development of yogurt analogs is targeted at specific groups of consumers with dietary restrictions, such as those with cow milk protein allergies and lactose intolerance [4]. Yogurt analogs are also gaining popularity among vegetarians seeking a broader range of food options to meet their dietary preferences. While soymilk is common as a dairy milk substitute in the development of yogurts analogue owing to its high protein content and quality, and functional properties [5], it also possesses off-flavors and allergens that make it unappealing to consumers [6].

Therefore, other alternative legumes are being explored as a potential ingredient in yogurt making such as chickpea (Cicer arietinum L.) as it has high protein content ranging from 18 to 29% [7, 8]. Chickpea also exhibits antioxidant, antibacterial, anticancer, and antidiabetic properties [9]. The production of yogurts analogue from chickpea (CYA) is expected to have good functional properties with a lower cost of production. However, limited information is available on the suitability of the chickpea as a substrate in yogurt making, which necessitates further research.

As the yogurt quality is mainly influenced by textural and sensorial attributes, producing plant-based yogurt analogs with the ideal body, texture, consistency, and no syneresis remains the primary technological challenge in the food industry [10]. Due to the nature of proteins, yogurt analogue tends to have structural disadvantages in contrast to yogurt made from cow milk [5]. Furthermore, plant proteins form poor gelation and network in an acidic environment which can result in syneresis at early storage or during storage [11].

Stabilizers are generally incorporated to overcome this drawback by enhancing consistency and viscosity, which results in lower whey separation, increased binding of free water, and maintenance of gel structure [12]. The stabilizers may increase the shelf life of the product and ensure uniformity among batches. The most suitable stabilizer for a specific yogurt analogue should be chosen as there are plenty of hydrocolloids available which perform varyingly in food systems [13]. Furthermore, the concentration at which the stabilizer is added to the yogurt formulation can affect its physical properties. Therefore, this study aims to evaluate the effect of different types of stabilizers (pectin, corn starch, and locust bean gum) at different ratios on the physical and chemical properties of chickpea yogurt analogue and to determine the consumer acceptance of chickpea yogurt analogue based on several sensory attributes.

2 Materials and methods

2.1 Raw materials

Chickpea, sugar, vanilla powder, and corn starch were purchased from a local supermarket at Nilai, Negeri Sembilan. Pectin (molecular weight: 194.1394 g/mol) and locust bean gum (226.660 g/mol) were purchased from Chemiz (Selangor, Malaysia) and Xintai Biological Technology Co. Ltd. (Shanghai, China), respectively. Commercial chickpea yogurt was obtained from Jaya Grocer, Selangor and yogurt starter culture (L. Acidophilus, L. Bulgaricus and S. Thermophilus) was obtained from belle + bella (Lexington, MA).

2.2 Chickpea milk preparation

The process of extracting the milk was adapted with modifications to the ratio used from Wang et al. (2018). The chickpeas were soaked overnight and blended with distilled water at a ratio of 1:4 (chickpea to water; v: v) for 1 min. The blended legume was drained using a cotton cheesecloth to separate the extract from its solid residue. The chickpea milk was kept at refrigerated storage (4 °C).

2.3 Yogurt preparation

The yogurt samples were prepared and the chickpea milk (1 L) was preheated to 40 °C [14]. Sugar (3%), vanilla powder (0.2%) and stabilizers (pectin, corn starch and locust bean gum) at different ratios (0.5 and 1.0%) were incorporated and homogenized using a heavy-duty mixer (L2R, Silverson Machines Ltd., Buckinghamshire, England). The selection of ratio of stabilizer incorporated was based on the range reported by previous studies [15,16,17]. No stabilizer was added for negative control sample. Then, the mixture was pasteurized at 80–85 °C for 15 min and cooled down to 42 °C. The starter culture (0.5%) was inoculated, and the milk was incubated at 40 °C for 16 h to obtain a set-type yogurt. The yogurt was stored at 5–8 °C. All samples were prepared in three different containers and analyzed in triplicate for each analysis.

2.4 Proximate analysis

Moisture content, ash content, protein content, and crude fiber was determined according to the standard method of the Association of Official Analytical Chemists [18]. Fat content was determined using a Gerber method [19]. The carbohydrate content was calculated based on the overall proximate content.

2.5 pH, titratable acidity, and apparent viscosity

The pH value of the yogurt samples was determined at room temperature (24 °C) using a pH meter (Delta 320, Mettler Toledo, Greifensee, Switzerland). The titratable acidity was acquired by direct titration method [20]. The viscosity of the yogurt was evaluated using a rotational rheometer (RheolabQC, Anton Paar, Graz, Austria) using a concentric cylinder at a constant shear rate of 100 s−1.

2.6 Texture profile analysis (TPA)

The texture profile of yogurt (firmness, consistency, cohesiveness, and viscosity index) was analyzed using a texture analyzer (TA.HDPlus Connect, Stable Micro Systems Ltd., Surrey, UK) and employed a cylindrical probe with 36 mm diameter (P36 R). The compression test was done at pre-test and test speeds of 1 mm/s and a depth of 10 mm.

2.7 Viable cells count

The viability of the starter cultures in the yogurt samples was carried out after 1 week storage at 4 °C. The sample (10 g) was homogenized in 90 mL sterile 0.1% peptone water (CM0009B, Oxoid, Ltd., Hampshire, UK), and proper serial dilutions were performed [21]. The diluted samples (1 mL) was inoculated on De Man, Rogosa, and Sharpe (MRS) agar (CM1153, Oxoid Ltd., Hampshire, UK) using the pour plate method and the agar plates were incubated in an anaerobic jar with the anaerobic bag at 37 °C for 48 h. The total count of the viable cells was determined using a colony counter (Galaxy 230 Wiggens GmbH, Straubenhardt, Germany), and the results were calculated and expressed as Log10 CFU/mL.

2.8 Sensory analysis

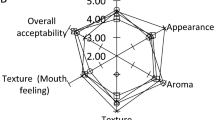

The sensory evaluation was conducted by employing an acceptance test method [22, 23]. A total of 50 panellists (aged 20–50, 35 females and 15 males) were included and the yogurt samples were evaluated based on the following attributes: appearance, colour, texture, aroma, flavour, aftertaste and overall acceptability. A seven-points hedonic scale was employed to evaluate the sensory acceptance of panelists on the samples, in which score 1 represents dislike extremely, score 4 for neither like or dislike and score 7 for like extremely.

2.9 Statistical analysis

All samples were analyzed in triplicate. The obtained data was analyzed using two-way Analysis of Variance (ANOVA) using Minitab 19.0 and Tukey’s test (Minitab, Pty Ltd., Sydney, Australia). The confidence level that was employed to decide the significant difference is 95% (p < 0.05). Data was expressed in mean with standard deviation (mean ± SD).

3 Results and discussion

3.1 Proximate analysis

The proximate compositions showed that different types of stabilizers significantly affects the moisture content ranging from 87.10 to 89.48% (Table 1). Among different concentrations, only LBG samples had no significant difference (p > 0.05) in moisture content. CYA with 1.0% of pectin showed a higher moisture content than 0.5%. An opposite trend was found for CYA with corn starch, in which a lower amount (0.5%) showed a higher moisture content than 1.0%. This relates to the water retention ability of a particular stabilizer as it behaves diversely depending on the concentration [24].

The fat content of the samples varied from 1.00 to 6.00%. According to CODEX Standard for fermented milk [25], dairy yogurt should possess milk fat less than 15%. Since there is no available standard for non-dairy yogurt, comparisons of fat content could not be made. Nevertheless, determination of fat content in yogurt is crucial as it influences the texture, flavor, taste, and appearance of yogurt [26].

The protein contents recorded in this study for plant-based yogurt made from chickpea was better compared to the commercial counterparts reported by Grasso et al. [27]. Their study reported protein content for commercial yogurt made from hemp (0.60 g of protein per 100 g of product) and coconut (0.60 g of protein per 100 g of product), while the values in this study were quite similar to those of cashew-based yogurt (2.00 g of protein per 100 g of product) and almond-based yogurt (2.30 g of protein per 100 g of product) [27]. However, it's noteworthy that the protein content significantly decreased (p < 0.05) when the concentration of pectin and corn starch was elevated to 1.0%, which resulted from the dilution effect associated with increasing stabilizer concentration, depending on the type of stabilizer used [24].

Interestingly, only LBG exhibits a significant effect (p > 0.05) on the ash content due to the high amount of sodium (125 mg) and calcium (294 mg) [28]. The results obtained for carbohydrate content (ranging from 5.40 to 9.88%) were almost similar to the previous studies [26, 29, 30]. In terms of each stabilizer type, the sample with 1.0% stabilizer showed significantly higher (p < 0.05) fiber content as compared to its respective sample with 0.5% stabilizer. This presence of fiber could be beneficial for enhancing the gel structure, increasing water-holding capacity, and viscosity [31].

3.2 pH, titratable acidity and colour

The pH of yogurt analogue (YA) containing pectin, corn starch, and LBG (Table 2) at both concentrations ranges from pH 4.00–4.22, while control A has the highest pH value of 4.33, which meets the standard of Food and Drug Administration (FDA) stating that yogurt should have pH of 4.6 or lower [32]. Increasing the concentration of stabilizer can cause pH reduction in YA due to the buffering capacity of the stabilizer, depending on its variety [24]. Based on the titratable acidity values, all samples possessed a lower percentage of titratable acidity as compared to the CODEX Standard for fermented milk which specifies that yogurt should have a titratable acidity of at least 0.6% [33]. This may occur due to the absence of lactose as the plant substrate in the yogurt [27]. Therefore, the LAB strain used for specific plant-based milk should be determined to ensure optimal fermentation is achieved [34].

3.3 Textural and rheological properties

Regarding viscosity properties (Table 3), there were significant differences (p < 0.05) observed between LBG(A) and LBG(B) samples, attributable to the distinct physical and chemical properties of the stabilizer itself [24]. LBG is composed of galactomannan with high molecular weight and low galactose residues as a side chain that contributes to its water-binding capacity, especially at high temperatures where it can completely solubilize [35]. LBG(A) exhibited significantly higher viscosity compared to control A, demonstrating LBG's ability to impart viscosity even at low concentrations [35].

Additionally, P(A) and CS(B) samples also revealed an apparent viscosity higher than that of control A, which can be attributed to the type and concentration of stabilizer used. It’s worth noting that there is a notable correlation between viscosity and fat content in studies involving dairy milk, where higher fat content in yogurt results in higher viscosity [24, 36]. In this study, the results were consistent with this correlation since fat content in P(A) was higher than in P(B), and this difference is dependent on the type of stabilizer employed. Furthermore, the high viscosity observed in the CS(B) sample can be explained by the ability of starch granules to absorb water and swell, leading to restricted movement of the swollen granules [23].

The firmness of yogurts formulated with LBG at distinct concentrations showed no significant difference (p > 0.05) compared to pectin and corn starch, in which the values were significantly different (p < 0.05). The high viscosity of the LBG samples hinders the association of starter culture with other yogurt ingredients, preventing the yogurt from achieving the desired texture [37].

The yogurt is considered viscous and thick in consistency if it flows slowly on the spoon [34]. The inclusion of commercial stabilizer, pectin at 0.5%, and corn starch at 1.0% enhanced the consistency of the yogurt due to the increase in consistency as compared to control A. Next, cohesiveness determines the strength of internal bonds in the yogurt structure and is often associated with viscosity as well [37]. The cohesiveness of the sample improved only with corn starch at 0.5% and pectin at 1.0%. The increases in cohesiveness was accompanied by an elevated concentration of partially hydrolyzed guar gum supplemented in the set-type yogurt [33]. Based on this, it is assumed that the addition of a stabilizer helps in strengthening the molecular linkage in yogurt composition.

3.4 Viable cells count

The viability of lactic acid bacteria (LAB) in the samples was measured following one week of storage at 4 °C and the findings were displayed in Table 4. A minimum of 107 cfu/g of total starter culture is required in yogurt products [38]. The recent study showed that viable cells count for the samples ranged from log10 5.21 ± 0.12 CFU/mL to log10 7.13 ± 0.04 CFU/mL. It was shown that the addition of corn starch at higher concentrations boosted the cell viability in the yogurt, whereas the cell viability was significantly decreased (p < 0.05) when the LBG level was higher. This was possible because the incorporation of corn starch at 1.0% imparted a favorable environment for the LAB to flourish. The reduction of viable cell count when the concentration of stabilizer was elevated from 0.5 to 1.0% [24] and depending on the concentration of stabilizer could provide optimum growth conditions for the starter cultures [24].

3.5 Sensory analysis

Sensory profile of the chickpea yogurt analogue was presented in Table 5. The commercial sample was a non-dairy oat milk yogurt and was used as a benchmark for the sensory profile of a plant-based yogurt analogue (YA) product. The results showed that control A has the lowest rating for all attributes with appearance and texture receiving significantly lower (p < 0.05) scores as opposed to other samples. This may be resulting from the absence of any stabilizer in the yogurt that made it unappealing to the panelists [22, 39].

Furthermore, CY showed no significant difference (p > 0.05) with the YA sample for appearance, color, and texture except for flavor. The developed CY formulation could mimic the commercially available YA in terms of these important sensory attributes. CY samples were rated significantly higher (p < 0.05) than other samples in the aspect of flavor, aftertaste, and overall acceptability. This was apparently due to the taste of oat that was more acceptable, given that oat-based foods are more popular and highly consumed as opposed to chickpea-based food.

4 Conclusion

The suitable concentration of stabilizer is employed in specific YA must be determined to obtain an optimum physical and chemical characteristic. This study concluded that different stabilizers at different ratios significantly impacted the physical and chemical properties of chickpea yogurt analogue, which mainly on the pH value, cell viability, textural and sensory quality of the yogurt. Based on the findings, the stabilizer’s behavior significantly impacts the features of CYA which with 0.5% LBG received high consumer acceptance, which proves a good potential for CYA to be on the same shelf with other commercial yogurts analogue in the market.

Data availability

All dataset used in this study has been provided in this article.

References

Fisberg M, Machado R. History of yogurt and current patterns of consumption. Nutr. 2015;73:4–7. https://doi.org/10.1093/nutrit/nuv020.

Willett W. Food in the anthopocene: the EAT–lancet commission on healthy diets from sustainable food systems. Lancet. 2019;393:447–92. https://doi.org/10.1016/S0140-6736(18)31788-4.

McClements DJ, Grossmann L. A brief review of the science behind the design of healthy and sustainable plant-based foods. NPJ Sci Food. 2021;5:17. https://doi.org/10.1038/s41538-021-00099-y.

Montemurro M, Pontonio E, Coda R, Rizzello CG. Plant-based alternatives to yogurt: state-of-the-art and perspectives of new biotechnological challenges. Foods. 2021;10:316. https://doi.org/10.3390/foods10020316.

Jeske S, Zannini E, Arendt EK. Past, present and future: the strength of plant-based dairy substitutes based on gluten-free raw materials. Food Res Int. 2018;110:42–51. https://doi.org/10.1016/j.foodres.2017.03.045.

Barbosa MLS, de Alencar ER, dos Santos LE, Borges RM, Mendonça MA, de Souza FWF. Characterization of fermented beverages made with soybean and Brazil nut hydrosoluble extracts. Int J Gastron Food Sci. 2020;21:100228. https://doi.org/10.1016/j.ijgfs.2020.100228.

Merga B, Haji J, Yildiz F. Economic importance of chickpea: production, value, and world trade. Cogent Food Agric. 2019;5(1):1615718. https://doi.org/10.1080/23311932.2019.1615718.

Muehlbauer FJ, Sarker A. Economic importance of chickpea: production, value, and world trade. In: Varshney Rajeev K, Thudi Mahendar, Muehlbauer Fred, editors. The chickpea genome. Cham: Springer; 2017.

Keyimu XG, Bozlar MA, Wulamujiang A. Pharmacology properties of Cicer arietinum L. Int J ChemTech Res. 2020;13:251–6. https://doi.org/10.20902/IJCTR.2019.130322.

El-Sayed E, El-Gawad A, Murad H, Salah S. Utilization of laboratory-produced xanthan gum in the manufacture of yogurt and soy yogurt. Eur Food Res Technol. 2002;215:298–304. https://doi.org/10.1007/s00217-002-0551-9.

Bernat N, Cháfer M, Chiralt A, González-Martínez C. Vegetable milks and their fermented derivative products. Int J Food Studies. 2014;3:93–124. https://doi.org/10.7455/ijfs/3.1.2014.a9.

Chandan RC, Gandhi A, Shah NP. Yogurt: historical background, health benefits, and global trade. In: Shah Nagendra P, editor. Yogurt in health and disease prevention. Cambridge: Academic Press; 2017. https://doi.org/10.1016/B978-0-12-805134-4.00001-8.

Saha D, Bhattacharya S. Hydrocolloids as thickening and gelling agents in food: a critical review. J Food Sci Technol. 2010;47:587–97. https://doi.org/10.1007/s13197-010-0162-6.

Wang S, Chelikani V, Serventi L. Evaluation of chickpea as alternative to soy in plant-based beverages, fresh and fermented. LWT. 2018;97:570–2. https://doi.org/10.1016/j.lwt.2018.07.067.

Rafiq L, Zahoor T, Sagheer A, Khalid N, Rahman UU, Liaqat A. Augmenting yogurt quality attributes though hydrocolloidal gums. Asian-Australas J Animal Sci. 2020;33(2):323–31. https://doi.org/10.5713/ajas.18.0218.

Sebayang F. The utilization of carboxymethyl cellulose (CMC) from groundnut (Arachis Hypogaea L) cellulose as stabilizer for cow milk yogurt. J Chem Natl Resour. 2019;1(2):38–51. https://doi.org/10.3273/jcnar.v1i2.1252.

Pachekrepapol U, Kokhuenkhan Y, Ongsawat J. Formulation of yogurtlike product from coconut milk and evaluation of physicochemical, rheological, and sensory properties. Int J Gastronomy Food Sci. 2021. https://doi.org/10.1016/j.ijgfs.2021.100393.

Association of Official Analytical Chemists (AOAC). Official methods of analysis. 18th ed. Rockville: AOAC Int; 2010.

Fahmid S, Sajjad A, Khan M, Jamil N, Ali J. Determination of chemical composition of milk marketed in Quetta, Pakistan. Int J Adv Res Biol Sci. 2016;3:98–103.

Association of Official Analytical Chemists (AOAC). Official methods of analysis. 21st ed. Rockville: AOAC Int; 2019.

Annan NT, Borza AD, Hansen LT. Encapsulation in alginate-coated gelatin microspheres improves survival of the probiotic Bifidobacterium adolescentis 15703T during exposure to simulated gastro-intestinal conditions. Food Res Int. 2008;41:184–93. https://doi.org/10.1016/j.foodres.2007.11.001.

Saleh A, Mohamed AA, Alamri MS, Hussain S, Qasem AA, Ibraheem MA. Effect of different starches on the rheological, sensory and storage attributes of non-fat set yogurt. Foods. 2020;9:61. https://doi.org/10.3390/foods9010061.

Rafiq L, Zahoor T, Sagheer A, Khalid N, Rahman UU, Liaqat A. Augmenting yogurt quality attributes though hydrocolloidal gums. Asian-Austral J Anim Sci. 2020;33:323–31. https://doi.org/10.5713/ajas.18.0218.

Eze CM, Aremu KO, Alamu EO, Okonkwo TM. Impact of type and level of stabilizers and fermentation period on the nutritional, microbiological, and sensory properties of short-set yogurt. Food Sci Nutr. 2021;9:5477–92. https://doi.org/10.1002/fsn3.2507.

Standard, C. (2011). Codex Standard for Fermented Milks: Codex Stan 243–2003. Codex Alimentarius. Milk and Milk Products; FAO United Nations: Roma, Italy.

Adeyanju AA, Adejuyitan JA, Ogunsimiro O, Adebowale OJ, Akinsanola B. Developing a plant-based yoghurt recipe that has the same high-quality characteristics as conventional yoghurt. Res Square. 2022. https://doi.org/10.21203/rs.3.rs-2139387/v1.

Grasso N, Alonso-Miravalles L, O’Mahony JA. Composition, physicochemical and sensorial properties of commercial plant-based yogurts. Foods. 2020;9:252. https://doi.org/10.3390/foods9030252.

U.S. Department of Agriculture (2018) Gums, Seed Gums (includes Locust Bean, Guar). FoodData Central, 169045.

Arise AK, Malomo SA, Jacob OA, Olagunju OF, Esan OT. Comparative studies of yogurt produced from animal and selected imitation vegetable milk. Nutrire. 2022;47:1–8. https://doi.org/10.21203/rs.3.rs-1846511/v1.

Elechi JOG, Abu JO, Eke MO. The application of blends of bambaranut and millet vegetable milk in the development of plant-based yogurt analogues: proximate composition, physiochemical properties, microbial safety and consumer’s acceptability. Food Health. 2023;9:43–60. https://doi.org/10.3153/FH23005.

Wang X, Kristo E, LaPointe G. The effect of apple pomace on the texture, rheology and microstructure of set type yogurt. Food Hydrocoll. 2019;91:83–91. https://doi.org/10.1016/j.foodhyd.2019.01.004.

Food and Drug Administration. (2022, November 29). CFR - Code of Federal Regulations Title 21, Section 131.

Rezaei R, Khomeiri M, Aalami M, Kashaninejad M. Effect of inulin on the physicochemical properties, flow behavior and probiotic survival of frozen yogurt. J Food Sci Technol. 2014;51:2809–14. https://doi.org/10.1007/s13197-012-0751-7.

Harper AR, Dobson RC, Morris VK, Moggré GJ. Fermentation of plant-based dairy alternatives by lactic acid bacteria. Microb Biotechnol. 2022;15:1404–21. https://doi.org/10.1111/1751-7915.14008.

Milovanovic B, Djekic I, Miocinovic J, Djordjevic V, Lorenzo JM, Barba FJ, Morlein D, Tomasevic I. What is the color of milk and dairy products and how is it measured? Foods. 2020;9:1629. https://doi.org/10.3390/foods9111629.

Barak S, Mudgil D. Locust bean gum: processing, properties and food applications—a review. Int J Biol Macromol. 2014;66:74–80. https://doi.org/10.1016/j.ijbiomac.2014.02.017.

Mohsin AZ, Marzlan AA, Muhialdin BJ, Wai LK, Mohammed NK, Hussin ASM. Physicochemical characteristics, GABA content, antimicrobial and antioxidant capacities of yogurt from Murrah buffalo milk with different fat contents. Food Biosci. 2022;49:101949. https://doi.org/10.1016/j.fbio.2022.101949.

Cayot P, Schenker F, Houzé G, Sulmont-Rossé C, Colas B. Creaminess in relation to consistency and particle size in stirred fat-free yogurt. Int Dairy J. 2008;18:303–11. https://doi.org/10.1016/j.idairyj.2007.06.009.

Mudgil D, Barak S, Khatkar BS. Texture profile analysis of yogurt as influenced by partially hydrolyzed guar gum and process variables. J Food Sci Technol. 2017;54:3810–7. https://doi.org/10.1007/s13197-017-2779-1.

Funding

This work was supported by the Universiti Putra Malaysia (Grant numbers: GP-IPM/2022/9740300).

Author information

Authors and Affiliations

Contributions

Authors 1 (S.N.M.F), 2 (A.A.M), and 6 (A.Z.M) wrote the manuscript test. Authors 3 (A.S.M.H), 4 (M.H.A.R), 5 (I.N.M), and 6 (A.Z.M) provide supervision, research materials, and funding acquisition. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

The results/data/figures in this manuscript have not published elsewhere, nor they are under consideration by another publisher.

Competing interests

The authors have no competing interests (financial or non-financial) to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mohd Fazla, S.N., Marzlan, A.A., Meor Hussin, A.S. et al. Physicochemical, microbiological, and sensorial properties of chickpea yogurt analogue produced with different types of stabilizers. Discov Food 3, 19 (2023). https://doi.org/10.1007/s44187-023-00059-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44187-023-00059-3