Abstract

Nanotechnology is a novel and promising technology that has been introduced into many fields, including medicine, agriculture, and the food industry. For the food industry, nanotechnology is of great interest as an emerging technology in the area of food processing, safety, and packaging. For example, nanotechnology can be used in food processing to enhance the overall quality of food including, taste, flavor, bioavailability, and can also help to extend product shelf life. With regard to food safety, nanotechnology is utilized to detect pathogens and toxins in food products and to strengthen barrier properties. Additionally, nanotechnology is widely used in food packaging as an antimicrobial and to produce intelligent packaging. However, nanoparticles may have a potential toxicity risk to human health. Therefore, establishing an adequate regulatory system to manage the potential risks associated with nanotechnology applications is recommended. This review covered nanotechnology in food safety and packaging, classifications, and safety concerns.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Nanotechnology is a multidisciplinary and promising technology that involves the advancement of organic and inorganic materials and the conversion and manipulation of these materials on an atomic and molecular scale, which feature custom-made biological, chemical, and physical properties [1,2,3]. Specifically, when the structure of materials is changed, and the particle size is reduced below its outset to approximately 1–100 nm, the physical and chemical properties of the material will show significant differences compared to the original materials even though they both contain the same base materials [2, 4, 5]. Due to their unique chemical and physical characteristics, nanoscale materials provide exceptional benefits to a wide variety of fields of sciences and technology, including engineering, materials science, chemistry, physics, biology, and medicine [5, 6]. These unique, incomparable properties of nanoscale materials are due to their high surface area-to-volume ratio compared to the microscale of the same materials [3, 7]. Therefore, nanotechnology has been given special attention by researchers and scientists across all disciplines over the last decade and continues to expand rapidly with potential applications in medical therapeutics and diagnostics, molecular computing, energy production, and structural materials [3, 7, 8].

In the food industry, as with other sectors, nanotechnology is playing a crucial role as a promising technology for solving problems via innovative solutions that relate to food safety, food processing, food packaging (Fig. 1) as well as functional foods [3, 6]. Among these, the application of nanotechnology to food packaging has taken more attention due to the enhancement of food product quality and safety [3, 4]. In this regard, nanotechnology can improve food packaging that provides safer, healthier, high-quality foods with increased shelf life without affecting the sensory and physical characteristics of the food products [4, 9].

Clearly, nanotechnology offers many benefits to the food packaging sector. For example, nanotechnology can be used to detect microbial contamination [5, 7], enhance the bioavailability of nutrients, and improve mechanical barriers [3, 10]. With regard to food processing, nanotechnology is used in various ways to improve flavor, color, texture, and nutritional quality [5, 10]. For example, nanocapsules are used to enhance the bioavailability of nutraceuticals, nanoencapsulation of flavor is used to improve the taste of food, and nanotubes; nanoparticles can be used as gelating and viscosifying agents [4]. Moreover, nanoemulsions and nanoparticles are used to improve the availability and dispersion of nutrients [7]. Nanocapsules can be used as nano food additives or nutritional supplements to modify or cover undesirable flavor or taste and support the better distribution of insoluble additives without adding surfactants or emulsifiers [11]. In this regard, bioactive nanoencapsulation applications are already in place and have been used in the area of release or delivery of nutrients [12, 13].

Whereas, the applications of nanotechnology in functional food are concentrated on nano-sized nutritional supplements and nutraceuticals and additives, including vitamins, antimicrobials, antioxidants, and preservatives [3, 7]. Therefore, nanotechnology changes the conventional way in which the food industry produces, packages transport food, and this can also have an effect on consumer attitudes [4]. However, most nanotechnology applications related to the food sector are currently in the R&D stages, and the food industry continuously invests billions of dollars in nanotechnology products. According to a report by Bernardes et al. [14], the nanotechnology market in the food industry has reached $1 billion, most of which is used in food packaging, particularly for nanoparticles coating, health-promoting products, and beverages [3].

Nanosensors are another application for the food sector. Nanosensors convert physical quantities into signals, which can be easily detected and analyzed. This approach is used to detect foodborne pathogens, food spoilage, toxins, vitamins, pesticides, and any unwanted taste or smell, as well as to monitor time–temperature and oxygen indicators [15]. Ultimately, nanosensors play a vital role in the food industry, especially in the area related to food safety and quality.

Nanotechnology is thus a novel technology that holds great promise in all aspects of the food industry, including food processing, food packaging, food safety, and functional food development. This review focuses on the benefits and role of nanotechnology in food safety and food packaging. In addition, we address the types and classifications of nanotechnology and nanotechnology safety.

2 Types and classifications of nanotechnology used in food industry

Different types of nanomaterials are utilized in the food sector for various purposes. This section covers a brief description of each type and the potential application of each one in the food industry. Nanomaterials are materials that can be in the form of powder or liquid solution that present significantly different physical and chemical properties at nanoscales compared to their micro size that contains the same chemical composition [1, 3]. Nanomaterials are assorted into different types based on their particle size, structure, and characteristics [1]. Accordingly, nanomaterials classifications include nanoparticles, nanocapsules, nanoclays, nanoemulsions, nanotubes, nanofibers, and nanolaminates [3]. Each of these nanomaterials has potential applications in the food industry and can be made via several methods [3].

Nanoparticles are among the most nontechnology system types that have attracted attention due to their adaptable chemical, physical, and mechanical properties that provide enhanced performance compared with a performance at their micro size [16]. Nanoparticles are classified into different categories based on their particle dimensions, nanoscale size (1–100 nm), morphology, and chemical composition [16]. Starting with biopolymeric nanoparticles, these are proteins and polysaccharides-based food-grade biopolymers that can be made through four different methods, including emulsification, desolvation, coacervation, and electrospray drying [17, 18]. For clarification, coacervation is a term originally derived from the Latin word “acervate,” it means “heap.” This method is similar to the desolvation method, which is based on partial desolvation, and it is carried out by mixing the liquid phase of a homogenous polymer solution with an organic solvent, such as acetone to obtain a polymer-rich (coacervate) [18]. The most common application for this type of nanomaterial is for encapsulation and delivery of micronutrients. For example, vitamins, iron, proteins [3], and the prevalent biodegradable nanoparticles that are used for encapsulations (carriers) are made of either synthetic polymer such as polylactic acid and poly (lactic-co-glycolic) (PLGA) [3, 19] or natural polymers such as agarose, chitosan, collagen, and fibrin [19]. The application of nanoparticles is also used in the area of bio-nanosensors. In this field, nanoparticles are used to immobilize enzymes in order to improve the efficiency of immobilized enzymes. Nanoparticles provide a large surface area for the attachment of enzymes and smaller size compared to bulk particles which improve the efficiency of immobilized enzymes and decrease the resistance to the diffusion of substrates [20].

Another type of nanomaterial is nanoemulsions, which are created by mixing two or more liquids that are not easily combined, such as oil and water. Such a mixture is called an emulsion [3]. Nanoemulsions are composed of dispersed droplets with a diameter of 500 nm or less. If the oil droplets are dispersed in water, the emulsions are called oil-in-water (o/w) emulsions, while the water droplets dispersed in oil are called water-in-oil (w/o) emulsions [21]. The emulsion applications are used in food systems for the delivery of hydrophobic active substances [21]. In the food industry, nanoemulsions can be used for the delivery of nutraceuticals, coloring and flavoring agents, and antimicrobials. Additionally, the active ingredients of nanoemulsion formulations can be utilized for generating biodegradable coating and packaging films in order to improve quality and nutritional value and to extend the shelf life of food products [21]. Nanoclay is another type of nanoparticle that consists of layered mineral silicates with layered structural units that can form complex clay crystallites via the stacking of these layers [22]. In addition, depending on the shape and chemical composition of the nanoparticles, nanoclays are arranged into a number of classes, including montmorillonite, bentonite, smectite, chlorite, illite, kaolinite, hectorite, and halloysite [22]. Moreover, nanoclays are widely available, cheap, and environmentally friendly. Therefore, their applications have been studied and expanded in many areas [22]. For example, in the food sector, nanoclay is regularly used in food packaging because it has a natural nanolayer structure that acts as a barrier for gas and moisture [3].

In this regard, some polymers, such as polystyrene, polyamides, polyolefins, polyurethane, nylons, and epoxy resins are combined with nanoclay to create nanoclay-polymer composites. These types of nanocomposites have a potential application in food packaging for cheeses, confectioneries, processed meats, and cereal products packaging materials as well as for extrusion-coating of fruit juices and liquid dairy products [3]. While nanolaminates, which is a coating of nanosized, are comprised of thin films formed by multiple layers of two or more materials of food-grade with layered thicknesses of one hundred nanometers or less [23]. However, the thickness of films depends on the number of layers deposited, and layer-by-layer can be assembled by several chemical interactions, including electrostatic bonding, hydrogen bonding, hydrophobic interactions, charge-transfer interactions, and covalent bonding, among others [23].

Typically, nanolaminates are made from proteins, lipids, and polysaccharides and their applications are used in packaging materials and other applications in the food sector [3]. In addition, there are opportunities for researchers to develop novel nanolaminate films for potential novel applications in the food industry [3]. For example, nanolaminates can be integrated as edible coatings and films on various food products such as vegetables, fruits, meats, candies, chocolates, and bakery products. In this case, coating or films could act as a barrier for moisture, gas, and lipids [3]. Moreover, nanolaminates can be used as carriers of functional components such as flavors, colors, antimicrobial compounds, and antioxidants [3]. In addition to the nanomaterials mentioned above, nanocapsules or nanoencapsulation is another emerging nano-technique based on the incorporation, absorption, or dispersion of bioactive compounds in reduced size nano-diameter using different techniques, such as nanocomposite formulation, nanoemulsification, and nanostructuring [3, 24]. This promising nanotechnology will enable the food industry to add more nutrients without changing or affecting the sensory or quality of food products. Additionally, the new technology will help to incorporate nutrients that are not naturally occurring or could not be integrated as well as enable increased nutrient absorption, resulting in extended shelf life [24]. Thus, nanoencapsulation is an emerging technology that can offer significant benefits to the food industry.

Lastly, nanotubes and nanofibers are two nanotechnology applications that are having application in the food industry. Nanotubes are formed from several global proteins such as A-Lactalbumin, a globular protein from milk, and have the potential to be used in enzyme immobilization processes. In addition, nanotubes can be used as encapsulating agents due to their ability to withstand pasteurization conditions of 72 °C for 40 s [3]. Nanofibers are nanomaterials with diameters ranging from 10 to 1000 nm. Nanofibers are simulated by electro-spinning technology, in which a solution is passed through a spinneret with a small capillary orifice, after which a strong electric field is applied to generate thin, solid polymer strands nanofibers [3, 25]. The application of nanofibers is more suitable in food packaging and artificial foods and can also be used as a platform for bacterial cultures [3, 25]. With growing nanotechnology applications in the food sector, the application of nanofibers will likely continue to expand in the food industry.

3 Nanotechnology in food safety

Despite the advances in technology in the areas of food preservation, sanitation and regulations, food safety continues to be a great public concern both nationally and internationally [9, 13, 20]. Foodborne pathogens and toxins can cause foodborne illnesses and present serious risks to human health [9]. In the United States, it is estimated that foodborne diseases cause approximately 9.4 million illnesses every year [26]. According to the Centers for Disease Control and Prevention (CDC) 2013 report, there were about 818 foodborne disease outbreaks that resulted in 13,360 illnesses, 1062 hospitalizations, and 16 deaths in the United States in 2013 [27]. Meanwhile, data from the Foodborne Disease Outbreak Surveillance System (FDOSS) received for the period 2009–2015 revealed that 5760 foodborne disease outbreaks were recorded and resulted in 100,039 illnesses, 5699 hospitalizations, and 145 deaths in all 50 states [26]. Clearly, the food industry must have a robust system in place for identifying and detecting foodborne pathogens, including bacteria, viruses, fungi, and any potential contaminants in food products or food contact surfaces. That objective continues to be the paramount aspiration for the scientific community and researchers [3, 20]. Rapid contaminant detection methods that are cheap, precise, and require fewer workers with less required training skills are essential for the food industry [3]. However, traditional detection methods and rapid molecular techniques that are used for detecting and identifying pathogenic microorganisms or toxins are expensive and require time and labor. More importantly, such traditional methods can be inaccurate or subject to self-contamination during processing [3].

Nowadays, nanotechnology applications have expanded into the food industry and play significant roles in all aspects of this sector [9, 13]. With regard to food safety, nanotechnology offers various tools and techniques that can solve food safety issues, including microbial and toxin detection, shelf life extension, and improvements in food packaging [9, 28]. Nanotechnology approaches in food safety are concentrated on the antimicrobial properties of nanoparticles and nanosensors for foodborne pathogens detection and other contaminants [29]. In recent years, the emergence of nanotechnology applications in the food safety area, including detection techniques and nanosensor devices, is becoming more important to researchers and receiving more attention from the food industry and the general public [20].

Presently, nanotechnology techniques offer faster, more accurate, cost-effective detection methods when compared to conventional and molecular detection methods [3]. Additionally, nanotechnology-based methods can detect pathogenic microorganisms at different stages of food production, which is not possible with conventional methods [3]. Nanotechnology detecting techniques also significantly reduce the time required for incubation and measurements and offer a high level of sensitivity and accuracy. For example, one study reported that it only took a 45 min incubation period to isolate 88% of E. coli in a sample using nanosized magnetic iron oxide particles with sugar molecules [5]. Thus, novel nanotechnology methods that enhance food safety and quality, specifically in the area of microbial detection and control, are on their way. This advancement in technology will help to empower the food industry by overcoming food safety issues related to inaccuracy and time concerns to provide safer, healthier, and high-quality food products [30].

With regard to the antimicrobial characteristics of nanoparticles, it was found that combining two or more nanoparticle materials provided a synergistic effect resulting in a more effective antimicrobial than a single nanoparticle [8]. For instance, combining sliver nanoparticles with titanium dioxide and carbon nanotubes was found to be twice as effective against E. coli and Bacillus cereus spores [31]. In addition, the combination of the silver and sodium dodecyl sulfate (SDS) nanoparticles resulted in stronger antimicrobial action against E. coli and S. aureus [32]. Studies also found that combining various nanoparticles, such as silver, gold, zinc, chitosan, platinum, iron, carbon nanotubes with natural derivative essential oils produced synergistic antimicrobial effects that were more powerful than nanoparticles alone or essential oils alone [8]. In this regard, a study has shown that incorporating eugenol and cinnamaldehyde in poly (d,l-lactide-co-glycolide) nanoparticles presented a potent biocidal against Salmonella and Listeria [33]. Another study demonstrated that combining nanoparticles of (Ag and ZnO) with essential oils in the application of pullulan film inhibited L. monocytogenes, S. Typhimurium, S. aureus, and E. coli O157:H7 in fresh turkey, raw beef, or processed turkey deli meat, under vacuum-packaged and stored at 4 °C for 2 weeks [34]. Thus, combining essential oils and nanoparticles enhances the antimicrobial activities against various foodborne pathogens as nanoparticles provide synergistic effects resulting in more potent antimicrobial activities. This type of application could be a very useful strategy against multi-drug-resistant microorganisms [8].

Nanotechnology can also be used for surfaces to remove or overcome the growth of biofilms using antimicrobial coatings [8, 9]. Biofilms are usually not easy to remove as they are resistant to most disinfecting agents [35]. The food industry environment provides ideal conditions for the growth of various microorganisms, including pathogenic bacteria. Commonly, bacteria are attached to the surfaces and form a biofilm. This biofilm is consisting of a complex consortium of microorganisms that stack together to form a hard-to-clean biofilm on surfaces, including food-contact surfaces. Such biofilm thus becomes a source of food product contamination that can lead to foodborne illnesses [35]. Typically, cleaning and disinfecting biofilms on surfaces is difficult to achieve as the biofilms are resistant to most disinfecting agents.

In this regard, nanoengineered surfaces with antimicrobial coatings were found to be one of the most potent antimicrobial agents against biofilms, thereby improving the safety of food contact surfaces as well as the safety and quality of food products themselves [8]. For this purpose, nano-coatings such as nanoscale silver, TiO2, and ZnO are used as disinfecting agents for surfaces in the food industry [8]. Additionally, UV-C ultraviolet light-activated TiO2 was found to be effective in controlling biocontamination issues in poultry operations, food processing, and food transportation [36]. Ultimately, nanotechnology and, specifically, antimicrobial nanomaterials coatings, have the potential to provide a solution for surface contamination issues in the food industry by preventing microbial attachment and the formation of biofilms.

So far in this section, we have addressed nanotechnology applications and their antimicrobial properties in food safety and quality. Nanosensors are another promising application for the detection of pathogenic microbes, including viruses and bacteria, as well as chemical contaminants in food. Nanosensors have emerged as novel nanotechnology in the area of food safety and can be used for the rapid detection of pathogens or other types of contaminants and as surface biocidal techniques [30]. To this end, numerous biosensors have been developed to detect foodborne pathogens including, Listeria monocytogenes, E. coli, and Salmonella, which are the most common foodborne pathogens linked to food contamination in addition to mycotoxins [4, 7].

Similar to antimicrobial nanoparticles, nanosensors are found to be faster, more reliable, and concise in detecting pathogenic microorganisms and their toxic metabolites compared to conventional detecting methods. This is especially true for biosensors with fluorescent dye particles that attach to antibodies on a silicon/gold nanoarray [3]. In recent years, various types of nanosensors have been designed to detect different pathogenic bacteria in food products [3], and some of this information is shown in Table 1. For this purpose, researchers have developed different nanosensors using metallic nanoparticles, carbon nanoparticles, magnetic nanoparticles, or cadmium quantum dots to detect specific foodborne pathogens or their toxic metabolites, as well as biofilm formation [3].

From this point, we can say that nanotechnology plays a tremendous role in food safety due to its potent antimicrobial properties and potential to overcome food safety challenges in the food sector.

4 Application of nanotechnology in food packaging and preservation

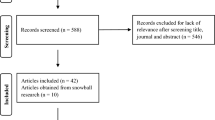

Freshly harvested fruits and vegetables are highly sensitive to oxygen, water permeability, and ethylene which are primarily responsible for the degradation of food quality [50]. Thus, food packaging plays an important role in resolving this issue. The primary aim of packaging is to suppress spoilage and contamination and provide physical protection to protect the food from temperature, external shock, vibration, and microbial infection by working as a barrier to prevent scavenging oxygen and other spoilage-causing gases [51]. Applications of nanotechnology such as nanoparticles and polymer-based composites in food packaging have proven to be the best solution in this regard [52, 53]. Biodegradable materials are mainly preferred for the development and manufacturing of food packaging in order to decrease environmental pollution [54]. In recent years, the coating of natural polymer or a biopolymer on the surface of the food has gained much attention and has shown promising results in preserving produce [8, 55]. Different applications of nanotechnology that are being used for the packaging and preservation of food are summarized in Table 1. Here, it is important to note that food industries, scientists, and researchers working in the area of food packaging should pay some attention to high barrier plastic, the introduction of antimicrobials in packaging, and detection measures for contamination during the packaging of food material. Freezing, dehydration, drying, canning, etc., are conventional methods that are generally being used as food preservation methods [51]. Food preservation is the process of treating and handling food to reduce spoilage and prevent the loss of food quality and nutrition value by microorganisms. The handling and managing of food involve several stages including, processing, packaging, and preservation. Nanotechnology has a wide application in each of these stages, as shown in Fig. 2.

4.1 Types of nanotechnology-based food packaging

Food packaging is broadly classified into two main groups, namely smart packaging and active packaging (Fig. 3). Smart packaging includes nanoparticle-based sensors that respond to environmental stimuli and alert consumers to product contamination or the presence of pathogens [76]. However, active packaging includes nanoparticles with antimicrobial activities and moisture regulating agents such as oxygen scavengers, CO2 scavengers and emitters, and antimicrobials [77].

4.2 Active packaging systems

Active packaging generally enhances shelf life and improves packaged food, and the development of active packaging systems primarily depends on the food storage objectives [78]. It is an intentionally designed packaging system that integrates components that could absorb oxygen or release antimicrobials or antioxidant agents into or from packaged food. The incorporation of active compounds such as nanoparticles, antimicrobials, water vapor, and oxygen absorbers, etc. with a polymer into the packaging makes it more resistant and effective towards increasing the shelf life and quality of packaged food [79]. Several types of metals and metal oxide nanoparticles viz. zinc, gold, silver, zinc oxide, titanium dioxide, silicon oxide, etc. have been extensively utilized in different applications of active packaging [80]. These nanoparticles work either on direct contact or they can migrate slowly and react with organics present in the food. Among different nanoparticles, silver nanoparticles are one of the most widely used nanoparticles because they are known for their well-established antimicrobial potential against pathogenic strains [81]. Besides this, they also inhibit several viruses and fungi (Monkey pox, and Fungi) [82]. It has also been observed that silver nanoparticles also inhibit the respiratory chain enzymes and can also stimulate the production of reactive oxygen species (ROS). For example, Damm et al. [83] incorporated silver micro and nanoparticles into the packaging film, and they have also investigated their effectiveness against E. coli. Nanoparticles added film inhibited the growth of E. coli completely. However, the film incorporated with silver micro-particles killed around 80% of the bacteria. Mohammed et al. [84] have incorporated silver nanoparticles into sodium alginate films in food packaging. They have reported a remarkable antibacterial effect of silver nanoparticles against E. coli and S. aureus. In another study, Rhim et al. [85] noticed the noteworthy antimicrobial activity of silver nanoparticles incorporated agar films against E. coli and Listeria monocytogenes. In literature, several authors have suggested different types of active packaging films with the incorporation of silver nanoparticles for the packaging of fresh fruits and vegetables. For example, Mohammed et al. [84] proposed an edible antibacterial film of alginate with silver nanoparticles for the sterilized carrot and pears. An et al. [86] have also proposed the nanocomposite film of silver nanoparticles/polyvinyl pyrrolidone for the fresh asparagus spears. They have reported the extension of 25 days in the shelf life of asparagus spears under refrigerated storage. In a few other studies, authors have also incorporated other nanoparticles such as ZnO and SiO2 into the active packaging systems. In one of the recent studies, Kraśniewska et al. [87], have reviewed the potential role of biopolymer-based materials containing silver nanoparticles as active packaging for food applications. Fasihnia et al. [88] proposed the nanocomposite films containing organoclay nanoparticles as an antimicrobial active packaging for potential food applications. Moreover, Dias et al. [78] investigated the effect of the incorporation of carbon nanotubes and allyl isothiocyanate into an antimicrobial film for packaging shredded and cooked chicken meat. They found that the incorporation of these materials into the active packaging system increased the shelf life of shredded, cooked chicken meat by up to 40 days by decreasing microbial contamination. Moreover, a decrease in both color change and regulation in the oxidation process has also been observed.

4.3 Smart packaging systems

Smart packaging systems consist primarily of nanosensors to detect food contaminants, and nanoparticles are mostly used for their development [8]. Nanoparticle-based nanosensors have a great potential in tracing the chemical, physical, and biological modifications during food processing and preservation. The use of these sensors in smart packaging helps in detecting chemicals, toxins, and food pathogens [7]. Moreover, smart packaging with nanosensors and indicators helps to easily track the information related to the quality of packaged food products during transport and storage [78]. It has been noted that smart packaging helps to retain the food quality during distribution as the attached sensors in the packaging record all the responses related to changes associated with the internal or external environmental stimuli. Some of the indicators are commonly attached in food packaging applications in order to measure the integrity of packaging, quality of packaging (freshness), time, and temperature-dependent changes. The monitoring of changes in the food product during production and supply chain by using indicators helps to maintain quality and increases the product shelf life [8]. In addition, nanoparticle-based nano-barcodes can be used as identity tags for smart packaging [89].

4.4 Nanosensors

A nanosensor also called a bio-analytical device is an integrated system that consists of different nanostructured materials and biological receptors. In recent years, nanosensors have been utilized in the food processing and packaging industries and have gained much attention due to their integrity, quick detection ability, and low cost [8]. Nanosensors are easily integrated with analytes due to their specificity and high sensitivity. The involvement of different types of nanomaterials, such as nanoparticles (metallic, non-metallic, and metal oxide), nanorods, nanowires, carbon nanotubes, and nanofibers in the development of nanosensors enhances its surface-to-volume ratios, optical, and electrical properties [90]. These sensors have the ability to detect color changes in the food as well as any gases that are being produced due to food spoilage. It has been observed that nanosensors are highly sensitive to various gases such as ammonia, hydrogen, hydrogen sulfide, sulfur dioxide, and nitrogen oxides [60]. Nowadays, nanosensors are widely used in the detection of food-borne pathogens, chemicals, toxins, and pesticides that are present in food products. As compared to conventional sensors, nanosensors are more prominent and efficient due to their high sensitivity and selectivity. Typically, nanosensors consist of electronic (data processing devices) and sensing devices that make them capable of detecting changes in heat, light, gas, and chemicals by converting them into electrical signals [91]. Mostly gas sensors consist of metallic nanoparticles such as gold, platinum, and palladium [92].

Currently, sensors such as electrochemical and biosensors based on metallic nanoparticles, super magnetic nanoparticles, and newly developed nanomaterials (carbon nanotubes) are used in the detection of different toxins present in food products. Metallic nanoparticles such as silver, gold, copper, platinum, and zinc are commonly used for the formation of sensors. In some studies, it has been observed that aflatoxins, a group of toxin and carcinogenic compounds, are commonly found in various foodstuffs. For example, Sharma et al. [93] noted the potential application of functionalized-gold nanoparticles in the detection of aflatoxin B1 from food samples. Similarly, Radoi et al. [94] have also used superparamagnetic nanoparticles and gold nanoprobes for the detection of aflatoxin M1 in milk samples. Moreover, in another study conducted by Zhou et al. [95], gold-based nanoprobe immunochromatographic assays have also been used for the detection of brevetoxins in fishery product samples. Similarly, gold-based immunochromatographic assays have been used for the detection of botulinum neurotoxin type B from processed foods [96]. Some of the studies detected palytoxin from contaminated seafood by using carbon nanotube-based electro-chemiluminescent sensors [97]. In the literature, microfluidic sensors have also been used for the detection of toxic substances present in aqueous samples. Normally, these sensors are very sensitive and effective even when detecting contaminants in the microliter range. Different types of nanoparticle-based nanosensors and their application in food quality and safety are listed in Table 2. It has been noted that several food packaging plants installed nanosensors at the packaging plant itself to detect harmful food microorganisms instead of sending the samples to the lab for testing [51]. These sensors can help consumers to estimate the quality of food products with the help of color change. Time–temperature detectors and gas detectors are commonly used in food packaging industries. Various types of nanosensors are used, for example, array biosensors, nanoparticle-based sensors, electronic noses, nano-test strips, nanocantilevers. The electronic nose is a device that detects the smell more effectively than the human sense of smell. An electronic nose consists of a mechanism for chemical detection, and it uses several chemical sensors that are mainly attached to the data processing system. Generally, it behaves like a human nose. Therefore, it is commonly known as the electronic nose. Like the electronic nose, other reports also reported electronic tongue sensors. It changes color when it comes in contact with any sign/symptom of food spoilage [62], thus indicating that the food is unfit for human consumption. Nano-barcodes are also an effective technology that is being successfully used in food quality determination [61]. In the literature, several other authors have described effective applications of biosensors, nano-biosensors, biomimetic sensors, etc. in various segments of the food industry [61]. Biomimetic sensors are developed by using protein and biomimetic membranes and can be used to detect mycotoxins and other toxic compounds. Reflective interferometry sensors that detect E. coli contaminations in packaged foods have also been reported in the literature [65]. This particular sensor works on the principle of scattering of light by the mitochondria and the scattering of light is detected by analyzing digital images with reflective interferometry, the E. coli protein is placed on the silicon chip which binds the similar protein in the presence of contamination. Table 3 presented the potential applications of various nanomaterials based nanosensors.

4.5 Nanoparticles in food packaging

The incorporation of nanoparticles into food packaging results in an improvement in the efficacy of foodstuff packages as well as longer shelf life and better food quality. In recent years, various nanoparticles have been developed and used in the food industry due to their encapsulation capacity in active compounds and their ability to increase the functionality, stability, and bioavailability of the packaging [8]. It has been estimated that a wide range of nanoparticles have antimicrobial activities, which clearly offers great potential with regard to food packaging. For example, silver nanoparticles have high antimicrobial activity and are commonly used as an active system in food packaging [119]. Various other nanoparticles such as zinc oxide, titanium oxide, and silicate nanoparticles are also being used in plastic films to reduce the flow of oxygen inside the packaging container [120]. These nanoparticles keep the food fresh for a longer time also help to prevent the leakage of moisture from the packaging [58].

In food packaging, silicon dioxide and titanium dioxide are the most commonly used nanoparticles. Silicon dioxide is used as a food colorant, anticaking agent, and drying agent for food preservation and packaging. It also helps in absorbing the water molecules and therefore has hygroscopic application [119]. Titanium dioxide nanoparticles are used as a food colorant and photocatalytic disinfecting agent. They can also be used as a whitener in dairy products such as milk and cheese [121]. Generally, titanium dioxide provides a barrier for UV protection in food packaging. These two nanoparticles can also be used as food additives even in bulk quantities. Several regulatory bodies have allowed the use of SiO2 and TiO2 (E551 and E171) in large quantities in foodstuffs [122]. Other metals and metal oxide nanoparticles such as silver, iron, carbon, zinc oxide, and magnesium oxide are also widely used as food ingredients because of their antimicrobial activities. Silver nanoparticles have a wide range of antibacterial activities that can protect food from microbial infestation. It has been reported that small-sized (nano) silver particles can serve as a potential antibacterial agent as they are easily dispersed in food because they provide a larger surface area and are also easily ionized and chemically active. Several studies have recommended the use of silver nanoparticles as effective antimicrobials as compared to other metallic nanoparticles because the silver ones have a broad spectrum of activity [119] As per the Food and Drug Administration (FDA) standard, the use of silver as a food ingredient within the set limit is safe and does not pose any serious threat to biological systems. In recent years, silver nanoparticles have been preferred over other antimicrobial nanoparticles that are readily available in the market because they can be easily incorporated into the packaging material [119]. A number of researchers have reported that because silver does not filter easily within the microbial system, it alters ribosomal activity and thereby inhibits the production of various enzymes [119]. Silver nanoparticles have shown favorable bactericidal effects against gram-positive and gram-negative bacteria. Several researchers have observed that the silver nanoparticles were found to be more active against gram-negative bacteria [119, 123,124,125]. Silver nanoparticles have also proven their ability to extend the shelf life of fruits and vegetables by absorbing and decomposing ethylene. Zinc oxide is another nanoparticle that has been recommended as “GRAS” by the FDA and canthus be used as a food additive or ingredient in day-to-day applications [126].

Several studies have also recommended the use of carbon nanotubes in food packaging albeit in very low amounts due to their high level of toxicity [8, 25, 51]. The high toxicity level in the carbon nanotubes limits its use. Titanium dioxide nanoparticles are also known to have antimicrobial activities, but their photocatalyzed nature limits their applications in the food industry. Typically, these nanoparticles are only active in the presence of UV light. It has been observed that titanium dioxide nanoparticles under UV illumination behave as an active bactericide against various pathogens. For example, titanium dioxide nanoparticles cause the peroxidation of phospholipids that are present in the cell membrane of the bacterial cell wall. Upon irradiation from ultraviolet light, TiO2 nanoparticles photosensitize the reduction of methylene blue [127]. During this process, irradiation bleaches the particles and changes their color to blue in the presence of oxygen. Other than the above-mentioned ones, various other nanoparticles such as copper, magnesium, copper and magnesium oxide, gold, cadmium, selenium, and chitosan are also well known to have antimicrobial activity [128, 129].

4.6 Chitosan nanoparticles and chitosan-based additives/ films in food packaging

Chitosan is a high molecular weight, polycationic heteropolysaccharide, and it is generally known for its biodegradability, biocompatibility, and metal complexation. Its polycationic nature is mainly responsible for its wide antimicrobial activity [130]. Chitosan has a wide range of applications in different areas of food sciences, biological and chemical systems, as well as in the food and pharmaceutical industries. Besides these, Chitosan-based nanoparticles have also various applications in non-parenteral drug delivery for the treatment of cancer, pulmonary diseases and drug delivery to the brain [131]. In the last few years, the role of chitosan nanoparticles and chitosan-based films in food packaging has been investigated by several researchers [121, 132] who observed chitosan applications with much functionality and positive outcomes. Chitosan is normally positively charged which binds it to the negatively charged cell wall. As a result, the permeability and disruption of the cell wall are increased.

Chitosan nanoparticles are formed through ionic gelation, where the positively charged amino groups of chitosan electrostatically interact with the polyanions engaged as cross-linkers [133]. For example, Tripathi et al. [134], proposed chitosan nanoparticles based antimicrobial film consisting of chitosan and polyvinyl alcohol. The developed film showed the antibacterial activity against E. coli, S. aureus, and B. subtilis and it has also increased the shelf life of tomatoes. Another study conducted by Burdock [135] suggested hydroxypropyl methylcellulose act as a potential material for edible packaging films. However, De Moura et al. [136] noticed that the incorporation of chitosan-based nanocomposite in hydroxypropyl methylcellulose enhanced its mechanical and barrier characteristics. Moreover, antimicrobial activities of chitosan/gold and chitosan/silver nanocomposite against E. coli, S. aureus, P. aeruginosa, and Aspergillus niger have been evidenced in other studies [137].

Chitosan-based films also possess antifungal, antimicrobial, and antioxidant activities which could make these films an acceptable alternative to the use of synthetic chemicals in food packaging [138]. Moreover, chitosan-based films provide a better solution with regard to increasing the shelf life of the product without affecting its sensorial properties [139]. In the literature, many studies have reported the use of chitosan-based derivatives in the preservation, clarification and encapsulation of alcoholic and non-alcoholic beverages as well as dairy-based products [140, 141]. In addition to these, some researchers have also tried the combination of different nanomaterials (nanocomposites) in food packaging and preservation. The use of nanocomposites in packaging results in effective thermal and barrier properties at a lower cost. It has been estimated that the use of nanocomposite-based membranes reduced the water permeability in foods by a value of 46 [142].

Edible coatings with nanomaterials have also shown remarkable benefits during the storage of fruits and vegetables. These coatings keep the food safe without causing any physical damage during the transportation of food and also help to maintain the overall food quality. Among different coatings, chitosan is considered to be one of the best edible and biologically safe coatings for different types of foods due to its biodegradable, biochemical, antimicrobial, and film-forming properties and lack of toxicity [132]. Even for fresh-cut fruits, chitosan is one of the best examples of edible coatings for improving quality and resistivity. Moreover, it has been noticed that chitosan can control various pre- and post-harvest diseases of fruits and vegetables. Chitosan edible coating increases the shelf life of fresh produce by reducing the rate of respiration and minimizing water loss. Moreover, it has also been observed that an increase in the concentration of the chitosan coating up to a certain limit increases the positive effects of chitosan on shelf life and food quality [132, 143]. For example, Ali et al. [144] investigated the effect of chitosan coating with varying percentages (0.5, 1.5, 2.0%) on Eksotika II papaya fruit during 5 weeks of cold storage. The quality of the fruit was analyzed with regard to weight loss reduction, maintained firmness, soluble solids concentration, and peel color change. The qualities of the fruits treated with 1.5% chitosan were found to be good and acceptable. The untreated fruit and fruit treated with 0.5% chitosan ripened after 3 weeks of storage after which it began to decompose. However, the fruit treated with 2.0% chitosan did not ripen properly even after 5 weeks of storage under cold conditions. Consequently, an edible coating of 1.5% chitosan was recommended for papaya fruit in order to maintain product quality and shelf life. Moreover, Ali et al. [144] also concluded that enhancement in the concentration of chitosan from 0.5 to 1.5% was very effective although any increase in concentration beyond that level was not. In addition, the fruit treated with 1.5% chitosan showed no wrinkles, higher value of gloss and attractive peel color, as compared to the other treated or untreated fruit. The pulp of the papaya fruit treated with 1.5% chitosan was found in reddish-orange color, followed by 1.0% chitosan. Sheikh and Han also recommended chitosan for increasing the shelf life of sliced apples and fresh strawberries [132, 145]. In addition to shelf life application, chitosan coating has been found to be more effective at delaying weight loss in mangoes, bananas [146], and strawberries [147]. Other authors have also investigated the effect of chitosan and chitosan-based edible coating on different fresh and fresh-cut fruits such as sliced mango [148], strawberries [149], fresh-cut Chinese water chestnut [150], grapes [151], cucumber and pepper [152], and longan fruit [153].

4.7 Nanocomposites

Other than nanoparticles, nanocomposites and nanolaminates also have a wide application in the packaging of food materials. In recent years, they have been used extensively in the antimicrobial packaging of food items. Nano-composites are mainly used to protect foodstuffs from mechanical and high temperature stunning and to increase their shelf life [154]. For example, zinc oxide nanocomposite has gained a great deal of attention from the food industry as it has antioxidant effects and is therefore widely used in the active packaging of food material [155]. Nanocomposites are typically comprised of polymers in combination with nanoparticles, and their presence extends the properties of the polymer [69]. Generally, nanocomposites help to maintain the freshness of food material and to delay microbial spoilage for a longer period of time by providing highly versatile and chemical functionality. As a result, they are used primarily for the production of materials that have high barrier properties [156]. Nanocomposites act as a gas barrier to prevent the leakage of carbon dioxide from carbonated beverage bottles and cans. Food industries that mainly produce carbonated beverages can use the nanocomposites layer on the cans or bottles of the beverage in order to minimize the leakage instead of using heavy glass bottles and expensive cans [156]. A nanoclay nanocomposite is normally used for the development of these gas barriers. Durethan, Aegis, Imperium, and Nanocar are some of the commercially available nanoclay based nanocomposites in the market. These nanoclays are very popular due to their transparency, low density, surface properties, biodegradable nature, and superior flow properties [68]. Durethan, for example, is used to provide stiffness for paper board fruit juice containers and is comprised of polyamide. The Aegis nanoclay, mainly used in the production of carbonated drinks, acts as an oxygen scavenger that helps to retain carbon dioxide by providing enhanced barrier properties to the clay [68]. Imperium, a nanoclay based polymer, is comprised of nylon and also acts as an oxygen scavenger. Nano-car is used in the manufacturing of plastic beer bottles towards minimizing the leakage of carbon dioxide from the beverage. Nano-car is also a nanoclay based polymer and acts as a gas barrier [157]. Nowadays, a variety of nanocomposite-based commercialized products that help with the preservation and packaging of fresh produce and enhance the product shelf life are available in the market. Some of the commercialized products are Guard IN Fresh, Top Screen DS13, Nano-Ceram PAC, among others [67]. Guard IN Fresh helps to expedite the ripening process of fruits and vegetables in order to move products to market more quickly by scavenging ethylene gas [158]. Top Screen DS13 is a biodegradable nanocomposite product and is thus easily degradable and recyclable after use [70]. Nano-Ceram PAC is a nanocomposite-based coating material, which generally helps in the absorption of certain components that can cause an unacceptable odor and taste [159]. Nanoparticles-based nanocomposites have a wide range of antimicrobial activity and are widely used in the formation of packaging films. Silver-coated nanocomposites also act as antimicrobial agents. When silver attaches to the cell surface, the silver degrades the lipopolysaccharide which results in an increase in permeability and irreversible damage to the bacterial DNA [70]. PEG coated with garlic oil nanocomposites was found to be very effective at controlling certain pests that infected the packaged food materials [70]. Nanoaliminates are another example of nanoencapsulation and are generally used for the coating of fruits, vegetables, meats, and baked items.

5 Safety concerns of nanotechnology

The advent of nanotechnology and its rapid growth in the food industry have resulted in public concern about the safety of nanotechnology and its potential impact on human health [6, 7, 12]. Since nanomaterials possess properties that are different from those of their bulk materials, such as large surface area, they could pose toxic risks to the human body [30]. Similarly, there is a potential risk related to the application of nanotechnology in food packaging [24]. Another noteworthy concern is the ability of nanoparticles to penetrate cellular and membrane barriers due to their nanoscale [30]. However, despite the growing concerns about the potential adverse effects on human health, nanotechnology applications are already being sold and implemented [24]. For example, nanoparticles used in food packaging are not harmful to human health per se, but may pose some risk when incorporated into the food products themselves [8]. Nanotechnology-based applications are chemical-based systems, and just like any other chemical-based system, they do not necessarily have toxins or present adverse effects on human health [30]. Therefore, building a regulatory system that serves to control and manage the potential risks and toxicity from nanoparticles is key to ensuring the safety of nanotechnology applications in the food industry. Additional research is warranted to investigate the potential adverse effects of nanoparticles on human health and the environment.

6 Conclusion

In summary, nanotechnology plays a significant role in the food industry via applications that have reached all food sectors, including food processing, food safety, and food packaging. In the area of food safety, nanotechnology applications have already been employed as antimicrobial agents for food contact surfaces, food packaging, and coatings.

Nowadays, nanotechnology in the food industry helps to enhance the safety of food products through its application to pathogens and toxin detection, and by providing information on nutritional status. Nanotechnology in food packaging has the potential to change the way food is packaged. Consequently, nanotechnology applications in food packaging are promising as they can enhance food safety, quality, and extend the shelf life of food products.

Data availability

Data sharing is not applicable to this article as no new data were created or analyzed in this study.

References

Chellaram C, et al. Significance of nanotechnology in food industry. APCBEE Procedia. 2014;8:109–13. https://doi.org/10.1016/j.apcbee.2014.03.010.

Dera MW, Teseme WB. Review on the application of food nanotechnology in food processing. J Eng Technol Manag. 2020;5(2):41–7. https://doi.org/10.11648/j.ajetm.20200502.12.

Grumezescu AM, Holban AM, editors. Impact of nanoscience in the food industry, vol. 12. London: Academic Press; 2018.

Colica C, et al. The role of nanotechnology in food safety. New York: Nova Science Publisher’s, Inc.; 2018.

Duncan TV. Applications of nanotechnology in food packaging and food safety: barrier materials, antimicrobials and sensors. J Colloid Interface Sci. 2011;363(1):1–24. https://doi.org/10.1016/j.jcis.2011.07.017.

Chaudhry Q, Watkins R, Castle L. Nanotechnologies in food: what, why and how? In: Nanotechnologies in food. Cambridge: Royal Society of Chemistry; 2017. https://doi.org/10.1039/9781782626879-00001.

Berekaa MM. Nanotechnology in food industry; advances in food processing, packaging and food safety. Int J Curr Microbiol Appl Sci. 2015;4(5):345–57.

Nile SH, et al. Nanotechnologies in food science: applications, recent trends, and future perspectives. Nano-Micro Lett. 2020;12(1):1–34. https://doi.org/10.1007/s40820-020-0383-9.

Bajpai VK, et al. Prospects of using nanotechnology for food preservation, safety, and security. J Food Drug Anal. 2018;26(4):1201–14. https://doi.org/10.1016/j.jfda.2018.06.011.

Singh T, et al. Application of nanotechnology in food science: perception and overview. Front Microbiol. 2017;8:1501. https://doi.org/10.3389/fmicb.2017.01501.

Duran N, Marcato PD. Nanobiotechnology perspectives. Role of nanotechnology in the food industry: a review. Int J Food Sci. 2013;48(6):1127–34. https://doi.org/10.1111/ijfs.12027.

Gallocchio F, Belluco S, Ricci A. Nanotechnology and food: brief overview of the current scenario. Procedia Food Sci. 2015;5:85–8. https://doi.org/10.1016/j.profoo.2015.09.022.

García-Pinilla S, et al. Nanotechnology in food processing. In: Advances in processing technologies for bio-based nanosystems in food. Boca Raton: CRC Press; 2019. p. 259–76.

Bernardes PC, de Andrade NJ, Soares NDFF. Nanotechnology in the food industry. Biosci J. 2014;30(6).

Kumar V, Guleria P, Mehta SK. Nanosensors for food quality and safety assessment. Environ Chem Lett. 2017;15(2):165–77.

Saleh TA. Nanomaterials: classification, properties, and environmental toxicities. Environ Technol Innov. 2020. https://doi.org/10.1016/j.eti.2020.101067.

Verma ML, et al. Carbohydrate and protein based biopolymeric nanoparticles: current status and biotechnological applications. Int J Biol Macromol. 2020;154:390–412. https://doi.org/10.1016/j.ijbiomac.2020.03.105.

Sundar S, Kundu J, Kundu SC. Biopolymeric nanoparticles. Sci Technol Adv Mater. 2010. https://doi.org/10.1088/1468-6996/11/1/014104.

Yu H, et al. An overview of nanotechnology in food science: preparative methods, practical applications, and safety. J Chem. 2018. https://doi.org/10.1155/2018/5427978.

Pérez-López B, Merkoçi A. Nanomaterials based biosensors for food analysis applications. Trends Food Sci Technol. 2011;22(11):625–39. https://doi.org/10.1016/j.tifs.2011.04.001.

Aswathanarayan JB, Vittal RR. Nanoemulsions and their potential applications in food industry. Front Sustain Food Syst. 2019;3:95. https://doi.org/10.3389/fsufs.2019.00095.

Guo F, et al. A review of the synthesis and applications of polymer–nanoclay composites. Appl Sci. 2018;8(9):1696. https://doi.org/10.3390/app8091696.

Acevedo-Fani A, Soliva-Fortuny R, Martín-Belloso O. Nanostructured emulsions and nanolaminates for delivery of active ingredients: improving food safety and functionality. Trends Food Sci Technol. 2017;60:12–22. https://doi.org/10.1016/j.tifs.2016.10.027.

Ravichandran R. Nanotechnology applications in food and food processing: innovative green approaches, opportunities and uncertainties for global market. Int J Green Nanotechnol. 2010;1(2):P72–96. https://doi.org/10.1080/19430871003684440.

Ameta SK, et al. Use of nanomaterials in food science. In: Biogenic nano-particles and their use in agro-ecosystems. Singapore: Springer; 2020. https://doi.org/10.1007/978-981-15-2985-6_24.

Dewey-Mattia D, et al. Surveillance for foodborne disease outbreaks—United States, 2009–2015. MMWR Surveill Summ. 2018;67(10):1. https://doi.org/10.15585/mmwr.ss6710a1.

Centers for Disease Control and Prevention (CDC). Surveillance for foodborne disease outbreaks, United States, 2013, annual report. Atlanta: US Department of Health and Human Services, CDC. 2015. https://www.cdc.gov/foodsafety/pdfs/foodborne-disease-outbreaks-annual-report-2013-508c.pdf.

Kumar A, Pratush A, Bera S. Significance of nanoscience in food microbiology: current trend and future prospects. In: Nanotechnology for advances in medical microbiology. Singapore: Springer; 2021. p. 249–67.

Nasr NF. Applications of nanotechnology in food microbiology. Int J Curr Microbiol App Sci. 2015;4(4):846–53.

Eleftheriadou M, Pyrgiotakis G, Demokritou P. Nanotechnology to the rescue: using nano-enabled approaches in microbiological food safety and quality. Curr Opin. 2017;44:87–93. https://doi.org/10.1016/j.copbio.2016.11.012.

Krishna V, et al. Photocatalytic disinfection with titanium dioxide coated multi-wall carbon nanotubes. Process Saf Environ Prot. 2005;83(4):393–7. https://doi.org/10.1205/psep.04387.

Cho KH, et al. The study of antimicrobial activity and preservative effects of nanosilver ingredient. Electrochim Acta. 2005;51(5):956–60. https://doi.org/10.1016/j.electacta.2005.04.071.

Gomes SC, et al. Influence of excitation wavelength (UV or visible light) on the photocatalytic activity of titania containing gold nanoparticles for the generation of hydrogen or oxygen from water. J Am Chem Soc. 2011;133(3):595–602. https://doi.org/10.1021/ja1086358.

Morsy MK, et al. Incorporation of essential oils and nanoparticles in pullulan films to control foodborne pathogens on meat and poultry products. J Food Sci. 2014;79(4):M675–84. https://doi.org/10.1111/1750-3841.12400.

Myszka K, Czaczyk K. Bacterial biofilms on food contact surfaces-a review. Polish J Food Nutr Sci. 2011;61(3):173–80.

Khan ST, Al-Khedhairy AA, Musarrat J. ZnO and TiO2 nanoparticles as novel antimicrobial agents for oral hygiene: a review. J Nanopart Res. 2015;17(6):1–16. https://doi.org/10.1007/s11051-015-3074-6.

Chen CS, Durst RA. Simultaneous detection of Escherichia coli O157:H7, Salmonella spp. and Listeria monocytogenes with an array-based immunosorbent assay using universal protein G-liposomal nanovesicles. Talanta. 2006;69(1):232–8. https://doi.org/10.1016/j.talanta.2005.09.036.

Ravindranath SP, et al. Biofunctionalized magnetic nanoparticle integrated mid-infrared pathogen sensor for food matrixes. Anal Chem. 2009;81(8):2840–6. https://doi.org/10.1021/ac802158y.

Zhou Z, et al. A dual amplification strategy for DNA detection combining bio-barcode assay and metal-enhanced fluorescence modality. Chem Commun. 2014;50(87):13373–6.

Cho EC, et al. Fabrication of an electrochemical immunosensor with self-assembled peptide nanotubes. Colloids Surf A Physicochem Eng Asp. 2008;313:95–9. https://doi.org/10.1016/j.colsurfa.2007.04.154.

Cheng Y, et al. Rapid amperometric detection of coliforms based on MWNTs/Nafion composite film modified glass carbon electrode. Talanta. 2008;75(1):167–71. https://doi.org/10.1016/j.talanta.2007.10.047.

Afonso AS, et al. Electrochemical detection of Salmonella using gold nanoparticles. Biosens Bioelectron. 2013;40(1):121–6. https://doi.org/10.1016/j.bios.2012.06.054.

Joung HA, et al. High sensitivity detection of 16s rRNA using peptide nucleic acid probes and a surface plasmon resonance biosensor. Anal Chim Acta. 2008;630(2):168–73. https://doi.org/10.1016/j.aca.2008.10.001.

Zhao G, Xing F, Deng S. A disposable amperometric enzyme immunosensor for rapid detection of Vibrio parahaemolyticus in food based on agarose/nano-Au membrane and screen-printed electrode. Electrochem Commun. 2007;9(6):1263–8. https://doi.org/10.1016/j.elecom.2007.01.036.

El Ichi S, et al. Microconductometric immunosensor for label-free and sensitive detection of Gram-negative bacteria. Biosens Bioelectron. 2014;54:378–84. https://doi.org/10.1016/j.bios.2013.11.016.

Wang J, et al. Rapid detection of pathogenic bacteria and screening of phage-derived peptides using microcantilevers. Anal Chem. 2014;86(3):1671–8. https://doi.org/10.1021/ac403437x.

Clotilde LM, et al. A 7-plex microbead-based immunoassay for serotyping Shiga toxin-producing Escherichia coli. J Microbiol Methods. 2013;92(2):226–30. https://doi.org/10.1016/j.mimet.2012.11.023.

Orlov AV, et al. Magnetic immunoassay for detection of staphylococcal toxins in complex media. Anal Chem. 2013;85(2):1154–63. https://doi.org/10.1021/ac303075b.

Feng L, et al. A nanosensor based on quantum-dot haptens for rapid, on-site immunoassay of cyanotoxin in environmental water. Biosens Bioelectron. 2014;53:1–4. https://doi.org/10.1016/j.bios.2013.09.018.

Gaikwad KK, Singh S, Negi YS. Ethylene scavengers for active packaging of fresh food produce. Environ Chem Lett. 2020;18(2):269–84. https://doi.org/10.1007/s10311-019-00938-1.

Pradhan N, et al. Facets of nanotechnology as seen in food processing, packaging, and preservation industry. BioMed Res Int. 2015. https://doi.org/10.1155/2015/365672.

Auffan M, et al. Towards a definition of inorganic nanoparticles from an environmental, health and safety perspective. Nat Nanotechnol. 2009;4(10):634–41. https://doi.org/10.1038/nnano.2009.242.

Rashidi L, Khosravi-Darani K. The applications of nanotechnology in food industry. Crit Rev Food Sci. 2011;51(8):723–30. https://doi.org/10.1080/10408391003785417.

Ncube LK, et al. Environmental impact of food packaging materials: a review of contemporary development from conventional plastics to polylactic acid-based materials. Mater. 2020;13(21):4994. https://doi.org/10.3390/ma13214994.

Luo Y, Wang Q, Zhang Y. Biopolymer-based nanotechnology approaches to deliver bioactive compounds for food applications: a perspective on the past, present, and future. J Agric Food Chem. 2020;68(46):12993–3000. https://doi.org/10.1021/acs.jafc.0c00277.

Arshak K, et al. Characterisation of polymer nanocomposite sensors for quantification of bacterial cultures. Sens Actuators B Chem. 2007;126(1):226–31. https://doi.org/10.1016/j.snb.2006.12.006.

Bouwmeester H, et al. Review of health safety aspects of nanotechnologies in food production. Regul Toxicol Pharm. 2009;53(1):52–62. https://doi.org/10.1016/j.yrtph.2008.10.008.

Horner SR, et al. A proteomic biosensor for enteropathogenic E. coli. Biosens Bioelectron. 2006;21(8):1659–63. https://doi.org/10.1016/j.bios.2005.07.019.

Jones N, et al. Antibacterial activity of ZnO nanoparticle suspensions on a broad spectrum of microorganisms. FEMS Microbiol Lett. 2008;279(1):71–6. https://doi.org/10.1111/j.1574-6968.2007.01012.x.

Kang S, et al. Single-walled carbon nanotubes exhibit strong antimicrobial activity. Langmuir. 2007;23(17):8670–3. https://doi.org/10.1021/la701067r.

Coles D, Frewer LJ. Nanotechnology applied to European food production—a review of ethical and regulatory issues. Trends Food Sci Technol. 2013;34(1):32–43. https://doi.org/10.1016/j.tifs.2013.08.006.

Vidhyalakshmi R, Bhakyaraj R, Subhasree RS. Encapsulation “the future of probiotics”—a review. Adv Biol Res. 2009;3(3–4):96–103.

Sozer N, Kokini JL. Nanotechnology and its applications in the food sector. Trends Biotechnol. 2009;27(2):82–9. https://doi.org/10.1016/j.tibtech.2008.10.010.

Biswal SK, et al. Applications of nanotechnology in agriculture and food sciences. Int J Sci Innov Discov. 2012;2(1):21–36.

Wanekaya AK, et al. Nanowire-based electrochemical biosensors. Electroanal Int J Devoted Fund Pract Asp Electroanal. 2006;18(6):533–50. https://doi.org/10.1002/elan.200503449.

Mousavi SR, Rezaei M. Nanotechnology in agriculture and food production. J Appl Environ Biol Sci. 2011;1(10):414–9.

Burdo OG. Nanoscale effects in food-production technologies. J Eng Phys. 2005;78(1):90–6. https://doi.org/10.1007/s10891-005-0033-6.

Flanagan J, Singh H. Microemulsions: a potential delivery system for bioactives in food. Crit Rev Food Sci. 2006;46(3):221–37. https://doi.org/10.1080/10408690590956710.

Yotova L, Yaneva S, Marinkova D. Biomimetic nanosensors for determination of toxic compounds in food and agricultural products. J Chem Technol Metall. 2013;48(3):215–27.

Mason TG, et al. Nanoemulsions: formation, structure, and physical properties. J Phys Condens Matter. 2006;18(41):R635. https://doi.org/10.1088/0953-8984/18/41/R01.

Thirumurugan A, Ramachandran S, Shiamala GA. Combined effect of bacteriocin with gold nanoparticles against food spoiling bacteria—an approach for food packaging material preparation. Int Food Res J. 2013;20(4):1909–12.

Yadav S, Mehrotra GK, Dutta PK. Chitosan based ZnO nanoparticles loaded gallic-acid films for active food packaging. Food Chem. 2021;334: 127605. https://doi.org/10.1016/j.foodchem.2020.127605.

Zhang X, et al. Preparation of chitosan-TiO2 composite film with efficient antimicrobial activities under visible light for food packaging applications. Carbohydr Polym. 2017;169:101–7. https://doi.org/10.1016/j.carbpol.2017.03.073.

Gu R, et al. Regenerated cellulose films with amino-terminated hyperbranched polyamic anchored nanosilver for active food packaging. ACS Appl Bio Mater. 2019;3(1):602–10. https://doi.org/10.1021/acsabm.9b00992.

Zhu Z, et al. Preparation of PAN@ TiO2 nanofibers for fruit packaging materials with efficient photocatalytic degradation of ethylene. Material. 2019;12(6):896. https://doi.org/10.3390/ma12060896.

Fuertes G, et al. Intelligent packaging systems: sensors and nanosensors to monitor food quality and safety. J Sens. 2016. https://doi.org/10.1155/2016/4046061.

Yildirim S, et al. Active packaging applications for food. Compr Rev Food Sci Food Saf. 2018;17(1):165–99. https://doi.org/10.1111/1541-4337.12322.

Dias MV, et al. Use of allyl isothiocyanate and carbon nanotubes in an antimicrobial film to package shredded, cooked chicken meat. Food Chem. 2013;141(3):3160–6. https://doi.org/10.1016/j.foodchem.2013.05.148.

Majid I, et al. Novel food packaging technologies: innovations and future prospective. J Saudi Soc Agric Sci. 2018;17:454–62. https://doi.org/10.1016/j.jssas.2016.11.003.

Bikiaris DN, Triantafyllidis KS. HDPE/Cu-nanofiber nanocomposites with enhanced antibacterial and oxygen barrier properties appropriate for food packaging applications. Mater Lett. 2013;93:1–4. https://doi.org/10.1016/j.matlet.2012.10.128.

Sharma C, et al. Nanotechnology: an untapped resource for food packaging. Front Microbiol. 2017;8:1735. https://doi.org/10.3389/fmicb.2017.01735.

Duncan TV. Applications of nanotechnology in food packaging and food safety: barrier materials, antimicrobials and sensors. J Colloid Interface Sci. 2011;363:1–24. https://doi.org/10.1016/j.jcis.2011.07.017.

Damm C, Münstedt H, Rösch A. The antimicrobial efficacy of polyamide 6/silver-nano- and microcomposites. Mater Chem Phys. 2008;108:61–6. https://doi.org/10.1016/j.matchemphys.2007.09.002.

Mohammed Fayaz A, et al. Mycobased synthesis of silver nanoparticles and their incorporation into sodium alginate films for vegetable and fruit preservation. J Agric Food Chem. 2009;57:6246–52. https://doi.org/10.1021/jf900337h.

Rhim J-W, et al. Preparation and characterization of bio-nanocomposite films of agar and silver nanoparticles: laser ablation method. Carbohydr Polym. 2014;103:456–65. https://doi.org/10.1016/j.carbpol.2013.12.075.

An J, et al. Physical, chemical and microbiological changes in stored green asparagus spears as affected by coating of silver nanoparticles-PVP. LWT Food Sci Technol. 2008;41:1100–7. https://doi.org/10.1016/j.lwt.2007.06.019.

Kraśniewska K, Galus S, Gniewosz M. Biopolymers-based materials containing silver nanoparticles as active packaging for food applications—a review. Int J Mol Sci. 2020;21(3):698. https://doi.org/10.3390/ijms21030698.

Fasihnia SH, Peighambardoust SH, Peighambardoust SJ. Nanocomposite films containing organoclay nanoparticles as an antimicrobial (active) packaging for potential food application. J Food Process Preserv. 2018;42: e13488. https://doi.org/10.1111/jfpp.13488.

Branton D, et al. The potential and challenges of nanopore sequencing. Nanosci Technol Collect Rev Nat J. 2010. https://doi.org/10.1142/9789814287005_0027.

Ansari AA, et al. Prospects of nanotechnology in clinical immunodiagnostics. Sensors. 2010;10(7):6535–81. https://doi.org/10.3390/s100706535.

Lopez-Rubio A, Gavara R, Lagaron JM. Bioactive packaging: turning foods into healthier foods through biomaterials. Trends Food Sci Technol. 2006;17(10):567–75. https://doi.org/10.1016/j.tifs.2006.04.012.

Mannino S, Scampicchio M. Nanotechnology and food quality control. Vet Res Commun. 2007;31(1):149–51. https://doi.org/10.1007/s11259-007-0081-9.

Sharma A, et al. Antibody immobilized cysteamine functionalized-gold nanoparticles for aflatoxin detection. Thin Solid Films. 2010;519(3):1213–8. https://doi.org/10.1016/j.tsf.2010.08.071.

Radoi A, et al. Enzyme-linked immunosorbent assay (ELISA) based on superparamagnetic nanoparticles for aflatoxin M1 detection. Talanta. 2008;77(1):138–43. https://doi.org/10.1016/j.talanta.2008.05.048.

Zhou Y, et al. Colloidal gold probe-based immunochromatographic assay for the rapid detection of brevetoxins in fishery product samples. Biosens Bioelectron. 2009;24(8):2744–7. https://doi.org/10.1016/j.bios.2009.01.034.

Chiao DJ, et al. Colloidal gold-based immunochromatographic assay for detection of botulinum neurotoxin type B. J Chromatogr B. 2004;809(1):37–41. https://doi.org/10.1016/j.jchromb.2004.05.033.

Zamolo VA, et al. Highly sensitive electrochemiluminescentnanobiosensor for the detection of palytoxin. ACS Nano. 2012;6(9):7989–97. https://doi.org/10.1021/nn302573c.

Xiulan S, et al. Preparation of gold-labeled antibody probe and its use in immunochromatography assay for detection of aflatoxin B1. Int J Food Microbiol. 2005;99(2):185–94. https://doi.org/10.1016/j.ijfoodmicro.2004.07.021.

Liu D, et al. A highly sensitive, dual-readout assay based on gold nanoparticles for organophosphorus and carbamate pesticides. Anal Chem. 2012;84(9):4185–91. https://doi.org/10.1021/ac300545p.

Huang H, et al. Visual detection of melamine in milk samples based on label-free and labeled gold nanoparticles. Talanta. 2011;85(2):1013–9. https://doi.org/10.1016/j.talanta.2011.05.006.

Su H, et al. Selective determination of melamine in milk samples using 3-mercapto-1-propanesulfonate-modified gold nanoparticles as colorimetric probe. Talanta. 2011;85(3):1338–43. https://doi.org/10.1016/j.talanta.2011.06.017.

Sanz VC, et al. Development of a tyrosinase biosensor based on gold nanoparticles-modified glassy carbon electrodes: Application to the measurement of a bioelectrochemical polyphenols index in wines. Anal Chim Acta. 2005;528(1):1–8. https://doi.org/10.1016/j.aca.2004.10.007.

Liu S, Yu J, Ju H. Renewable phenol biosensor based on a tyrosinase-colloidal gold modified carbon paste electrode. J Electroanal Chem. 2003;540:61–7. https://doi.org/10.1016/S0022-0728(02)01276-7.

Mak AC, et al. Sensitive giant magnetoresistive-based immunoassay for multiplex mycotoxin detection. Biosens Bioelectron. 2010;25(7):1635–9. https://doi.org/10.1016/j.bios.2009.11.028.

Zhao Y, et al. Simultaneous detection of multifood-borne pathogenic bacteria based on functionalized quantum dots coupled with immunomagnetic separation in food samples. J Agric Food Chem. 2009;57(2):517–24. https://doi.org/10.1021/jf802817y.

Ansari AA, et al. Nanostructured zinc oxide platform for mycotoxin detection. Bioelectrochemistry. 2010;77(2):75–81. https://doi.org/10.1016/j.bioelechem.2009.06.014.

Najafi M, Khalilzadeh MA, Karimi-Maleh H. A new strategy for determination of bisphenol A in the presence of Sudan I using a ZnO/CNTs/ionic liquid paste electrode in food samples. Food Chem. 2014;158:125–31. https://doi.org/10.1016/j.foodchem.2014.02.082.

Wang L, et al. Simple, rapid, sensitive, and versatile SWNT− paper sensor for environmental toxin detection competitive with ELISA. Nano Lett. 2009;9(12):4147–52. https://doi.org/10.1021/nl902368r.

Villamizar RA, et al. Fast detection of Salmonella Infantis with carbon nanotube field effect transistors. Biosens Bioelectron. 2008;24(2):279–83. https://doi.org/10.1016/j.bios.2008.03.046.

Zhao X, et al. A rapid bioassay for single bacterial cell quantitation using bioconjugated nanoparticles. Proc Natl Acad Sci. 2004;101(42):15027–32. https://doi.org/10.1073/pnas.0404806101.

Sánchez-Acevedo ZC, Riu J, Rius FX. Fast picomolar selective detection of bisphenol A in water using a carbon nanotube field effect transistor functionalized with estrogen receptor-α. Biosens Bioelectron. 2009;24(9):2842–6. https://doi.org/10.1016/j.bios.2009.02.019.

Xiao F, et al. Single-walled carbon nanotube-ionic liquid paste electrode for the sensitive voltammetric determination of folic acid. Sens Actuators B Chem. 2008;134(2):895–901. https://doi.org/10.1016/j.snb.2008.06.037.

Yang D, Zhu L, Jiang X. Electrochemical reaction mechanism and determination of Sudan I at a multi wall carbon nanotubes modified glassy carbon electrode. J Electroanal Chem. 2010;640(1–2):17–22. https://doi.org/10.1016/j.jelechem.2009.12.022.

Ye JS, et al. Nonenzymatic glucose detection using multi-walled carbon nanotube electrodes. Electrochem Commun. 2004;6(1):66–70. https://doi.org/10.1016/j.elecom.2003.10.013.

Devaramani S, Malingappa P. Synthesis and characterization of cobalt nitroprusside nano particles: application to sulfite sensing in food and water samples. Electrochim Acta. 2012;85:579–87. https://doi.org/10.1016/j.electacta.2012.08.105.

Wu RJ, et al. Ag@ SnO2 core–shell material for use in fast-response ethanol sensor at room operating temperature. Sens Actuators B Chem. 2013;178:185–91. https://doi.org/10.1016/j.snb.2012.12.052.

García-Aljaro C, et al. Conducting polymer nanowire-based chemiresistive biosensor for the detection of bacterial spores. Biosens Bioelectron. 2010;25(10):2309–12. https://doi.org/10.1016/j.bios.2010.03.021.

Liu YJ, et al. Magnetic bead-based DNA detection with multi-layers quantum dots labeling for rapid detection of Escherichia coli O157: H7. Biosens Bioelectron. 2008;24(4):558–65. https://doi.org/10.1016/j.bios.2008.06.019.

Zhao R, Torley P, Halley PJ. Emerging biodegradable materials: starch-and protein-based bio-nanocomposites. J Mater Sci. 2008;43(9):3058–71. https://doi.org/10.1007/s10853-007-2434-8.

Chaudhary P, Fatima F, Kumar A. Relevance of nanomaterials in food packaging and its advanced future prospects. J Inorg Organomet Polym Mater. 2020;30(12):5180–92. https://doi.org/10.1007/s10904-020-01674-8.

Acosta E. Bioavailability of nanoparticles in nutrient and nutraceutical delivery. Curr Opin Colloid Interface Sci. 2009;14(1):3–15. https://doi.org/10.1016/j.cocis.2008.01.002.

European Food Safety Authority (EFSA). The potential risks arising from nanoscience and nanotechnologies on food and feed safety. EFSA J. 2009;7(3):958. https://doi.org/10.2903/j.efsa.2009.958.

Dakal TC, et al. Mechanistic basis of antimicrobial actions of silver nanoparticles. Front Microbiol. 2016;7:1831. https://doi.org/10.3389/fmicb.2016.01831.

Wang L, Hu C, Shao L. The antimicrobial activity of nanoparticles: present situation and prospects for the future. Int J Nanomed. 2017;12:1227. https://doi.org/10.2147/IJN.S121956.

Yin IX, et al. The antibacterial mechanism of silver nanoparticles and its application in dentistry. Int J Nanomed. 2020;15:2555–62. https://doi.org/10.2147/IJN.S246764.

Jiang J, Pi J, Cai J. The advancing of zinc oxide nanoparticles for biomedical applications. Bioinorg Chem Appl. 2018. https://doi.org/10.1155/2018/1062562.

Arora A, Padua GW. Nanocomposites in food packaging. J Food Sci. 2010;75(1):R43–9. https://doi.org/10.1111/j.1750-3841.2009.01456.x.

Sánchez-López E, et al. Metal-based nanoparticles as antimicrobial agents: an overview. Nanomaterials. 2020;10(2):292. https://doi.org/10.3390/nano10020292.

Umar MF, et al. Bio-mediated synthesis of reduced graphene oxide nanoparticles from chenopodium album: their antimicrobial and anticancer activities. Nanomaterials. 2020;10(6):1096. https://doi.org/10.3390/nano10061096.

Arora D, et al. An update on polysaccharide-based nanomaterials for antimicrobial applications. Appl Microbiol Biotechnol. 2016;100:2603–15. https://doi.org/10.1007/s00253-016-7315-0.

Mohammed M, et al. An overview of chitosan nanoparticles and its application in non-parenteral drug delivery. Pharmaceutics. 2017;9:53. https://doi.org/10.3390/pharmaceutics9040053.

Shiekh RA, et al. Chitosan as a novel edible coating for fresh fruits. Food Sci Technol Res. 2013;19(2):139–55. https://doi.org/10.3136/fstr.19.139.

Ahmed T, Aljaeid B. Preparation, characterization, and potential application of chitosan, chitosan derivatives, and chitosan metal nanoparticles in pharmaceutical drug delivery. Drug Des Dev Ther. 2016;10:483. https://doi.org/10.2147/DDDT.S99651.

Tripathi S, Mehrotra GK, Dutta PK. Physicochemical and bioactivity of cross-linked chitosan–PVA film for food packaging applications. Int J Biol Macromol. 2009;45:372–6. https://doi.org/10.1016/j.ijbiomac.2009.07.006.

Burdock GA. Safety assessment of hydroxypropyl methylcellulose as a food ingredient. Food Chem Toxicol. 2007;45:2341–51. https://doi.org/10.1016/j.fct.2007.07.011.

De Moura M, et al. Improved barrier and mechanical properties of novel hydroxypropyl methylcellulose edible films with chitosan/tripolyphosphate nanoparticles. J Food Eng. 2009;92:448–53. https://doi.org/10.1016/j.jfoodeng.2008.12.015.

Youssef AM, Abdel-Aziz MS, El-Sayed SM. Chitosan nanocomposite films based on Ag-NP and Au-NP biosynthesis by Bacillus Subtilis as packaging materials. Int J Biol Macromol. 2014;69:185–91. https://doi.org/10.1016/j.ijbiomac.2014.05.047.