Abstract

Fresh fruits like bananas are very susceptible to mechanical damage during postharvest handling which can result in a substantial decline in quality. The study aims to evaluate the effect of bruise damage and storage temperatures on the quality of banana fruits after 48 h storage. Each ‘Grand Naine’ banana fruit was impacted once by using a drop impact test using three different heights (10, 30, and 50 cm) and storage temperatures (13 and 22 °C) after 48 h of storage. Different quality analyses were measured like bruise measurements (impact energy, bruise area, bruise volume, and bruise susceptibility), weight loss, total soluble solids (TSS), color (L*, a*, b*, hue°, chroma, yellowness index, yellowness value) headspace gases (respiration and ethylene production rate). The results showed that bruise measurements (bruise area, bruise volume, and bruise susceptibility) were highly affected by drop height. The quality parameters like weight, color, total soluble solids and headspace gases were affected by drop height and storage condition. Weight loss, total soluble solids, respiration rate, and ethylene production rate increased as drop height and storage temperature rise. Storage at ambient conditions (22 °C) accelerated bruising occurrence in banana fruits. Fewer changes were observed after 48 h of storage. The least value of yellowness index was observed on the non-bruised banana fruits (84.03) under 13 °C storage conditions. The findings of the study can provide baseline data to understand the mechanical damage mechanism on fruit quality, hoping to create awareness and educate farming communities and consumers. Storage temperature management is another approach that needs to be followed to reduce the occurrence of mechanical damage in fresh produce.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Banana (Musa spp.) is one the widely produced and consumed tropical fruits worldwide [37] with the highest production of 127.3 million tonnes and ranked fourth in terms of other agricultural commodities value (63.6 billion US$) after rice, wheat, and milk. The current global cultivated area for bananas is around 5 million ha. Being a main staple food product, it is a significant global tropical fruit, feeding almost 400 million people in tropical areas [27]. Banana contains special flavor, many vital nutrients for consumers as well as global availability around the year [9]. Besides, it is rich in crucial ingredients with health care functions like depression resistance, oxidation resistance, constipation prevention, etc. [18].

Banana is considered as a climacteric perishable fruit which makes its postharvest loss relatively high and occurs mostly during transportation, handling, and storage in the supply chain [30, 36]. The quality of bananas can be affected by superficial defects caused by mechanical damage [12]. Similar to any other perishable fresh produce, the postharvest losses in banana fruits are high due to mechanical damage that occurs during postharvest distribution and handling [6]. Besides, bananas are harvested and then transported at the mature green phase, the external appearance of ripened bananas at the retail outlets could be extremely poor as a consequence of mechanical damages due to inadequate handling practices throughout the supply chain [38].

Mechanical damage is a result of one or more force loadings occurring on produce resulting in the outer layer of the fresh produce pericarp [8, 26]. Also, consumers can cause mechanical damage in supermarkets when handling ripened banana fruits or by distributors during handling and transporting [10]. Banana is an example of a fruit crop where the impact of mechanical damages has a severe effect on the visual quality appearance of the fruit by causing skin color changes from brown to black [12]. Generally, bruising is the most common form of mechanical damages that downgrades the quality of any fresh produce and causes high economic losses [23]. Bruising is characterized by undesirable marks (brownish to black) and the symptoms become visible in the banana peel epidermal layer. Since the external quality attributes of fruits are very essential in the markets, bruised banana is unsalable [10]. Bruise damage is a consequence of action resulting from an extreme external force on the fruit surface during the impact against other fruit or a rigid body during handling [34]. Bruise damage is a form of failure in the subcutaneous tissue without causing rupture of the skin where the discoloration of injured tissues indicates the damaged spot [29].

The severity of the bruise may be recorded as diameter, area, and volume of the bruise. Bruise depth and diameter are considered to be the main measurements used to distinguish bruise size [26]. Fruit bruise damage can be replicated on the laboratory scale using different techniques, mostly designed to simulate various types of dynamic loadings which could be involved in real-time harvesting operations. Impact techniques including dropping fresh fruits on a rigid surface or using a uniform steel ball of a known mass dropped from different heights into the fruit have been implemented to investigate the bruise damage susceptibility of various fruits [31].

As reviewed by Hussein et al. [14], bruise damage on harvested fresh produce significantly influences the physiological processes like moisture content, the respiration rate of the injured skin. Additionally, Opara and Pathare [26] stated that bruising can affect the metabolic processes (transpiration, ethylene production, and relative electrical conductivity) and other biological processes (microbial spoilage), thus, reducing the shelf life and increasing fruit postharvest losses. Bruise susceptibility of fresh produce is a measure for the response to external loading. Based on our knowledge, the majority of studies focused on the effect of different impact levels on the quality of fresh produce (e.g. banana) at one storage condition [21, 22]. Also, few studies investigated the effect of bruising on banana fruits [10]. Therefore, this study evaluated the effect of simulated handling practices on the mechanical damage of bananas by using a drop impact test by dropping a steel ball from different heights in the fruit surface. It also assessed the impact of two storage conditions on the bruised and non-bruised banana quality attributes.

2 Materials and methods

2.1 Plant material and bruise measurement, and storage

Boxes of mature (Phase 3), healthy, and unbruised ‘Grand Naine’ banana fruits, were purchased from the market (23° 35′ 28.1″ N latitudes and 58° 13′ 28.3″ E longitudes) and delivered to Postharvest Technology Laboratory, College of Agricultural and Marine Sciences at Sultan Qaboos University (23° 35′ 25.1″ N latitudes and 58° 10′ 07.9″ E longitudes), Oman. The selected banana fruits were similar in weight, color, and sugar content (Table 1). The total number of samples used for this study was 90.

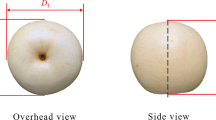

Banana samples were damaged by impact using the drop impact test (Fig. 1) as described by Pathare and Al-Dairi [29]. This test includes dropping a steel ball (66.05 g) on banana fruits from different heights. Accordingly, bananas were divided into groups (treatments) consisting of T1—control (without damage), and impact from heights of T2—10 cm (low), T3—30 cm (medium), and T4—50 cm (high), where each treatment included 20 replications. Impact energy (Ei) (Eq. 1), bruise area (BA) (Eq. 2), bruise volume (BV) (Eq. 3), and bruise susceptibility (BS) (Eq. 4) were calculated by using the following formulas [31].

where mb is the mass of steel ball, g is the gravitational constant (9.81 ms−2), h is the drop height, w1 and w2 are major and minor width, d is bruise diameter, and hb is bruise depth. Also, bruise diameter and bruise depth were measured by using a digital calliper (Model: Mitutoyo, Mitutoyo Corp., Japan).

Thereafter, each treatment was separated equally into two storage conditions namely, 13 °C ± 0.5 °C (90 ± 5% RH) a and 22 °C ± 1 °C (80 ± 5% RH). To assess the effect of impact damage and storage temperatures on bananas, different quality measurements were assessed after 48 h of storage such as physical (weight loss % and color parameters), chemical (total soluble solids), and physiological (respiration rate, and ethylene production rate) analysis. Also, a total of 10 samples were analyzed prior to the impact test and storage.

2.2 Determinations of physical analysis

2.2.1 Weight loss %

A total of 10 banana fruits per treatment were weighed prior to the impact test and after 48 h of storage. This was conducted by using electric weight balance (Model: GX-4000, Japan) with an accuracy of ± 0.01 g. Weight loss (%) was calculated by subtracting the weight of banana fruits from their initial weights.

2.2.2 Color measurements

A total of 240 peel color readings were recorded after 48 h of storage [30 readings per 10 replicates per treatment (n = 8)] using a colorimeter (Model: NR110, Shenzhen ThreeNH Tech, China). The main color space coordinates (CIEL*a*b*) were recorded like L* (lightness and darkness), a* (redness and greenness), and b* (yellowness and blueness) [3, 7]. Besides, other color parameters were calculated like Chroma (C*) that donates color saturation (Eq. 5), hue angle (Hue°) which donates color purity (Eq. 6), yellowness index (YI) (Eq. 7), and yellow color value (Eq. 8) [32] as follow:

2.3 Determinations of chemical analysis

2.3.1 Total soluble solids (TSS)

For this experiment, the banana juice was prepared by blending 30 g of banana pulp tissue and 90 mL distilled water using a blender (Model: LM2201, Moulinex, China) for 2 min. Later, the blended juice was filtered through a filter paper. A single drop of the filtered juice was placed in the prism of the digital refractometer (Model: PR-32 α, ATAGO Co., Ltd, Japan) and was presented as °Bx at 20 °C [11]. Since the initial pulp sample was dilated three times with distilled water, the recorded values were multiplied by 3. A total of 20 readings of total soluble solids were determined from each treatment (2 readings from 10 replicates).

2.4 Determinations of physiological analysis

2.4.1 Respiration and ethylene production rate

The procedures explained by Pathare and Al-Dairi [28] were used to measure the headspace gases. For each treatment, 2 plastic containers (2.3 L) containing 5 banana fruits were used to measure respiration (CO2 and O2) rate and ethylene (C2H4) production rate. To measure respiration rate and ethylene production rate, O2/CO2 analyzer (Model: 90 2D, Quantek Instruments, Inc., Grafton, Australia) and ethylene detector (Model: SCS 56, Fricaval89, Valencia, Spain) were used, respectively. Respiration rate CO2 rate and C2H4 rate were calculated according to Opara et al. [25].

2.5 Statistical analysis

Data were statistically analyzed using two factorial analyses of variance (ANOVA) (Factor A: drop height; factor B: storage condition) of the SPSS 20.0 (International Business Machine Crop., USA) to determine the effect of both factors and their interaction at a 5% significance level (P < 0.05). The resulted data were expressed in mean ± standard deviation. Also, the method of LSD Test was used to differentiate treatment means at P ≤ 0.05.

3 Results and discussions

3.1 Bruise area, volume, and susceptibility

The impact energy at each of the selected drop heights (10, 30, and 50 cm) is shown in Table 2. Results showed that the influence of both storage temperature and drop impact height on bruise area (BA) and bruise volume (BV) was significant during 48 h storage (P < 0.05). Also, statistical variation differences on BA and BV values were observed between the overall treatments. The results showed that the high drop-impact bruised banana fruits stored at 22 °C had a higher BA and BV with 163.45 mm2 and 3.41 × 10–5 m3, respectively. This was followed by medium drop-impact bruised banana fruits under the same storage condition which recorded a bruise area and volume with 128.78 mm2 and 2.04 × 10–4 m3, respectively. The current study detected that banana fruits impacted from the lowest drop height (10 cm) and stored under low temperature (13 °C) resulted in less BA (17.30 mm2) and BV (2.12 × 10–6 m3). Overall, both the bruise area (BA) and bruise volume (BV) increased with the impact energy (Ei)/drop height and storage temperature (Fig. 2). Similar results were observed by Pathare et al. [31], where damage from high impact level (60 cm) and storage at room temperature (22 °C) recorded the highest BA and BV with 184 mm2 and 4.75 × 10–4 m3, respectively. Tabatabaekoloor [35] revealed that elevating the drop height from 5 to 15 cm can increase the BA by 15% on peach fruit.

The bruise susceptibility (BS) of damaged banana fruits was varied significantly with drop height (P ≤ 0.000001) and storage temperature (P = 0.002136) after 48 h storage period (Fig. 3). The mean value of bruise susceptibility (BS) of bruised bananas from 50 cm drop height (Ei = 0.323 J) stored under ambient storage condition was 1.056 × 10–3 m3J−1. The lowest bruise susceptibility (BS) value (3.32 × 10–3 m3J−1) was observed in banana fruit stored at 13 °C and impacted from the low drop-impact (10 cm, Ei = 0.064 J). The relationship between bruise volume (BV) and impact energy (Ei) highlighted the key role played by drop height or impact level. Impact energy (Ei) increased with increasing the drop height, thus, increase fruit bruise size (BA and BV) and bruising incidence/susceptibility (BS). Tabatabaekoloor [35] indicated that the highest drop height released higher energy which potentially expedites the contact intensity, hence, increasing fresh produce bruised area (BA).

Bruise susceptibility of ‘Grand Naine’ banana fruits impacted at different drop heights; 10 cm, 30 cm, 50 cm after 48 h at 13 °C and 22 °C storage conditions. Error bars represent the standard deviation (SD) of the mean values ± S.D. of 10 readings of 10 replicates. Data were subjected to a two-factorial analysis of variance (ANOVA) (factor A; drop height, factor B; storage temperature). Mean separation was carried out using LSD test. Bars with different letters are significantly different (p < 0.05)

The effect of bruising or impact energy was highly pronounced in banana fruits stored at ambient temperature (22 °C). Impact energy was highly absorbed by banana fruits stored under this condition, where much bruise depth and bruise size were observed as shown in Fig. 2. Also, Ahmadi et al. [2] also reported similar findings, where high storage temperature can increase bruising on peach fruit. This might be attributed to the active enzymes that degrade the cell wall, which causes mechanical damage and stiffness on the damaged fresh produce. Besides, Bugaud et al. [10] studied the effect of different impact energies (20–200 mJ) on banana fruits stored at 18 °C throughout ripening and 13 °C between day 2 and day 6 after ethylene induction. Their study align with the results of the current study where reducing temperature can decrease bruise susceptibility (BS).

3.2 Effect on weight loss

Weight loss (%) of ‘Grand Naine’ banana fruits in all studied treatments is shown in Fig. 4. Impact damage from different heights and storage temperatures significantly affect (P < 0.05) the weight loss (%) of banana fruits after 48 h of storage. The weight loss increased by 0.83%, 0.71%, 0.40%, and 0.39% for banana fruits stored at ambient temperature (22 °C) after being impacted by the steel ball from 50 cm, 30 cm, 10 cm, and for the one with no bruise (control), respectively. Storage at 13 °C recorded less weight reduction (%) on banana fruits subjected to a damage from 10 cm (0.27%), 30 cm (0.37%), 50 cm (0.33%) and control (0.27%) groups. The variation between banana fruits impacted from the lowest height and the one with no bruise (control) was not significant. Overall, impact from the highest drop level (50 cm) recorded the highest weight loss (%), particularly at ambient temperature (22 °C). The high reduction observed on a banana at ambient conditions (22 °C) was probably due to increased banana fruit evapotranspiration generated from higher temperatures [22]. Also, it is attributed to changes in cell wall permeability and tissue damage leading to higher moisture content through the cells wall of fresh produce like bananas [1] and tomatoes [4]. Maia et al. [21] stated that mechanical injuries and damages can increase the weight loss of “Prata Anã” banana fruits. They recorded 1.2% losses in banana fruits due to impact (0.9711 J) after 9 days of storage at room temperature. They emphasized that the mechanical injuries could cause intense dehydration in the affected region of the damaged fruit which subsequently increased the weight loss of bananas. Hussein et al. [16] stated that bruising damage might change the tissue permeability. The resulting small cracks connecting to the external and internal atmosphere allow the interchange of atmospheric factors, mainly water vapor. This effect accelerates the weight loss of fresh produce. A recent study by Pathare et al. [31] found that exposing pear fruit to damage using impact test from 60 cm drop height showed 0.97% and 0.32% losses after 48 h of storage at 10 and 22 °C.

Weight loss (%) of ‘Grand Naine’ banana fruits impacted at different drop heights; 10 cm, 30 cm, 50 cm with non-bruised samples (Control) after 48 h at 13 °C and 22 °C storage conditions. Error bars represent the standard deviation (SD) of the mean values ± S.D. of 10 readings of 10 replicates. Data were subjected to a two-factorial analysis of variance (ANOVA) (factor A; drop height, factor B; storage temperature). Mean separation was carried out using LSD test. Bars with different letters are significantly different (p < 0.05)

3.3 Effect on color

The L* (lightness) color value (mean ± sd) in the banana peel during 48 h storage after being impacted from three drop heights is shown in Table 3. The L* value was statistically influenced by temperature storage (P = 0.000900) and impact drop height (P = 0.000911). The highest L* value was observed on banana fruits impacted from 50 cm (67.05) drop height and stored at 22 °C, while the lowest one was for a banana with no bruise (62.96) stored at 13 °C. Similar trends were observed with other banana fruit groups, where the highest drop-impact and storage at higher temperature showed a higher L* value compared to medium and low heights and the control groups under the same storage temperature. Besides, fewer variations were observed on the a* value (redness) of bruised banana fruits at both storage conditions. However, the study found a significant impact (P < 0.05) between the a* value and studied factors (drop height and storage temperature) (Table 3). Results showed that 50 cm drop height bruised banana stored at 22 °C had the highest a* value with 3.18 compared to the non-impact (control) banana fruits (1.74) stored at 13 °C.

There were marked significant differences in the b* (yellowness) values of bruised banana fruits at both storage conditions (Fig. 5). The b* value was affected by the storage temperature (P = 0.001279) and drop height impact (P ≤ 0.00001). Storage at 22 °C increased the b* value of high drop-impact bruised bananas (45.96), whereas storage at 13 °C delayed the increase of the b* value of high drop-impact bruised bananas (43.43). The lowest b* value was observed in low drop-impact bruised bananas (36.96) stored at 13 °C. The hue° (yellow color purity) was significantly different and highly influenced by both investigated factors (P < 0.05) after 48 h of storage (Table 3). The damaged banana fruits showed a noticed significance in their hue° value when compared to the non-bruised fruits at both conditions. Also, storage under ambient temperature accelerated the occurrence of color purity (hue°). However, chroma (the saturation of yellow color) value was statistically affected by the storage temperature (P < 0.000001) but it was not affected by drop impact height (P = 0.953450). The highest chroma value of 41.95 was observed in low drop-impact bruised banana fruits stored at 13 °C, while the lowest value of 33.34 was detected in medium drop-impact bruised banana fruits stored at 22 °C (Table 3).

b* value (yellowness) of ‘Grand Naine’ banana fruits impacted at different drop heights; 10 cm, 30 cm, 50 cm with non-bruised samples (Control) after 48 h at 13 °C and 22 °C storage conditions. Error bars represent the standard deviation (SD) of the mean values ± S.D. of 30 readings of 10 replicates. Data were subjected to a two-factorial analysis of variance (ANOVA) (factor A; drop height, factor B; storage temperature). Mean separation was carried out using LSD test. Bars with different letters are significantly different (p < 0.05)

The Fig. 6 presents the yellowness index (YI) and yellowness value of ‘Grand Naine’ banana fruits impacted at different drop heights with non-bruised samples (control) after 48 h of storage at two storage conditions. Both color parameters (yellowness index and yellowness value) of bruised and non-bruised banana fruits were statistically influenced (P < 0.05) by storage temperature and drop height impact. The non-damaged banana fruits were the least yellowish with a yellowness index of 84.03 and 84.11 stored at 13 and 22 °C, respectively when compared to high drop-impact bruised bananas as shown in Fig. 6A. Similar trends were observed on the yellowness value of damaged and non-damaged banana fruits at both storage conditions (Fig. 6B).

A Yellowness index (YI) and B yellowness value of ‘Grand Naine’ banana fruits impacted at different drop heights; 10 cm, 30 cm, 50 cm with non-bruised samples (Control) after 48 h at 13 °C and 22 °C storage conditions. Error bars represent the standard deviation (SD) of the mean values ± S.D. of 30 readings of 10 replicates. Data were subjected to a two-factorial analysis of variance (ANOVA) (factor A; drop height, factor B; storage temperature). Mean separation was carried out using LSD test. Bars with different letters are significantly different (p < 0.05)

The higher changes observed on the majority of color attributes on bruised and non-bruised banana fruits at elevated storage conditions could be attributed to the degradation of chlorophyll in the peel of banana fruits after storage which leads to the conversion of color from green to yellow [33] particularly at higher temperature [17]. Also, it has been discussed that bananas are categorized with yellow peels when ripe, which could be related to the accumulation (synthesis) of carotenoids [13] and reduction in chlorophylls (breakdown of green pigments) [20]. Similar results were obtained on pear by Pathare et al. [31], where the highest damage and storage at higher temperature accelerated green color loss after 48 h of storage. Besides, Maia et al. [21] reported that mechanical damage accelerated the changes of banana peel color index compared to control banana fruits. The color changes of tomatoes at ambient storage temperature were more significant than low storage temperature [5].

3.4 Effect on total soluble solids (TSS)

The total soluble solids content (TSS) was significantly affected by drop height (P ≤ 0.00001) and storage temperature (P = 0.001371) (Fig. 7). The highest total soluble (TSS) content was observed with a value of 12.42 °Bx for the high drop-impacted bruised banana fruits at ambient temperature storage conditions. The TSS content of medium and high drop-impacted bruised banana fruits was 11.49 °Bx after 48 h of storage at 22 °C and 13 °C, respectively. The TSS content of ‘Grand Naine’ banana fruits impacted from 10 cm drop height and the control stored at 22 °C were 10.68 and 10.02 °Bx, respectively. However, the control and low drop-impacted bruised banana fruits stored at 13 °C showed the lowest TSS content with 9.90 and 9.96 °Bx, respectively. This could be attributed to the low temperature which slowed down the respiration rate and starch conversion resulting in lower total soluble content in refrigerated banana fruits [25]. It was found that the TSS content of banana fruits increased due to mechanical damage which accelerated the transformation of starch into simpler sugars in banana fruits. The pulp cells of banana fruits are probably influenced by the impact damage collapse, which may compromise the enzymes, such as α-amylase, glycosidases, and β-amylase, from breaking the starch [21], particularly at ambient temperature. Hussein et al. [16] reported that sugars are highly consumed during respiration. Besides, the reduction in moisture content observed in bruised and stressed damaged fruit affects the total soluble solids of fruits during storage. The results of this study were in line with the findings of Pathare and Al-Dairi [28], where total soluble solids increased as bruise damage increased.

Total soluble solids (°Bx) of ‘Grand Naine’ banana fruits impacted at different drop heights; 10 cm, 30 cm, 50 cm with non-bruised samples (Control) after 48 h at 13 °C and 22 °C storage conditions. Error bars represent the standard deviation (SD) of the mean values ± S.D. of 20 readings of 10 replicates. Data were subjected to a two-factorial analysis of variance (ANOVA) (factor A; drop height, factor B; storage temperature). Mean separation was carried out using LSD test. Bars with different letters are significantly different (p < 0.05)

3.5 Effect on respiration rate

Cellular respiration is considered a metabolic process, where chemical energy is produced for essential internal reactions and cellular maintenance and synthesis [15]. The respiration rate was statistically affected by the storage temperature (P = 0.003084) and drop impact height (P = 0.000011) (Fig. 8). At the same temperature condition, bruised (damaged) fruit respired faster than non-bruised (control) banana fruit. Furthermore, banana fruit impacted at higher and medium drop impact levels (50 cm and 30 cm) exhibited a higher respiration rate than fruit bruised at lower impact level (10 cm) or non-bruised (control) fruit. In this study, storage at ambient conditions (22 °C) and impact from a drop height of 50 cm showed the greatest influence on the rate of respiration on banana fruits. The respiration rate of high drop-impacted banana fruits stored at 22 °C was 11.00 CO2 mL kg−1 h−1, while it was 7.59 CO2 mL kg−1 h−1 on bananas stored at 13 °C. The medium drop-impacted banana fruits stored at 22 °C and 13 °C recorded a respiration rate of 9.41 and 6.75 CO2 mL kg−1 h−1 after 48 h storage. A low respiration rate was reported in control and low drop-impacted banana fruits at both storage conditions; where, it was a little higher at the ambient temperature of the same treatment. The observed increment in respiration rate after 48 h of storage could be attributed to increased banana fruits stresses resulting from impact/bruise damage. This is in support of findings reported by Hussein et al. [15], which stated that mechanical damage like bruising can affect the respiration rate of fresh produce. Furthermore, the intensity of respiration rate of bruised pomegranate fruit increased with the damage level (degree) to the fruit. Besides, Maia et al. [21] confirmed that increasing the action of α-amylase, glycosidases, and βamylase expedite the degradation and the available content of glucose and sucrose which are the major respiratory substrates to increase the respiration rate of the mechanically damaged banana fruits. The increase in respiration rate at higher temperatures could occur due to the increase in metabolic activities [25]. As observed in ‘Wonderful’ pomegranate fruit, Hussein et al. [16] reported a 1.4-fold respiration rate in bruised fruit compared to non-bruised (control) fruits.

Respiration rate of ‘Grand Naine’ banana fruits impacted at different drop heights; 10 cm, 30 cm, 50 cm with non-bruised samples (Control) after 48 h at 13 °C and 22 °C storage conditions. Error bars represent the standard deviation (SD) of the mean values ± S.D. of 2 replicates. Data were subjected to a two-factorial analysis of variance (ANOVA) (factor A; drop height, factor B; storage temperature). Mean separation was carried out using LSD test. Bars with different letters are significantly different (p < 0.05)

3.6 Effect on ethylene production rate

Ethylene (C2H4) production of ‘Grand Naine’ banana impacted from three different heights during two storage conditions are given in Fig. 9. The results of fruit ethylene production rate were a result of a combined effect of impact damage drop height (P = 0.025752) and storage temperature (P ≤ 0.00001). Under ambient temperature (22 °C) and bruising from high drop-impact, the ethylene production rate was the highest (0.20 C2H4 mL kg−1 h−1) followed by medium (0.19 C2H4 mL kg−1 h−1), low (0.16 C2H4 mL kg−1 h−1) drop-impact, and control (0.15 C2H4 mL kg−1 h−1). After 24 h of storage, the ethylene production rate of the low drop-impact and control groups were 0.05 C2H4 mL kg−1 h−1and 0.04 C2H4 mL kg−1 h−1, respectively stored at 13 °C. However, the high drop-impact bruised bananas showed an ethylene production rate of 0.06 C2H4 mL kg−1 h−1 under low storage temperature (13 °C). The findings of this study revealed that storage at higher temperatures and the high drop-impact damage can accelerate the ethylene production rate. This is attributed to the changes in the metabolic processes that are highly occurred at room temperature. Such change is a consequence of the process of ripening in the injured banana fruit causing a huge increase in ethylene production rate [19]. As reported by Maia et al. [21] and Mebratie et al. [24], mechanical damage expedited the occurrence of the ethylene production rate of banana fruits during storage.

Ethylene production rate of ‘Grand Naine’ banana fruits impacted at different drop heights; 10 cm, 30 cm, 50 cm with non-bruised samples (Control) after 48 h at 13 °C and 22 °C storage conditions. Error bars represent the standard deviation (SD) of the mean values ± S.D. of 2 replicate. Data were subjected to a two-factorial analysis of variance (ANOVA) (factor A; drop height, factor B; storage temperature). Mean separation was carried out using LSD test. Bars with different letters are significantly different (p < 0.05)

4 Conclusions

The study investigated the effect of mechanical damage like bruising (generated from different impact levels) and storage temperatures on the quality of banana fruits after 48 h of storage. The findings of this study revealed that the impact energy is correlated with drop impact/height level which leads to an increase in the potential of bruise incidence in banana fruits during simulated handling. Increasing drop height (50 cm) and storage temperature (22 °C) showed a remarkable rise in bruise area, bruise volume, bruise susceptibility, weight loss, total soluble solids, respiration rate, and ethylene production rate. Both studied factors (storage temperature and drop height) affected the color quality attributes except for chroma which was not influenced by drop height. Storage temperature at 13 °C reduced the majority of studied quality attributes. The non-damaged bananas showed fewer changes in total soluble solids, weight, color, and headspace gases. Bruise parameters are the most common measures of the amount of most fresh produce damage like a banana. Therefore, reducing impact damage during handling is the first recommended step to minimize the damage along with storage management, particularly during grading, sorting, and packing.

Data availability

All data generated or analysed during this study are included in this published article.

References

Adi DD, Oduro IN, Tortoe C. Physicochemical changes in plantain during normal storage ripening. Sci Afr. 2019;6: e00164.

Ahmadi E, Ghassemzadeh HR, Sadeghi M, Moghaddam M, Neshat SZ. The effect of impact and fruit properties on the bruising of peach. J Food Eng. 2010;97:110–7.

Al-Dairi M, Pathare PB. Kinetic modeling of quality changes of tomato during storage. Agric Eng Int CIGR J. 2021;23:183–93.

Al-Dairi M, Pathare PB, Al-Mahdouri A. Effect of storage conditions on postharvest quality of tomatoes: a case study at market-level. J Agric Mar Sci. 2021;26:13–20.

Al-Dairi M, Pathare PB, Al-Mahdouri A. Impact of vibration on the quality of tomato produced by stimulated transport. In: Proc. IOP conference series: earth and environmental science, vol. 653. IOP Publishing; 2021. p. 012101.

Al-Dairi M, Pathare PB, Al-Yahyai R. Chemical and nutritional quality changes of tomato during postharvest transportation and storage. J Saudi Soc Agric Sci. 2021;20:401–8.

Al-Dairi M, Pathare PB, Al-Yahyai R. Effect of postharvest transport and storage on color and firmness quality of tomato. Horticulturae. 2021;7:163.

Al-Dairi M, Pathare PB, Al-Yahyai R. Quality changes kinetic of tomato during postharvest transportation and storage. J Food Proc Eng. 2021;44: e13808.

Alali AA, Awad MA, Al-Qurashi AD, Mohamed SA. Postharvest gum Arabic and salicylic acid dipping affect quality and biochemical changes of ‘Grand Nain’ bananas during shelf life. Sci Horticulturae. 2018;237:51–8.

Bugaud C, Ocrisse G, Salmon F, Rinaldo D. Bruise susceptibility of banana peel in relation to genotype and post-climacteric storage conditions. Postharvest Biol Technol. 2014;87:113–9.

Dadzie BK, Orchard JE. Routine post-harvest screening of banana/plantain hybrids: criteria and methods, vol. 1. Rome: Bioversity International; 1997.

Fernando I, Fei J, Stanley R, Enshaei H, Eyles A. Quality deterioration of bananas in the post-harvest supply chain-an empirical study. Modern Supply Chain Res Appl. 2019;1:135–54.

Fu X, Cheng S, Liao Y, Huang B, Du B, et al. Comparative analysis of pigments in red and yellow banana fruit. Food Chem. 2018;239:1009–18.

Hussein Z, Fawole OA, Opara UL. Preharvest factors influencing bruise damage of fresh fruits—a review. Sci Hortic. 2018;229:45–58.

Hussein Z, Fawole OA, Opara UL. Bruise damage susceptibility of pomegranates (Punica granatum L.) and impact on fruit physiological response during short term storage. Sci Hortic. 2019;246:664–74.

Hussein Z, Fawole OA, Opara UO. Effects of bruising and storage duration on physiological response and quality attributes of pomegranate fruit. Sci Hortic. 2020;267: 109306.

Kusumaningrum D, Lee S-H, Lee W-H, Mo C, Cho B-K. A review of technologies to prolong the shelf life of fresh tropical fruits in Southeast Asia. J Biosyst Eng. 2015;40:345–58.

Li J, Sun Q, Sun Y, Chen B, Wu X, Le T. Improvement of banana postharvest quality using a novel soybean protein isolate/cinnamaldehyde/zinc oxide bionanocomposite coating strategy. Sci Hortic. 2019;258: 108786.

Lohani S, Trivedi PK, Nath P. Changes in activities of cell wall hydrolases during ethylene-induced ripening in banana: effect of 1-MCP, ABA and IAA. Postharvest Biol Technol. 2004;31:119–26.

Maduwanthi S, Marapana R. Biochemical changes during ripening of banana: a review. Inte J Food Sci Nutr. 2017;2:166–9.

Maia VM, Salomão LCC, Siqueira DL, Aspiazú I, Maia LCB. Physical and metabolic changes induced by mechanical damage in ‘Dwarf-Prata’ banana fruits kept under cold storage. Aust J Crop Sci. 2014;8:1029–37.

Maia VM, Salomão LCC, Siqueira DL, Puschman R, Mota Filho VJG, Cecon PR. Physical and metabolic alterations in “Prata Anã” banana induced by mechanical damage at room temperature. Sci Agricola. 2011;68:31–6.

Manetto G, Cerruto E, Pascuzzi S, Santoro F. Improvements in citrus packing lines to reduce the mechanical damage to fruit. Chem Eng Trans. 2017;58:391–6.

Mebratie MA, Haji J, Woldetsadik K, Ayalew A, Ambo E. Determinants of postharvest banana loss in the marketing chain of central Ethiopia. J Food Sci Qual Manag. 2015;37:53–63.

Opara UL, Al-Yahyai R, Al-Waili N, Said FA, Al-Ani M, Manickavasagan M, Al-Mahdouri A. Postharvest responses of ‘Malindi’ cavendish banana to various storage conditions. Int J Fruit Sci. 2013;13:373–88.

Opara UL, Pathare PB. Bruise damage measurement and analysis of fresh horticultural produce—a review. Postharvest Biol Technol. 2014;91:9–24.

Panigrahi N, Thompson AJ, Zubelzu S, Knox JW. Identifying opportunities to improve management of water stress in banana production. Sci Hortic. 2021;276: 109735.

Pathare PB, Al-Dairi M. Bruise damage and quality changes in impact-bruised, stored tomatoes. Horticulturae. 2021;7:113.

Pathare PB, Al-Dairi M. Bruise susceptibility and impact on quality parameters of pears during storage. Front Sustain Food Syst. 2021;5: 658132.

Pathare PB, Al-Dairi M. Effect of simulated vibration and storage on quality of tomato. Horticulturae. 2021;7:417.

Pathare PB, Al-Dairi M, Al-Mahdouri A. Bruise damage susceptibility and fruit quality assessment of pear. Open Agric J. 2021;15:82–90.

Pathare PB, Opara UL, Al-Said FA. Colour measurement and analysis in fresh and processed foods: a review. Food Bioprocess Technol. 2013;6:36–60.

Soltani M, Alimardani R, Omid M. Prediction of banana quality during ripening stage using capacitance sensing system. Aust J Crop Sci. 2010;4:443–7.

Stropek Z, Gołacki K. A new method for measuring impact related bruises in fruits. Postharvest Biol Technol. 2015;110:131–9.

Tabatabaekoloor R. Engineering properties and bruise susceptibility of peach fruits (Prunus persica). Agric Eng Int CIGR J. 2013;15:244–52.

Wasala CB, Dissanayake C, Dharmasena D, Gunawardane C, Dissanayake T. Postharvest losses, current issues and demand for postharvest technologies for loss management in the main banana supply chains in Sri Lanka. J Postharvest Technol. 2014;2014(2):80–7.

Wasala W, Benaragama C, Kumara G, Sarananda K, Dissanayake C. Application of 1-methylcyclopropene (1-MCP) for delaying the ripening of banana: a review. Asian Res J Agric. 2020;14:44–56.

Wasala W, Dharmasena D, Dissanayake C, Tilakarathne B. Feasibility study on styrofoam layer cushioning for banana bulk transport in a local distribution system. J Biosyst Eng. 2015;40:409–16.

Acknowledgements

We would like to thank Sultan Qaboos University for their financial support under the project code: IG/AGR/SWAE/19/03.

Author information

Authors and Affiliations

Contributions

PBP: conceptualization, supervision, formal analysis, funding acquisition, writing—review and editing. MA-D: data curation, formal analysis, writing—original draft. Both authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Pathare, P.B., Al-Dairi, M. Effect of mechanical damage on the quality characteristics of banana fruits during short-term storage. Discov Food 2, 4 (2022). https://doi.org/10.1007/s44187-022-00007-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44187-022-00007-7