Abstract

Currently, the district heating (DH) in Poland is facing many challenges. The business model used hitherto was very simple—in most cities, heating plants produced heat, and centralized heating systems supplied the "product" at a price approved annually by the president of the Energy Regulatory Office (URE). However, recent years have brought significant changes on the market. EU regulations force the elimination of old coal-fired plants that were still built in the Polish People's Republic (PRL), moreover, high prices of CO2 emission allowances aggravate the financial situation of companies. In addition, in the heating sector, the trend observed in the power sector is becoming increasingly visible—limiting the role of large sources in favor of energy generated locally, closer to the customer. One of the biggest challenges is achieving the targets set by the EU for the share of renewable energy sources (RES) in the heating sector. The present conflicts and problems with the supply of coal and gas are an additional impulse to turn to RES. Thus, the development of sustainable and innovative solutions for energy production and supply at the level of urban networks is currently one of the main technical challenges. The purpose of the paper is to present the current situation and perspectives of development of district heating systems in Poland with a view to the status of district heating in the world, and some deeper insight into European conditions. The review presents energy sources with particular emphasis on renewable energy sources (RES) and their cogeneration for heat production. The examples of existing heating network solutions using renewable energy sources, based on the selected published case studies, are also discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The world’s population surpassed eight billion people on November 15, 2022 and it is projected to reach nine billion until 2037 [1]. According to [2], this dynamics of increase in population is expected to result in a growth in the number of dwellings from 1.9 billion in 2010 to 3.2 billion in 2050. With respect to all households in the US and Europe, and their total energy consumption, the residential and commercial buildings are responsible for the consumption of 40% and 26% of energy, respectively [2, 3]. The inevitable consequence of such a state of affairs is the emission of carbon dioxide (CO2), which is at the level of 38% for the US and 36% for Europe. Furthermore, the rapid increase in urbanization is associated with undesirable effects, e.g., in the form of urban heat islands [4, 5]. Therefore, the statistics provide a rationale for the necessity of a global goal to diminish CO2 emission by half by 2050 on a global scale with emphasis on Pathway to Net Zero in 2050, which, however, is associated with the fact that emissions must fall by 8% each year [6]. The outlook [6] also forecasts that the supply shock brought on by Russia's invasion of Ukraine and the demand shock caused by the pandemic, despite having caused a temporary slowdown, exert little long-term influence over a transition that will be fast and widespread. The flagship documents regulating the energy transformation and reduction of CO2 emissions in the European Union are Fit for 55 package [7] and RePowerUE [8], and in Poland—the Polish Energy Policy until 2040 (PEP2040) [9] as well as the National Energy and Climate Plan (KPEiK) [10].

Cities have been noted to utilize two-thirds of the world's total energy and emit seventy-five percent of the planet's CO2 emissions [11], indicating that they are crucial to preventing climate change. The transformation of district heating (DH) networks is the key to individual heating transformation, as they provide a large proportion of heating and cooling services in many urban areas around the world. For example, more than 50% of the heat demand is satisfied by DH in countries such as Denmark, Estonia, Finland, Iceland, Latvia, Lithuania, Poland, Russia, Sweden, and northern China. That data can be found in an overview of district heating and cooling across the world, along with some in-depth analyses of the situation in Europe with discussion on the market, technical, supply, environmental, institutional, and prospective backgrounds [12]. Typical characteristics and categorizing of DH with regard to geographical location, size, heat density, consumer as well as ongoing advancements and main limitations of the existing methods can be found in [13,14,15]. An extensive review of the implementation of heating and cooling systems in the US was carried out in [16]. The current status and DH challenges for the UK can be found in [17]. The analysis of the Polish heat market, its current situation and key issues for future development was conducted in [18].

Decarbonization of the DH sector is of utmost importance to promote the conversion to carbon neutrality in countries and cities where district heating is a significant part of the energy infrastructure. There is a great potential for decarbonizing the DH sector, in particular in terms of heat sources. In [19], an innovative cogeneration system is advocated, which can support, through research, the development of heating technology and thus enhance the methods of energy savings and CO2 reduction. Current state of carbon dioxide removals policies in the US, the UK, and the EU's member states with the emphasis on biofuels with carbon capture and storage was provided in [20]. The paper [21] offers legislative steps and highlights significant turning points on the path to a full heat transition in order to accelerate the execution of the roadmap for the decarbonization of the European heating and cooling sector. A case study in Italy concerning the efficient DH in a decarbonization perspective can be found in [22]. To reduce the harmful emissions in DH systems smart technologies can be applied. Smart asset management for DH systems in the area of Baltic Sea have been discussed in [23], whereas simulation results for Metropolis GZM, Poland—in [24].

The district heating system is relatively flexible and permits the use of various energy conversion technologies to produce heat. The involvement and market potential of new technologies and technology coupling in order to improve the profitability of thermal enterprises and the development of renewable energy sources were revised in [25]. The optimal planning of future district heating systems has been taken up in [26]. The authors of [27] provide crucial recommendations for design and construction approaches for the fourth generation (4GDH) systems as well as a critical analysis of the obstacles to reduce temperature levels and the causes of excessive return temperatures in current third generation (3GDH) systems. An analysis of 40 DH networks operating in Europe was presented in [28]. The objective of the paper was to reassess the definitions found and introduce a clear definition of fifth generation heating and cooling networks. The study showed that three fifth generation district heating (5GDH) and cooling systems per year were emerging the heating and cooling market in the last ten years. Germany and Switzerland are leaders in this field. A comparison of three alternative DH temperature level concepts, namely low temperature (55/25 °C), very low temperature with electric enhancement (45/25 °C), and very low temperature with heat pump enhancement (35/20 °C), considering network losses, production efficiency, and building requirements, based on Danish conditions, was provided in [29]. According to research [30], upgrading from 3GDH to fourth generation 4GDH systems can improve energy sector integration, lower grid losses, and aid in the inclusion of RES. The economical and energy impacts were discussed with reference to Aalborg, Denmark. The authors of [31], on the basis of the results of the conducted analyzes, emphasized the positive role of innovative cogeneration (CHP) solutions securing the supply of electricity and heat, the significance of network congestion management with the use of flexibility resulting from the interconnection of sectors and the necessary network expansion plans. The article presents a comprehensive analysis of Germany's coal withdrawal plans by 2038.

The renewable energy sources (RES) in the heating sector are of the greatest interest, especially in the context of low-temperature district heating networks [32, 33]. An opportunity for the development of heating and achieving efficiency is power to heat, i.e., the use of electricity produced by wind farms to produce heat. The numerous benefits of this solution, based on 34 projects and an overview from the 1950s, are presented in [34]. Integration of solar heat [35], heat pumps [36], nuclear reactors [37], or geothermal energy [38, 39] in DH causes what is inevitable, namely radical technological change [40].

According to published statistics [41], the rate and direction of the alteration of the heating sector in Europe can be observed. Heat production from fossil fuels continued its long-lasting downward tendency until 2021—since 2000, it fell by 40.5% to 125 TWh (451 PJ) in 2021 and declined by 5.6% to 118 TWh (426 PJ) in 2022. The record-breaking decline was recorded in 2020—to 117 TWh (422 PJ). As for the use of crude oil and oil products for heat production, they showed a similar trend, a decrease of 67.2% from 2000 to 2021 can be indicated with a record low of 21 TWh (74 PJ) in 2020, with an increase of 35.2% in 2022 compared to 2021. Natural gas, which reached its peak in 2005, rose by 14.3% in 2021 compared to 2000. Natural gas and industrial gases combined fell by 11.9% in 2022 in relation to the previous year. Renewable energy persisted in its permanent upward trend until 2021, but a slight decrease of 6.5% could be observed in 2022 compared to 2021. From 2000 to 2021, renewable heat generation increased by as much as 408.7%. This is an obvious direction for the transformation of the district heating sector.

The main goal of the paper is to provide an overview of the state of district heating in Poland as well as future development prospects with a focus on global trends and a view on the European situation. Apart from the introduction, the paper is organized as follows: The second section describes the district heating systems with a short history and evolution of DH in Poland as well as DH sources and generations. In the third section, the heating state in Poland through structure of heating companies and heat prices is discussed. The next part, section four, development goals of Poland being part of EU. The article ends with conclusions in section five.

2 District heating systems

2.1 State of the art of DH in major Polish cities

In Warsaw, Poland, at the beginning, heating installations were intended for individual buildings. In 1841, the first building heated in this way was erected at Jan Mitkiewicz Square [42]. Built at the beginning of the twentieth century, the Infant Jesus hospital complex on Lindley Street and the Warsaw University of Technology were equipped with their own combined heat and power plants and a heating system [43]. In the 1920s and 1930s, a modernist Warsaw housing estate for workers in Żoliborz was built, with a central boiler house heating the blocks of flats. The heating boom in the capital of Poland appeared during its reconstruction after WW2. Currently, the Warsaw heating network is the largest system of this type in the European Union, it is about 1800 km of networks that provide heat to 19 thousand facilities in Warsaw, covering 80% of the capital's needs [42]. The Warsaw heating system is supplied from four sources, and its ring structure guarantees the security of heat supply in the city [44].

Pre-war Cracow, Poland, was heated mainly by stoves in apartments. Occasionally, there were boiler houses for individual buildings or small housing estates. They gave rise to the Municipal Heating Company (MC), which was established in 1953. The company took over the management of these boiler houses. There were a total of 12 of them, and the total heat distribution network was only 30 km long. In the following years, MC took over the management of subsequent local heating plants, and in 1962, it was transformed into the Municipal Heat Energy Company (MPEC) [45]. In the early 1960s, Cracow was heated mainly thanks to the heat produced by the Lenin Steelworks. In 1970, a new large heat and power plant was launched, and in the mid-1980s, the heating system in Cracow was once again revolutionized, i.a. through the creation of the first ring-connection of the northern and western mains [42]. In 1995, a computer monitoring and surveillance system, unique in the Polish DH industry, was designed, developed, and implemented, and, one year later, one of Poland's most important monuments, i.e., the Wawel Royal Castle, was connected to MPEC. At the beginning of the new millennium, it was possible to decommission all coal-fired boiler plants owned by MPEC, so the company no longer uses solid fuels for heat production. Between 2014 and 2020, MPEC carried out three district heating projects to increase the use of energy generated by high-efficiency cogeneration through the construction of a DH network, together with heat substations and connections to enable the incorporation of new buildings and existing buildings with another heat source [45].

In the interwar Łódź, Poland, power plants were primarily built for the needs of individual industrial companies. In order to meet the demand of the textile industry for a technological steam and initiate the start of the city's heat supply system, a plan was created to build four heat and power plants and adopt the existing historical one—EC-1. However, despite the fact that the history of Łódź professional energy sector dates back to 1907, the power plant began to give up steam for the industry in 1953. In 1957, the Łódź District Heating Plant (ZSC) was created. In subsequent years, steam networks were dynamically expanded, connecting industrial customers to them. In 1959, another heat and power plant was launched—EC-2; then, in the 1960s and 1970s another tens of kilometers of heating network were built and two more EC-3 and EC-4 heat and power plants were built [42]. In 1989, a company managing the whole district heating system in Łódź was established [46]. Today, it is based on two heat and power plants and over 820 km of heating networks.

In Poznań, Poland, as in most cities, the beginning was electricity production. Already in 1904, the first power plant, Grobla, was built here, another one was launched 25 years later in Garbary. However, the Poznań II Karolin heat and power plant, built in the 1970s, provided opportunities to meet the challenges of the rapidly developing capital of Greater Poland. Along with it, in 1967, the Municipal Heat Energy Company (MPEC) was established. Today, under the name Veolia Energy S.A. [47], it offers its customers comprehensive solutions in the fields of electricity, heat, and industrial media supplies, as well as technical service for installations. The systematic investment work in the infrastructure of the district heating network and heat substations, as well as the marketing reorientation and the introduction of intelligent network and source management systems, have helped prepare the company for the future. These days, Veolia manages both the CHP plant and the network. The company has been actively involved in the program to revitalize the historic housing stock of the Old Town, Wilda, Łazarz and Jeżyce. It offers customers comprehensive solutions for the supply of electricity, heat, industrial utilities, and plant maintenance.

The beginnings of the heating industry in Lublin, Poland, date back to the late 1950s and 1960s, when the Department of Heat Management started operating at the Municipal Board of Residential Buildings. Then, under the name of the Municipal Heat Energy Company, it took over the tasks of operation and development of the heating system in Lublin. The current name, Lublin Heat Energy Company (LPEC), has been in use since 1974. The result of the centralization of the Lublin heating sector in the 1970s was the elimination of local and regional boiler houses and the connection of as many facilities as possible to the municipal network. In the 1980s, the company sought to combine all heat sources and create the so-called ring heating system. LPEC [48] has become one of the pioneers in the automation of heat energy transmission, distribution, and the conversion. Currently, LPEC supplies heat to almost 75% of households in Lublin, heating nearly 250 thousand of its inhabitants. The company presently operates 460 km of district heating networks and over 2 thousand of heat substations [42].

In Wrocław, Poland, the decision to build a power plant for municipal purposes was taken in the 1890s. Electricity began to be produced in 1901. After WW2, in 1947, the power plant was handed over to Polish management. First, it was rebuilt from Second World War damage, and in the 1950s, it was transformed into a combined heat and power plant. At the same time, the Czechnica Power Plant was modernized and included in the network, which was transformed into a combined heat and power plant in the early 1980s [42]. In July 1997, the CHP plant was flooded during the 'flood of the millennium'. The damage caused was quickly repaired with the help of energy specialists from all over Poland, and the plant regained production capacity. In 1999, the entire district heating system in Wrocław was concentrated in the Wrocław Heat and Power Plant Group Cogeneration JSCo, consisting of CHP Wrocław, CHP Czechnica, and CHP Zawidawie [49].

The Municipal Heat Management Company in Szczecin, Poland, was established in 1962 on the basis of local coal-fired boiler houses. There were as many as 160 of them scattered throughout the city. In the mid-1970s, a company that managed networks in the entire Szczecin voivodeship was established. Therefore, it was given the name Voivodeship Heat Energy Company (WPEC). Heating systems became the property of the communes in 1997, and since then, the recent history of the company named Szczecin District Heating (SEC) [50] begins. In 2016, the Thermal Waste Treatment Plant was included in the system. Today, it heats nearly 18.9 thousand inhabitants, operates 366 km of district heating networks, and over 3.8 thousand heat substations.

The 1970s also marked the beginning of heating in Opole, Poland. One of the most dynamically operating companies on the Polish heating market, Opolszczyzna District Heating (ECO), was founded and developed here [51]. The basis for the establishment of ECO was a pioneering organizational solution that consisted of creating a company based on the heating assets of the communes of the Opolskie Voivodeship. These days, ECO operates 27 DH systems in a number of cities of different sizes across 5 voivodeships and conducts a number of works reducing the environmental impact of the heat production process, e.g., construction of a geothermal heating plant in Kutno, operation of a high-efficiency gas cogeneration system in Jelenia Góra or construction of a PV farm in Opole, aiming for zero carbon in 2050 [52].

The end of the 1990s and the beginning of the twenty-first century marked a new period in the Polish district heating sector. Foreign capital with new know-how and a strategy for the development of modern, energy-efficient heating systems appears in many companies. In addition, there are new opportunities related to access to EU funds for network modernization and the construction of new heat sources. Along with the Baltic countries, Poland can boast the most extensive heating networks. 50% of the population uses system heat [42]. At the same time, heating companies and heat producers face new challenges—meeting the requirements regarding environmental protection and the share of RES in energy production. This is a challenge for the next years of the energy history of our country.

2.2 DH sources

An exceptionally important feature of district heating is its versatility with the use of various heat sources. Lots of diverse centralized and decentralized sources can be incorporated into a district heating network for reliable operation and flexibility thanks to basic control strategies. Considering economic, energy, and environmental factors, the most common technologies for generating heat have been ranked in [53]. The authors applied a fuzzy comprehensive evaluation method and arranged these technologies in the following order, starting with the ones used most often: Combined heat and power (CHP), gas boilers, water source heat pumps, coal boiler, ground source heat pumps, solar energy heat pumps, and the last one—oil boilers. In the light of decarbonization, renewable and waste sources are certainly the most valued [54], especially since they can be utilized in a low temperature heat grid [55]. Waste heat can be obtained from industrial or agricultural processes [56,57,58] as well as from the combustion of the waste, which is called Energy from waste (EfW) [59,60,61]. Bioenergy, sourced from wood pellets and chips as well as from biofuels, biogas in particular, is a developed technology to be applied in a district heating network on a larger scale [62,63,64,65]. Bioenergy is commonly applied as a co-fired fuel or as an alternate for fossil fuels in CHP plants. Solar thermal energy is the conversion of solar radiation into heat, and it is a very promising alternative energy that can be harvested in two forms: solar thermal energy or electrical energy. This technology can be incorporated into both large-scale and small-scale setups [66,67,68,69]. The role of heat pumps in supplying energy to the DH network is of increasing interest. Due to the source from which the heat is obtained, one can distinguish heat pumps extracting low-temperature heat from, e.g., geothermal water [38, 39, 70, 71], seawater [72,73,74], or air absorption [75,76,77].

Thermal storages are an option for energy accumulation in periods of lower demand, and, on the other hand, at times of high demand, they can serve as heat sources. Energy storages are intended to be an inherent part of DH to eliminate the effects of unpredictable fluctuations in the supply of energy from RSEs [78]. Heat storages have mainly the form of large hot water tanks [79], especially in the context of centralized storage [80]. The estimated efficiency of the energy storage system is within 20–60% [81]. Different types of energy storage are listed and characterized, according to [82], in Table 1, and the main concept of each is shown in Fig. 1 [83].

Different thermal energy storage types [83]

In Poland, an increase in the use of large TES systems for DH has been observed recently [84]. The first TES system has been in use at the power company (PEC) in Siedlce since 2002. The largest TES was built in Poland at Combined Heat and Power Plant (CHP) Siekierki in Warsaw and has been operational since 2009. The next four were established in the years 2011–2015, namely CHP Cracow, Białystok, Ostrołęka, and Bielsko-Biała. The latter is the highest tank in Poland. Since 2017, the TES system has been commissioned in CHP Toruń. The technical characteristics of large TES systems built in Poland can be found in [84]. The review of thermal and mechanical energy storage solutions with discussion on the good practices of energy storage technology and the prospect of using them in Poland was presented in [85].

2.3 DH generations

In the first heating networks, called the first generation networks, which were created at the end of the nineteenth century in the US and Western Europe, the heat carrier was steam with a temperature above 150 °C [86]. In the second generation DH systems, the heat carrier was pressurized water with a temperature exceeding 130 °C, sent through poorly insulated steel pipes that ran in concrete channels. This technology has been used since the 1930s, and it was popular until the 1970s, especially in socialist countries, including Poland [86]. Transmission losses were high for both of these technologies. The third generation of heating systems was developed in the 1970s in Scandinavia—the water temperature was lowered below 100 °C and pre-insulated pipes dug into the ground were used. This technology currently serves as the basis for the vast majority of networks worldwide [87], with supply temperatures of 70–120 °C and return temperatures of 40–70 °C [88]. Transmission losses are much lower, and network construction is cheaper compared to the two previous generations.

After the third generation, the time has come for the fourth generation in the heating sector—the water temperature drops below 70 °C, the municipal heating, energy, sewage, and gas infrastructure are integrated into one system. In this generation, the importance of the central heat source, e.g., the main heat and power plant, is decreasing. Its place is taken by RES installations (solar collectors, geothermal sources, wind farms) and also waste heat transferred to the grid from industrial plants (see Fig. 2 [89]). Low-temperature district heating networks develop, among others, in Denmark, Sweden, Finland, and Germany [90]. Low-temperature networks require new infrastructure—energy storage and IT systems to regulate the operation of many energy sources. Heat is also to be provided by buildings with a positive energy potential. The heating system will be profiled for the recipient and his needs, which will enable the creation of energy solutions, e.g., for selected districts, shopping centers, and public utility buildings. District heating, similarly to roads and highways, has been an investment for years. The networks being built now will be operational by the middle of the century. Therefore, it is worth investing in modern systems.

Directions of development of heating systems (redrawn from [89])

3 Heating state in Poland

According to the annual publication by the Energy Regulatory Office (URE) [91], as of the last day of 2020, there were 387 licensed energy companies dealing with heat supply in Poland. The potential of these enterprises was demonstrated by the installed capacity of 53,271 MW in the generation sources of these enterprises and the distribution networks with a length of 22,123 km. Among the surveyed enterprises, 8.4% did not have a network and 65.8% had networks longer than 10 km, 1/3 of which were over 50 km long. In 2020, licensed companies sold 95,753,511 MWh of heat. Information on the production of licensed heat as well as the volume of heat supplied to the network from recipients is presented in Fig. 3 [92].

Another 5 MW of capacity is ordered from energy companies that are not included among the licensed companies. It is estimated that these companies sell 50,000 TJ of heat to their customers. Further, 500,000 TJ of heat is produced for own needs by households and local heating plants that meet the thermal needs of residents of multi-unit buildings. Also, the industry that generates over 200,000 TJ of heat cannot be forgotten.

With such ambitious goals of the European Union's climate and energy policy and the adopted Polish Energy Policy until 2040 [9], it should be indicated that the process of diversification of fuels used for heat production is progressing very slowly, in particular in the situation of the energy crisis caused by the Russian military attack in Ukraine.

The data published by the Energy Regulatory Office [91] shows that:

-

The majority of fuels used in heat sources continue to be coal fuels, with a proportion of about 69% in 2020 (up from 71% in 2019, 72.5% in 2018, and 74% in 2017);

-

In 2020, the sector's financial liquidity grew while the overall amount of debt dropped;

-

The replacement rate of fixed assets increased noticeably between 2002 and 2020. This value grew by 37.5%, surpassing the rate of depreciation of fixed assets and indicating a high degree of investment;

-

In 2020, over 90% of all surveyed heating companies dealt with the production of heat. They produced over 394,000 TJ of heat, including heat recovered via technical operations, which represents a 1.6% reduction in production over the prior year;

-

Cogeneration accounted for 65.2% of all heat production in 2020;

-

128 of the 370 heat production enterprises (i.e., 34.6%) that took part in the research also produced heat through cogeneration;

-

The average single-component price of heat in 2020 amounted to PLN 55.95 / GJ and was higher by 7.7% than the 2019 price (PLN 51.93 / GJ), and by 13.1% (PLN 49.46 / GJ) compared to the 2018 price;

-

The total quantity of heat sold by licensed heating corporations in 2020 was around 344,000 TJ, which was 0.3% less than in 2019 (including resale to other enterprises);

-

The average cost of heat sold from all permitted sources in 2020 was PLN 44.33 / GJ, an increase of 8.2% compared to 2019 (PLN 40.97 / GJ), when the average cost of heat produced by accredited sources without cogeneration was PLN 51.87 / GJ and the average cost of heat produced by licensed heat-generating sources with cogeneration was PLN 41.32 / GJ.

3.1 The structure of heating companies in Poland

According to the data of the President of the URE published in [93] as of December 31, 2020, a license to conduct activities in the fields of generation, transmission, distribution, and trade in heat was held by 387 companies (a total of 797 individual licenses for a given type of activity in the field of supplying heat to consumers). As reported, the first research on the heating sector was carried out by the Energy Regulatory Office in 2002. Since then, the number of licensed heating companies in Poland has decreased by more than half, which was mainly caused by the change in the Energy Law and had an impact on the size of the regulated heating market. Analyzing the data in Table 2 regarding the installed thermal power, it can be indicated that the total amount of thermal power installed by producers has decreased since the first study in 2002 by 25% and has a value of 53,271 MW. The stabilization has been observed in recent years. Licensed heating companies had 22,123 km of networks in 2020. This amount included heating networks connecting heat sources with heat nodes and low-parameter networks—external receiving installations. Out of the surveyed enterprises, 8.5% did not have networks, 67.9% had networks over 10 km long, and 31.4% had networks over 50 km.

According to [93], from 2022, a significant change in the legal structures of heating companies can be observed. The trend of changing the structure, shown in Table 3, has an impact on the transformation of the ownership of individual enterprises.

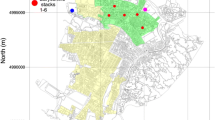

In 2020, enterprises generated heat from different-sized sources, with a quantitative prevalence of small sources up to 50 MW (44.6% of companies). Only ten of them had the achievable power of sources exceeding 1000 MW each. The structure of enterprises is shown in Fig. 4.

3.2 Fuel consumption for heat production

As mentioned in the introduction, in line with the URE, the variety of fuels used to generate heat is increasing, albeit very slowly. Unfortunately, coal fuels are the predominant source, accounting for over 69% of fuels utilized in heating sources in 2020 (in 2019 it was 71%, in 2018—72.5%, and in 2017—74%). Very detailed data can be found in [94]. Figures 5, 6, 7 summarizes the structure of fuel and energy consumption for total activity in enterprises in the energy sector and other enterprises producing and selling heat.

Production and distribution companies include distributors and professional producers of heat, i.e., companies that have only district heating (distribution) networks or district heating and heating networks or combined heat and power plants (distribution and generation) or only heating plants or combined heat and power plants (generation). Companies that are heat producers do not deal with distribution. In the group of producers, heat is produced for own use in CHP plants and is sold only as surpluses.

The share of coal as a heating source has decreased by 12.8 pp. since 2002 [93]. Concurrently, the share of gaseous fuels increased in the same years by 6.9 pp. and that of RESs by 7.2 pp. On the other hand, heat from cogeneration amounted to 7% in 2020, from 65.2% of total heat production. The data is presented in Fig. 8.

Enterprises producing heat in cogeneration are characterized by more diversified fuel consumption for heat production. Unfortunately, coal fuels also dominate in the group of these enterprises, but one third are other fuels, including 10.1% of renewable energy sources, 10.6% of natural gas, and 4.8% of heating oil, which is presented in Table 4.

Fuel consumption for heat production varies by voivodeship. The largest diversity can be noted in the Mazowieckie voivodeship. The frontrunners in terms of the share of RES are three voivodeships: Kujawsko-Pomorskie, Podlaskie, and Pomorskie, whereas in the Lubuskie voivodeship, over 95% of heat is generated from natural gas. Hard coal decidedly prevails in nine voivodeships: Dolnośląskie, Świętokrzyskie, Łódzkie, Opolskie, Małopolskie, Lubelskie, Warmińsko-Mazurskie, Wielkopolskie, and Zachodniopomorskie, and the share of consumption is over 80%, with the highest share in Lower Silesia—about 90.4% [92, 94].

As stated in the Energy Forum report [95], the heating is still based to a great extent on coal, moreover, individual heating uses technology from the 1950s and 1960s, and the society suffers huge costs of air pollution—the consequences of damage to health cost the Polish society PLN 120 billion annually [95]. In order to meet the assumptions of the country's policy to obtain effective heating, a change in technology based on solutions from RES is necessary and inevitable. According to [91], the dependence on coal fuels in Poland is yet far greater than that of other EU Member States, which is why a fair transition is extremely crucial to Poland, which implies considering the starting point and the social context of the use of carbon fuels.

3.3 Sale and sale prices for heat

The European Emissions Trading System, Just Transition, Supply Diversification, and Network Expansion of Natural Gas, are issues that are often discussed in the media and in many analyzes. The heat sector, which has been a bit neglected so far, is becoming one of the key transformation sectors. Assumptions and, e.g., the amendment to the building law led to an increase in the share of DH. According to [91], by 2030, about 1.5 million new households are to be connected to the heating network. Concurrently, changes in technology must go hand in hand to achieve the goal of having at least 85% of systems (heating or cooling) with a capacity exceeding 5 MW by 2030 to meet the criterion of an energy-efficient system.

The price of heat will play a significant role in the entire transition. According to the URE data [93], the average cost of heat sold in 2020 from all licensed heat generating sources was PLN 44.33 / GJ, which means a raise of 8.2% with respect to the price in 2019 (PLN 40.97 / GJ). At the same time, the average price of heat sold from licensed heat-generating sources without cogeneration amounted to PLN 51.87 / GJ, while the average price of heat sold from licensed heat-generating sources with cogeneration was PLN 41.32 / GJ (see Fig. 9).

The following years showed a significant increase in prices. According to the data published by URE in 2021 [96], the average sales prices of heat generated in units owned by licensed heating companies amounted to PLN 51.91 / GJ in units fired with coal fuels, PLN 75.66 / GJ in units fired with fuel oil, PLN 72.02 / GJ in units fired with gaseous fuels, and PLN 46.12 / GJ in units representing RES. The selling prices depending on the type of fuel are shown in Fig. 10. In 2021, compared to 2020, the price of coal and gas fuel is growing, only the prices of heating oil and fuel from RESs have decreased.

When analyzing the fuel price, one should mention the constantly growing cost of CO2 emission allowances in the total production costs. As reported by PSE [97], the average price of CO2 in July 2022 ranges from PLN 370.96 / t to PLN 413.59 / t. The recorded rapid increase in the price of allowances means an increase in the price of energy. It should be noted that the prices of CO2 emission allowances have been rising for several years. In recent months, a significant acceleration in price growth has been observed. Early in 2022, markets struggled with record commodity prices, which were especially felt in the case of gas. It was undoubtedly the result of the Russian invasion of Ukraine. Another factor were the quotations of CO2 emission allowances, which rubbed against nearly EUR 100 / t. This situation certainly translated into even higher costs of heat production in 2022, thus worsening the results for enterprises.

In line with the data of the Energy Regulatory Office [93], in 2020, the revenues generated by the licensed heating enterprises did not cover the costs of conducting activities related to supplying heat to end-users. The recorded gross financial result amounted to PLN (–) 473 million. As a result, heating companies have become unprofitable, with profitability parameters of (–) 2.4% (in 2019 it was (–) 2.9%). The main reason for such poor profitability in these years are the very high costs of purchasing CO2 allowances. According to the figures presented in the charts (see Fig. 11), a decrease in CO2 and other gas emissions can be seen in the period from 2002 to 2020. However, it is necessary to maintain this downward trend, which requires constant restructuring and financial outlays. Figure 12 shows the profitability of heating companies in the period from 2010 to 2020. It can be seen that in 2020, most companies in the heating sector were unprofitable. In 2020, the profitability of companies generating heat without cogeneration was ( +) 2.49 and with cogeneration (–) 6.25. This proves the great financial outlay that had to be expended in order to restructure the company.

Index of profitability of warmer energy [94]

In accordance with the opinion of the President of URE [98], high CO2 prices and predictions of their further growth arouse legitimate concerns among all market participants due to their direct influence on the prices of both electricity and heat. Simultaneously, failure to make the required investments in emission reduction, modernization, and changing the method of generation in individual sources could, over time, result in a permanent increase in heat prices and, consequently, a decrease in the use of DH to provide customers with heat. It is indisputable when analyzing the galloping prices of fuels and CO2 emissions, the only right thing to do is to develop a technology based on RES, biomass and hydrogen.

4 Development goals

4.1 Goals of the European Union and Poland

The vast majority of district heating systems in Poland still remain ineffective. The current definition of an effective heating and cooling system states, that it is a system in which heat or cold is used to produce:

-

no less than 50% of the energy from RES or

-

no less than 50% of the waste heat, or

-

no less than 75% of the heat from cogeneration, or

-

no less than 50% of the combination of such energy and heat.

Since 1996, the European Union has adopted many guidelines regulating the energy transformation, which can be summarized in Fig. 13.

The directions of transformation of the entire heating sector have been strongly emphasized in two basic strategic documents for the Polish energy sector, namely the National Energy and Climate Plan for 2021–2030 (KPEiK) [10] and Poland's Energy Policy until 2040 (PEP2040) [9]. All actions indicated by PEP 2040 are to be based on three pillars. The first one says that only the transition, where energy poverty is eradicated and jobs related to the extraction of fossil fuels are eliminated, is supplemented by new industries related to RES (also in heating) and nuclear energy. The second pillar indicates that a zero-emission energy system in which, apart from offshore wind energy and nuclear energy, a prominent place is taken by local and community energy, which, for heat, may mean a revival of prosumer activity not less than that observed recently in electricity generation. Finally, the third pillar emphasizes good air quality, which makes it necessary to transform heating, especially local heating, and thus the heat generated in home furnaces.

Moreover, PEP 2040 includes the guidelines, as the key elements, for district heating.

-

1.

By 2040, the thermal requirements of all dwellings are to be met by system heat and by zero-emission or low-emission individual sources;

-

2.

There should be a large rise in photovoltaic installed capacity, approximately 5–7 GW in 2030 and approximately 10–16 GW in 2040, which will enable low-cost use of electricity used to drive heat pumps and switch to heat generation from electricity for auto producers and prosumers;

-

3.

It is expected that natural gas will serve as a transitional fuel throughout the energy transformation, and in 2030 the capacity to convey a mixture containing about 10% of decarbonized gasses via gas networks will be achieved, which will enable low-emission heat generation in cogeneration, both in economic activity and for personal needs. The possibility of using decarbonized fuel will facilitate the transformation of energy companies towards effective heating systems (an appropriate share of heat from cogeneration, heat from RES, or waste heat in the system;

-

4.

The low-emission direction of individual sources conversion should be implemented through the use of heat pumps, solar collectors, and electric heating, which will facilitate the achievement of the goal of eliminating coal combustion in households in cities by 2030 and in rural regions by 2040;

-

5.

The most anticipated innovations for heating may be:

-

heat storage technologies that will allow for the optimization and effective operation of sources generating heat and electricity in cogeneration, regardless of the passing peaks of the demand for these products, which will increase the operational safety of the entire power system;

-

electricity storage facilities, which will allow for further dynamic development of sources based on solar and wind energy as they will eliminate their most serious disadvantage, instability and dependence on natural conditions;

-

hydrogen technologies, especially technologies enabling the production of "green hydrogen", which will allow the development of local hydrogen clusters based on local production of hydrogen associated with decentralized production of renewable energy (including "green heat") and local demand. The specialized hydrogen infrastructure can use hydrogen for the production and supply of heat to residential and commercial buildings.

-

In addition to energy security, competitiveness, and energy efficiency, the goal of PEP 2040 is to limit the influence of the energy sector on the environment. Therefore, with regard to heating, specific objectives were included, the leading of which are:

-

The need to cover heat needs on an individual basis by using sources with the lowest possible emission (heat pumps, electric heating, natural gas—preferably with decarbonized gas) and the coal phase-out—in cities by 2030, and in agricultural regions by 2040;

-

The assumption that approximately 1.5 million new dwellings will be incorporated into the heating network by 2030;

-

Heating or cooling systems, in which the required capacity exceeds 5 MW, will meet at least 85% of the criteria for an energy-efficient heating system in 2030 (currently it is approx. 10%);

-

Assumption that in the next decade there will be an increase in heat generation from RES by at least 1.1 pp. every year, which, according to the KPEiK, gives the expected 28.4% share of RES in the entire heating sector in 2030.

One cannot forget about the challenges of Fit for 55 [92]. The package consists of several legislative proposals related to greenhouse gas emissions and is intended to enable the EU to achieve a higher net greenhouse gas emission reduction target of at least 55% in 2030. The district heating sector is mainly influenced by the following directives: the Energy Efficiency Directive (EED) [99], the Renewable Energy Directive (RED III) [100] and the Energy Performance of Buildings Directive (EPBD) [101].

The Energy Efficiency Directive states:

-

There is a new criterion to introduce a limit for direct CO2 emissions (for units using fossil fuels) of less than 270 g CO2 per kWh of combined heat and power (combined heat, electricity, and mechanical energy). The direct emissions limit will apply from the entry into force of the recast directive, while its role will be particularly important from January 1, 2026, when the criteria in the definition of an effective heating and cooling system will refer directly to high-efficiency cogeneration;

-

Prevent coal-fired cogeneration from maintaining its high-efficiency status and, at the same time, introduce an emission limit for gas-fired units. The entry of the new criterion will mean that coal-fired cogeneration units, which will not be modernized by the end of 2025, will lose the status of high-efficiency cogeneration, which in the vast majority of systems will also translate into the loss of the status of an effective heating and cooling system. The draft EED directive does not explicitly define the methodology for calculating the new emission criterion. This is important in the context of the operating conditions of cogeneration units, including the seasonal change in the heat curve and system services provided for the power system—factors affecting the level of direct CO2 emissions.

The above mentioned criteria pose a high risk for the heating sector in Poland. In the event of failure to implement new technologies and decarburization strategies, enterprises may lose financial support resulting from subsidies from the European Union.

The Renewable Energy Directive changes the definition of district heating and cooling in order that in the upcoming years it satisfies the following criteria:

-

by December 31, 2025, a system that uses at a minimum 50% renewable energy, 50% waste heat, 75% cogeneration heat, or 50% a combination of such energy and heat (existing definition);

-

since January 1, 2026, a system that uses at a minimum 50% of energy from renewable sources, 50% of waste heat, 80% of heat from high-efficiency cogeneration, or at least a combination of such heat supplied to a network with a renewable energy share of at a minimum 5%, and the total share of renewable energy, waste heat, or heat from high-efficiency cogeneration is at a minimum 50%;

-

since January 1, 2035, a system that uses at a minimum 50% of energy from renewable sources and waste heat with a share of energy from renewable sources of at a minimum 20%;

-

since January 1, 2045, a system that uses at a minimum 75% of energy from renewable sources and waste heat, with a share of energy from renewable sources of at a minimum 40%;

-

since January 1, 2050, a system that uses only renewable energy and waste heat with a share of energy from renewable sources of at a minimum 60%.

This criterion will enable heating plants to become effective only in the case of a growth in the share of renewable energy and waste heat. In addition, gas cogeneration with a large admixture of hydrogen or only hydrogen will be the preferred technology (in the case of green hydrogen). Taking into consideration the conditions of Polish heating, the success and postulate of the European Commission is to divide the systems into smaller installations.

The Energy Performance of Buildings Directive assumes:

-

a national building renovation plan to replace long-term renovation strategies. One of the elements of the plan is to identify policies and measures to decarbonize the heating and cooling sector through district heating and cooling, and phase out fossil fuels in these sectors with a view to their complete phase-out by 2040 at the latest;

-

complete gas elimination by 2040—target inconsistent with overall policy objectives;

-

inability to connect new buildings after 2030 to efficient heating systems that are not completely decarbonized.

The idea behind the implementation of RED and a fair energy transformation demands a fusion of technical solutions with more open decision-making based on trustworthy data, expertise in the fields of engineering, spatial planning, and social sciences [102]. However, the new EU climate package "Fit-for-55" prepares a change in the definition of an effective heating system and excludes heat from sources with emissions above 270 kg CO2 / MWh [103], which means that it is impossible to obtain investment support by gas cogeneration (this is also confirmed in the principles of the so-called green taxonomy). Therefore, cogeneration does not fully meet the idea of a transitional fuel, as it is inflexible, poorly controllable, and does not eliminate the limitations of solar and wind sources, while being constantly emissive and dependent on the rapidly growing price of gas fuel. Cogeneration systems must undergo a strong transformation towards zero-emission systems in the near future. To be competitive, they will also have to be emission-free and operate flexibly in the heating system, in synergy with the operation of weather-dependent sources.

4.2 The involvement of renewable energy sources in heat engineering and potential directions of development

The share of renewable energy in district heating in selected EU Member States was discussed in [103] and is shown in Fig. 14. According to these data, it can be concluded that heating companies in Poland, compared to other countries, face a significant challenge in implementing the requirements of the directives. This transformation is time-consuming and requires a large financial investment.

Share of renewable energy in district heating [103]

The very right and accurate goals of technology change for the energy sector in the context of the impact of the European Union's policy in the perspective of 2025 and 2030 were set by the Chamber of Commerce of Polish District Heating [104], namely:

-

Generation of energy from emission-free sources;

-

Energy storage;

-

Development of decentralized production of energy from RES;

-

Electrification of the heating sector;

-

Promoting more sustainable and efficient technologies and solutions;

-

Closer integration of the heating and electrical industries;

-

Use of waste for energy production;

-

Advancement in modern, low-temperature heating systems;

-

Improving the energy infrastructure and making it resistant to climate change;

-

Adapt infrastructure with intelligent and cybersecurity digital solutions.

The directions of development can be found in Fig. 2. However, according to the Institute for Renewable Energy [105], large cities are forced to spread the energy transformation process towards zero-emission ones over a longer period and rely on the import of low-emission energy carriers, at least until zero-emission (green) hydrogen becomes popular or until the share of renewable energy sources is 100% in electricity generation. The period of this perspective for the next 20 years will still result in high costs of heat generation, and thus high heat prices for consumers. Smaller cities look different, as their location gives them greater access to other fuel sources, including renewable energy.

In the climatic conditions of Poland, from 1 km2 allocated to the production of energy from RES can be obtained respectively [106]:

-

1440 TJ from solar thermal energy (solar collectors, efficiency 40%);

-

360 TJ from solar photovoltaic energy (efficiency 10%);

-

up to 150 TJ from wind energy (with a high density of windmills of 20 MW / km2);

-

up to 15 TJ from biomass (with the most efficient energy crops).

According to the research carried out by IEO [107] in cooperation with the Chamber of Commerce Polish District Heating as part of the work for the National Fund for Environmental Protection and Water Management, previous years have shown an increase in the acceleration of energy transformation towards RES in smaller towns. Heating companies intended to invest in and use various renewable energy sources (also other than biomass, which, as a result of the EU policy on taking into account its carbon footprint, is losing significantly) but have not used them so far (see Fig. 15).

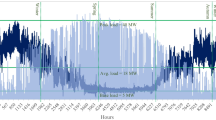

The research also showed great interest among enterprises in small towns in daily heat storage and in the Green Power-to-Heat (PtH) technology, which allows, for example, the use of unbalanced wind energy in heat plants, which is very popular. We still do not have the technologies implemented. This requires large financial outlays. This is what the research programs of the National Center for Research and Development [108] under pre-commercial procurement are to serve.

4.3 New technologies for construction

Rising energy costs from fossil fuels generate great interest in devices that use renewable energy. Biomass fuel is increasingly being used by heating companies. Biomass is considered a renewable energy solution. The most popular types of biomass for boilers are: wood chips, pellets, and lump wood. A case study of heating solutions based on renewable energy sources in France was presented in [109]. Heat pumps or biomass centralized installations are resistant to different future conditions, while current natural gas domestic heating is underperforming compared to renewable technologies. It should be noted that the RED III directive imposes a reduction in the use of biomass after 2020. According to IEO, biomass boilers can complement hybrid installations [107].

When replacing new technologies, one should remember solar collectors and geothermal energy. Geothermal energy is a beneficial solution that does not adversely affect the environment. Unfortunately, it depends on the company's location and is still limited by high financial outlays and the lack of technology [94]. On the other hand, solar collectors are the most popular innovative technology. Its universality and availability translate into low costs. In Poland, the largest solar collectors that produce electricity for district heating are in Olsztyn, Iłża [110]. It is worth emphasizing that solar collectors can work with central heating boilers or heat pumps, both on a large scale and on a smaller scale as home systems.

Fuel cells are very interesting and are becoming increasingly popular technologies. The cell generates electricity from the oxidation of the fuel constantly supplied to it. Fuel cells, according to the electrolyte used, can be divided into [111]:

-

Alkaline (AFC—Alkaline Fuel Cell);

-

With molten carbonate (MCFC—Molten Carbonate Fuel Cell);

-

With phosphoric acid (PAFC—Phosphoric Acid Fuel Cell);

-

With a proton exchange membrane (PEMFC—Proton Exchange Membrane Fuel Cell);

-

Oxide (SOFC—Solid Oxide Fuel Cell).

The use of cells is very wide. They can be used in individual and collective transport, in power to gas (P2G) technology, where the source is hydrogen, in combined systems generating electricity and heat for heating and cooling purposes, in large cogeneration units and micro, energy storage [112]. The P2G technology makes it possible, using hydrogen as a carrier, to store the resulting surplus electricity. The direction of the development of the P2G methodology was presented in [113].

Fuel cells in cooperation with a pump or cooling can form a total micro-combined heating, cooling, and power (CCHP) system [112]. A study [114] explored the potential of installed heating, cooling, and power systems to support grid flexibility for each of the seven US Independent System Operators (ISO) / Regional Transmission Organizations (RTOs) using their operational data on three time scales (i.e., yearly, monthly, and hourly). The findings showed that regardless of ISO / RTO, sector, or season, more than 40% of existing combined heat and power (CHP) capacity has not been completely utilized and may be available to boost network adaptability. The peak electricity consumption in the relevant ISO / RTO was 1–9% of the total CHP power available, which varied from 0.7 to 8.7 GW. Utilizing this accessible cogeneration capacity, it would be possible to avoid installation costs of up to USD 16.4 billion for new peak load plants to meet peak demand, grow capacity, or meet other needs related to increasing levels of renewable energy generation. As a result of shorter cold start cycles and part-load operation, installed CHP systems can reduce criteria pollutants and greenhouse gas emissions to a greater extent than new peaking plants. Although this study concentrated on seven US ISO / RTOs, the methodology might be implemented in other regional circumstances.

The development of technology would not be possible without the development of heat storage technology. Thanks to the storage, one can use energy that depends on the weather. According to the IEO [107], thermal stores have a significant advantage over electric ones, which can only store energy in hourly cycles and are more expensive. In [115], different types of magazines were presented.

On December 7th, 2021, the Polish Hydrogen Strategy until 2030 [116] with a perspective until 2040, was announced. In accordance with the policy, "green" hydrogen is a fuel that can very effectively replace gas and coal and appears as a remedy for the current problems of heating companies. The main assumptions of the Strategy are the objectives: implementation of hydrogen technology in the energy and heating sectors, as well as the use of hydrogen as a fuel for transport, supporting the decarbonization of the industry. In order to achieve the goals in line with the Policy the following actions should be taken:

-

Implement hydrogen technology in the energy sector, along with the definition of the legal framework;

-

Launch a P2G class 1 MW installation—assistance for distribution networks stability; such a facility will produce 3150 MWh of hydrogen annually;

-

Implement the possibility of co-firing hydrogen in gas turbines (based on the turbine's technological capabilities);

-

Launch cogeneration and polygeneration installations, such as medium-sized combined heat and power plants (50 MWt), where the hydrogen will serve as the primary fuel (demand is around 580 GWh annually);

-

Start using hydrogen as an energy store;

-

Installation of polygeneration berths for blocks of flats, small housing estates, and public utility buildings ranging in power from 10 to 250 kW with the use of fuel cells.

4.4 Future of DH in Poland—selected case studies

An example of a successful use of biomass in cogeneration is Ostrów Wielkopolski. The local municipal heating company, in place of the liquidated coal boiler, built a modern cogeneration unit powered by wood biomass with a capacity of 11.4 MW. At the same time, the heat and power plant was connected by a distribution network to the local public transport depot, which enabled the chargers for electric buses to be powered with locally produced green electricity. This is the first case of a city in Poland that has created its own system of powering bus chargers with energy from RES. Annual savings from the implementation of this system are estimated at PLN 0.5 million with four electric buses and are expected to increase to PLN 1 million with ten vehicles [90].

The project of Heat Energy Plant Ltd. (ZEC) in Wałcz is planned in collaboration with the Danish investor Eurowind Energy Ltd. and it will involve the construction of wind [117] and photovoltaic farms within a radius of 30 km from Wałcz. The KR2 boiler houses in Wałcz will be supplied with a direct power line. With the use of a private off-grid network, green energy from RES farms will be delivered straight to the boiler house in Wałcz, where an electrode boiler will transform it to create thermal energy, assuming 100% efficiency. The electrode boiler is constructed as a cylindrical high-pressure tank to which electricity is supplied at a voltage of 10–11 kV for the 10 MW boiler. The temperature in the boiler circuit is 130 °C/95 °C. The details of the boiler’s operating principles can be found in [118]. 100 MWh of energy from the wind farm is expected to be converted into 99.8 MWh of heat and transferred to the Wałcz district heating network. It means that the production efficiency of the boiler in discussion is 99.8%, whereas the efficiency of coal boilers is 84% and that of gas boilers is 95% [118].

5 Conclusions

The real problems faced by the heating industry, especially the difficult time for investment implementation and the increase in energy awareness in society for consent and acceptance of the transformation, give the green light to heating companies to undertake their own development strategies based on renewable energy. EU and national regulations should create conditions for the safe operation of heating companies as well as the development of the entire energy industry. Although there is currently an accumulation of so many unfavorable business phenomena, the investment effort made will not be wasted. There is also the issue of financing this transformation, and here there remains a large role for the EU and the Polish government. It is important to emphasize that on March 9, 2023, an act amending the act on investments in wind farms and some other acts was adopted [119]. The act allowed the location of wind turbines within 700 m from the nearest residential development. The introduced change will allow for an increase in the number of wind projects in Poland, which will have the consequence of increasing the potential possibilities of developing power to heat projects and carrying out the expected restructuring of the heating sector, i.e., the process of generating thermal power used for heating and cooling, usually utilizing heat pumps or boilers.

While analyzing the goals of the European Union, the transformation of the heating sector is inevitable. Such a large reform requires, on the one hand, financial outlays and, on the other hand, knowledge of potential directions of development and products available on the market. Therefore, it is necessary to expand engineering knowledge and develop technology.

Along with technological development and reaching for new solutions, legislative support and a modern (pro-development) industrial policy are necessary. It is not enough to focus on large domestic enterprises, but small and individual heat engineering should be supported. The nation should have a sense of security, no fear of galloping prices, and awareness of the purpose of the transformation being implemented, i.e., the need to increase the role of decarbonization in heating.

The increase in the role of RES with the simultaneous change in the structures of fuel demand in heating, reducing the heat demand by 21% should be a key factor in the current times of pandemic and international conflicts restricting access to sources. It is worth remembering Stephen Covey's sentence "The best way to predict the future is to create it".

Data availability

Not applicable.

Abbreviations

- 3GDH:

-

Third generation district heating

- 4GDH:

-

Fourth generation district heating

- 5GDH:

-

Fifth generation district heating

- ASHP:

-

Air source heat pump

- ATES:

-

Aquifer thermal energy storage

- BTES:

-

Borehole thermal energy storage

- CCHP:

-

Combined heating, cooling and power

- CHP:

-

Combined heating and power

- DH:

-

District Heating

- ECO:

-

Opolszczyzna District Heating

- EED:

-

Energy Efficiency Directive

- EfW:

-

Energy from waste

- EPDB:

-

Energy Performance of Buildings Directive

- GPtH:

-

Green power to heat

- GSHP:

-

Ground source heat pump

- IED:

-

Industrial Emissions Directive

- IEO:

-

Institute of Renewable Energy

- LPEC:

-

Lublin Heat Energy Company

- MC:

-

Municipal Heating Company

- MPEC:

-

Municipal Heat Energy Company

- KB:

-

Biomass boilers

- KPEiK:

-

National Energy and Climate Plan

- KS:

-

Solar collectors

- PC:

-

Heat pumps

- PEP2040:

-

Polish Energy Policy up to 2040

- PRL:

-

Polish People's Republic

- PSE:

-

Polish Power Grids

- PTES:

-

Pit thermal energy storage

- PtH:

-

Power to heat

- P2G:

-

Power to gas

- PV:

-

Photovoltaics

- RED III:

-

Renewable Energy Directive

- RES:

-

Renewable energy sources

- SEC:

-

Szczecin District Heating

- STES:

-

Seasonal heat storage

- TES:

-

Thermal energy storage

- TTES:

-

Tank thermal energy storage

- URE:

-

Energy Regulatory Office

- WTG:

-

Wind turbine generator

- WPEC:

-

Voivodship Heat Energy Company

- ZEC:

-

Heat Energy Plant in Wałcz

- ZSC:

-

ŁÓdź District Heating Plant

References

United Nations. Day of eight billlion. Available online: https://www.un.org/development/desa/pd/events/day-eight-billionUnitedNations. Accessed 20 Nov 2022.

Report: Pathways to a Clean Energy System; Energy Technology Perspectives, I.E. Agency, 2012.

Mertens, R.; Manual for Statistics on Energy Consumption in Households. Publications Office of the European Union, Luxembourg, 2013. Available on: http://ec.europa.eu/eurostat/documents/3859598/5935825/KS-GQ-13-003-EN.PDF/baa96509-3f4b-4c7a-94dd-feb1a31c7291. Accessed 20 Nov 2022.

Mirzaei PA. Recent challenges in modeling of urban heat island. Sustain Cities Soc. 2015;19:200–6.

Mirzaei PA, Olsthoorn D, Torja M, Haghighat F. Urban neighborhood characteristics influence on a building indoor environment. Sustain Cities Soc. 2015;19:403–13.

Report: Energy transition outlook 2022. A global and regional forecast to 2050. DNV Group, 2022.

Proposal for a Directive of the European Parliament and of the Council Amending Directive 2003/87/EC Establishing a System for Greenhouse Gas Emission Allowance Trading within the Union, Decision (EU) 2015/1814 Concerning the Establishment and Operation of a Market Stability Reserve for the Union Greenhouse Gas Emission Trading Scheme and Regulation (EU) 2015/757. Available online: https://ec.europa.eu/info/sites/default/files/revision-eu-ets_with-annex_en_0.pdf. Accessed 20 Nov 2022.

RePowerEU: a plan to rapidly reduce dependence on Russian fossil fuels and fast forward the green transition. 2022. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52022DC0230&from=EN. Accessed 20 Nov 2022.

Polityka Energetyczna Polski do 2040 r./Poland’s Energy Policy until 2040 (PEP2040). Ministry of Climate and Environment: Warsaw, Poland. 2021. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WMP20210000264. Accessed 11 Aug 2022. (In Polish)

Krajowy Plan na Rzecz Energii i Klimatu na Lata 2021–2030 (KPEiK)/The National Energy and Climate Plan for the Years 2021–2030. 2019. Available online: https://www.gov.pl/web/aktywa-panstwowe/krajowy-plan-na-rzecz-energii-i-klimatu-na-lata-2021-2030-przekazany-do-ke. Accessed 18 Aug 2022. (In Polish)

Reda F, Ruggiero S, Auvinen K, Temmes A. Towards low-carbon district heating: investigating the socio-technical challenges of the urban energy transition. Smart Energy. 2021;4: 100054. https://doi.org/10.1016/j.segy.2021.100054.

Werner S. International review of district heating and cooling. Energy. 2017;137:617–31. https://doi.org/10.1016/j.energy.2017.04.045.

Mazhar AR, Liu S, Shukla A. A state of art review on the district heating systems. Renew Sustain Energy Rev. 2018;96:420–39. https://doi.org/10.1016/j.rser.2018.08.005.

Talebi B, Mirzaei PA, Bastani A, Haghighat F. A review of district heating systems: modeling and optimization. Front Built Environ. 2016;2:22. https://doi.org/10.3389/fbuil.2016.00022.

Buffa S, Fouladfar MH, Franchini G, Lozano Gabarre I, Andrés Chicote M. Advanced control and fault detection strategies for district heating and cooling systems—a review. Appl Sci. 2021;11:455. https://doi.org/10.3390/app11010455.

Lake A, Rezaie B, Beyerlein S. Review of district heating and cooling systems for a sustainable future. Renew Sustain Energy Rev. 2017;67:417–25. https://doi.org/10.1016/j.rser.2016.09.061.

Millar M-A, Burnside NM, Yu Z. District heating challenges for the UK. Energies. 2019;12:310. https://doi.org/10.3390/en12020310.

Kamiński J, Malik A. An analysis of the Polish district heating sector: present situation and key issues for further development. Bull Miner Energy Econ Res Inst Polish Acad Sci. 2016;92:307–23 (In Polish).

Yang YP, Li PF, Ge ZH, Wang NL, Song ZP. Green heating: theory and practice. Sci China Technol Sci. 2015;58:2003–15. https://doi.org/10.1007/s11431-015-5858-4.

Lundberg L, Fridahl M. The missing piece in policy for carbon dioxide removal: reverse auctions as an interim solution. Discov Energy. 2022;2:3. https://doi.org/10.1007/s43937-022-00008-8.

Mathiesen BV, Bertelsen N, Schneider NCA, García LS, Paardekooper S, Thellufsen JZ, Djørup SR. Towards a decarbonised heating and cooling sector in Europe: Unlocking the potential of energy efficiency and district energy. Aalborg Universitet, 2019. Available online: https://vbn.aau.dk/en/publications/towards-a-decarbonised-heating-and-cooling-sector-in-europe-unloc. Accessed 14 July 2023.

Ricci M, Sdringola P, Tamburrino S, Puglisi G, Donato ED, Ancona MA, Melino F. Efficient district heating in a decarbonisation perspective: a case study in Italy. Energies. 2022;15:948. https://doi.org/10.3390/en15030948.

Grzegórska A, Rybarczyk P, Lukoševičius V, Sobczak J, Rogala A. Smart asset management for district heating systems in the Baltic Sea Region. Energies. 2021;14:314. https://doi.org/10.3390/en14020314.

Kinelski G, Stęchły J, Sienicki A, Czornik K, Borkowski P. Application of smart technologies in metropolis GZM to reduce harmful emissions in district heating systems. Energies. 2021;14:7665. https://doi.org/10.3390/en14227665.

Salman CA, Li H, Li P, Yan J. Improve the flexibility provided by combined heat and power plants (CHPs)—a review of potential technologies. Adv Electr Electron Eng. 2021;1: 100023. https://doi.org/10.1016/j.prime.2021.100023.

Jiang M, Rindt C, Smeulders DMJ. Optimal planning of future district heating systems—a review. Energies. 2022;15:7160. https://doi.org/10.3390/en15197160.

Averfalk H, Werner S. Essential improvements in future district heating systems. Energy Procedia. 2017;116:217–25. https://doi.org/10.1016/j.egypro.2017.05.069.

Buffa S, Cozzini M, D’Antoni M, Baratieri M, Fedrizzi R. 5th generation district heating and cooling systems: a review of existing cases in Europe. Renew Sust Energ Rev. 2019;104:504–22. https://doi.org/10.1016/j.rser.2018.12.059.

Lund R, Østergaard DS, Yang X, Mathiesen BV. Comparison of low-temperature district heating concepts in a long-term energy system perspective. Int J Sustain Energy Plan Manag. 2017;12:5–18. https://doi.org/10.5278/ijsepm.2017.12.2.

Sorknæs P, Østergaard PA, Thellufsen JZ, Lund H, Nielsen S, Djørup S, Sperling K. The benefits of 4th generation district heating in a 100% renewable energy system. Energy. 2020;213: 119030. https://doi.org/10.1016/j.energy.2020.119030.

Metzger M, Duckheim M, Franken M, Heger HJ, Huber M, Knittel M, Kolster T, Kueppers M, Meier C, Most D, Paulus S, Wyrwoll L, Moser A, Niessen S. Pathways toward a decarbonized future—impact on security of supply and system stability in a sustainable german energy system. Energies. 2021;14:560. https://doi.org/10.3390/en14030560.

Neirotti F, Noussan M, Riverso S, Manganini G. Analysis of different strategies for lowering the operation temperature in existing district heating networks. Energies. 2019;12:321. https://doi.org/10.3390/en12020321.

Pellegrini M, Bianchini A. The innovative concept of cold district heating networks: a literature review. Energies. 2018;11:236. https://doi.org/10.3390/en11010236.

Gjorgievski VZ, Markovska N, Abazi A, Neven Duić N. The potential of power-to-heat demand response to improve the flexibility of the energy system: an empirical review. Renew Sustain Energy Rev. 2021;138: 110489. https://doi.org/10.1016/j.rser.2020.110489.

Reiter A, Poier H, Holter C. BIG Solar Graz: solar district heating in Graz—500,000 m2 for 20% solar fraction. Energy Procedia. 2016;91:578–84.

David A, Mathiesen BV, Averfalk H, Werner S, Lund H. Heat roadmap Europe: large-scale electric heat pumps in district heating systems. Energies. 2017;10:578. https://doi.org/10.3390/en10040578.

Teräsvirta A, Syri S, Hiltunen P. Small nuclear reactor—Nordic district heating case study. Energies. 2020;13:3782. https://doi.org/10.3390/en13153782.

Sáez Blázquez C, Farfán Martín A, Nieto IM, González-Aguilera D. Economic and environmental analysis of different district heating systems aided by geothermal energy. Energies. 2018;11:1265. https://doi.org/10.3390/en11051265.

Romanov D, Leiss B. Geothermal energy at different depths for district heating and cooling of existing and future building stock. Renew Sustain Energy Rev. 2022;167: 112727. https://doi.org/10.1016/j.rser.2022.112727.

Djørup S, Sperling K, Nielsen S, Østergaard PA, Zinck Thellufsen J, Sorknæs P, Lund H, Drysdale D. District heating tariffs, economic optimisation and local strategies during radical technological change. Energies. 2020;13:1172. https://doi.org/10.3390/en13051172.

Eurostat Statistics Explained. Electricity and heat statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Electricity_and_heat_statistics#Derived_heat_production. Accessed 15 Jul 2023.

Sto lat, sto lat już grzeje, grzeje nam…Magazyn Ciepła Systemowego 2018; 3(40): 20–22. Available online: https://magazyncieplasystemowego.pl/cieplownictwo/sto-lat-sto-lat-juz-grzeje-grzeje-nam/. Accessed 5 February 2023. (In Polish)

Wojdyga K. Polish District heating systems—development perspectives. J Civ Eng. 2016;10:268–79. https://doi.org/10.17265/1934-7359/2016.03.002.

Veolia Energia Warszawa SA. Available online: https://energiadlawarszawy.pl/#. Accessed 18 February 2023. (In Polish)

MPEC S.A. Kraków, Available online: https://www.mpec.krakow.pl/. Accessed 18 February 2023. (In Polish)

Veolia Energia Łódź SA. Available online: https://energiadlalodzi.pl/. Accessed 18 February 2023. (In Polish)

Veolia Energia Poznań SA, Available online: https://energiadlapoznania.pl/. Accessed 15 February 2023. (In Polish)

Lubelskie Przedsiębiorstwo Energetyki Cieplnej SA. Available online: https://lpec.pl/. Accessed 15 February 2023. (In Polish)

Zespół Elektrociepłowni Wrocławskich Kogeneracja SA. Available online: https://www.kogeneracja.com.pl/en/. Accessed 15 February 2023.

Szczecińska Energetyka Cieplna Sp. z o.o., Available online: https://sec.com.pl/en/. Accessed 15 February 2023.

Energetyka Cieplna Opolszczyzny SA. Avaliable online: https://www.ecosa.pl/. Accessed 15 February 2023. (In Polish)

[AK2]ECO na drodze transformacji/ECO on the path of transformation, Available online: https://www.ecosa.pl/aktualnosci/eco-na-drodze-transformacji-rozmowa-z-miroslawem-romanowiczem-czlonkiem-zarzadu-ds-operacyjnych-eco.html. Accessed 15 July 2023. (In Polish)

Wei B, Wang S-L, Li L. Fuzzy comprehensive evaluation of district heating systems. Energy Policy. 2010;38:5947–55.

Zvingilaite E, Balyk O. Heat savings in buildings in a 100% renewable heat and power system in Denmark with different shares of district heating. Energy Build. 2014;82:173–86.

Lund H, Werner S, Wiltshire R, Svendsen S, Thorsen JE, Hvelplund F, et al. 4th Generation District Heating (4GDH). Integrating smart thermal grids into future sustainable energy systems. Energy. 2014;68:1–11.

Persson U, Werner S. District heating in sequential energy supply. Appl Energy. 2012;95:123–31.

Fang H, Xia J, Jiang Y. Key issues and solutions in a district heating system using low-grade industrial waste heat. Energy. 2015;86:589–602.

Yang B, Jiang Y, Fu L, Zhang S. Experimental and theoretical investigation of a novel full-open absorption heat pump applied to district heating by recovering waste heat of flue gas. Energy Build. 2018;173:45–57.

Eriksson O, Finnveden G, Ekvall T, Bjorklund A. Life cycle assessment of fuels for district heating: a comparison of waste incineration, biomass- and natural gascombustion. Energy Policy. 2007;35:1346–62.

Persson U, Münster M. Current and future prospects for heat recovery from waste in European district heating systems: a literature and data review. Energy. 2016;110:116–28.

Udomsri S, Bales C, Martin AR, Martin V. Decentralised cooling in district heating network: monitoring results and calibration of simulation model. Energy Build. 2011;43:3311–21.

Djuric Ilic D, Dotzauer E, Trygg L, Broman G. Introduction of large-scale biofuel production in a district heating system—an opportunity for reduction of global greenhouse gas emissions. J Clean Prod. 2014;64:552–61.

Djuric Ilic D, Dotzauer E, Trygg L, Broman G. Integration of biofuel production into district heating—part II: an evaluation of the district heating production costs using Stockholm as a case study. J Clean Prod. 2014;69:188–98.

Karschin I, Geldermann J. Efficient cogeneration and district heating systems in bioenergy villages: an optimization approach. J Clean Prod. 2014;104:305–14.