Abstract

Background

The high number of confined space incidents in Malaysia suggests that working in a confined space exposes workers to a substantial risk of serious injury or fatality. The rapid development of industry and technology has increased the need to work in confined spaces and significantly impacted the risk management of confined spaces. Utilizing past incident data through investigation will help develop risk management and preventive measures related to confined spaces. As a result, this paper will conduct a fatal incident investigation associated with confined spaces from 2010 to 2020 in Malaysia.

Methodology

The incident investigation uses the improved systematic casual analysis technique (SCAT) to identify the immediate cause and the direct cause. From the identified fatal incidents immediate causes, the study will highlight the main hazard that causes fatal incidents in confined spaces. The preventive measure is developed based on the main hazard of confined spaces that cause fatalities.

Result

The result of the study has identified that physical and atmospheric hazards are the main factors that cause fatal incidents associated with confined spaces in Malaysia. Moreover, from the SCAT checklist, the study has revealed that failing to use PPE properly and hazardous environmental conditions are the main immediate cause of fatal incidents in confined spaces.

Conclusion

Effective risk management of confined spaces, with a particular focus on addressing atmospheric and physical hazards, is crucial for preventing accidents, especially those incidents resulting in fatalities. Future studies should expand their focus to include injuries and near-miss events in confined spaces, aiming to develop more effective and inclusive safety measures by analyzing a broader range of incidents.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Working in confined spaces is a necessity because multiple jobs and sectors require entry into such confined spaces. According to the United States Occupational Safety and Health Administration (OSHA) approximated that each year, there were 4.8 million entries into confined spaces in the United States, involving an average of 1.6 million workers [1]. In Malaysia, various jobs and sectors involve confined space activities such as construction, factories, and utilities [2]. As a developing country involved in various developments, Malaysia needs to ensure that issues related to the safety and health of workers, especially those concerning confined spaces, are not overlooked.[3, 4]. This is because there are many potential hazards in confined spaces, such as atmospheric hazards (e.g., poisoning, asphyxiation, and explosions) and physical hazards (e.g., mechanical, electrical, engulfment, and falls) which have a high potential to result in fatal accidents [5,6,7,8,9,10,11].

According to the Department of Safety and Health Malaysia (DOSH), 5% of workplace incidents resulted in death between 2015 and 2020 [12]. Meanwhile, fatalities related to confined spaces, as recorded by DOSH, have amounted to 30 deaths from 2010 to 2021 [12]. Incidents in confined spaces often lead to rescue victims; an average of one person for every two victims dies trying to rescue work mate [13]. Similarly, in the United States, between 1992 and 2005, nearly 38 people died each year from confined space poisoning or asphyxiation; on average, 20% of workplace incidents resulted in multiple fatalities [14, 15]. This indicates that not only entry into confined spaces needs to be emphasized but also confined space rescue efforts should be given attention to prevent fatalities in confined spaces [15, 16]. Fatal incidents related to confined spaces have happened in various countries, as listed in the literature. To prevent incidents in confined spaces, a systematic inspection approach should be conducted before anyone enters, encompassing checks for damage to protective equipment, ensuring appropriate training, and implementing effective management and supervision [2, 9, 10]. In other words, an employer should properly assess risks associated with all work activities to determine the required safety measures [17, 18]. An organization with effective and efficient confined space risk management can prevent any incidents in the workplace.

The need for entry into confined spaces and previous data regarding worker fatalities in confined spaces indicate an urgent necessity to analyze fatal incidents to enhance safety measures. Furthermore, comprehensive prevention measures should be implemented to reduce the risk of fatalities in confined spaces [19, 20]. The issue of confined spaces related to safety, emergency preparedness, and incident investigation has been widely discussed in various mediums [1, 6, 21, 22]. Studies and investigations have been widely published, including comprehensive reports and academic studies. However, the issue of working in confined spaces still needs to be discussed, as indicated by the continued recording of fatalities in confined spaces. The main cause of confined space incidents is the workers are unaware and unable to identify the hazards associated with their confined space work [5, 6]. Therefore, it's important to emphasize hazard identification in confined spaces. Studying and investigating past incidents involving fatalities can increase awareness of the hazards associated with confined space [23, 24]. This matter can also help develop incident and emergency preparedness related to confined spaces [15, 25].

Per the Industry Code of Practice for Safe Working in a Confined Space Malaysia, a confined space is defined as an enclosed or partially enclosed space that is at atmospheric pressure during occupancy and is not intended or designed primarily as a place of work. These places are liable to have an atmosphere containing potentially harmful levels of contaminants; have an oxygen deficiency or excess at any time. Or cause engulfment and could have restricted means of entry and exit [8]. Working in confined spaces is life-threatening to the worker because it involves high-risk work activity [7, 10].

The occupational incident analysis's key goal is identifying the incidents' root causes which consist of unsafe acts and unsafe conditions [26, 27]. Additionally, it is essential to analyze incidents based on the work sector and type of hazards to determine their important causes and implement preventative measures [28, 29]. The productivity of employees can be increased, and occupational illnesses and injuries can be decreased if data analysis can be used to identify incident root causes in confined spaces [30]. As a result, this study aimed to identify the incident root causes that contributed to greater incident frequency using a number allocation table and descriptive statistics. To determine the main root cause causing fatal occupational incidents in confined spaces, 30 incidents that occurred between 2010 and 2021 in confined spaces due to atmospheric and physical hazards that resulted in fatalities were further investigated using the systematic causal analysis technique (SCAT). This paper will discuss the Characterization of Fatal Work Incidents in Confined Spaces in Malaysia based on the year of occurrence and the type of incidents. Using this data, preventive measures will be developed according to the prioritization of unsafe acts and unsafe conditions. This information is useful to provide references to the related parties for improving and developing safety measures.

2 Methodology

2.1 Subject

Common injury incident analysis typically focuses on the unsafe act of the worker as the main cause of the incident. Suppose the incident is not sufficiently investigated using a modern multi-cause theory or structure. In that case, all factors that contributed to the incident are not likely to be identified, resulting in similar incidents occurring repeatedly. The study by Adam Hulme on the systems thinking accident analysis method between 1990 and 2018, has found that conventional injury incident analyses often attribute incidents primarily to the unsafe acts of workers, providing a limited understanding of their root causes [31]. Applying the SCAT methods in an incident investigation to the fatal incidents related to confined space activities from 2010 to 2021 in Malaysia, the factors that caused safety measure failure could be investigated comprehensively, and the main cause of incidents can be highlighted.

2.2 Data collection

Analysis of the 30 fatal incident reports related to confined spaces in Malaysia from 2010 to 2021 retrieved from the official website of the Department of Safety and Health (DOSH) Malaysia [12]. DOSH Malaysia is an occupational safety regulatory body in Malaysia. DOSH Malaysia is also the primary authority responsible for collecting and managing workplace accident statistics in Malaysia. The department operates under the purview of the Ministry of Human Resources and is tasked with ensuring that all workplaces in Malaysia are safe and healthy for workers. In Malaysia, it is the legal responsibility of both employers and workers to report workplace accidents to DOSH Malaysia under the Occupational Safety and Health Act 1994 and its regulations. Specifically, the regulation of Notification of Accident, Dangerous Occurrence, Occupational Poisoning and Occupational Disease) Regulations 2004 under the same act stated that it is the responsibility of the employee to report any accident or near-miss incident to their employer as soon as possible after the incident occurs. The employer must then report the incident to DOSH within 7 days. Thus, this study will rely on incident data from the DOSH Malaysia database as it is the primary authority in Malaysia for collecting and maintaining information on workplace incidents, accidents, and illnesses.”

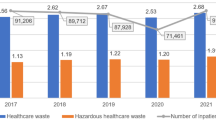

As shown in Fig. 1, it revealed that 42 fatal cases had been reported that involved 24 physical hazards and 17 atmospheric hazards. This incident statistic shown was occurred in Malaysia and was related to all factors associated with confined space activities. This study will only focus on analyses of the 30 confined space incidents that occurred in Malaysia, as it is limited to the scope of Malaysia.

The DOSH Malaysia launched an industry code of practice known as Safe Working in a Confined Space in 2010. The industry code of practice emphasizes the hazards of working in confined spaces and provides guidelines for managing the safety of working in confined spaces. The figure shows that the reported fatalities are significantly reduced after 2010, indicating increased awareness among the industrial players. The highest number of reported fatality cases occurred in 2010 and 2014, both years witnessing events with multiple fatalities. The year that recorded the lowest fatality cases was 2019, attributed to the slowdown in industrial activity due to the COVID-19 outbreak.

As shown in Table 1, 30 reports associated with fatal incidents in confined spaces were consolidated, involving 41 deaths. Further analysis, as illustrated in Fig. 2, indicated that the work sector associated with the highest fatalities and incidents rate was construction, with 53%(16), followed by utilities at 17%(5), factories at 10%(3), fishery at 7%(2), business services at 7%(2), agriculture with 3%(1) and 3%(1) cases reported with work sector not specified. The construction sector recorded more than half of the cases reported. Therefore, if the safety and preventive measures related to confined spaces are focussed on construction activities, the fatalities associated with confined spaces could be reduced significantly.

To be highlighted, trenches have been associated with a significant number of fatalities, with seven reported cases resulting in ten fatalities. According to the Occupational Safety and Health Administration (OSHA) in the United States, trenches are governed under the regulation known as 29 CFR 1926 Subpart P-Excavations. This regulation specifically addresses safety requirements for excavations, including trenches, and provides guidelines to protect workers from hazards associated with trenching operations. Most countries do not explicitly define trenches as confined spaces in their regulations, there is a case to be made for considering certain trenches as confined spaces based on their characteristics and potential hazards. Confined spaces are typically characterized by limited entry and exit points, restricted ventilation, and the potential for hazardous conditions to arise. In some instances, trenches can exhibit these features, thereby meeting the criteria for a confined space.

The criteria of a trenches fatality incident to be included in this study is the space large enough to bodily enter, has limited or restricted means of entry/exit and is not designed for continuous occupancy. Under this circumstance the trenches is known as confined spaces.

2.3 Method

This study applies the loss causation model developed by International Loss Control Institute (ILCI) [32] as shown in Fig. 3. As specified by this model, immediate causes consist of unsafe acts and unsafe conditions. Referring to the loss causation model, the study extracted unsafe acts and unsafe conditions from the SCAT checklist, which consists of 16 unsafe acts and 13 unsafe conditions, as specified in Table 2. An unsafe act is defined as an individual who ignores the safe action. In contrast, unsafe conditions are known as a condition that is hazardous to any person to make the incident investigation more comprehensive [33]. Determining the immediate causes of incidents is particularly important to analyze the failure at the management level. Thus, effective safety and preventive measure can be developed. Therefore, this study will investigate reported fatal incidents associated with confined spaces in Malaysia from 2010 to 2021 using the SCAT to clarify the immediate cause and identify the cause of risk control failure. To be highlighted, an incident could have more than one immediate cause. The result of the investigation is used to improve and develop preventive measures.

3 Results and discussion

3.1 Characterization of fatal work incidents in confined spaces in Malaysia

In this study, the investigation of the incident was conducted according to the 30 fatal incidents associated with confined spaces reported by DOSH. The relevant result analysis is as follows.

3.1.1 Year of occurrence

Based on the fatal incidents associated with confined spaces reported by DOSH Malaysia, there were three fatal incidents resulting in a total of 9 deaths, in 2019. These deaths accounted for 21% of the total fatalities during the statistical period. The year with the highest number of fatal incidents was 2014, with five incidents. However, the total number of deaths in 2014 was lower than in 2010, with seven deaths. The occurrence of fatal incidents involving multiple victims depends on the specific type of confined space activity. Notably, there was a significant decrease in the number of reported deaths by DOSH Malaysia from 2010 to 2011. In 2010, DOSH Malaysia intensified enforcement efforts regarding work activities in confined spaces through the implementation of the industry code of practice for safe working in confined spaces (2010)[8]. The industry code of practice 2010 specified the requirement, program, risk control, and emergency procedure that need to be emphasized by the employer for work related to confined spaces. The significant reduction in the total number of deaths positively affects enforcement.

On average, three fatal incidents associated with confined spaces are reported in Malaysia annually. Therefore, it is essential to identify the root cause of fatal incidents in confined spaces to avoid repeated incidents.

3.1.2 Type of incidents

The type of incidents is categorized based on the direct cause of fatal incidents. Figure 4 shows the direct cause of fatal hazards in confined spaces. In an incident investigation, it's important to recognize the direct causes of the fatalities [34, 35]. Figure 4 shows that landslide is the highest number of occurrences that cause fatal hazards. The landslide in a confined space causes the worker to be buried alive in the confined spaces, leading to fatalities. According to the data collected, landslides in confined spaces are associated with trenches at the construction site that are categorized as physical hazards. The second highest direct cause of fatal incidents is slip, trip, and unclosed entrance, with both recorded in four cases. These two factors cause falling incidents which are known as physical hazards. Other direct cause that develops physical hazards is a hot object, heavy water flow, falling objects, and faulty appliances.

Moreover, oxygen deficiency and toxic gas also cause fatal incidents, with both recorded in 3 cases. Oxygen deficiency and toxic gas are categorized as atmospheric hazards that can cause asphyxiation and poison. Another atmospheric hazard is nitrogen exposure which was recorded in one case. Nitrogen is an inert gas that can displace oxygen and cause asphyxiant [36].

There are four identified hazards in confined space which consist of atmospheric, physical, biological, and ergonomic [5, 6, 37]. However, the direct causes in Fig. 4 indicate that only two hazards cause fatalities in Malaysia. The two fatal hazards are atmospheric and physical, as shown in Fig. 5. An atmospheric hazard is a dangerous atmosphere that harms the worker's health [38]. In comparison, a physical hazard can be defined as a condition within the environment that can potentially cause harm to health [38].

As shown in Fig. 5, there are two types of incidents caused by an atmospheric hazard that led to fatal incidents in confined spaces: poisonous and asphyxiation. Poisonous gas is known as toxic and hazardous gases that harm living things. In contrast, asphyxiation is a condition where the body is not getting enough oxygen, which is fatal. As shown in the figure, asphyxiation is the highest occurrence compared to toxic gas exposure, with 4 cases. Oxygen deficiency is a major hazard that causes asphyxiation. According to the Malaysian industry code of practice for safe working in a Confined Space 2010, an oxygen level below 19.5% is categorized as a hazardous atmosphere. Atmospheric hazard is difficult to be recognized and identified. Therefore, the appropriate safety measures should be conducted before entering confined spaces. For the physical hazard, falls and buried are recorded with the highest occurrences, with 8 and 7 cases, respectively. At the same time, electrocution is recorded as the lowest number of occurrences with only 1 case. An incident caused by a physical hazard in confined spaces is very dangerous because it can potentially cause fatalities. Unsafe conditions in a confined space usually cause physical hazards, and the unsafe act of the worker will cause the incidents to become worse.

Overall, the figure shows that 59% of the total fatal incidents associated with confined space in Malaysia from 2010 to 2021 were caused by physical hazards. Classifying the occurrence of fatal incidents based on the type of hazards can help to prioritize the main hazards in confined spaces while developing a preventive strategy. The result shows that only atmospheric and physical hazards will cause fatal incidents.

3.2 Development of a preventive measure

The analysis of unsafe acts and unsafe conditions using SCAT is shown in Table 3. The data demonstrates for unsafe acts the failing to use PPE are the highest immediate cause with 16 cases, followed failure to warn in 4 cases and inadequate equipment maintenance in 2 cases. For unsafe conditions, the highest proportion of immediate cause is hazardous environmental conditions with 26 cases, inadequate protective equipment with 16 cases, inadequate guards or barriers with 8 cases, inadequate ventilations with 7 cases, inadequate warning system with 4 cases, defective tools, equipment or materials with 2 cases and fire and explosion hazards with 2 cases.

The failing to use PPE for the unsafe act was associated with 53% of the total incidents per SCAT immediate cause analysis. In contrast, hazardous environmental conditions for unsafe conditions were associated with 86% of the total incidents. If the appropriate preventive strategy addresses these immediate causes, the probability of fatal incidents related to confined space activity can be reduced.

The results of the study reveal that the lack of awareness among employers about confined space hazards leads to issues for personnel. Consequently, his lack of awareness results in the violation of safety procedures and exposes workers to a hazardous workplace with improper safety conditions without appropriate PPE. Tragically, this situation has led to fatal incidents for workers in confined spaces.

The suggested strategies for prevention measures represent the most important part of the results and conclusions of this study. When listing suggested coping strategies and practical considerations for preventing confined space incidents, as displayed in Table 4, this study will give more attention and space to coping strategies for the immediate cause involved in greater incidents. Therefore, the study will focus on failing to use PPE properly for unsafe acts while for unsafe conditions the study will focus on hazardous environmental conditions and inadequate or improper protective equipment. The study will discuss preventive strategy of confined space based on the framework in Fig. 6.

The result shows that the improper use of PPE is a leading cause of unsafe acts that can result in fatal incidents. Addressing this critical issue requires the development of a comprehensive plan to enhance workplace safety. A study by Sehsah has brought attention to the low utilization of PPE, which is significantly associated with inadequate safety training [39]. Occupational accidents are prevalent and often linked to deficiencies in both safety training and the correct use of PPE [39,40,41]. To instill safety awareness among workers, effective training becomes important. As per the Law of Malaysia Occupational Safety and Health Act 1994 section 15, employers have a general duty to provide information, instruction, training, and supervision to employees for ensuring, as far as practicable, safety and health at work [42].

The training provided to workers should emphasize the critical importance of wearing the appropriate PPE and offer clear insights into the potential dangers associated with specific tasks and work environments. By enhancing employees' understanding of the risks associated with disregarding safety guidelines, they can be empowered to make informed decisions regarding the use of PPE [43]. Moreover, the training should specifically address situations with higher risks to enable employees to effectively use PPE without compromising their safety.

To monitor progress and reinforce safety initiatives, regular safety assessments and evaluations must be conducted. These assessments will measure the extent to which employees are adhering to PPE guidelines, identify areas with potential for improvement, and recognize instances where exemplary adherence to safety practices is observed. Furthermore, continues enforcement in PPE at workplace also a effective strategy for monitoring.

In addition to training and assessments, ongoing supervision is crucial to prevent the improper use of PPE, especially in confined spaces. While some workers may recognize the importance of PPE, others may be prone to bypassing safety procedures, leading to non-compliance with PPE usage [44, 45]. Employers must ensure that competent individuals are assigned to supervise work in confined spaces, thereby ensuring that workers adhere to instructions and guidelines. This proactive approach helps mitigate the risk of incidents stemming from non-compliance with PPE protocols.

Hazardous environmental conditions have been identified as the primary immediate causes of incidents in confined spaces. These hazardous conditions, based on fatal incident data, include unclosed entrances, toxic gases, flammable gases, oxygen deficiency, and landslides. Three safety measures need to be implemented to avoid fatal cases caused by hazardous environmental conditions which is pre-assessment before confined space entry, continued risk control and monitoring, and eliminating the necessity of confined space entering through inherently safer design.

Conducting a thorough risk assessment before commencing work in confined spaces is very important. This is because a significant number of incidents occur due to workers' inability to identify the risks they will face while working in confined spaces [38, 46]. This assessment aids in devising an appropriate strategy to mitigate risks associated with confined space work. To ensure a proper assessment is conducted before working in confined spaces, a permit-to-work system can be implemented. The employer should designate a competent person capable of identifying hazards in confined spaces to issue the permit-to-work. The implementation of permit-to-work will prevent workers from working in the hazardous environmental condition of confined spaces.

Based on the data derived from fatal incidents, it is evident that landslides represent the most significant hazardous condition leading to fatalities in confined spaces within Malaysia. To effectively mitigate the risks posed by landslides and ensure the safety of workers, a thorough risk assessment is imperative before commencing any work in confined spaces, particularly those prone to landslides [47]. This assessment should involve geological studies and expert evaluations to identify areas vulnerable to such events [48, 49]. By understanding the geological conditions and history of the site, potential landslide risks can be anticipated, and appropriate precautions can be established.

While for hazardous environment conditions caused by atmospheric hazards pre-assessment can be conducted by carrying out an air quality assessment within a confined space. This involves performing gas testing to identify the presence of hazardous gases. Gas testing serves the dual purpose of detecting hazardous gases and measuring oxygen levels. Gas testing before confined spaces entry are very important as toxic gases and oxygen deficiency can create highly dangerous conditions. These hazards are often not visually apparent, leading to instances where workers become trapped in such perilous situations [38, 47]. Furthermore, the oxygen levels within confined spaces cannot be determined through mere observation; therefore, specific testing is required to measure the oxygen content. In Malaysia, a code of practice for working in confined spaces mandates the testing of gas before entry [8]. Authorized gas testers registered with DOSH Malaysia are responsible for conducting these tests [8]. Air quality monitoring isn't limited to entry alone; continuous monitoring throughout work in confined spaces is essential. The fatal incidents in confined spaces studied by P. Liu underscore the importance of continuous air quality monitoring which have been find out that absence of such monitoring has been identified as a critical factor contributing to these fatalities [46, 50].

If hazardous gases are detected within confined spaces, the implementation of purging methods becomes crucial to eliminate these risks [47, 51]. Among the most prominent purging techniques is the use of nitrogen gas. Nitrogen, being an inert gas, helps displace and remove potentially harmful gases from the confined space environment. However, it's important to note that the choice of purging method should be based on the specific circumstances and the types of gases involved.

The next safety measure that needs to be implemented to avoid hazardous environmental conditions is continued risk control and monitoring. In the aspect of landslides in confined spaces, the implementation of structural reinforcement as a continued risk control strategy are very effective. Ensuring that the confined space's structure is capable of withstanding potential landslides greatly enhances worker safety [52, 53]. Reinforcement measures might include installing robust barriers, shoring up weak points, and fortifying the surrounding environment to minimize the impact of a potential landslide. Regular monitoring is equally essential. Utilizing advanced monitoring technologies such as ground movement sensors, inclinometers, and weather forecasting tools can provide early warning signs of possible landslides [48]. Establishing a reliable monitoring system enables timely evacuation and intervention, preventing workers from entering the confined space when a landslide risk is imminent.

In the aspect of atmosphere conditions, to establish and maintain a continuous safe atmosphere within confined spaces, a well-designed ventilation system is essential [24, 38]. This system aims to consistently replace the existing atmosphere with fresh air, reducing the concentration of hazardous gases and ensuring a breathable environment for workers. To determine the suitable capacity for the air fan required in the ventilation system, workers should seek advice from experts or professionals familiar with confined space safety protocols. Calculating the appropriate capacity for the air fan involves considering factors such as the volume of the confined space, the type of hazardous gases present, and the rate at which they need to be removed. Implementing the correct method of ventilation in confined spaces is very crucial to ensure the effectiveness of the ventilation. The ineffectiveness of ventilation method will leading to serious damage to occupational health of workers [54, 55].

The last control measure and the most effective approach to preventing hazardous environmental conditions in confined spaces caused by hazardous environmental conditions is to eliminate the necessity of working within confined spaces altogether. While this might seem challenging, it can be achieved through the concept of inherently safer design [11, 21]. This method involves designing and planning confined spaces from their very early stages in a way that negates the need for workers to enter these spaces. Although this strategy requires commitment from multiple stakeholders, including engineers, architects, and other parties involved, its implementation can drastically enhance safety.

Inherently safer design principles prioritize hazard elimination or reduction right from the outset of a project [11, 21]. This could entail designing the layout, structure, and systems of confined spaces to minimize or eliminate potential risks. For example, creating access points that allow maintenance and inspections to be carried out externally, without the need for workers to physically enter the confined space, can significantly enhance safety. The success of this strategy hinges on a collaborative effort among various disciplines. Architects and engineers play pivotal roles in integrating safety considerations into the design and construction phases. This necessitates heightened awareness of occupational safety requirements within these fields. By recognizing the importance of safety and considering it as a central aspect of their design and planning discussions, these professionals can ensure that safety measures become an integral part of the project's specifications.

Fostering a culture of safety awareness among architects and engineers is vital because they often develop a false sense of safety [21]. This can be achieved through comprehensive training and educational initiatives that emphasize the significance of designing spaces that prioritize human safety. As a result, safety requirements become non-negotiable elements of the project, rather than optional additions.

The second most prevalent immediate cause of unsafe conditions is the inadequate or improper use of protective equipment. This issue is the extension of the unsafe act of failing to use PPE correctly. To prevent such instances of improper PPE use, employers must establish an effective PPE enforcement program. This program involves creating well-defined procedures for working within confined spaces and employing visual reminders to reinforce safety measures.

Documented procedures should offer clear guidance to workers and outline the steps to be followed while operating in confined spaces. Workers should be required to acknowledge their understanding of these procedures, underscoring the importance of adhering to proper protocols. This step ensures that workers consistently follow the correct safety measures when working in confined spaces [45]. Notably, the procedure must explicitly specify the type of PPE mandated for each task. If a worker needs to wear a mask or respirator, the specific type, such as N95, P95, or a full-face respirator, should be clearly mentioned.

Visual reminders, including noticeable signs strategically placed in the work area, play a vital role in maintaining PPE compliance. These measures serve as continuous reminders for workers, reinforcing the necessity of wearing the designated PPE at all times. This visual reinforcement fosters an environment of heightened awareness and ensures that safety protocols are consistently upheld by the workforce.

Addressing the broader context of PPE provision, it's crucial for employers to ensure the issuance of appropriate PPE for confined space work. Analyzing incident data reveals that falling is a significant direct cause of physical accidents. To mitigate this risk, the proper selection and provision of suitable PPE are pivotal. This might involve equipping workers with safety harnesses featuring lanyards and safety shoes designed with anti-slip properties, effectively mitigating the potential for falls.

Additionally, recognizing atmospheric hazards is very important. Depending on the nature of the confined space work, providing workers with respirators and breathing apparatus is essential for safeguarding against atmospheric risks. It's imperative that the PPE provided adheres to the standards set by local regulatory bodies. For instance, in Malaysia, PPE must be approved by SIRIM, the certifying authority responsible for market approval in the country. In conclusion, the improper use of protective equipment remains a significant concern in confined space work. Implementing a comprehensive PPE enforcement program through well-defined procedures and visual reminders can help rectify this issue.

To continue monitoring of the effectiveness of PPE, regular inspections need to be conducted. Certain types of personal protective equipment (PPE) have limitations, such as a limited duration of effectiveness and susceptibility to physical deterioration caused by environmental and user factors. Regular inspections can prevent employees from using ineffective PPE, thereby reducing the risk of exposure to hazards in confined space.

After all safety measures have been taken, it is crucial to conduct an evaluation to ensure the effectiveness of the steps taken and to implement improvement measures. There are several practices that can be applied to the evaluation process, namely, data analysis, employee feedback, and audits.

Data analysis plays a pivotal role in OSH evaluation by leveraging statistical tools to examine incident reports, accident trends, and near misses. This analytical scrutiny enables organizations to identify potential hazards, assess risk factors, and implement targeted interventions to mitigate workplace dangers.

The integration of an employee feedback mechanism is essential for a holistic OSH evaluation. Employees, as frontline participants, offer valuable perspectives on the practicality and effectiveness of safety measures. Establishing a mechanism for open communication ensures that the workforce's experiences and observations are considered, fostering a culture of safety awareness and collaboration.

Audits are systematic assessments that provide a structured examination of OSH protocols and procedures. Whether conducted internally or externally, audits identify areas of compliance, uncover potential gaps in safety measures, and offer recommendations for corrective actions. Regular audits are instrumental in maintaining and improving OSH standards within the organization

4 Conclusions

In conclusion, this study employed the SCAT checklist method to diligently investigate the root causes of fatal incidents within confined spaces in Malaysia. The findings unequivocally highlight the pivotal role played by the improper use of personal protective equipment (PPE) and exposure to hazardous environmental conditions in contributing to the fatal incident in confined spaces. This is supported by the data indicating that 16 out of 30 reported casualties were caused by a failure to use PPE, while 26 out of the 30 reported casualties were attributed to working in hazardous environmental conditions. The overarching revelation of a pervasive lack of awareness among both employees and employers regarding confined space hazards serves as a crucial insight into the central underlying cause of these incidents.

To effectively address and mitigate the identified root causes, a comprehensive preventive strategy framework is imperative. The first step involves robust identification of issues, focusing on raising awareness about the specific hazards associated with confined spaces. This necessitates targeted training initiatives aimed at educating both workers and management about the risks involved. Concurrently, there is a need for stringent enforcement of safety protocols to ensure adherence to established guidelines and standards.

The second component of the preventive strategy framework entails the development and implementation of proactive preventive measures. This includes measures such as ensuring proper and consistent usage of PPE through continuous training and reinforcement programs. Additionally, creating a hazard-free environment through effective ventilation and control measures becomes paramount in preventing incidents related to hazardous environmental conditions.

Monitoring and evaluation constitute the third crucial element of the preventive strategy framework. Regular and thorough assessments of safety measures, coupled with ongoing training and awareness programs, are essential to ensure their effectiveness. Periodic evaluations can help identify any gaps or areas of improvement in the safety protocols, allowing for timely adjustments and enhancements.

However, it's essential to recognize the limitations of this study. It specifically focused on fatal incidents for the purpose of developing safety measures in confined spaces. Future studies should broaden their scope to encompass incidents resulting in injuries and near-miss events. By incorporating a more comprehensive range of incidents into the analysis, a more robust and inclusive set of safety measures can be formulated to address the risks associated with confined spaces.

In conclusion, this study employed the SCAT checklist method to identify predominant root cause in fatal incidents within confined spaces in Malaysia. The findings underscore the significance of failing to use PPE and working in hazardous environmental condition as primary contributors to these incidents. Through targeted efforts to raise awareness and enforce safety protocols, the study suggests a viable pathway to mitigating risks and enhancing safety in confined space work environments. Nonetheless, future research should extend its focus to encompass a broader spectrum of incidents for a more comprehensive safety approach+.

Data availability

The datasets generated during and/or analysed during the current study are available in the Department of Occupational safety and Health Malaysia repository, (https://www.dosh.gov.my/index.php/fatal-accident-case-1).

Code availability

Not applicable.

References

Burlet-Vienney D, Chinniah Y, Bahloul A, Roberge B. Occupational safety during interventions in confined spaces. Saf Sci. 2015;1(79):19–28.

Amin Z, Mohammad R, Othman N. Review and comparison of confined space risk assessment tools practised by industry code of practice for safe working in confined space of Malaysia, 2010 (ICOP 2010). J Adv Res Bus Manag Stud. 2020;18(1):16–23.

Arifin K, Aiyub K, Razman MR, Jahi JM, Awang A, Hussain SSH. Occupational safety management in Malaysia. J Food Agric Environ. 2013;13:995–8.

Jaafar MH, Arifin K, Aiyub K, Razman MR, Ishak MIS, Samsurijan MS. Occupational safety and health management in the construction industry: a review. Int J Occup Saf Ergonomics. 2018;24:493–506.

Liu Y, Yang C. Characteristics and causes of accident in confined spaces. China Saf Sci J. 2017;27(3):141–6.

Botti L, Duraccio V, Gnoni MG, Mora C. An integrated holistic approach to health and safety in confined spaces. J Loss Prev Process Ind. 2018;1(55):25–35.

Stojkovic A. Occupational safety in hazardous confined space. Saf Eng. 2013;3(3):137–44.

Department of occuopational safety and health Malaysia. Industry code of practice for safe working in a confined space. 2010.

Mohammadi L, Meech JA. Atmospheric fuzzy risk assessment of confined space entry at mine reclamation sites. 2011. http://thetyee.ca/News/2007/07/09/MineDeaths/;

Burlet-Vienney D, Chinniah Y, Bahloul A, Roberge B. Design and application of a 5 step risk assessment tool for confined space entries. Saf Sci. 2015;1(80):144–55.

Gonzalez-Cortes A, Burlet-Vienney D, Chinniah Y. Inherently safer design: an accident prevention perspective on reported confined space fatalities in Quebec. Process Saf Environ Prot. 2021;1(149):794–816.

DOSH. Official Website Department of Occupational Safety and Health Malaysia - Fatal Accident Cases. https://www.dosh.gov.my/index.php/fatal-accident-case-1. Accessed 21 Sep 2022.

Abelmann A, Lacey SE, Gribovich A, Murphy C, Hinkamp D. Hazard evaluation and preventive recommendations for an unusual confined space issue in an opera set design. J Occup Environ Hyg. 2011;8(9):D81–5.

Wilson MP, Madison HN, Healy SB. Confined space emergency response: assessing employer and fire department practices. J Occup Environ Hyg. 2012;9(2):120–8.

Selman J, Spickett J, Jansz J, Mullins B. Confined space rescue: a proposed procedure to reduce the risks. Saf Sci. 2019;113:78–90.

Zhou Y, Li Y, Li H, Cui J, Gao S. Design of emergency rescue plans and rescue equipment for confined spaces. Int J Comput Sci Math. 2023;18(1):94–102.

Jaafar MH, Arifin K, Aiyub K, Razman MR, Ahmad M. A review of occupational safety and health (OSH) accidents and contributing factors in construction industry. J Food Agric Environ. 2015;13(2):238–44.

Lazim SHIM, Arifin K, Abas A, Khairil M, Ali MN, Lampe I, et al. A systematic literature review on leadership practices for safety in the education sector. Sustainability. 2022;14:8262.

Arifin K, Derahim N. Co-workers’ safety climate dimension in urban rail transport system. Geogr Malays J Soc Space. 2020;16(2):53–65.

Rahman FA, Arifin K, Abas A, Mahfudz M, Basir Cyio M, Khairil M, et al. Sustainable safety management: a safety competencies systematic literature review. Sustainability. 2022;14(11):6885.

Gonzalez-Cortes A, Burlet-Vienney D, Chinniah Y, Ben Mosbah A, Bahloul A, Ouellet C. Inherently Safer Design (ISD) solutions in confined spaces: experts’ practical feedback in Quebec, Canada. Process Saf Environ Protect. 2021;157:375–89.

Abdalwhab SM, Yassin KEE. Hazards arising from working in confined spaces case study: Khartoum North Industrial Area. Sudan Univ Khartoum Eng J. 2022. https://doi.org/10.53332/kuej.v5i1.1023.

Khan F, Ahmed S, Yang M, Hashemi SJ, Caines S, Rathnayaka S, et al. Safety challenges in harsh environments: lessons learned. Process Saf Progr. 2015;34(2):191–5.

McManus N, Haddad AN. Confined space incident reconstruction: the future depends on understanding the past. Prof Saf. 2014;59(10):51–9.

Bin AK, Abudin R, Razman MR, Ismail ZS, Ahmad M. Safety climate assessment on priority, commitment and the efficiency of safety management. J Food Agric Environ. 2016;14(2):141–56.

Arifin K, Derahim N, Aiyuba K. Analysis of worker safety climate assessment at Malaysia city rail management’s operation division. Akademika. 2020;90(1 (SI)):03–113.

Ali MXM, Arifin K, Abas A, Ahmad MA, Khairil M, Cyio MB, et al. Systematic literature review on indicators use in safety management practices among utility industries. Int J Environ Res Public Health. 2022;19(10):6198.

Ziegler-Barranco A, Mera-Barco L, Aramburu-Rojas V, Raymundo C, Mamani-Macedo N, Dominguez F. SCAT Model based on bayesian networks for lost-time accident prevention and rate reduction in Peruvian mining operations. In: Advances in intelligent systems and computing. 2020.

Pitblado R, Potts T, Fisher M, Greenfield S. A method for barrier-based incident investigation. Process Saf Progr. 2015;34(4):328–34.

Arifin K, Razman MR. Organisations’ perceptions towards the effectiveness of integrated management system in Malaysia. Information (Japan). 2015;18(6):2283.

Hulme A, Stanton NA, Walker GH, Waterson P, Salmon PM. What do applications of systems thinking accident analysis methods tell us about accident causation? A systematic review of applications between 1990 and 2018. Saf Sci. 2019;117:164–83.

Bird FE, Loftus RG. Loss control management. Institute Press; 1976

Baldissone G, Comberti L, Bosca S, Murè S. The analysis and management of unsafe acts and unsafe conditions. Data collection and analysis. Saf Sci. 2019;119:240–51.

Xu Q, Xu K. Analysis of the characteristics of fatal accidents in the construction industry in china based on statistical data. Int J Environ Res Public Health. 2021;18(4):2162.

Park IS, Kim J, Han S, Hyun C. Analysis of fatal accidents and their causes in the Korean construction industry. Sustainability. 2020;12(8):3120.

Korea Occupational Safety and Health Agency. Manual for the Prevention of Asphyxiation Accidents in Confined Space Work. 2016.

Muré S, Camuncoli G, Demichela M. A semi-quantitative risk assessment method in process plants: Confined spaces. Chem Eng Trans. 2019;77.

Selman J, Spickett J, Jansz J, Mullins B. An investigation into the rate and mechanism of incident of work-related confined space fatalities. Saf Sci. 2018;1(109):333–43.

Sehsah R, El-Gilany AH, Ibrahim AM. Personal protective equipment (Ppe) use and its relation to accidents among construction workers. Med Lav. 2020;111(4):285–95.

Wong TKM, Man SS, Chan AHS. Critical factors for the use or non-use of personal protective equipment amongst construction workers. Saf Sci. 2020;126: 104663.

Martin H, Mohan N, Ellis L, Dunne S. Exploring the role of PPE knowledge, attitude, and correct practices in safety outcomes on construction sites. J Arch Eng. 2021. https://doi.org/10.1061/(ASCE)AE.1943-5568.0000501.

OSHA. Act 514 Occupational Safety and Health Act 1994. Act 514 Occupational Safety and Health Act 1994. 1994;(1990).

Doll M, Feldman M, Hartigan S, Sanogo K, Stevens M, Mcreynolds M, et al. Acceptability and necessity of training for optimal personal protective equipment use. Infect Control Hosp Epidemiol. 2017;38(2):226–9.

Su Y, Cong W, Liang H. The impact of supervisor–worker relationship on workers’ safety violations: a modified theory of planned behaviour. J Civil Eng Manag. 2019;25(7):631–45.

Dodoo JE, Al-Samarraie H. Factors leading to unsafe behavior in the twenty first century workplace: a review. Manag Rev Q. 2019;69(4):391–414.

Kiehl ZA, Durkee KT, Halverson KC, Christensen JC, Hellstern GF. Transforming work through human sensing: a confined space monitoring application. Struct Health Monit. 2020;19(1):186–201.

Arifin K, Ahmad MA, Abas A, Mansor Ali MX. Systematic literature review: characteristics of confined space hazards in the construction sector. Results Eng. 2023;18: 101188.

Tan Q, Bai M, Zhou P, Hu J, Qin X. Geological hazard risk assessment of line landslide based on remotely sensed data and GIS. Measurement (Lond). 2021;169: 108370.

Li L, Lan H, Strom A, Macciotta R. Landslide longitudinal shape: a new concept for complementing landslide aspect ratio. Landslides. 2022;19(5):1143–63.

Liu P, Ma X. Lessons learned in confined space entry management after a gas poisoning accident in China. Process Saf Progr. 2023;43:170–6.

Zhan G, Bai L, Wu B, Cao F, Duan Y, Chang F, et al. Dynamic process simulation and optimization of CO2 removal from confined space with pressure and temperature swing adsorption. Chem Eng J. 2021;416: 129104.

Tian X, Song Z, Zhang Y. Monitoring and reinforcement of landslide induced by tunnel excavation: a case study from Xiamaixi tunnel. Tunnel Undergr Space Technol. 2021;110: 103796.

Murgia I, Giadrossich F, Mao Z, Cohen D, Capra GF, Schwarz M. Modeling shallow landslides and root reinforcement: a review. Ecol Eng. 2022;181: 106671.

Quan M, Wang Y, Zhou Y, Xu K, Cao Y, Ren X. Effect of swirl ventilation on contaminant removal in a cylindrical confined space. Build Environ. 2021;205: 108227.

Hajji Y, Bouteraa M, Bournot P, Bououdina M. Assessment of an accidental hydrogen leak from a vehicle tank in a confined space. Int J Hydrogen Energy. 2022;47(66):28710–20.

Acknowledgements

The authors would like to thank Universiti Kebangsaan Malaysia for providing funding for this study and Indah Water Konsortium for their support in this research

Funding

This study has been supported by Universiti Kebangsaan Malaysia through research Grant (SK-2020-011 and SK-2021-011).

Author information

Authors and Affiliations

Contributions

Conceptualization, KA and MAA; methodology, KA; formal analysis, KA and MAA; investigation, MAA; resources, MXMA; data curation, AA; writing—original draft preparation, KA and MAA; writing—review and editing, AA and LMF; visualization, MAA and MXMA; supervision, AA and MLJ; project administration, MAA; funding acquisition, KA and AA. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflicts of interest.

Ethics approval and consent to participate

The research did not require ethical committee approval as the data study conducted in this manuscript exclusively uses data obtained from the authoritative source, the Department of Occupational Safety and Health Malaysia. This research did not involve human research participants or live vertebrates.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Arifin, K., Ahmad, M.A., Abas, A. et al. Identification of root cause of fatal confined space incidents in Malaysia and strategies for prevention. Discov Sustain 5, 36 (2024). https://doi.org/10.1007/s43621-024-00197-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43621-024-00197-3