Abstract

Coffee is one of the tropical crops of great relevance. Mexico occupies one of the first places to produce it. Chiapas is the state that contributes the most significant amount of grain to the national and international market, harvested by organized groups such as cooperatives of origin indigenous. In these regions, cultivation is divided into five stages: cultivation, harvest, wet processing, dry processing and roasting. Thus, the agroecological approach based on the agroforestry system of coffee in the community of Ocotepec allowed generating an intercultural dialogue with a Zoque indigenous cooperative, where its members expressed the need to develop information regarding their production process and thus take the relevant decisions. Concerning environmental impacts. The life cycle analysis was applied as a methodological tool to evaluate the process of producing a kilogram of ground coffee in its honey and specialty varieties offered to the national market, showing the most significant impacts for both types of coffee. Cultivation level (water consumption around 80% and land use with effects close to 98%), wet processing (impacting the ecotoxicity of water sources close to 99% followed by marine ecotoxicity with 73%) and in its distribution stage affecting at least 15 environmental categories, likewise, comparative tests were carried out to calculate the carbon footprint and the water footprint, with shade-grown honey coffee being the type of coffee that has the most negligible environmental impact and contributes the most profits to the cooperative.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Coffee is one of the most important tropical crops worldwide. It was a species introduced in Mexico approximately 200 years ago (end of the eighteenth century). Since then, it has become one of the essential agroforestry products for the livelihood of thousands of families [1].

The coffee is a perennial shrub that develops ideally in the lower strata of cloudy mountain forests and tropical forests. According to Barrera and Parra [2], in the past decade, coffee cultivation generated one of the highest incomes for the local economies of more than 50 tropical countries, preceded in some cases only by oil and tourism.

According to the International Coffee Organization, Mexico is among the top 10 countries out of 55 that have produced the most coffee in the last five years. In the 2020-21 cycle, 2420 thousand bags (60 kg) of the Arabica variety (Coffea arabiga) were produced, which is the most cultivated species with 94.5% and 5.5% is associated with the robusta variety (Coffea canephora) [3,4,5].

According to the Ministry of Agriculture [4], the cultivated area for 2016 was 730,001 hectares with a potential growth by 2030 of 471.47% thousand tons, of which 94.98% is cultivated traditionally. This productive capacity satisfies the demands of 100% of the national market, with exports destined mainly to the United States and Spain.

Coffee plantations in Mexico are mostly affected by rust (Hemileia vastatrix), a pathogen that was detected since 1981 and is currently widely distributed in all regions of the country [5], with the Arabica variety being the most vulnerable species to said disease [6].

That is, according to Nájera [7] and Santacruz-De León et al. [8], coffee is a product that is part of the popular diet and is a product appreciated by families, in addition to being cultivated by about 300,000 producers, of which about 60% belong to indigenous groups that inhabit the territories of Oaxaca, Chiapas, Puebla, Veracruz and Guerrero.

The indigenous and rural producers of the states mentioned above develop cultivation on hillsides and orographically rough places where highly biodiverse ecosystems coincides with Moguel and Toledo, [9]. The coffee plantations are developed under a system of minimal impact on natural ecosystems called a diversified agroforestry system, coffee gardens or shaded coffee plantations [9, 10] producing mostly organic coffee, where the collection, benefit, and processing processes are in the majority artisanal or semi-technified.

Chiapas is one of the states where the most considerable amount of coffee is produced by indigenous hands-on surfaces of less than two hectares [2]. Ocotepec is a community with a majority indigenous population of the Zoque ethnic group dedicated to this crop and the associated agricultural production (corn, beans, bananas, Etc.), practically for self-consumption [11]. Cadena and collaborators [12] comment that, despite promoting polycultures in their territory, few products are destined for trade; coffee is one of them, although it is only marketed as parchment (green) coffee to intermediaries.

It is worth mentioning that the cultivation of coffee in the region, "as it is a subsistence crop” [12] for more than 60 years, families have dedicated little time to cultivation since productive diversification limits the time devoted to cultivation. The plantations, that is, the coffee plantations, develop spontaneously with the ecosystem.

In 2016, the Organización de Productores Zoques A.C. was established as the first cooperative focused on the benefit and processing of organic coffee in the municipality of Ocotepec, Chiapas. This organization is made up of 19 Zoque families that have begun to change the way they cultivate and care for the coffee plantation, incorporating good organic management practices, renovating, and weaving technology to add value to the grain they produce, as well as being the first group in the area that does not depend on an intermediary to offer its final product.

Social and academic organizations have progressively accompanied this change process, which has promoted participatory action research [13] to establish a dialogue of intercultural knowledge [14] that has made self-management possible. Of the cooperative expressing the need to enrich its production processes.

In recent years, coffee cultivation in Mexico has been surrounded by practices derived from modern agriculture that was historically driven by "The Green Revolution" [15], where the main component is the use of agrochemicals and technology to achieve high production, was how Rachel Carson [16] showed the negative impacts of these practices, evidencing the need to promote a new agricultural paradigm.

With the proposal of the Brundtland Report [17] to define sustainability to preserve present and future planetary resources, the trends to theorize from a consumption perspective have promoted disciplines such as the green economy, the circular economy, and the bioeconomy. (GE, CE and BE) [18]. In particular, the circular economy (CE) is considered an alternative to reorient the flows of resources and materials by using them more than once, minimizing or not using renewable resources as well as waste from a cyclical point of view [19, 20].

From this approach, the implementation of CE in agri-food systems has a diversity of potentially viable applications to improve production processes and supply chains (50); in the case of coffee production, the possibility of reusing waste arises, improve technologies, to influence global markets, although this implies continuing to generate information for decision making [21,22,23].

In this sense, this study addresses two lines of analysis related to the coffee production process. Firstly, the aim is to evaluate the environmental impacts associated with the industry in accordance with Industrial Ecology (EI), which seeks to restructure processes towards more sustainable modes, using the Lifecycle Assessment (LCA) as a principle [24].

Secondly, traditional and agroecological production is considered defined by Sarandón and Flores [25], such as the management of agroecosystems from a complex approach including all possible interactions the knowledge of various disciplines in addition to considering "traditional ecological knowledge (TEK)" [26], where coffee produced under shade and from small producers in accordance with [10, 27] guarantee the sustainability of the landscapes and the livelihoods of the producers.

On the other hand, this study aims to generate evidence on the impacts associated with CO2 emissions and water consumption related to the coffee production process carried out by the cooperative. Thus, the indigenous productive system will be of great importance to value and document the processes carried out by communities aimed at the need to promote more sustainable practices with the environment without leaving aside the livelihood of families [28].

Based on the above, it is expected that the coffee produced by the cooperative organization, which includes agroecological and sustainable land management practices, will have lower environmental impacts with respect to a large-scale production process.

To evaluate this process, a dialogue was established with the cooperative in question to apply the life cycle analysis (LCA) model and analyze the impacts of the current coffee production process and thus generate information to suggest and, to the extent possible, incorporate best low environmental impact practices privileging the identity of the cooperative's indigenous coffee.

2 Methods

2.1 Study area

The research was carried out in the municipality of Ocotepec (from the Nahuatl meaning hill of ocotes) and its prominent homonymous locality, located northeast of the state of Chiapas between coordinates 17º13′21" N and 93º10′28" W at an average altitude of 1460 m above sea level, the study area has an average annual temperature of 19.3 °C and average annual precipitation of 304.9 mm [29] (Fig. 1).

It has 11,878 inhabitants, of which 80% speak Zoque, a population distributed in 43 localities, and all considered highly marginalized [30]. Most of the population is dedicated to subsistence agriculture, and the leading products in their crops are bananas, corn, beans, chayote, and pumpkin.

The climate is warm and humid with rains all year round, and its physiography allows the distribution of the cloud forest also called tropical montane cloud forest or the mountain mesophyllous forest and high evergreen forest [9], ideal conditions for growing coffee under shade.

2.2 Methodological model

Based on the needs expressed by the cooperative members, the environmental impacts of coffee processing were analyzed by LCA. This methodology aims to evaluate and analyze the potential environmental impacts of a given process or product following ISO 14044 and 14040 [31, 32] standards. The following steps were developed:

2.2.1 Definition of objectives and scope

It was proposed as a goal to evaluate and analyze the production process of the types of coffee produced by the cooperative, considering cultivation, processing, and market disposition.

2.2.2 Description of the system

Were conducted directed interviews to five representatives’ members of the cooperative and apply participant observation in each of production stage for to find out data, stages and inputs used throughout the process, which allowed for a description of the entire process in the community of Ocotepec, should be noted that traditional practices and knowledge that are applied throughout the system were contemplated.

For this work, we analyzed a production cycle between 2021 and 2022. Eight visits were made to the community from August 2021 to March 2022. The information related to the cultivation stage, wet milling, dry milling, roasting and distribution was recorded and analyzed.

Likewise, the cooperative has incorporated machinery and processes associated with modern instruments in the dry and wet processing stages, which imply different environmental impacts from a rudimentary process such as self-consumption (as it is carried out in cookers and manual processes within the home), as well as having built an alternative space to the homes locally called "La bodega", in this space the dry processing and roasting stage is carried out. In contrast, the cultivation-harvesting stage is carried out in the plots, and the wet processing is carried out in the homes. It is important to note that this collection and processing center or storage place (La bodega) is located approximately five to eight kilometers away from the households and plots.

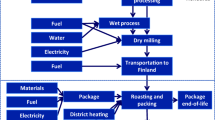

Based on this context, the limits of the system to develop the LCI were defined (Fig. 2), describing and contemplating the following stages of the production cycle:

-

a)

Cultivation: includes the establishment of plots, planting, and cultural work such as fertilization, weeding and pruning; it does not contemplate the nursery production stage or restitution of coffee plants. All activities are carried out manually with tools that depend solely on people's physical strength. Likewise, the inputs necessary to apply agroecological formulas for treating and preventing pests and diseases were considered for the LCI, as the cooperative does not use synthetic fertilizers, elements, or agrochemicals. The coffee cultivated depends on the shade of the trees to thrive, using at least ten species. However, locally the "Chelel" tree (Inga sp.) is considered the preferred species for the coffee plantation, as it has been observed that under the canopy of this leguminous plant, better conditions of organic matter, shade and shelter for other species are created.

-

b)

Harvesting: This involves manual harvesting, as well as the selection of cherries based on ripening criteria by colour. The participation of the members of the family is essential for this task.

-

c)

Wet milling: This includes the manual pulping process, washing, fermentation and selection by flotation of the best seeds, concluding with the first stage of sun drying. According to the region, the coffee that is most produced is the Coffea arabiga variety, from which two types of coffee benefit in the cooperative were identified: "specialty coffee" and "honey coffee". The differentiated treatment of the seeds distinguishes this classification during the wet milling process, where the use of water to remove the mucilage that accompanies the seed in the case of specialty coffee is removed by much washing, leaving the seed to macerate in water for 12 h, this technique is known locally as "fermentation", and the washed seeds are then dried in the sun. On the other hand, honey coffee is washed only once and is not fermented with water. In this case, the mucilage, locally called "mielecilla", remains and is dried in the sun together; this practice implies greater vigilance on the part of the producer as he must move the seed continuously to avoid the appearance of fungi. For carrying out the LCI, the calculations considered the differences in water use.

-

d)

Dry processing: from this process onwards, the activities are carried out in the processing warehouse, where the necessary machinery is found for grinding, classifying by size and density, and packaging. At this stage, the coffee is called green coffee or golden coffee. At this stage, the coffee is stored in sacks of ixtle, or natural fibers and hermetic bags are used to conserve the moisture content necessary for its preservation in the warehouse.

-

e)

Roasting and sale: this is the cooperative's final phase, using machinery to roast, grind and package the coffee in the presentations offered to the public. For sales and distribution, the distances and transport needed to move the packaged product from the warehouse in the community to the state capital were considered, where commercial parcel services distribute it.

-

f)

Waste: analysis of waste mainly generated in the wet and dry processing stage was not included in the system. The most common waste generated is pulp, mucilage, and shell. In the case of the pulp, it is discarded with the ferment water in an area designated as waste and in the case of the husk, it is used as part of the greenhouse compost.

The production process carried out by this community was identified as semi-technified. In accordance with (7) and (42) where the use of technology is only focused on the benefit process since during cultivation and harvest the entire process is completely manual and cultivated in a traditional way under shade. The data necessary to elaborate the LCI were collected considering the average inputs and outputs for each stage of the production process, differentiating between each type of coffee, considering materials, resources, tools, energy, emissions, fuel, equipment, machinery, Etc. Necessary to produce the functional unit.

A fundamental element of the LCI was validating the data with cooperative members, thus ensuring that the information represents the process and its components. This validation made it possible to standardize the units of measurement according to the stage and the tools, resources or input and output elements of the system that contemplates the production process for both types of coffee.

2.2.3 Definition of the functional unit

The functional unit was defined as 1.0 kg of roasted and ground coffee packaged and ready for distribution. The difference in the functional unit per type of coffee was considered, i.e. 1.0 kg of ground and roasted coffee called specialty and the same amount for coffee called honey. It was considered the varieties of coffee offered to the public.

2.2.4 Limits of the system

This study was analyzed from door to door, leaving out of the system the nursery stage, the distribution that implies moving the product from the capital of the state to the hands of the client, as well as the origin of the resources; the production was considered that as it is a crop with an agroecological approach, only elements to prepare remedies such as "bordelés" broth based on calcium hydroxide (lime), copper sulphate and biopesticides such as Beauveria bassiana, and biotraps are used.

2.2.5 Inventory analysis

The information was collected by elaborating a spreadsheet matrix to elaborate the life cycle inventory (LCI), considering some recommendations suggested by Mourad and collaborators [33], establishing the essential criteria to generate an LCI that includes the crucial stages in an agricultural production cycle. Thus, through the application of interviews to the members of the cooperative for document the production process, the components defined by the system were established, including supplies, materials, tools, and energy. These data were supported by testimonials, short videos, records, receipts or respective documentation, and pertinent calculations to standardize the functional unit and calculate the intermediate inputs and outputs. It should be noted that, traditionally, the organization carries out a differentiated treatment of the seeds during the wet processing, generating two types of coffee: specialty and honey. The fundamental difference lies in the use of water to remove the mucilage that accompanies the seed; in specialty coffee is removed by washing with plenty of water in addition to allowing the seed to macerate, a technique that is locally recognized as "fermentation" to dry it in the sun later.

On the other hand, honey coffee is washed only once and is not fermented with water to be dried in the sun, although it implies greater vigilance on the producer. They must move the seed to avoid the appearance of fungi continuously. In this case, to consider the outputs in the LCI for both types of coffee, the chemical components consulted in Saud and Salamatullah [34] and Braham and Bressani [35] contained in the mucilage and husk, considered waste in the coffee industry, were considered. The complete inventory can be found in the supplementary material.

2.2.6 Impact evaluation

We were using the SimaPro v9.0 software and EcoInvent 3.0 database. Then the inventory components were analyzed, processing the respective results for a detailed investigation. Recipe method used to explore the environmental impacts by impact category for homologating with similar studies such as that of Rapa and Ciano [36], identifying them as follows: Global warming potential (GWP), Stratospheric ozone depletion (SOD), Ionizing radiation (IR), Ozone formation, Human health (OFHH), Fine particulate matter formation (FPMF), Ozone formation, Terrestrial ecosystems (OFTE), Terrestrial acidification (T.A.), Freshwater eutrophication (F.E.), Marine eutrophication (M.E.), Terrestrial ecotoxicity (TEC), Freshwater ecotoxicity (FEC), Marine ecotoxicity (MEC), Human carcinogenic toxicity (HCT), Human non-carcinogenic toxicity (HNCT), Land use (LU), Mineral resource scarcity (MRS), Fossil resource Scarcity (FRS) and Water consumption (WC).

Based on the information shared by the members of the cooperative concerning the use of water to differentiate the production processes of specialty and honey coffee, apply an additional evaluation through the AWARE method to verify what was observed in the field and investigate the possible differences concerning the water footprint in both treatments.

2.2.7 Interpretation

Finally, an analysis and discussion of the results were carried out, establishing the most relevant aspects of the process and where the most critical environmental incidents are found, to share the analysis with the members of the cooperative and promote a dialogue of knowledge that seeks to sustain decisions to influence production processes, recognizing the importance of the environment.

3 Results

The LCI data was processed by SimaPro v9.0 using the EcoInvent 3.0 database analyzed with the Recipe methodology for both production processes. The process examined to the production of 1 kg of coffee classified as specialty (Fig. 3) which, in the production stage, it was observed that, in the cultivation phase, the most significant impacts are found in the WC with 79% and LU with 98%.

In the wet processing stage, it is evident that the categories with the most significant impact are FEC with 99%, followed by MEC with 73%. For the dry processing stage, the effects are considerably low in all categories, averaging no more than 2–4%, with FPMF being the category with the highest impact with a value of 6.8%. Finally, the impacts are considered in at least 15 categories in the distribution stage, with the most significant results in OFHH and for OFTE with 83% impact.

Similarly, the analysis process was applied to the production of honey coffee (Fig. 4), resulting in an 85% impact in the cultivation stage in the category of WC and 98% in the LU, in the wet benefit, as the production of specialty coffee, the impacts are in the category of FEC with 99% followed by MEC with 73%. Similarly, it is like the specialty coffee production in the dry benefit. Finally, in the distribution phase, the affected categories are 15 of the 18, where the most significant impacts were observed in the OFHH and for OFTE with 83% impact.

In both analyses (Figs. 3 and 4), the impacts associated with GWP are primarily associated with roasting and distribution (> 50%) since, according to the data collected and the LCI calculations, during the cultivation and harvesting process, no machinery is used, all operations are manual, and the current organic approach to cultivation only contemplates the application of preventive remedies such as calcium hydroxide (lime), copper sulphate, pheromone traps, Etc. Elements that were accounted for in the LCI and extrapolated to the area of plants cultivated per square meter. Furthermore, in the roasting and distribution part, energy is used, either electricity for the oven or petrol for the transport.

With a high impact on ozone formation that can harm human health and ecosystems, this behavior is probably related to the use of machinery and vehicles that may be underutilized. That is, the cooperative, by 2021, will produce an average of 2 tons of coffee, which are channelled in the stage of dry benefit and distribution by machinery that can process a more significant amount of grain; on the other hand, distribution to the market is carried out by commercial parcels where the collection points are located in the state capital (Tuxtla Gutiérrez), so the vehicle used to transport the coffee to the parcel at centers make one trip per month, transporting an average of 20 kg. The vehicle used for this activity can transport more significant quantities of processed and packaged coffee per month. If the vehicle were used to its maximum capacity, probably this use would reduce the environmental impacts per functional unit.

As a next step, both production processes were compared using the Recipe methodology (Fig. 5). Both types of coffee production systems are practically similar, showing subtle differences in the categories of FEC with a normalized value of 0.410 for specialty coffee and 0.412 for honey coffee, followed by an impact on MEC with values of 0.020 for specialty coffee and 0.016 for honey coffee, in addition to having effects on TEC with normalized values of 0.00465 and 0.00464 for specialty and honey, respectively, this indicator coincide in the impacts linked to wet processing.

These results opened the possibility of applying a more specific comparison using the AWARE methodology. This analysis was carried out to understand the effects in a more particular way and know if there are differences shown by the Recipe method when applying another methodology, in this case, to observe the impacts related to WC. The result shows differences between the production process of specialty coffee with water consumption of 2.24 m3 and honey coffee which uses 2.07 m3; specialty coffee uses the most water for the procedure. This difference opens the possibility of analyzing with the cooperative the advantages of producing any of the types of coffee and perhaps showing the consumer the environmental impacts related to the water footprint, for example, publishing the water consumption on the packaging to motivate the final consumer to reflect on the advantages of consuming any coffee. This result indicates the possibility of substituting the production of specialty for honey coffee and achieving a considerable reduction in water consumption, with the consequent environmental benefits.

On the other hand, a comparative test of the water footprints by type of methodology was carried out: AWARE or Recipe water consumption, analyzing the stages and their relationship concerning WC (Table 1), where it can be observed that in both tests, the cultivation stage reflects the greater demand for water that is used throughout the process followed by the wet processing, in this second stage is where both methodologies indicate that the production of specialty coffee requires more water than honey, which reaffirms the observation made in the field as well as what was commented by the producers.

When analyzing the general results of both processes (Figs. 3 and 4), another of the categories with the most significant impacts was the one related to the global warming potential (GWP) since in its distribution stage, it has the highest values, for which we proceeded to carry out an additional test comparing the carbon footprint (CF) for both production cycles (Table 2) observing that the highest values are those associated with the Recipe methodology for both types of coffee and the most conservative is that of IPCC 20 years.

The highest CF is associated with the distribution stage followed by the cultivation stage for both processes; like the evaluation of this case, the process of producing specialty coffee has a higher CF than the other type, although the value difference is at the rate of two points.

The application of these tests provides an overview of coffee production impacts in the locality of Ocotepec, Chiapas, showing that the production of specialty coffee has a more significant water footprint than honey coffee.

4 Discussion

Based on the results obtained, developing a research process hand in hand with an organization of indigenous Zoque coffee growers in Chiapas, Mexico, allows us to discuss the local, regional, and global scope of bringing this type of tool closer to assessing environmental impacts and provide data from a local scale to a production system such as coffee that is inserted in a global supply and demand.

Swarr [37] raised the possibility of incorporating models and tools focused on the evaluation of environmental impacts such as LCA to agribusinesses such as coffee, which contributes approximately 29% of greenhouse gases (GHG) emitted into the atmosphere of which the majority is associated with the change and use of land from forest land to crops [38,39,40].

In this context, most of the studies that applied LCA or some of its components as an environmental impact assessment tool were carried out in coffee-producing and exporting countries such as Brazil and Costa Rica in the American continent [41,42,43,44,45,46] and Vietnam and Indonesia on the Asian continent [40, 46,47,48,49,50,51]. These studies evaluated the impact of coffee cultivation (parchment) in the regions above, complementing the following stages (roasting and consumption) in importing countries like Finland, Italy, Germany, the United Kingdom, and the United States.

On the other hand, some investigations were identified, such as those carried out by Acosta-Alba et al. [52]; Birkenberg and Birner [41]; Brenes-Peralta et al. [53]; Barrera-Ramírez et al. [54] and Giraldi-Díaz et al. [55], where they apply LCA in regions of Colombia, Costa Rica and Mexico, including a production analysis approach based on local consumption or small producers that may or may not export or be consumed in the country of origin.

This last differentiation is essential to highlight because the present study is focused on studying the case of a cooperative of small producers considering processes aimed at organic production for national consumption, for which would be expected that the environmental impacts, when compared with large producers with a commercial focus and export, were different.

The analysis that was carried out is based on a comparison of studies carried out in other regions of the world, including Mexico, contrasting only the stages of the LCA that correspond to the production of the coffee bean in its green state since each study shows particularities in the subsequent processes such as in processing, disposal and even consumption, which was not considered in this study.

Based on this assumption, it was observed that in the study carried out by Barrera-Ramírez et al. [54] in the Catatumbo region of Colombia; the most significant impacts resulted in the categories of eutrophication, climate change, and acidification, coinciding with the present analysis in the categories of terrestrial acidification, marine and freshwater eutrophication with the second-highest values after water consumption.

For Acosta-Alba et al. [52] in Costa Rica, the most significant impacts in the green coffee production phase are in the categories of climate change, acidification, terrestrial eutrophication, freshwater eutrophication, especially in the plots that were associated with the cultivation of coffee as the only product and the lower values in the cultivated coffee under shade, once again coinciding with this work in the categories of terrestrial acidification and freshwater eutrophication.

In the case of research on the Asian continent, the LCA analysis carried out by Situmorang and Manik [49] in Indonesia for farms with coffee dedicated to export stands out; in this study, the effects found in the eutrophication categories (2.6 kg PO43−eq.) and acidification (0.13 kg SO2eq.), having the highest values for these categories compared to the data obtained for specialty coffee with 2.46 kg PO4 3− eq. for eutrophication and 0.00056 kg SO2eq. in the acidification category, while for honey coffee, they yielded values of 2.45 kg PO43−eq. in eutrophication and 0.00055 kg SO2eq. for acidification.

In addition, Hamdan et al. [48] applied the methodology to small-scale producer lands, finding the most significant number of affectations in the same categories of acidification resources (0.3457 kg SO2eq.) and eutrophication (0.2854 kg PO43−eq.). It is noted that the values of these categories are lower concerning the analysis by Situmorang and Manik [49] for eutrophication and higher in acidification, as in the present study.

In Vietnam, the assessment carried out by Trinh et al. [47] sought to compare high-production commercial coffee farms and organic farms, the former being the ones that showed more significant effects in the categories of climate change, human toxicity, photochemical oxidant formation, particulate matter formation, agricultural land occupation, natural land transformation, metal depletion, freshwater eutrophication, terrestrial acidification, and fossil depletion. In the case of organic and export coffee farmland, the effects are in the categories of freshwater eutrophication and terrestrial acidification, with values above 50% above those of this study for both types of coffee (Fig. 3 and 4).

In the case of the work carried out by Salomone [44], where she analyses the coffee consumption process in Italy, she shows that the cultivation stage is also the part of the cycle that contributes the most impact in the category of terrestrial ecotoxicity and eutrophication. However, it is impossible to determine the origin of the coffee since the study does not mention the cultivation region; despite this lack of information, the values in both categories are higher than in this work.

An important aspect is that some studies used LCA to calculate only specific categories associated with the impacts of CO2eq emissions, water consumption and soil damage. For this reason, the results compared independently to the evaluation generated by all the Recipe categories sharing the following aspects:

4.1 Water use

According to the productive cycle of coffee in regions of Asia and America, the application of LCA adds value when analyzing the categories of water consumption since, for cultivation and production, the vital liquid is a fundamental element for its success; in this aspect, some studies that evaluated water consumption for three primary purposes were compared:

-

A)

Irrigation in the case of high production coffee plantations or monocultures.

-

B)

Washing, fermentation and waste, depending on the region or country.

-

C)

Consumption.

For the comparative analysis, only the cultivation and benefits stage were considered to produce green coffee; thus, the results generated by: Acosta-Alba et al. [52], Situmorang and Manik [49] were analyzed. Usva et al. [46], Coltro et al. [43] and Giraldi-Díaz et al. [55] concerning the values obtained by Recipe for specialty coffee and honey (Fig. 6).

Comparison of studies evaluating WF on land producing commercial or export coffee with land producing organic smallholder coffee in coffee-growing regions. They are contrasted with the values of Recipe for the community of Ocotepec, Chiapas, Mexico. Source: Own elaboration with data from [43, 46, 49, 52] and [55]

In Fig. 6, the study that shows the highest consumption values is the one reported by Usva et al. [46] in farms with high coffee production in Brazil, followed by the data by Situmorang and Manik [49] for Indonesia and from Coltro et al., [43] for Brazilian coffee lands.

It is essential to mention that the results by Acosta-Alba et al. [52] and Giraldi-Díaz et al. [55] show that water consumption, despite being carried out on coffee lands under a commercial and export approach, data are like those obtained in this study for both types of coffee.

On the other hand, we can see that the coffee farms of small producers of organic origin in Costa Rica [52] have the lowest values of all the studies, including this work.

4.2 Soil impacts

According to the results obtained, the cultivation stage has a considerable impact on the establishment and maintenance of the coffee plantation, where the effects on the soil reach values close to 80%; studies such as that of Salomone in 2003 [44] mention that the impacts associated with the soil have values above 97%, on the other hand, Trinh et al. [47], show that organic coffee cultivation lands were affected in values close to 50% by the high use of organic fertilizers and in intensive management plots above 50% due to the use of agrochemicals and pesticides.

According to the literature review, the use of these inputs of chemical origin is one of the leading environmental effects reported throughout the evaluations carried out by Viere et al. [51]; Trinh et al. [47], Salomone [44]; Usva et al., [46]; Birkenberg and Birner [41]; Situmorang and Manik [49]; Nab and Maslin [50]; Rega and Ferranti [45]; Giraldi-Díaz et al. [55], among others where they analyze the productive relationship with the use of high environmental impact fertilizers such as urea (nitrogen) followed by phosphorus and potassium, as the main chemical elements necessary for the productive development of the coffee plantation.

The case of studies such as the one by Trinh and collaborators [47] show that when evaluating plots with an organic production approach, the use of organic alternatives such as animal manure also hurts the soil, so it is interesting to reflect on the most suitable options friendly that contribute fertility to the soil.

Under this same scheme, Acosta-Alba et al. [52] evaluated in the Cauca region, Colombia, the use of compost based on animal manure, mixed with coffee residues, providing nutrients to the plots being assessed, resulting in little effect on the soil acidification compared to other sites under a monoculture system.

The same authors mention that the benefits of including some species that provide shade to the coffee plantation, such as leguminous trees of the genus Inga sp., are significant since, in this study, they highlighted the value of these trees to channel nitrogen naturally to the soil being an excellent alternative to reduce nitrogenous fertilization of chemical origin. This result reaffirms the knowledge shared by the cooperative in preferring trees of this genus as coffee shade.

The toxicity to the soil promoted by modern agriculture has its antecedents in countries of the American continent, such as Brazil since 1784, being the country with the most extensive areas planted with coffee in full sun, highly productive and demanding in water and pesticides [56].

Usva and collaborators [46] analyzed the impacts of the coffee production system in Nicaragua, Honduras and Brazil, the region with the highest demand for agrochemicals focused on coffee production and consequently with the most significant damage to the soil.

In the case of the study carried out in Mexico by Giraldi-Díaz et al. in 2018 [55], they once again coincide in the effects on the soil derived from the use of fertilizers in the plantations and the machinery in some respects within the process, despite these results. A large part of the coffee system in Mexico varies from very diverse agroforestry systems to monocultures, although all of them are based on standard practices [9], such as the one carried out in the state of Chiapas evaluating the case of the cooperative in the community study.

4.3 Emissions to the atmosphere

In all the comparative studies, regardless of the origin of the country or coffee region, the authors conclude that the most significant load of emissions emitted into the atmosphere is associated with the cultivation, distribution, and consumption stage.

For this component, they are studies that applied LCA to calculate the carbon footprint were consulted, highlighting those of Hamdan et al. [48]; Situmorang and Manik [49]; Trinh et al. [47]; Nab and Maslin [50]; Birkenberg and Birner [41]; Killian et al., [42]; Usva et al., [46]; Acosta-Alba et al., [52]; Barrera-Ramírez et al. [54], and Giraldi-Díaz et al. [55], considering only the CO2eq that is emitted in the green coffee production stage (Fig. 6). The data to elaborate Fig. 5 were normalized to our functional unit concerning the functional unit reported in each study. Only the stages related to wet processing and drying that result in green coffee were considered. The relevant calculations were made to homologate the information and to be able to compare 1.0 kg as a functional unit, considering only the CO2eq that is emitted in green coffee production.

Figure 7 shows that the most significant amount of CO2eq emissions per kilogram of green coffee was produced by sites with a large-scale export or monoculture system, with Indonesia, Brazil and Colombia being the countries that documented the most remarkable impacts with emissions of 6.8, 6.6 and 5.8 kg CO2eq respectively, associated with the use of fertilizers, machinery, and transportation in the case of green coffee that is exported to other countries.

Comparison of studies evaluating CO2eq emissions on land producing commercial or export coffee with land producing organic on small-scale coffee in coffee-growing regions. It is contrasted with the values of Recipe GW and IPCC at 20 years for Ocotepec, Chiapas, Mexico. Source: Own elaboration with data from [41, 42, 46,47,48,49,50, 52, 54, 55]

In the case of farms or lands that produce organic coffee or small producers, emissions do not exceed 3 kg CO 2 eq reported by Acosta-Alba et al. [52] in communities in Colombia, followed by an analysis carried out by Trinh et al. [47] which wrote 0.64 kg CO2eq for small producers in Vietnam.

All the studies that evaluated sites with organic production, local consortiums or small producers, and shade-grown reported values below the average of the rest of the lands that do not have this approach.

Based on the system's limits, the most significant burden of emissions is in the distribution stage since the coffee is transported (regardless of quantity) in pooled vehicles to the state capital, where external parcel services distribute it to other points within the country. In this sense, being a small cooperative and not having its vehicles, the cost of CO2eq emissions to transport coffee is very high and inefficient.

Another aspect to highlight with the rest of the studies is associated with the environmental load derived from the use of fertilizers since. However, they have an organic origin. The impact was lower in terms of CF, so the cultivation practices are possibly associated with very traditional forms of management since, compared to other reported sites with similar characteristics, CO2eq emissions are very low.

4.4 Other aspects

Considering the CE approach in the present study, despite not considering waste (pulp, mucilage, shell), it is suggested to revalue the waste generated in wet and dry processing within the impacts since according to [57,58,59] secondary products can be generated such as: biocomposites for crops, development of nutritional supplements, biofuels, construction materials, etc., however, many of these by-products require infrastructure in addition to investing in capacity development within the community, which allows us to open a range of possibilities to continue providing improvements to the current productive process.

Another aspect to consider is the type of coffee that the cooperative produces, since it was decided to compare honey and specialty coffee due to the types of products they generate, the farmers who produce honey coffee invest more hours a day to attend to and care for the coffee. When drying it, carelessness can lead to a fungal attack in addition to requiring completely sunny days, which due to the climate and physiography of the place is complicated since there is generally constant rain or cloudy days.

According to those interviewed, specialty coffee is much easier to produce since it requires less attention in the drying stage and can even be dried without having to be exposed to the sun, unlike honey, which also reduces the workload and hours of work of the people involved in the process.

5 Conclusions

To the best of our knowledge, this research is one of the first carried out in Mexico using LCA for coffee-producing communities on indigenous lands. This project corresponds to an advance in the exchange of knowledge that seeks to dialogue with interest expressed by the original communities that want to promote better practices for their crops, eliminate intermediaries, preserve their biocultural heritage, and reduce the environmental impacts caused by coffee production.

It is possible to conclude that the environmental impact generated by the production of a kilogram of coffee (specialty or honey) in the community of Ocotepec, Chiapas, Mexico has a lower environmental impact than that carried out in other coffee regions of the world, highlighting that the type of honey coffee has the most negligible impact and is also sold to the national trade with a premium, which implies higher profits for the cooperative.

Additionally, the management practices on the plot still represent relatively minor impacts concerning the categories of effects on soil and water, so it is possible to recommend continuing to maintain the productive system under shade and evaluating some organic practices to improve soil fertility and the potential lowering of impacts on the ground.

With this we can respond to the central approach that establishes that the production of small indigenous producers uses low environmental impact practices compared to high production schemes, however, based on the sustainability and circular economy approach there is an area of opportunity to raise awareness, train and undertake new alternatives to reduce impacts that were not considered in addition to creating new byproducts from the use of pulp, mucilage and shell.

Finally, in a globalized system, it would be essential that LCA be applied as a means of environmental certification in the coffee production chain so that the final consumer can make the best decision to consume a product that represents less environmental impact and is economically viable, especially for small producers who have sustained their livelihood in the cultivation of organic coffee under shade.

Data availability

The data is available in the supplementary material.

References

Escamilla Prado E, Ruiz Rosado O, Zamarripa Colmenero A, González Hernández VA. Calidad en variedades de café orgánico en tres regiones de México. Rev Geogr Agrícola. 2015;55:45–55.

Barrera JF, Parra M. El café en Chiapas y la investigación en ECOSUR. Ecofronteras. 2000;4(12):3–6.

ICO, “International Coffee Organization,” Estadísticas de producción total a partir de 1990 al 2020, 2021. https://www.ico.org/es/new_historical_c.asp?section=Estad%EDstica.

SAGARPA, “Planeación Agrícola Nacional 2017–2030. Cuadernillo de investigación sobre el Café en México.” 2017.

FIDEICOMISOS INSTITUIDOS EN RELACIÓN CON LA AGRICULTURA (FIRA). Panorama agroalimentario: Café 2016. https://www.gob.mx/cms/uploads/attachment/file/200636/Panorama_Agroalimentario_Caf__2016.pdf

Henderson TP. La roya y el futuro del café en Chiapas. Revista mexicana de sociología. 2019;81(2):389–416.

Nájera EO. El café orgánico en México Una alternativa para los productores indígenas. Cuad Desarro Rural. 2002;48:59–75.

Santacruz-De León EE, Pérez Díaz OL, Palacio Muñoz VH. “Competitiveness of farmers organizations of organic coffee of soconusco, chiapas; analysis of the perception of their leaders” Rev. OIDLES—Obs. Iberoam. DEL Desarro. LOCAL Y LA Econ Soc. 2010;9:1–38.

P. Moguel V M. Toledo, “El café en México, ecología, cultura indígena y sustentabilidad.” Ciencias. 1996;43

Toledo VM, Barrera-Bassols N. en siete regiones indígenas de México. Saberes ambientales campesinos. Cultura Saberes tradicionales y adaptaciones ecológicas y naturaleza en comunidades indígenas y mestizas de México. 2011;15–60

LKI Garrido, “Determinación del impacto socioeconómico de los programas de apoyo gubernamentales en el sector productivo rural en la región sur sureste de México; caso Ocotepec y Copainalá, Chiapas,” Universidad Autónoma de Chiapas. 2012.

Cadena Iñiguez P, Garrido Leyva KI, Rendón Medel R, Rangel Quintos J, Salinas Cruz E, Fernández González I. Persistencia campesina: estrategias de vida en áreas marginadas de Chiapas. Rev Mex Ciencias Agrícolas. 2017;7(4):809.

Borda O. Action researchin the convergence of disciplines. Int J Action Res. 2013;92:155–67.

C. Walsh, “Construyendo Interculturalidad Crítica,” Construyendo Intercult. Crítica, pp. 75–96, 2010.

W. Gaud, “The Green Revolution: Accomplishments and Apprehensions. Transcripción del speech de William Gaud del 8 de marzo de 1968 in the Society for International Development.,” 1968. [Online]. Available: https://www.agbioworld.org/biotech-info/topics/borlaug/borlaug-green.html.

Carson R. The silent spring. New York: Houghton Mifflin Company; Anniversary edition; 1964.

World Commission on Environment and Development (WCED). Our common future. Oxford: Oxford University Press; 1987.

D’Amato D, Korhonen J. Integrating the green economy, circular economy and bioeconomy in a strategic sustainability framework. Ecol Econom. 2021;188:107143. https://doi.org/10.1016/j.ecolecon.2021.107143.

Macarthur E. Towards the circular economy. J Ind Ecol. 2013;2:23–44.

Kirchherr J, Reike D, Hekkert M. Conceptualizing the circular economy: an analysis of 114 definitions. Resour Conserv Recycl. 2017;127:221e232. https://doi.org/10.1016/j.resconrec.2017.09.005.

Gonçalves ML, Maximo GJ. Circular economy in the food chain: production, processing and waste management. Circular Econ Sustain. 2023;3(3):1405–23. https://doi.org/10.1007/s43615-022-00243-0.

van Keulen M, Kirchherr J. The implementation of the Circular Economy: Barriers and enablers in the coffee value chain. J Cleaner Product. 2021;281:125033. https://doi.org/10.1016/j.jclepro.2020.125033.

Abuabara L, Paucar-Caceres A, Burrowes-Cromwell T. Consumers’ values and behaviour in the Brazilian coffee-in-capsules market: promoting circular economy. Int J Prod Res. 2019;57(23):7269–88. https://doi.org/10.1080/00207543.2019.1629664.

Romero D, Molina A. Towards a sustainable development maturity model for green virtual enterprise breeding environments. IFAC Proc Vol. 2014;47(3):4272–9. https://doi.org/10.3182/20140824-6-ZA-1003.00430.

Sarandón SJ, Flores CC. Agroecología: Bases teóricas para el diseño y manejo de agroecosistemas sustentables. In: Sarandón SJ, Flores CC, editors. Facultad de Ciencias Agrarias y Forestales. La Plata: Universidad Nacional de la Plata; 2014.

Snively G, Corsiglia J, Cobern WW. Discovering indigenous science: implications for science education. Sci Educ. 2001;85(1):6–34.

Jha S, Bacon CM, Philpott SM, Rice RA, Méndez VE, Läderach P. A review of ecosystem services, farmer livelihoods, and value chains in shade coffee agroecosystems. In: Campbell W, Lopez Ortiz S, editors. Integrating agriculture, conservation and ecotourism: examples from the field issues in agroecology—present status and future prospectus, vol. 1. Dordrecht: Springer; 2011.

Antonelli A. Indigenous knowledge is key to sustainable food systems. NatureOpen AccessVolume. 2023;613(7943):239–24212.

Sistema Meterológico Nacional. Normales Climáticalógicas por Estado. In https://smn.conagua.gob.mx/es/climatologia/informacion-climatologica/normales-climatologicas-por-estado

S. de D. S. SEDESOL, “Informe anual sobre la situación de pobreza y rezago social 2015. Ocotepec, Chiapas.” 2015.

I. O. for S. ISO, Environmental management—Life cycle assessment—Principles and framework. Geneva, Switzerland, 2006.

ISO and I. O. for Standardization., Environmental management—Life cycle assessment—Requirements and guidelines. Geneva, Switzerland, 2006.

Mourad AL, Coltro L, Oliveira PAPLV, Kletecke RM, Baddini JPOA. A simple methodology for elaborating the life cycle inventory of agricultural products. Int J Life Cycle Assess. 2007;12(6):408–13.

Saud S, Salamatullah AM. Relationship between the chemical composition and the biological functions of coffee. Molecules. 2021;26(24):1–14.

JE Braham, R Bressani. Coffee pulp : composition, technology, and utilization. Institute of Nutrition of Central America and Panama. 1978.

Rapa M, Ciano S. A Review on life cycle assessment of the olive oil production. Sustain. 2022;14(2):654.

Swarr TE. Societal life cycle assessment—could you repeat the question? Int J Life Cycle Assess. 2009;14(4):285–9.

Bellarby J, Foereid B, Hastings AFSJ, Smith P. Cool Farming: climate impacts of agriculture and mitigation potential. Greenpeace Int. 2008;2014:44.

Vermeulen SJ, Campbell BM, Ingram JSI. Climate change and food systems. Annu Rev Environ Resour. 2012;37:195–222.

Clay J. World agriculture and the environment: a commodity-by-commodity guide to impacts and practices. Chicago Press: Bibliovault OAI Repos. Univ; 2004.

Birkenberg A, Birner R. The world’s first carbon neutral coffee: lessons on certification and innovation from a pioneer case in Costa Rica. J Clean Prod. 2018;189:485–501.

Killian B, Rivera L, Soto M, Navichoc D. Carbon footprint across the coffee supply chain: the case of Costa Rican coffee. J Agric Sci Technol. 2013;3:151–70.

Coltro L, Mourad AL, Oliveira PAPLV, Baddini JPOA, Kletecke RM. Environmental profile of Brazilian green coffee. Int J Life Cycle Assess. 2006;11(1):16–21.

R. Salomone. “Coffee Life Cycle.pdf.” 2003:1(2):295–300

Rega FV, Ferranti P. Life cycle assessment of coffee production in time of global change. Amsterdam: Elsevier; 2018.

Usva K, Sinkko T, Silvenius F, Riipi I, Heusala H. Carbon and water footprint of coffee consumed in Finland—life cycle assessment. Int J Life Cycle Assess. 2020;25(10):1976–90.

Trinh LTK, Hu AH, Lan YC, Chen ZH. Comparative life cycle assessment for conventional and organic coffee cultivation in Vietnam. Int J Environ Sci Technol. 2020;17(3):1307–24.

Hamdan H, Fauzi A, Rusli M, Rustiadi E. A study of the smallholder coffee agroindustry sustainability condition using the life cycle assessment approach in Bengkulu Province, Indonesia. J Ecol Eng. 2019;20(6):153–60.

Situmorang A, Manik Y. Life cycle assessment of food processing systems in Toba Samosir regency. E3S Web Conf. 2018;73:3–7.

Nab C, Maslin M. Life cycle assessment synthesis of the carbon footprint of Arabica coffee: case study of Brazil and Vietnam conventional and sustainable coffee production and export to the United Kingdom. Geo Geogr Environ. 2020;7(2):1–19.

Viere T, von Enden J, Schaltegger S. Life cycle and supply chain information in environmental management accounting: a coffee case study. In: Burritt Roger, Schaltegger Stefan, Bennett Martin, Pohjola Tuula, Csutora Maria, editors. Environmental management accounting and supply chain management. Dordrecht: Springer, Netherlands; 2011.

Acosta-Alba I, Boissy J, Chia E, Andrieu N. Integrating diversity of smallholder coffee cropping systems in environmental analysis. Int J Life Cycle Assess. 2020;25(2):252–66.

Brenes-Peralta L, Jiménez-Morales MF, Campos-Rodríguez R, Vittuari M. Unveiling the social performance of selected agri-food chains in Costa Rica: the case of green coffee, raw milk and leafy vegetables. Int J Life Cycle Assess. 2021;26(10):2056–71.

Barrera-Ramírez J, Prado V, Solheim H. Life cycle assessment and socioeconomic evaluation of the illicit crop substitution policy in Colombia. J Ind Ecol. 2019;23(5):1237–52.

Giraldi-Díaz MR, De Medina-Salas L, Castillo-González E, León-Lira R. Environmental impact associated with the supply chain and production of grounding and roasting coffee through life cycle analysis. Sustain. 2018. https://doi.org/10.3390/su10124598.

Perfecto I, Jiménez-Soto ME, Vandermeer J. Coffee landscapes shaping the anthropocene: forced simplification on a complex agroecological landscape. Curr Anthropol. 2019;60(S20):S236–50.

Pagliarini E, Totaro G, Saccani A, Gaggìa F, Lancellotti I, Di Gioia D, Sisti L. Valorization of coffee wastes as plant growth promoter in mulching film production: a contribution to a circular economy. Sci Total Environ. 2023. https://doi.org/10.1016/j.scitotenv.2023.162093.

Machado M, Helena Ferreira M, Oliveira BPP, Rita CA. Coffee by-products: an underexplored source of prebiotic ingredients. Crit Rev Food Sci Nutr. 2023. https://doi.org/10.1080/10408398.2023.2181761.

Durán-Aranguren DD, Robledo S, Gomez-Restrepo E, Arboleda Valencia JW, Tarazona NA. Scientometric overview of coffee by-products and their applications. Molecules. 2021;26:7605. https://doi.org/10.3390/molecules26247605.

Acknowledgements

PXS-N thanks CONACYT and the program CATEDRAS-CONACYT for the support of project 492. "Public policies, prospects and sustainability of biorefineries in Mexico".

Funding

This work has been possible thanks to the support of the Transdisciplinary Doctorate Program in Scientific and Technological Development for Society, the Center for Research and Advanced Studies (CINVESTAV), and the National Council for Science and Technology (CONACYT Grantee Number 191290002). Also, with deep affection and respect, we thank the members of the Organization of Zoques Indigenous Organic Producers, A.C., Owners of the Kajwel Tøjk brand, for their facilities and willingness to dialogue and build these results.

Author information

Authors and Affiliations

Contributions

AEC-A: Collected the data; contributed data or analysis tools and wrote the paper. PXS-N: Conceived and designed the analysis, performed the analysis contributed data or analysis tools and wrote the paper.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Informed consent was obtained from all individual participants included in the study.

Consent for publication

The participant has consented to the submission of the case report to the journal.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Calvillo-Arriola, A.E., Sotelo-Navarro, P.X. A step towards sustainability: life cycle assessment of coffee produced in the indigenous community of Ocotepec, Chiapas, Mexico. Discov Sustain 5, 17 (2024). https://doi.org/10.1007/s43621-024-00194-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43621-024-00194-6