Abstract

Purpose of Review

Drying as a preservation method for plant materials improves microbial and nutritional quality, however, such processing needs a lot of energy. Thus, different approaches are described as the use of the nonthermal processing (pulsed electric field, ultrasound, high-pressure processing, ethanol application) to reduce drying time and obtain a higher quality of final product.

Recent Findings

There are given several examples for nonthermal processing, which highlight the positive impact on drying time, bioactive compounds content, and energy consumption for different food products. Also, the other aspects are described of the use of conventional drying methods, including hot-air drying, freeze-drying, microwave drying, infrared drying, and vacuum drying, emphasizing their advantages and limitations. Furthermore, the concept of hybrid drying technologies, integrating various methods is described. Additionally, the importance of solar drying is presented as an eco-friendly method, and the growing interest in combined drying methods. Also, a practical example of a mobile drying unit project is presented, showcasing its potential for versatile use in different locations and farms. However, for scaling up the processing, the optimization of the drying process in the laboratory scale into industrial scales is done through methods like Response Surface Methodology (RSM) and others. This paper presents a brief overview of developing drying technologies according to the sustainable approach in the food industry.

Summary

In the aim of sustainability and efficiency in food science, innovative pretreatments coupled with hybrid drying methods, play a crucial role in producing high-quality products with lower energy consumption and reduced investment costs, emphasizing the importance of incorporating renewable energy in new drying solutions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Plant materials contain a high amount of water, which plays a crucial role in the microbial and nutritional quality of the food products [1]. For preservation purpose can be used one of the oldest method—drying [2]. By limiting the water content and its activity, the growth of microorganisms in the material is constrained, resulting in obtaining of a product with extended durability, which allows its consumption throughout the year [3•, 4]. Furthermore, the drying process leads to a reduction in the product's weight, facilitating its transport and storage, consequently lowering associated costs [5, 6].

There are several ways to make the drying process more sustainable. The main challenge is to reduce the energy consumption of this operation, which is estimated to even 25% of the global energy consumption of the industry [7]. In the last years, numerous cutting-edge drying technologies have been developed, aiming to enable sustainable production (environmentally friendly) and enhance energy efficiency [8], while obtaining high-quality products [9, 10]. Therefore, some of these achievements will be described in the next chapters.

Innovative Technologies Used for Drying Process

Treatment Applied Before or During Drying

The properties of the matrix can be modified using various preliminary treatments, which have an impact on the course of this process and the quality of the obtained product. Among the pretreatment methods before the drying process, we can distinguish traditional operations, e.g., cutting [11] and blanching [5], as well as unconventional ones, which involve the use of mainly nonthermal methods, e.g., pulsed electric field, ultrasound, high hydrostatic pressures, ethanol applications, and others [3•, 12,13,14,15]. Nonthermal technologies can be applied either independently as pretreatment or design as a hybrid drying process [16, 17]. Their primary objective is to improve the heat and mass transfer processes, leading to the production of higher-quality products compared to those achieved through conventional means. This improvement is attributed to the partial inactivation of enzymes, a reduction in drying time, and consequently, a shorter exposure of the product to elevated temperatures, minimizing the degradation of thermolabile ingredients [18].

Pulsed Electric Field (PEF)

Recently, special attention has been paid to pulsed electric field technology. In this case, the modification of the structure of the treated material is caused by the electroporation of its cell membrane, which leads to an increase in its permeability. The number and size of pores in the matrix processed in this way increase, which improves processes based on mass exchange, i.e., drying, extraction, and osmotic dehydration [4, 19]. The sustainable aspect of this technology consists of its low energy consumption resulting from short processing time—the treatment of a given material can take up to several microseconds, depending on the desired effect. It is worth mentioning that this technology is also characterized by a lack of environmental pollution or chemical residue, and lower treatment temperature than traditional techniques [20, 21].

Pulsed electric field (PEF) has already been analysed as a treatment used prior to various drying methods (Table 1). Yamakage et al. [15] investigated the effect of PEF (without using water as a conductive medium) on hot-air drying (HAD) of spinach. It was shown that PEF, by limiting the shrinkage of the dried material, led to a reduction of its drying time. Additionally, no negative impact of this nonthermal technology on the retention of L-ascorbic acid has been demonstrated. A reduction in drying time as a result of the application of PEF technology was also noted in studies conducted, among others, on zucchini—HAD [12], apple—HAD, and carrots—HAD and microwave-assisted air drying—MW-HAD [14]. In the last case, the environmental impact of production of those dried products with PEF pretreatment was lower than in the traditional process. PEF, by accelerating the drying process, contributed to increasing the retention of betalains in freeze-dried (FD) red beet [22] and β-carotene in HAD and MW-HAD carrots, but at the same time caused a decrease in the content of phenolic compounds and the antioxidant activity of HAD and MW-HAD apples [14]. This could be the result of increased extractability of these compounds flowing through the PEF-treated cell membrane.

Ultrasound (US)

Ultrasound is another nonthermal technology that has already been examined to enhance mass transfer in various processes such as: drying, extraction, freezing, osmotic dehydration, and thawing. The mechanism of action of this method depends on the treated matrix. When a liquid medium is used, phenomena called microstreaming and cavitation occur. This is the formation of cavitation bubbles, which expand until they reach a critical size and then rapidly collapse, disturbing the structure of the material they surround and/or penetrate (this phenomenon occurs most intensely at the boundary surface of these phases). In turn, in the case of solid-like materials, the structure is transformed into a sponge-like tissue, which results from its cyclic compression and decompression as a result of the ultrasonic wave action. Another characteristic feature is the creation of microchannels in the structure treated in this way, which increase its permeability [4, 23,24,25,26]. Similarly to PEF, material processing using ultrasound is fast (even a few minutes—depending on the intended purpose) and is characterized by low energy consumption—it is worth adding that the energy requirement is higher than in the case of PEF [25, 27].

Table 1 shows several ultrasound (US) applications for boosting drying efficiency and minimizing quality reduction. Modifying the structure of windfall apple [28] and kiwifruit [29] by US treatment used prior to MW-HAD, and supportive technique during HAD, respectively, resulted in a shortening of the drying time of these raw materials, without a negative impact on the content of bioactive ingredients in them (in reference to untreated samples). Similar results were achieved in studies conducted on sweet potatoes dried using HAD and infrared drying (IRD) methods, where a reduction in specific energy consumption was noted as a result of accelerated drying by US [26]. In turn, Karacabey et al. [27] proved the importance of appropriate selection of process parameters. US did not reduce the duration of HAD of purple-fleshed potato, but in the case of relatively mild US treatment, it was possible to significantly improve the retention of bioactive ingredients (total phenolic content, total antioxidant capacity, total monomeric anthocyanin content), which was explained by the increased release of these heat-sensitive compounds from the treated tissue.

High Pressure Processing (HPP)

Other environment-friendly treatment is high hydrostatic pressure processing [30]. This technique involves the use of high-pressure, which damage cell walls, create cavities, increase the permeability of cell membranes, and enlarge intracellular spaces [31].

Table 1 shows the results regarding the use of high hydrostatic pressure processing (HHP) to support the two most energy-consuming drying methods—HAD and FD. HHP-promoted cell disruption resulted in reduction of the drying time of carambola—FD [30], strawberry—FD [32], and plum—HAD [33] (in relation to traditional drying, without pretreatment). Increased cell permeability intensified the diffusion of water during drying. The release of various bioactive substances (L-ascorbic acid, total phenolic content, total flavonoid content, total anthocyanin content, antioxidant activity) from the structure of tissues treated with HHP has also been proven, thanks to which a higher retention of these compounds after drying was obtained [30,31,32,33]. HHP could induce conformational changes in chemical compounds by breaking hydrophobic bonds and salt bridges, which, combined with the disruption of the continuity of plant cell elements (cell wall and cell membrane), escalated the extraction of bioactive compounds from treated tissues [33].

Ethanol Application

Ethanol is an organic solvent that can function as a drying accelerator. It causes modifications in the structural properties of the treated tissue, which mainly include cell walls. Namely, it removes air from the tissue and generates changes in vapour pressure due to the Marangoni effect, which is important from the perspective of capillary flow. This effect enhances the mass exchange that takes place at the interface between two fluids that differ in surface tension. Ethanol, which evaporates first during drying, creates a water/ethanol concentration gradient, which accelerates drying [34, 35]. Immersing food products in ethanol may raise doubts among consumers, but this alcohol is not harmful to human health and evaporates completely during drying, leaving no residues in the dried tissue [36].

The literature also discusses the potential use of ethanol as a pretreatment prior to drying (Table 1). For example, Rojas et al. [34] and Santos et al. [35] checked how this organic solvent would affect the HAD of pumpkin and carrot, respectively. The results are very promising—as a result of the structure disruption, the drying time was shortened, which in turn allowed for a reduction in energy consumption (in relation to drying without pretreatment). Additionally, no negative effect of this method on the carotenoid content was observed. The possibility of shortening the HAD time was also noted in studies conducted on melon [36], where the appropriate selection of process parameters also led to an increase in the retention of bioactive ingredients in the tissue immersed in ethanol (total phenolic content, total carotenoid content, ascorbic acid). The ethanol-damaged and foam-mat-dried (FMD) avocado tissue also had a higher total phenolic content and antioxidant activity than the sample which was only dried [37].

Application of Different Methods of Drying

Several types of drying methods are commonly employed for food drying, each offering unique advantages and applications. Hot-air drying is the most popular method of drying due to its simplicity and low investing cost [38]. However, several drawbacks, such as prolonged exposure to high temperatures leading to the loss of valuable nutrients and vitamins, low energy efficiency, and large energy consumption affect looking for better solutions in drying technologies [3•, 39,40,41,42]. In the last years, the gentle drying process at low temperatures (with hot air around 50 °C) has been considered a good solution for obtaining high-quality products [43]. An alternative approach involves the use of heat expelled at the dryer outlet, circulating it back into the drying cycle [44]. However, other innovative technological solutions have emerged, including the utilization of microwaves, infrared radiation, reduced pressure, and hybrid methods that integrate different techniques [45].

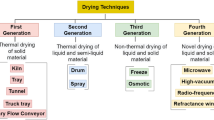

The best method for preserving the nutritional value, color, bioactive compounds, and structure of the raw material is the freeze-drying. This is linked to the low temperature, reduced pressure and lack of air access during the process [46, 47]. Freeze-drying is often used for sensitive food products such as coffee, fruits, vegetables, etc. [48]. However, this method is complex and involves changing the state of water four times (freezing, sublimation, condensation, thawing). This makes this operation very energy-intensive, expensive, and time-consuming [49]. Thus, numerous of new techniques are developed for removing water from food, each exhibiting varying degrees of advancement and technology readiness levels. Such emerging techniques include microwave drying, infrared drying, vacuum drying, and hybrid approaches that involve the combination of different drying methods [45, 50, 51].

One of the new techniques is drying with the use of infrared radiation in the range of near infrared 0.78—1.4 µm, medium infrared 1.4—3 µm, and far infrared 3—1000 µm. Infrared radiation penetrates the product to a certain depth depending on the type of material and ingredients contained in it. The action of infrared radiation leads to rapid heating of the outer layer of the dried food, and then the thermal energy is transferred through conduction to the interior of the material [52]. Infrared radiation shortens drying times, elevating the quality of the final food product compared to conventional methods. Furthermore, infrared drying can be integrated with various drying methods, including hot air, vacuum, microwave, and freeze-drying, to accelerate the process and improve overall outcomes [53, 54].

Microwave drying utilizes electromagnetic energy within specific frequency ranges (300 to 300 000 MHz), predominantly employing the 915 and 2450 MHz bands in food technology [55, 56]. This technique induces volumetric heating, penetrating the product, and causing internal warming through molecular friction, driven by energetic particle movement in response to microwave waves. Microwave drying serves as a fundamental method for heating foods with high water content, enabling rapid drying while preserving superior sensory quality [57]. Furthermore, the acceleration of the drying process will result in significant energy savings, ranging from 32 to 71% [58]. Microwaves are increasingly combined as an additional heat source in hot-air, vacuum, and sublimation drying processes [59]. For example, by combining microwave and vacuum drying, water evaporation occurs more rapidly at lower temperatures, which protect the quality of temperature-sensitive components in the food [60, 61].

Vacuum drying is conducted under reduced pressure conditions, which facilitates faster water evaporation at lower temperatures, minimizing oxidation due to the absence of air. This preservation of temperature-sensitive components, particularly observed in vegetables and fruits, sets vacuum drying apart as an effective method [54, 62, 63]. Recent scientific research emphasizes the optimization of combined drying techniques, notably incorporating microwaves into vacuum drying processes, which can reduce the energy consumption from 50 to even 96% [25, 61].

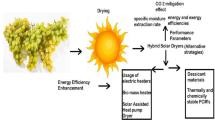

Due to the need to reduce energy consumption during the drying process, solar drying is the next direction of development. Using solar energy to dehydrate food is an eco-friendly method, especially in regions with lots of sunlight and recommended for small scale enterprises and developing countries [64••, 65]. Generally, solar drying method is regarded as a superior method compared to sun drying, as it ensures better quality of the final product (e.g., color, texture) and hygienic processing [66]. Given the current shift towards elevated fossil fuel costs and the uncertainty surrounding future availability and prices, the utilization of solar energy in food processing is likely to rise, becoming increasingly economically viable in the foreseeable future [67,68,69].

To enhance the efficiency and effectiveness of the drying process, combined drying methods are based on integrating two or more drying techniques. This approach aims to use the strengths of individual methods while mitigating their respective limitations [60]. Therefore, numerous research studies are currently being conducted in this area. The literature shows that hybrid drying technologies involve the integration of various methods, including microwave, radio frequency, infrared, ultrasound, heat pump, adsorption into hot air drying, solar drying, fluidized bed drying, vacuum drying, freeze drying, and others [3•, 68]. Also, some of the solutions can be used for a mobile drying unit for use in several places and farms. Such a project is presented in Fig. 1. The dryer in a mobile container can work in a wide range of operating temperatures (0–280 °C) as well as has a rotating trolley, which assures a homogenous drying process. Furthermore, this dryer was equipped with infrared lamps, which fastened the drying process. Furthermore, the PEF treatment can be applied before the drying process to alter the final product and facilitate the drying process [70].

Optimization of the Drying Process

According to the proposed hybrid methods for drying which are studied by scientists on a laboratory scale, to use such methods commercially they have to be built on a larger scale based on data obtained on a smaller scale. Scaling up a dryer poses significant challenges, especially the impact of drying process variables on key characteristics of the dried product [72]. Therefore, it is extremely crucial to select the appropriate drying method for the type of matrix to be dried as well as the applied process parameters. Optimizing the drying process demands a comprehensive approach that integrates technological innovation, process expertise, and sustainable practices. However, optimization of the process helps with the planning of the industrial-scale processing. For this issue are used several solutions that help with this step as RSM [73,74,75] and ANFIS methods [76], Box–Behnken design [77] and others. Nevertheless, there are some differences between the laboratory scale and the industrial scale operations, however, comparable results can still be achieved. Furthermore, each dryer has its own characteristics, thus some level of optimization should be done also at an industrial scale.

Conclusions

The field of food science and industry consistently seeks innovative and cost-effective methods to modernize processes and choose environmentally friendly and sustainable technologies. Pretreatments such as pulsed electric field, ultrasound, high hydrostatic processing, ethanol applications, and others, which are applied before drying, play a crucial role in producing high-quality products with lower energy consumption. Another direction in assuring sustainability in food drying is based on developing new types of dryers based on combining different methods and creating hybrid dryers. Such an approach is important, especially considering the most common drying method using hot air. The use of hybrid methods allows to shorten the drying time and obtain products with usually higher quality. Additionally, this approach ensures relatively low investment costs compared to replacing the entire machinery necessary to conduct the drying process with new types of dryers. An important aspect is the use of renewable energy when developing new drying solutions.

Data Availability

No datasets were generated or analysed during the current study.

References

Papers of particular interest, published recently, have been highlighted as:• Of importance •• Of major importance

Alp D, Bulantekin Ö. The microbiological quality of various foods dried by applying different drying methods: a review. Eur Food Res Technol. 2021;247:1333–43. https://doi.org/10.1007/s00217-021-03731-z.

Arenas-Jal M, Suñé-Negre JM, Pérez-Lozano P, García-Montoya E. Trends in the food and sports nutrition industry: A review. Crit Rev Food Sci Nutr. 2020;60:2405–21. https://doi.org/10.1080/10408398.2019.1643287.

• Hii CL, Ong SP, Yap JY, Putranto A, Mangindaan D. Hybrid drying of food and bioproducts: a review. Dry Technol. 2021;39:1554–76. https://doi.org/10.1080/07373937.2021.1914078. This article present the role of drying in processing food and bioproducts, where moisture removal significantly impacts kinetics, efficiency, and product quality, has led researchers to explore hybrid drying methods that combine various mechanisms for enhanced efficiency, energy efficiency, improved moisture removal, superior product quality, and better retention of nutritional compounds, offering a more sustainable and efficient approach to drying processes.

Radojčin M, Pavkov I, Bursać Kovačević D, Putnik P, Wiktor A, Stamenković Z, Kešelj K, Gere A. Effect of Selected Drying Methods and Emerging Drying Intensification Technologies on the Quality of Dried Fruit: A Review. Processes. 2021;9:132. https://doi.org/10.3390/pr9010132.

Deng L-Z, Mujumdar AS, Zhang Q, Yang X-H, Wang J, Zheng Z-A, Gao Z-J, Xiao H-W. Chemical and physical pretreatments of fruits and vegetables: Effects on drying characteristics and quality attributes – a comprehensive review. Crit Rev Food Sci Nutr. 2019;59:1408–32. https://doi.org/10.1080/10408398.2017.1409192.

Rybak K, Wiktor A, Kaveh M, Dadan M, Witrowa-Rajchert D, Nowacka M. Effect of Thermal and Non-Thermal Technologies on Kinetics and the Main Quality Parameters of Red Bell Pepper Dried with Convective and Microwave-Convective Methods. Molecules. 2022;27:2164. https://doi.org/10.3390/molecules27072164.

Li M, Liu M, Xu C, Wang J, Yan J. Thermodynamic and sensitivity analyses on drying subprocesses of various evaporative dryers: A comparative study. Energy. 2023;284: 128571. https://doi.org/10.1016/j.energy.2023.128571.

Chojnacka K, Mikula K, Izydorczyk G, Skrzypczak D, Witek-Krowiak A, Moustakas K, Ludwig W, Kułażyński M. Improvements in drying technologies - Efficient solutions for cleaner production with higher energy efficiency and reduced emission. J Clean Prod. 2021;320: 128706. https://doi.org/10.1016/j.jclepro.2021.128706.

Link JV, Tribuzi G, Laurindo JB. Improving quality of dried fruits: A comparison between conductive multi-flash and traditional drying methods. LWT. 2017;84:717–25. https://doi.org/10.1016/j.lwt.2017.06.045.

Ghurchaee A, Rezaei R, Moghimi M. Optimization of combined drying (osmotic-hot air) of aloe vera slice using response surface methodology. J Food Sci Technol. 2024;20:1–23. https://doi.org/10.22034/FSCT.20.144.1.

Wiktor A, Nowacka M, Anuszewska A, Rybak K, Dadan M, Witrowa-Rajchert D. Drying Kinetics and Quality of Dehydrated Cranberries Pretreated by Traditional and Innovative Techniques. J Food Sci. 2019;84:1820–8. https://doi.org/10.1111/1750-3841.14651.

Andreou V, Dimopoulos G, Tsonas T, Katsimichas A, Limnaios A, Katsaros G, Taoukis P. Pulsed Electric Fields-Assisted Drying and Frying of Fresh Zucchini. Food Bioprocess Technol. 2021;14:2091–106. https://doi.org/10.1007/s11947-021-02705-z.

Ostermeier R, Parniakov O, Töpfl S, Jäger H. Applicability of Pulsed Electric Field (PEF) Pre-Treatment for a Convective Two-Step Drying Process. Foods. 2020;9:512. https://doi.org/10.3390/foods9040512.

Wiktor A, Parniakov O, Toepfl S, Witrowa-Rajchert D, Heinz V, Smetana S. Sustainability and bioactive compound preservation in microwave and pulsed electric fields technology assisted drying. Innov Food Sci Emerg Technol. 2021;67: 102597. https://doi.org/10.1016/j.ifset.2020.102597.

Yamakage K, Yamada T, Takahashi K, Takaki K, Komuro M, Sasaki K, Aoki H, Kamagata J, Koide S, Orikasa T. Impact of pre-treatment with pulsed electric field on drying rate and changes in spinach quality during hot air drying. Innov Food Sci Emerg Technol. 2021;68: 102615. https://doi.org/10.1016/j.ifset.2021.102615.

Namjoo M, Moradi M, Niakousari M, Karparvarfard SH. Ultrasound-assisted air drying of cumin seeds: modeling and optimization by response surface method. Heat Mass Transf. 2023;59:1073–91. https://doi.org/10.1007/s00231-022-03306-y.

Szadzińska J, Łechtańska J, Kowalski SJ, Stasiak M. The effect of high power airborne ultrasound and microwaves on convective drying effectiveness and quality of green pepper. Ultrason Sonochem. 2017;34:531–9. https://doi.org/10.1016/j.ultsonch.2016.06.030.

Bassey EJ, Cheng J-H, Sun D-W. Novel nonthermal and thermal pretreatments for enhancing drying performance and improving quality of fruits and vegetables. Trends Food Sci Technol. 2021;112:137–48. https://doi.org/10.1016/j.tifs.2021.03.045.

Neri L, Giancaterino M, Rocchi R, Tylewicz U, Valbonetti L, Faieta M, Pittia P. Pulsed electric fields (PEF) as hot air drying pre-treatment: Effect on quality and functional properties of saffron (Crocus sativus L). Innov Food Sci Emerg Technol. 2021;67:102592. https://doi.org/10.1016/j.ifset.2020.102592.

Zhang Z, Zhang B, Yang R, Zhao W. Recent Developments in the Preservation of Raw Fresh Food by Pulsed Electric Field. Food Rev Int. 2022;38:247–65. https://doi.org/10.1080/87559129.2020.1860083.

Matys A, Witrowa-Rajchert D, Parniakov O, Wiktor A. Assessment of the effect of air humidity and temperature on convective drying of apple with pulsed electric field pretreatment. LWT. 2023;188: 115455. https://doi.org/10.1016/j.lwt.2023.115455.

Ammelt D, Lammerskitten A, Wiktor A, Barba FJ, Toepfl S, Parniakov O. The impact of pulsed electric fields on quality parameters of freeze-dried red beets and pineapples. Int J Food Sci Technol. 2021;56:1777–87. https://doi.org/10.1111/ijfs.14803.

Cao X, Islam MN, Zhong S, Pan X, Song M, Shang F, Nie H, Xu W, Duan Z. Drying kinetics, antioxidants, and physicochemical properties of litchi fruits by ultrasound-assisted hot air-drying. J Food Biochem. 2020;44:1–9. https://doi.org/10.1111/jfbc.13073.

Huang D, Men K, Li D, Wen T, Gong Z, Sunden B, Wu Z. Application of ultrasound technology in the drying of food products. Ultrason Sonochem. 2020;63:104950. https://doi.org/10.1016/j.ultsonch.2019.104950.

Nowacka M, Wiktor A, Anuszewska A, Dadan M, Rybak K, Witrowa-Rajchert D. The application of unconventional technologies as pulsed electric field, ultrasound and microwave-vacuum drying in the production of dried cranberry snacks. Ultrason Sonochem. 2019;56. https://doi.org/10.1016/j.ultsonch.2019.03.023

Tayyab Rashid M, Liu K, Ahmed Jatoi M, Safdar B, Lv D, Wei D. Developing ultrasound-assisted hot-air and infrared drying technology for sweet potatoes. Ultrason Sonochem. 2022;86: 106047. https://doi.org/10.1016/j.ultsonch.2022.106047.

Karacabey E, Bardakçı MS, Baltacıoğlu H. Physical Pretreatments to Enhance Purple-Fleshed Potatoes Drying: Effects of Blanching, Ohmic Heating and Ultrasound Pretreatments on Quality Attributes. Potato Res. 2023;66:1117–42. https://doi.org/10.1007/s11540-023-09618-8.

Çetin N, Sağlam C. Effects of ultrasound pretreatment assisted drying methods on drying characteristics, physical and bioactive properties of windfall apples. J Sci Food Agric. 2023;103:534–47. https://doi.org/10.1002/jsfa.12164.

Llavata B, Femenia A, Clemente G, Cárcel JA. Combined Effect of Airborne Ultrasound and Temperature On the Drying Kinetics and Quality Properties of Kiwifruit (Actinidia Deliciosa). Food Bioprocess Technol. 2023. https://doi.org/10.1007/s11947-023-03138-6.

Zhang S, Zhao Y, Yao X, Zheng Z, Zheng C, Jiang Z. Effect of high hydrostatic pressure pretreatment on flavour and physicochemical properties of freeze-dried carambola slices. Int J Food Sci Technol. 2022;57:4245–53. https://doi.org/10.1111/ijfs.15748.

Yuan L, Lao F, Shi X, Zhang D, Wu J. Effects of cold plasma, high hydrostatic pressure, ultrasound, and high-pressure carbon dioxide pretreatments on the quality characteristics of vacuum freeze-dried jujube slices. Ultrason Sonochem. 2022;90: 106219. https://doi.org/10.1016/j.ultsonch.2022.106219.

Zhang L, Qiao Y, Wang C, Liao L, Shi D, An K, Hu J, Wang J, Shi L. Influence of high hydrostatic pressure pretreatment on properties of vacuum-freeze dried strawberry slices. Food Chem. 2020;331: 127203. https://doi.org/10.1016/j.foodchem.2020.127203.

Santos NC, Almeida RLJ, da Silva GM, Monteiro SS, de Alcântara Ribeiro VH, de França Silva AP, de Alcântara Silva VM, de Sousa Rodrigues LM, André AMMCN, de Almeida Mota MM. Influence of high hydrostatic pressure (HHP) pretreatment on plum (Prunus salicina) drying: Drying approach, physical, and morpho-structural properties of the powder and total phenolic compounds. J Food Process Preserv. 2022;46:1–13. https://doi.org/10.1111/jfpp.16968

Rojas ML, Silveira I, Augusto PED. Ultrasound and ethanol pre-treatments to improve convective drying: Drying, rehydration and carotenoid content of pumpkin. Food Bioprod Process. 2020;119:20–30. https://doi.org/10.1016/j.fbp.2019.10.008.

Santos KC, Guedes JS, Rojas ML, Carvalho GR, Augusto PED. Enhancing carrot convective drying by combining ethanol and ultrasound as pre-treatments: Effect on product structure, quality, energy consumption, drying and rehydration kinetics. Ultrason Sonochem. 2021;70: 105304. https://doi.org/10.1016/j.ultsonch.2020.105304.

da Cunha RMC, Brandão SCR, de Medeiros RAB, da Silva Júnior EV, Fernandes da Silva JH, Azoubel PM. Effect of ethanol pretreatment on melon convective drying. Food Chem. 2020;333:127502. https://doi.org/10.1016/j.foodchem.2020.127502

Santos NC, Almeida RLJ, de Andrade EWV, de Fátima Dantas de Medeiros M, da Silva Pedrini MR. Effects of drying conditions and ethanol pretreatment on the techno-functional and morpho-structural properties of avocado powder produced by foam-mat drying. J Food Meas Charact. 2023;17:3149–3161. https://doi.org/10.1007/s11694-023-01857-0

Zhao R, Gao T. Research Progress of Hot Air Drying Technology for Fruits and Vegetables. Adv J Food Sci Technol. 2016;10:160–6. https://doi.org/10.19026/ajfst.10.2045.

Dönmez A, Kadakal Ç. Hot-air drying and degradation kinetics of bioactive compounds of gilaburu (Viburnum opulus L.) fruit. Chem Ind Chem Eng Q. 2023;30:11–11. https://doi.org/10.2298/CICEQ220614011D

Tylewicz U, Nowacka M, Rybak K, Drozdzal K, Dalla Rosa M, Mozzon M. Design of Healthy Snack Based on Kiwifruit. Molecules. 2020;25:3309. https://doi.org/10.3390/molecules25143309.

Stojceska V, Atuonwu J, Tassou SA. Ohmic and conventional drying of citrus products: energy efficiency, greenhouse gas emissions and nutritional properties. Energy Procedia. 2019;161:165–73. https://doi.org/10.1016/j.egypro.2019.02.076.

Kittibunchakul S, Temviriyanukul P, Chaikham P, Kemsawasd V. Effects of freeze drying and convective hot-air drying on predominant bioactive compounds, antioxidant potential and safe consumption of maoberry fruits. LWT. 2023;184: 114992. https://doi.org/10.1016/j.lwt.2023.114992.

Rezaei R, Moghimi M. Optimization of combined drying (osmotic-hot air) of aloe vera slice using response surface methodology. J Food Sci Technol. 2024;20(144):1–24.

Velmurugan C, Sivakumar S, Bala A, Harish Kumar N, Prithviraj S. Experimental & Analytical Investigation on Modified Solar Dryer with Recirculation of Air. Int J Eng Res Technol. 2013;6:441–8.

Sonarthi H, Supreetha S, Mall S. Emerging Novel Technologies for Food Drying. In: Malik JA, Goyal MR, Kumari A, editors. Food Process Engineering and Technology. Singapore: Springer; 2023. p. 3–12.

Lammerskitten A, Wiktor A, Siemer C, Toepfl S, Mykhailyk V, Gondek E, Rybak K, Witrowa-Rajchert D, Parniakov O. The effects of pulsed electric fields on the quality parameters of freeze-dried apples. J Food Eng. 2019;252:36–43. https://doi.org/10.1016/j.jfoodeng.2019.02.006.

Różyło R. Recent trends in methods used to obtain natural food colorants by freeze-drying. Trends Food Sci Technol. 2020;102:39–50. https://doi.org/10.1016/j.tifs.2020.06.005.

Ozcelik M, Ambros S, Morais SIF, Kulozik U. Storage stability of dried raspberry foam as a snack product: Effect of foam structure and microwave-assisted freeze drying on the stability of plant bioactives and ascorbic acid. J Food Eng. 2020;270: 109779. https://doi.org/10.1016/j.jfoodeng.2019.109779.

Morais RMSC, Morais AMMB, Dammak I, Bonilla J, Sobral PJA, Laguerre J-C, Afonso MJ, Ramalhosa ECD. Functional Dehydrated Foods for Health Preservation. J Food Qual. 2018;2018:1–29. https://doi.org/10.1155/2018/1739636.

Kowalska H, Marzec A, Kowalska J, Trych U, Masiarz E, Lenart A. The use of a hybrid drying method with pre-osmotic treatment in strawberry bio-snack technology. Int J Food Eng. 2020;16. https://doi.org/10.1515/ijfe-2018-0318

Maftoonazad N, Dehghani MR, Ramaswamy HS. Hybrid microwave-hot air tunnel drying of onion slices: Drying kinetics, energy efficiency, product rehydration, color, and flavor characteristics. Dry Technol. 2022;40:966–86. https://doi.org/10.1080/07373937.2020.1841790.

Delfiya DSA, Prashob K, Murali S, Alfiya PV, Samuel MP, Pandiselvam R. Drying kinetics of food materials in infrared radiation drying: A review. J Food Process Eng. 2022;45:1–19. https://doi.org/10.1111/jfpe.13810.

Sakare P, Prasad N, Thombare N, Singh R, Sharma SC. Infrared Drying of Food Materials: Recent Advances. Food Eng Rev. 2020;12:381–98. https://doi.org/10.1007/s12393-020-09237-w.

Riadh MH, Ahmad SAB, Marhaban MH, Soh AC. Infrared Heating in Food Drying: An Overview. Dry Technol. 2015;33:322–35. https://doi.org/10.1080/07373937.2014.951124.

Jha P, Meghwal M, Prabhakar PK. Microwave drying of banana blossoms ( Musa acuminata ): Mathematical modeling and drying energetics. J Food Process Preserv. 2021;45:1–14. https://doi.org/10.1111/jfpp.15717.

Wray D, Ramaswamy HS. Novel Concepts in Microwave Drying of Foods. Dry Technol. 2015;33:769–83. https://doi.org/10.1080/07373937.2014.985793.

İlter I, Akyıl S, Devseren E, Okut D, Koç M, Kaymak EF. Microwave and hot air drying of garlic puree: drying kinetics and quality characteristics. Heat Mass Transf. 2018;54:2101–12. https://doi.org/10.1007/s00231-018-2294-6.

An N, Li D, Wang L, Wang Y. Factors affecting energy efficiency of microwave drying of foods: an updated understanding. Crit Rev Food Sci Nutr. 2022;1–16. https://doi.org/10.1080/10408398.2022.2124947

Radoiu M. Microwave drying process scale-up. Chem Eng Process - Process Intensif. 2020;155: 108088. https://doi.org/10.1016/j.cep.2020.108088.

Chua KJ, Chou SK. Recent Advances in Hybrid Drying Technologies. In: Sun D-W, editor. Emerging Technologies for Food Processing. Academic Press; 2014. p. 447–59.

González-Cavieres L, Pérez-Won M, Tabilo-Munizaga G, Jara-Quijada E, Díaz-Álvarez R, Lemus-Mondaca R. Advances in vacuum microwave drying (VMD) systems for food products. Trends Food Sci Technol. 2021;116:626–38. https://doi.org/10.1016/j.tifs.2021.08.005.

Richter RF. Studies on Conventional Vacuum Drying of Foods. In: Richter Reis F, editor. Vacuum Drying for Extending Food Shelf-Life. Cham: Springer; 2014. p. 7–18.

Orrego CE, Salgado N, Sarmiento LF. Freeze drying and vacuum drying. In: Jafari SM, Malekjani N, editors. Drying Technology in Food Processing. Woodhead Publishing; 2023. p. 203–40.

•• Shimpy, Kumar M, Kumar A. Designs, Performance and Economic Feasibility of Domestic Solar Dryers. Food Eng Rev. 2023;15:156–86. https://doi.org/10.1007/s12393-022-09323-1. This article provides an overview of solar drying technologies tailored for small rural agricultural farms with a focus on domestic applications, addressing the significant issue (ca. 61%) of perishable item wastage at the household level; it reviews domestic solar dryers categorized as natural and forced convection modes, noting maximum attainable temperatures, thermal efficiency, and advantages, highlighting the potential to reduce conventional drying costs by 50% and improve returns by 30%.

Kamran M. Energy sources and technologies. In: Fundamentals of smart grid systems. Academic Press; 2023. pp. 23–69.

Srivastava A, Anand A, Shukla A, Sharma A. Solar applications for drying of agricultural and marine products. In: Gorjian S, Campana PE, editors. Solar Energy Advancements in Agriculture and Food Production Systems. Academic Press; 2022. p. 313–50.

Inyang U, Oboh I, Etuk B. Drying and the different techniques. Int J Food Nutr Saf. 2017;8:45–72.

Acar C, Dincer I, Mujumdar A. A comprehensive review of recent advances in renewable-based drying technologies for a sustainable future. Dry Technol. 2022;40:1029–50. https://doi.org/10.1080/07373937.2020.1848858.

Qu H, Masud MH, Islam M, Khan MIH, Ananno AA, Karim A. Sustainable food drying technologies based on renewable energy sources. Crit Rev Food Sci Nutr. 2022;62:6872–86. https://doi.org/10.1080/10408398.2021.1907529.

Fox-Food processing in a box. 2023. Available on https://www.fox-foodprocessinginabox.eu/. Accessed 25 Jan 2024.

CEDRUS Sp. K. Paweł Jarzębowski. https://www.cedrus.org.pl/en/. Accessed 25 Jan 2024.

Genskow LR. Dryer scale-up methodology for the process industries. Dry Technol. 1994;12:47–58. https://doi.org/10.1080/07373939408959949.

Majdi H, Esfahani JA, Mohebbi M. Optimization of convective drying by response surface methodology. Comput Electron Agric. 2019;156:574–84. https://doi.org/10.1016/j.compag.2018.12.021.

Soltani A, Azzouz S, Romdhana H, Goujot D, Elcafsi MA. Multi-response optimization of drying process parameters for Laurus Nobilis. J Appl Res Med Aromat Plants. 2021;22:100302. https://doi.org/10.1016/j.jarmap.2021.100302.

Akter F, Akther S, Sultana A, Rahman MM, Deb UK. Optimization of Drying Parameters for Total Phenolic Content of Papaya Using Response Surface Methodology. Int J Food Sci. 2022;2022:1–15. https://doi.org/10.1155/2022/4819725.

Taghinezhad E, Kaveh M, Szumny A. Optimization and Prediction of the Drying and Quality of Turnip Slices by Convective-Infrared Dryer under Various Pretreatments by RSM and ANFIS Methods. Foods. 2021;10:284. https://doi.org/10.3390/foods10020284.

Machado JCB, Ferreira MRA, Soares LAL. Optimization of the drying process of standardized extracts from leaves of Spondias mombin L using Box-Behnken design and response surface methodology. J Food Process Preserv. 2021;45:1–17. https://doi.org/10.1111/jfpp.15595.

Funding

This project has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement No 817683 (acronym FOX).

Author information

Authors and Affiliations

Contributions

M.N., A.M. and D.W-R. wrote the main manuscript text, A.M. prepared the Table 1 and M.N. prepared Figure 1. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Human and Animal Rights and Informed Consent

This article does not include any experiments with human or animal subjects done by the authors.

Competing Interests

The authors declare no competing interests.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nowacka, M., Matys, A. & Witrowa-Rajchert, D. Innovative Technologies for Improving the Sustainability of the Food Drying Industry. Curr Food Sci Tech Rep 2, 231–239 (2024). https://doi.org/10.1007/s43555-024-00026-8

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43555-024-00026-8