Abstract

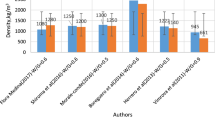

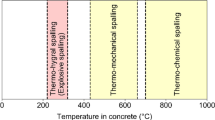

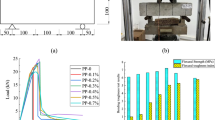

The adoption of natural fiber reinforced polymer (FRP) composites as an eco-friendly substitute for synthetic FRPs in structural strengthening applications is gaining substantial momentum. This study delves into the effectiveness of jute fabric reinforced epoxy composites in bolstering the flexural strength of impaired concrete beams. An array of variables, encompassing the number of fabric layers (ranging from 1 to 3), fiber heat treatment, externally bonded reinforcement (EBR) configuration (soffit vs. U-shape), and fiber type (jute vs. glass), underwent systematic scrutiny. The comprehensive analysis of 30 pre-cracked high-performance concrete beams yielded compelling findings. In particular, the application of heat-treated jute EBR, especially when employing two or three layers, resulted in significant increases in peak loads, translating to improvements ranging from 85 to 120% when compared to the control beam. This treatment significantly improves the bond between the fibers and the matrix, consequently enhancing the structural performance. Notably, jute composites can attain equivalent strengthening performance compared to glass FRP while offering substantial cost savings and significantly reducing carbon emissions, rendering them a more environmentally sustainable and economically viable choice.

Graphical Abstract

Similar content being viewed by others

Data availability

The data underpinning this research is accessible upon reasonable request from the corresponding author.

References

Shakir Abbood I, Aldeen Odaa Hasan Jasim SKFMA. Properties evaluation of fiber reinforced polymers and their constituent materials used in structures—a review. Mater Today Proc. 2021;43:1003–8. https://doi.org/10.1016/j.matpr.2020.07.636.

Nwankwo CO, Mahachi J, Olukanni DO, Musonda I. Natural fibres and biopolymers in FRP composites for strengthening concrete structures: a mixed review. Constr Build Mater. 2023;363:129661. https://doi.org/10.1016/j.conbuildmat.2022.129661.

Shah DU, Schubel PJ, Licence P, Clifford MJ. Hydroxyethylcellulose surface treatment of natural fibres: the new ‘twist’ in yarn preparation and optimization for composites applicability. J Mater Sci. 2012;47(6):2700–11. https://doi.org/10.1007/s10853-011-6096-1.

Das S, La Rosa A, Goutianos S, Grammatikos S. Flax fibers, their composites and application. 2022;209–32. https://doi.org/10.1016/B978-0-12-824528-6.00017-5.

Mahir FI, Keya KN, Sarker B, Nahiun KM, Khan RA. A brief review on natural fiber used as a replacement of synthetic fiber in polymer composites. Mater Eng Res. 2019;1(2):86–97. https://doi.org/10.25082/MER.2019.02.007.

Navaratnam S, Selvaranjan K, Jayasooriya D, Rajeev P, Sanjayan J. Applications of natural and synthetic fiber reinforced polymer in infrastructure: a suitability assessment. J Build Eng. 2023;66:105835. https://doi.org/10.1016/j.jobe.2023.105835.

Chlela R, Bigaud D, Riahi H, Quiertant M, Curtil L, Benzarti K. Durability and lifetime prediction of flax fiber reinforced polymer composites. In: Ilki A, Ispir M, Inci P, editors. 10th international conference on FRP composites in civil engineering. Lecture notes in civil engineering, vol. 198. Cham: Springer International Publishing; 2022. p. 695–705. https://doi.org/10.1007/978-3-030-88166-5_60.

Duc F, Bourban PE, Plummer CJG, Månson JAE. Damping of thermoset and thermoplastic flax fibre composites. Compos Part Appl Sci Manuf. 2014;64:115–23. https://doi.org/10.1016/j.compositesa.2014.04.016.

Ben Ameur M, El Mahi A, Rebiere JL, Beyaoui M, Abdennadher M, Haddar M. Bending fatigue behavior of flax and carbon fiber reinforced epoxy resin. In: Aifaoui N, Affi Z, Abbes MS, Walha L, Haddar M, Romdhane L, Benamara A, Chouchane M, Chaari F, editors. Design and modeling of mechanical systems-IV. Lecture notes in mechanical engineering. Cham: Springer International Publishing; 2020. p. 567–75. https://doi.org/10.1007/978-3-030-27146-6_61.

Di Luccio G, Michel L, Ferrier E, Martinelli E. Seismic retrofitting of RC walls externally strengthened by flax–FRP strips. Compos Part B Eng. 2017;127:133–49. https://doi.org/10.1016/j.compositesb.2017.06.017.

Wang W, Mo Z, Zhang Y, Chouw N. Dynamic splitting tensile behaviour of concrete confined by natural flax and glass FRP. Polymers. 2022;14(20):4424. https://doi.org/10.3390/polym14204424.

Wang W, Zhang X, Mo Z, Chouw N, Li Z, Xu Z-D. A comparative study of impact behaviour between natural flax and glass FRP confined concrete composites. Constr Build Mater. 2020;241:117997. https://doi.org/10.1016/j.conbuildmat.2020.117997.

Ferrier E, Michel L, Ngo MD. Experimental study on the shear behavior of RC beams reinforced by natural composite materials (flax fibers). Structures. 2021;33:637–54. https://doi.org/10.1016/j.istruc.2021.03.027.

Yooprasertchai E, Wiwatrojanagul P, Pimanmas A. A use of natural sisal and jute fiber composites for seismic retrofitting of nonductile rectangular reinforced concrete columns. J Build Eng. 2022;52:104521. https://doi.org/10.1016/j.jobe.2022.104521.

Chen C, et al. Eco-friendly and mechanically reliable alternative to synthetic FRP in externally bonded strengthening of RC beams: natural FRP. Compos Struct. 2020;241:112081. https://doi.org/10.1016/j.compstruct.2020.112081.

Abdulla A, Thaker R, Khazaal A. Toughness of timber beams strengthened with jute fibers. Tikrit J Eng Sci. 2020;27:94–112. https://doi.org/10.25130/tjes.27.3.11.

Lu T, Jiang M, Jiang Z, Hui D, Wang Z, Zhou Z. Effect of surface modification of bamboo cellulose fibers on mechanical properties of cellulose/epoxy composites. Compos Part B Eng. 2013;51:28–34. https://doi.org/10.1016/j.compositesb.2013.02.031.

Langhorst A, Ravandi M, Mielewski D, Banu M. Technical agave fiber tensile performance: the effects of fiber heat-treatment. Ind Crops Prod. 2021;171:113832. https://doi.org/10.1016/j.indcrop.2021.113832.

Neto JSS, Lima RAA, Cavalcanti DKK, Souza JPB, Aguiar RAA, Banea MD. Effect of chemical treatment on the thermal properties of hybrid natural fiber-reinforced composites. J Appl Polym Sci. 2019;136(10):47154. https://doi.org/10.1002/app.47154.

Bamboo heat treatments and their effects on bamboo properties. Constr Build Mater. 2022; 331: 127320. https://doi.org/10.1016/j.conbuildmat.2022.127320.

Cao Y, Chan F, Chui Y-H, Xiao H. Characterization of flax fibres modified by alkaline, enzyme, and steam-heat treatments. BioRes. 2012;7:4109–21.

Chang BP, Chan WH, Zamri MH, Md Akil H, Chuah HG. Investigating the effects of operational factors on wear properties of heat-treated pultruded Kenaf fiber-reinforced polyester composites using Taguchi method. J Nat Fibers. 2019;16(5):702–17. https://doi.org/10.1080/15440478.2018.1432001.

Mishra S, Parashar V. Experimental analysis of duo-fiber interaction on the tensile strength of surface-modified flax–kenaf-reinforced epoxy composite. Polym Bull. 2023;80:13159–79. https://doi.org/10.1007/s00289-023-04708-6.

Azadeh A, Ghavami K, García JJ. The influence of heat on mechanical properties of Dendrocalamus giganteus bamboo. J Build Eng. 2021;43:102613. https://doi.org/10.1016/j.jobe.2021.102613.

Cui J, et al. Effects of thermal treatment on the mechanical properties of bamboo fiber bundles. Materials. 2023;16(3):1239. https://doi.org/10.3390/ma16031239.

Voravutvityaruk T, Jirawattanasomkul T, Ueda T, Wuttiwannasak N, Poonsawat T. Behavior of concrete confined by jute natural fiber reinforced polymer with heat treatment. 2017.

Jirawattanasomkul T, Likitlersuang S, Wuttiwannasak N, Ueda T, Zhang D, Voravutvityaruk T. Effects of heat treatment on mechanical properties of jute fiber-reinforced polymer composites for concrete confinement. J Mater Civ Eng. 2020;32:04020363. https://doi.org/10.1061/(ASCE)MT.1943-5533.0003456.

Campana C, Leger R, Sonnier R, Ferry L, Ienny P. Effect of post curing temperature on mechanical properties of a flax fiber reinforced epoxy composite. Compos Part Appl Sci Manuf. 2018;107:171–9. https://doi.org/10.1016/j.compositesa.2017.12.029.

Carus M, de Beus N, Barth M. Carbon footprint and sustainability of different natural fibres for biocomposites and insulation material. Comprehensively. [En ligne]. 2019. Disponible sur: https://growinghempassociation.org/wp-content/uploads/2022/11/19-08-06-Study-Natural-Fibre-Sustainability-Carbon-Footprint-1.pdf

Kolesov YuI, Kudryavtsev MYu, Mikhailenko NYu. Types and compositions of glass for production of continuous glass fiber (review). Glass Ceram. 2001;58(5):197–202. https://doi.org/10.1023/A:1012386814248.

Yoo D-Y, Banthia N. Size-dependent impact resistance of ultra-high-performance fiber-reinforced concrete beams. Constr Build Mater. 2017;142:363–75. https://doi.org/10.1016/j.conbuildmat.2017.03.080.

Zhang Z, Shakoorioskooie M, Griffa M, Lura P, Angst U. A laboratory investigation of cutting damage to the steel-concrete interface. Cem Concr Res. 2020;138:106229. https://doi.org/10.1016/j.cemconres.2020.106229.

Sen T, Paul A. Confining concrete with sisal and jute FRP as alternatives for CFRP and GFRP. Int J Sustain Built Environ. 2015;4(2):248–64. https://doi.org/10.1016/j.ijsbe.2015.04.001.

Sreekumar PA, Thomas SP, Marc Saiter Joseph Unnikrishnan Thomas JKGS. Effect of fiber surface modification on the mechanical and water absorption characteristics of sisal/polyester composites fabricated by resin transfer molding. Compos Part Appl Sci Manuf. 2009;40(11):1777–84. https://doi.org/10.1016/j.compositesa.2009.08.013.

ASTM D 3039: Standard test method for tensile properties of polymer matrix composite materials.

Chen C, et al. Effect of transverse groove on bond behavior of FRP-concrete interface: experimental study, image analysis and design. Compos Part B Eng. 2019;161:205–19. https://doi.org/10.1016/j.compositesb.2018.10.072.

Lorenzis LD, Miller B, Nanni A. Bond of FRP laminates to concrete. ACI Mater J. 2001;98(3):256–64.

ASTM C78/C78M-18. Standard test method for flexural strength of concrete (using simple beam with third-point loading). West Conshohocken, USA: ASTM International; 2018. p. 1–5.

Salih YA, Sabeeh NN, Yass MF, Ahmed AS, Khudhurr ES. Concrete beams strengthened with jute fibers. Civ Eng J. 2019;5(4):767–76. https://doi.org/10.28991/cej-2019-03091286.

Sen T, Reddy HNJ. Pretreatment of woven jute FRP composite and its use in strengthening of reinforced concrete beams in flexure. Adv Mater Sci Eng. 2013;2013:e128158. https://doi.org/10.1155/2013/128158.

Attari N, Amziane S, Chemrouk M. Flexural strengthening of concrete beams using CFRP, GFRP and hybrid FRP sheets. Constr Build Mater. 2012;37:746–57. https://doi.org/10.1016/j.conbuildmat.2012.07.052.

Chen W, Pham TM, Sichembe H, Chen L, Hao H. Experimental study of flexural behaviour of RC beams strengthened by longitudinal and U-shaped basalt FRP sheet. Compos Part B Eng. 2018;134:114–26. https://doi.org/10.1016/j.compositesb.2017.09.053.

Yuvaraj S, Chithra K, Nirmalkumar K, Jeyanth B. Performance evaluation of hybrid fibers strengthened reinforced concrete. Today Proc Mater. 2023. https://doi.org/10.1016/j.matpr.2023.03.667.

Hong K-N, Cho C-G, Lee S-H, Park Y. Flexural behavior of RC members using externally bonded aluminum-glass fiber composite beams. Polymers. 2014;6:667–85. https://doi.org/10.3390/polym6030667.

Smith ST, Teng JG. FRP-strengthened RC beams. II: assessment of debonding strength models. Eng Struct. 2002;24:397–417. https://doi.org/10.1016/S0141-0296(01)00106-7.

Amirhafizan MH, Yuhazri MY, Umarfaruq HM, Lau STW, Kamarul AM, Zulfikar AJ. Laminated jute and glass fibre reinforced composite for repairing concrete through wrapping technique. Int J Integr Eng. 2023;15:2023.

Wilhem G. Clasen (2023) Rapport du Marché de Jute pour janvier 2023. Natural fiber worldwid. [En ligne]. Disponible sur: https://www.wgc.de/media/pages/produkte/jute/b5792261d3-1675415945/fr_jute-marketreport_01.2023.pdf

Glass fiber price in the United States-2023-charts and tables-indexbox. Consulté le: 6 Oct, 2023. [En ligne]. Disponible sur: https://www.indexbox.io/search/glass-fiber-price-the-united-states/

Acknowledgements

The authors would like to express their gratitude to the Civil Engineering Laboratory at the University of Bordj Bou Arreridj for facilitating the experimental work in this study, as well as to the 'Microscopies and Analyse’s imaging center, I-Mat Federation (FR4122) at CY Cergy Paris University (France) for conducting the SEM analyses.

Funding

This study did not receive any external financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author affirms the absence of any conflicts of interest.

Ethical approval

This article does not involve experiments with human participants or animals conducted by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Benaddache, L., Belkadi, A.A., Kessal, O. et al. Comparative study on externally bonded heat-treated jute and glass fiber reinforcement for repair of pre-cracked high performance concrete beams. Archiv.Civ.Mech.Eng 24, 82 (2024). https://doi.org/10.1007/s43452-024-00899-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-024-00899-5