Abstract

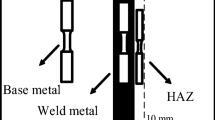

A fracture model has been established for simultaneously determining the strength and fracture parameters of materials without size effect using double symmetrical edges notched specimens of metal. The specific method is presented for determining yield strength and fracture toughness using experimental yield loads of the small specimens in laboratory. The formula of nominal stress of double symmetrical edges notched specimen under uniaxial tension considering plastic zone is derived. The influence of different plastic zones size on calculating the fracture and strength parameters has been analyzed. The complete fracture failure curves of the metal material are obtained. The theoretical minimum size of metal specimen satisfying the conditions of linear elastic fracture mechanics is given. The normal method is used to analyze the dispersion of small-size double symmetrical edges notched specimens of hot-rolled carbon steel to predict the fracture properties of large-size specimens. A novel approach has been provided for the rational determination of realistic material parameters and the prediction of load carrying capacity of large-size structures by experimental fracture tests for small-size specimens.

Similar content being viewed by others

Data availability

All data included in this study are available upon request by contact with the corresponding author.

Abbreviations

- a 0 :

-

Initial crack length for notched specimen

- a e :

-

Equivalent crack length

- \(a_{\infty }^{*}\) :

-

Characteristic crack

- B :

-

Thickness of specimen

- K C :

-

Plane stress fracture toughness

- K C,0 :

-

Plane stress fracture toughness obtained by regression fitting when Δap = 0

- K IC :

-

Plane strain fracture toughness

- P :

-

External load of specimen

- P Y :

-

Yield loads of specimen

- W :

-

Width of specimen

- Y(α):

-

Geometric parameter

- α :

-

Ratio of initial notch length to width

- Δa p :

-

Size of metal plastic zone of specimen

- \(\Delta a_{P - 1}^{{{\text{Irwin}}}}\) :

-

First-order estimate of the size of plastic zone in the Irwin model

- \(\Delta a_{P - 2}^{{{\text{Irwin}}}}\) :

-

Second-order estimate of the size of plastic zone in the Irwin model

- σ n :

-

Nominal stress at the crack plane of specimen with a finite size

- σ Y :

-

Yield strength

- σ Y ,0 :

-

Yield strength obtained by regression fitting when Δap = 0

- σ e(x):

-

Nominal stress on the crack surface of specimen

References

Mindess S. The effect of specimen size on the fracture energy of concrete. Cem Concr Res. 1984;14(3):431–6. https://doi.org/10.1016/0008-8846(84)90062-0.

Nallthambi P, Karihaloo B, Heaton BS. Effect of specimen and crack sizes, water/cement ratio and coarse aggregate texture upon fracture toughness of concrete. Mag Concr Res. 1984;36(129):227–36. https://doi.org/10.1680/macr.1984.36.129.227.

Hillerborg A. Results of three comparative test series for determining the fracture energy GF of concrete. Mater Struct. 1985;18(5):407–13. https://doi.org/10.1007/BF02472416.

Alexander MG, Blight GE. A comparative study of fracture parameters in notched concrete beams. Mag Concr Res. 1988;40(142):50–8. https://doi.org/10.1680/macr.1988.40.142.50.

Guan JF, Li QB, Wu ZM, Zhao SB, Dong W, Zhou SW. Minimum specimen size for fracture parameters of site-casting dam concrete. Constr Build Mater. 2015;93:973–82. https://doi.org/10.1016/j.conbuildmat.2015.05.060.

Li QB, Guan JF, Wu ZM, Dong W, Zhou SW. Equivalent maturity for ambient temperature effect on fracture parameters of site-casting dam concrete. Constr Build Mater. 2016;120:293–308. https://doi.org/10.1016/j.conbuildmat.2016.05.111.

Guan JF, Li QB, Wu ZM, Zhao SB, Dong W, Zhou SW. Fracture parameters of site-cast dam and sieved concrete. Mag Concr Res. 2016;68(1):43–54. https://doi.org/10.1680/macr.15.00008.

Zhang T, Zhang JZ. Numerical estimate of critical failure surface of slope by ordinary state-based peridynamic plastic model. Eng Fail Anal. 2022. https://doi.org/10.1016/j.engfailanal.2022.106556.

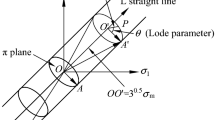

Zhang T, Zhou XP, Qian QH. Drucker–Prager plasticity model in the framework of OSB-PD theory with shear deformation. Eng with comput. 2021. https://doi.org/10.1007/s00366-021-01527-z.

ASTM E399–12e2. Standard test method for linear-elastic plane-strain fracture toughness testing of high strength metallic materials. ASTM International. 2013.

ASTM E399–19. Standard test method for linear-elastic plane-strain fracture toughness testing of high strength metallic materials. ASTM International. 2019.

BS EN ISO 12737:2010. Metallic materials—determination of plane-strain fracture toughness. London: British Standard. 2010.

GB/T 4161–2007. Metallic materials-determination of plane-strain fracture toughness. Standards Press of China, Beijing. 2008. (in Chinese)

GB/T 21143–2014. Metallic materials-unified method of test for determination of quasistatic fracture toughness. Standards Press of China, Beijing. 2014. (in Chinese)

DL/T 5332–2005. Norm for fracture test of hydraulic concrete. China Electric Power Press, Beijing 2006. (in Chinese)

SL 352–2020. Test code for hydraulic concrete. China Water & Power Press, Beijing 2020. (in Chinese)

ASTM C293/C293M-16. Standard test method for flexural strength of concrete (using simple beam with center-point loading)1. ASTM International. 2016.

ASTM C78/C78M-18. Standard test method for flexural strength of concrete (using simple beam with third-point loading)1. ASTM International. 2018.

Çağlar Y, Şener S. Size effect tests of different notch depth specimens with support rotation measurements. Eng Fract Mech. 2016;157:43–55. https://doi.org/10.1016/j.engfracmech.2016.02.028.

Bažant ZP, Oh BH. Crack band theory for fracture of concrete. Mater Struct. 1983;16(3):155–77. https://doi.org/10.1007/BF02486267.

Bažant ZP. Size effect in blunt fracture: concrete, rock, metal. J Eng Mech. 1984;110(4):518–35. https://doi.org/10.1061/(asce)0733-9399(1984)110:4(518.

Bažant ZP. Scaling of quasibrittle fracture: asymptotic analysis. Int J Fract. 1997;83(1):19–40. https://doi.org/10.1023/a:1007387823522.

Negi A, Kumar S. Localizing gradient damage model with smoothed stress based anisotropic nonlocal interactions. Eng Fract Mech. 2019;214:21–39. https://doi.org/10.1016/j.engfracmech.2019.04.011.

Negi A, Soni A, Kumar S. An anisotropic localizing gradient damage approach for failure analysis of fiber reinforced composites. Compos Struct. 2022;294:115677. https://doi.org/10.1016/j.compstruct.2022.115677.

Negi A, Kumar S. A continuous-discontinuous localizing gradient damage framework for failure analysis of quasi-brittle materials. Comput Meth Appl Mech Eng. 2022;390:114434. https://doi.org/10.1016/j.cma.2021.114434.

Hu XZ, Duan K. Size effect: influence of proximity of fracture process zone to specimen boundary. Eng Fract Mech. 2007;74(7):1093–100. https://doi.org/10.1016/j.engfracmech.2006.12.009.

Hu XZ, Duan K. Size effect and quasi-brittle fracture: the role of FPZ. Int J Fract. 2008;154(1–2):3–14. https://doi.org/10.1007/s10704-008-9290-7.

Hu XZ, Wittmann F. Size effect on toughness induced by crack close to free surface. Eng Fract Mech. 2000;65(2–3):209–21. https://doi.org/10.1016/s0013-7944(99)00123-x.

Hu XZ, Duan K. Mechanism behind the size effect phenomenon. J Eng Mech ASCE. 2010;136(1):60–8. https://doi.org/10.1061/(asce)em.1943-7889.0000070.

Guan JF, Hu XZ, Yao XH, Wang Q, Li QB, Wu ZM. Fracture of 0.1 and 2 m long mortar beams under three-point-bending. Mater Des. 2017;133:363–75. https://doi.org/10.1016/j.matdes.2017.08.005.

Guan JF, Hu XZ, Li QB. In-depth analysis of notched 3-p-b concrete fracture. Eng Fract Mech. 2016;165:57–71. https://doi.org/10.1016/j.engfracmech.2016.08.020.

Guan JF, Hu XZ, Xie CP, Li QB, Wu ZM. Wedge-splitting tests for tensile strength and fracture toughness of concrete. Theor Appl Fract Mech. 2018;93:263–75. https://doi.org/10.1016/j.tafmec.2017.09.006.

Guan JF, Li CM, Wang J, Qing LB, Song ZK, Liu ZP. Determination of fracture parameter and prediction of structural fracture using various concrete specimen types. Theor Appl Fract Mech. 2019;100:114–27. https://doi.org/10.1016/j.tafmec.2019.01.008.

Guan JF, Yuan P, Hu XZ, Qing LB, Yao XH. Statistical analysis of concrete fracture using normal distribution pertinent to maximum aggregate size. Theor Appl Fract Mech. 2019;101:236–53. https://doi.org/10.1016/j.tafmec.2019.03.004.

Guan JF, Xie CP, Hu XZ, Yao XH, Bai WF. Determination of fracture toughness and yield strength of hot rolled carbon steel based on boundary effect theory. Eng Mech. 2019;36(3):231–9. (in Chinese) http://engineeringmechanics.cn/article/doi/10.6052/j.issn.1000-4750.2017.07.0988.

Yao XH, Li LL, Guan JF, Zhang M, Liu ZP, Han RC, He SH (2021) Initial cracking strength and initial fracture toughness from 3-p-b and WS concrete specimens. Fatigue Fract Eng Mater Struct 44(3):601–21. https://doi.org/10.22541/au.159446175.57577238

Qing L, Cheng Y, Mu R. Toughness enhancement and equivalent initial fracture toughness of cementitious composite reinforced with aligned steel fibres. Fatigue Fract Eng Mater Struct. 2019;42(11):2533–43. https://doi.org/10.1111/ffe.13102.

Tada H, Paris PC, Irwin GR. The stress analysis of cracks handbook. 3rded. ASME Press, New York 2000. https://doi.org/10.1115/1.801535.

Jia YJ, Shi MX, Zhao Y, Liu B. A better estimation of plastic zone size at the crack tip beyond Irwin’s model. J Appl Mech. 2013;80(5):051014. https://doi.org/10.1115/1.4023642.

Irwin GR. Linear fracture mechanics, fracture transition, and fracture control. Eng Fract Mech. 1968;1(2):241–57. https://doi.org/10.1016/0013-7944(68)90001-5.

Hui F, Lam YC, Zhou K, Kumar SB, Wu WJ. Elastic-plastic behavior analysis of an arbitrarily oriented crack near an elliptical inhomogeneity with generalized Irwin correction. Eur J Mech A Solids. 2017;67:177–86. https://doi.org/10.1016/j.euromechsol.2017.10.001.

Anyang Iron & Steel Co., Ltd. Accessed April 19, 1999. http://www.aysteel.com.cn.

Acknowledgements

This research was supported by National Natural Science Foundation of China (No. 52179132); Program for Science & Technology Innovation Talents in Universities of Henan Province (No. 20HASTIT013); Scientific and Technological Research Projects of Henan Province (No. 212102210452, 212102310934); Sichuan University, State Key Laboratory of Hydraulics & Mountain River Engineering (No. SKHL2007); Fund of Innovative Education Program for Graduate Students at North China University of Water Resources and Electric Power, China) (No. YK2020-13).

Author information

Authors and Affiliations

Contributions

RH: conceptualization, supervision, writing—review and editing, funding acquisition; WM: data curation, writing—original draft, formal analysis, visualization, writing—review and editing, funding acquisition; JG: conceptualization, supervision, funding acquisition; YH: conceptualization, supervision, writing—review and editing, funding acquisition; XY: supervision, writing—review and editing; LL: supervision, writing—review and editing; SH: supervision, writing—review and editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest to this work.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Han, R., Meng, W., Guan, J. et al. A novel model for determining the strength and fracture parameters of Q235 steel using double symmetrical edges notched specimens. Archiv.Civ.Mech.Eng 23, 75 (2023). https://doi.org/10.1007/s43452-023-00611-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-023-00611-z