Abstract

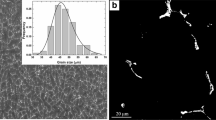

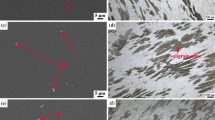

This study mainly focuses on the newly developed (Al, Zn)3Zr precipitates through double aging treatment in an Al–Zn–Mg–Cu alloy (Al alloy) and their response to dynamic compression. The results show that the strength of the Al alloy after aging treatment (393 K for 8 h + 433 K for 10 h) is increased with an increasing strain rate from 1.0 × 10−3 to 3.0 × 103 s−1 assisted by the strain hardening rate effect. The microstructures of Al alloy after the double aging treatment and dynamic compression at \(\sim\) 3.0 × 103 s−1 contain novel (Al, Zn)3Zr precipitate with LI2 ordered and tetragonal structures. The small inter-particle spacing of precipitates after double aging, solute diffusion during the aging treatment, and dynamic compression lead to the overlapping of the different precipitates. For instance, the overlapping of (Al, Zn)3Zr and θ′ precipitates is observed. The overlapped (Al, Zn)3Zr contains Cu solutes, while the θ′ precipitate contains Zr solutes assisted by solute diffusion through dislocations and the increase in temperature during the compression. Besides, the number and size of the platelet precipitates are also increased after the dynamic compression compared to the double aging treatment Al alloy. In this research, the newly observed (Al, Zn)3Zr precipitate after double aging treatment, and post-high strain rate compression is suitable for successfully tailoring the precipitation of Al–Zn–Mg–Cu alloy and achieving optimum properties in the near future.

Graphical abstract

Similar content being viewed by others

Data availability

Data will be made available on request.

Change history

08 December 2022

A Correction to this paper has been published: https://doi.org/10.1007/s43452-022-00583-6

References

Khan M, Wang Y, Malik A, Nazeer F, Yasin G, Khan W, Ahmad T, Zhang H. Microstructure characterization of 7055-T6, 6061-T6511 and 7A52-T6 Al alloys subjected to ballistic impact against heavy tungsten alloy projectile. Arch Civ Mech Eng. 2019;19(4):1484–96.

Berg L, Gjønnes J, Hansen V, Li X, Knutson-Wedel M, Schryvers D, Wallenberg L. GP-zones in Al–Zn–Mg alloys and their role in artificial aging. Acta Mater. 2001;49(17):3443–51.

Morere B, Shahani R, Maurice C, Driver J. The influence of Al3Zr dispersoids on the recrystallization of hot-deformed AA 7010 alloys. Metall Mater Trans A. 2001;32(3):625–32.

Hansen V, Gjønnes J, Skjervold S. Effect of predeformation and preaging at room temperature in Al–Zn–Mg–(Cu, Zr) alloys. Mater Sci Eng, A. 2001;303(1–2):226–33.

Robson J. A new model for prediction of dispersoid precipitation in aluminium alloys containing zirconium and scandium. Acta Mater. 2004;52(6):1409–21.

Deschamps A, Bréchet Y. Influence of quench and heating rates on the ageing response of an Al–Zn–Mg–(Zr) alloy. Mater Sci Eng, A. 1998;251(1–2):200–7.

Robson J, Prangnell P. Dispersoid precipitation and process modelling in zirconium containing commercial aluminium alloys. Acta Mater. 2001;49(4):599–613.

Zhao H, Chen Y, Gault B, Makineni SK, Ponge D, Raabe D. (Al, Zn) 3Zr dispersoids assisted η′ precipitation in an Al–Zn–Mg–Cu–Zr alloy. Materialia. 2020;10: 100641.

Afifi MA, Wang YC, Langdon TG. Effect of dynamic plastic deformation on the microstructure and mechanical properties of an Al–Zn–Mg alloy. Mater Sci Eng, A. 2020;784: 139287.

Varas D, López-Puente J, Zaera R. Experimental analysis of fluid-filled aluminium tubes subjected to high-velocity impact. Int J Impact Eng. 2009;36(1):81–91.

Mirihanage W, Robson J, Mishra S, Hidalgo-Manrique P, Da Fonseca JQ, Daniel C, Prangnell P, Michalik S, Magdysyuk O, Connolley T. Direct observation of the dynamic evolution of precipitates in aluminium alloy 7021 at high strain rates via high energy synchrotron X-rays. Acta Mater. 2021;205: 116532.

Khan MA, Wang Y, Yasin G, Nazeer F, Malik A, Ahmad T, Khan WQ, Nguyen TA, Zhang H, Afifi MA. Adiabatic shear band localization in an Al–Zn–Mg–Cu alloy under high strain rate compression. J Market Res. 2020;9(3):3977–83.

Bobel A, Kim K, Wolverton C, Walker M, Olson GB. Equilibrium composition variation of Q-phase precipitates in aluminum alloys. Acta Mater. 2017;138:150–60.

Marlaud T, Deschamps A, Bley F, Lefebvre W, Baroux B. Influence of alloy composition and heat treatment on precipitate composition in Al–Zn–Mg–Cu alloys. Acta Mater. 2010;58(1):248–60.

Khan MA, Wang Y, Afifi MA, Malik A, Nazeer F, Yasin G, Jiawei B, Zhang H. Microstructure and mechanical properties of an Al–Zn–Cu–Mg alloy processed by hot forming processes followed by heat treatments. Mater Charact. 2019;157: 109901.

Khan MA, Wang Y, Hamza M, Yasin G, Tabish M, Feng C, Khan WQ, Ahmad T, Liao W-B, Afifi MA. Precipitation behaviour in an Al–Zn–Mg–Cu alloy subjected to high strain rate compression tests. Mater Charact. 2021;180: 111398.

Khan MA, Wang Y, Yasin G, Nazeer F, Malik A, Khan WQ, Ahmad T, Zhang H, Afifi MA. The effect of strain rates on the microstructure and the mechanical properties of an over-aged Al–Zn–Mg–Cu alloy. Mater Charact. 2020;167: 110472.

Afifi MA, Wang YC, Cheng X, Li S, Langdon TG. Strain rate dependence of compressive behavior in an Al–Zn–Mg alloy processed by ECAP. J Alloy Compd. 2019;791:1079–87.

Wu X, Li L, Liu W, Li S, Zhang L, He H. Development of adiabatic shearing bands in 7003-T4 aluminum alloy under high strain rate impacting. Mater Sci Eng, A. 2018;732:91–8.

Pereira PHR, Wang YC, Huang Y, Langdon TG. Influence of grain size on the flow properties of an Al–Mg–Sc alloy over seven orders of magnitude of strain rate. Mater Sci Eng, A. 2017;685:367–76.

Kverneland A, Hansen V, Vincent R, Gjønnes K, Gjønnes J. Structure analysis of embedded nano-sized particles by precession electron diffraction. η′-precipitate in an Al–Zn–Mg alloy as example. Ultramicroscopy. 2006;106(6):492–502.

Khan MA, Wang Y, Cheng H, Yasin G, Malik A, Nazeer F, Ahmad T, Kamran M, Afifi MA. Microstructure evolution of an artificially aged Al–Zn–Mg–Cu alloy subjected to soft-and hard-steel core projectiles. J Market Res. 2020;9(5):11980–92.

Wang S, Starink M. Precipitates and intermetallic phases in precipitation hardening Al–Cu–Mg–(Li) based alloys. Int Mater Rev. 2005;50(4):193–215.

Cassell A, Robson J, Race C, Eggeman A, Hashimoto T, Besel M. Dispersoid composition in zirconium containing Al–Zn–Mg–Cu (AA7010) aluminium alloy. Acta Mater. 2019;169:135–46.

Robson J, Prangnell P. Modelling Al3Zr dispersoid precipitation in multicomponent aluminium alloys. Mater Sci Eng, A. 2003;352(1–2):240–50.

Nie JF, Muddle BC. Strengthening of an Al–Cu–Sn alloy by deformation-resistant precipitate plates. Acta Mater. 2008;56(14):3490–501.

Adlakha I, Garg P, Solanki K. Revealing the atomistic nature of dislocation-precipitate interactions in Al–Cu alloys. J Alloy Compd. 2019;797:325–33.

Byrne J, Fine M-E, Kelly A. Precipitate hardening in an aluminium-copper alloy. Phil Mag. 1961;6(69):1119–45.

Pandey S, Gangopadhyay D, Suryanarayana C. Metastable phases in vapour-deposited Al–Zr thin films. Thin Solid Films. 1987;146(3):273–82.

Wilson C, Sams D. The crystal structure of Zr2Al. Acta Crystallogr A. 1961;14(1):71–2.

Wang F, Gong Y, Du Y, Song M. Microstructures and mechanical properties of an Al–Zn–Mg–Cu alloy processed by two-step aging treatment. J Mater Eng Perform. 2020;29(7):4404–11.

Afifi MA, Wang YC, Pereira PHR, Huang Y, Wang Y, Cheng X, Li S, Langdon TG. Mechanical properties of an Al–Zn–Mg alloy processed by ECAP and heat treatments. J Alloy Compd. 2018;769:631–9.

Sha G, Cerezo A. Early-stage precipitation in Al–Zn–Mg–Cu alloy (7050). Acta Mater. 2004;52(15):4503–16.

Hull D, Bacon DJ. Introduction to dislocations. Elsevier; 2011.

Gibbs JW. The collected works of J. Willard Gibbs. Yale Univ. Press; 1948.

Blavette D, Cadel E, Fraczkiewicz A, Menand A. Three-dimensional atomic-scale imaging of impurity segregation to line defects. Science. 1999;286(5448):2317–9.

Huang J, Meyer M, Pontikis V. Is pipe diffusion in metals vacancy controlled? A molecular dynamics study of an edge dislocation in copper. Phys Rev Lett. 1989;63(6):628.

Rabier J, Puls M. Atomistic calculations of point-defect interaction and migration energies in the core of an edge dislocation in NaCl. Philos Mag A. 1989;59(3):533–46.

Legros M, Dehm G, Arzt E, Balk TJ. Observation of giant diffusivity along dislocation cores. Science. 2008;319(5870):1646–9.

Wang Z, Beyerlein I, LeSar R. Dislocation motion in high strain-rate deformation. Phil Mag. 2007;87(16):2263–79.

Acknowledgements

This research was supported by the Guangdong Basic and Applied Basic Research Foundation (Grant Nos. 2021A1515012278 and 2022A1515010288), and the National Natural Science Foundation of China (Grant No. 51801128). Wei-Bing Liao would like to acknowledge the technical support from the Instrumental Analysis Center of Shenzhen University.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

Informed consent was obtained from all individual participants included in the study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised to add Wei-Bing Liao as an additional corresponding author.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Khan, M.A., Wang, Y., Afifi, M.A. et al. The formation of new (Al, Zn)3Zr precipitates in an Al–Zn–Mg–Cu aluminum alloy after aging treatment and their response to dynamic compression. Archiv.Civ.Mech.Eng 23, 33 (2023). https://doi.org/10.1007/s43452-022-00571-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-022-00571-w