Abstract

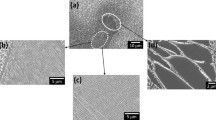

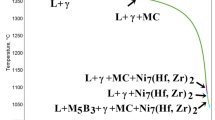

The X-40 Co-based superalloy is often used in the aerospace industry directly in as-cast condition and its analysis in this state is essential to understand further possible phase transformations during service. With this in mind, this work focuses on characterizing the material’s as-cast microstructure, phase transformation temperatures and oxidation resistance. Observations and analyses were performed via thermodynamic simulations, X-ray diffraction (XRD), light microscopy (LM), scanning electron microscopy (SEM), scanning-transmission electron microscopy (STEM-HAADF), energy-dispersive X-ray spectroscopy (EDX), dilatometry (DIL) and differential scanning calorimetry (DSC). The microstructure of the dendritic regions consisted of the α matrix, with MC, M7C3 and M23C6 carbides being present in the interdendritic spaces. Based on DIL, it was found that precipitation of the Cr-rich carbides from the saturated α matrix may occur in the range 650–750 °C. DSC determined the incipient melting and liquidus temperatures of the X-40 superalloy during heating to be 1405 °C and 1421 °C, respectively. Based on oxidation resistance tests carried out at 860 °C, it was found that the mass gain after 500 h exposure was 3 times higher in the air than in steam.

Similar content being viewed by others

Change history

27 July 2022

A Correction to this paper has been published: https://doi.org/10.1007/s43452-022-00500-x

References

Davies J. ASM specialty handbook. Heat-resistant materials. ASM International: Metals Park; 1997.

Klastrom D. Wrought cobalt-base superalloys. J Mater Eng Perform. 1993;2:523–30. https://doi.org/10.1007/BF02661736.

Coutsouradis D, Habraken L. Metallurgical applications of cobalt: a critical review. J Met. 1983;35:40–7. https://doi.org/10.1007/BF03338183.

Singh K. Advanced materials for land based gas turbines. Trans Indian Inst Met. 2014;67(5):601–15. https://doi.org/10.1007/s12666-014-0398-3.

Keyvani M, Garcin T, Fabregue D, Militzer M, Yamanaka K, Chiba A. Continous measurements of recrystallization and grain growth in cobalt super alloys. Metall Mater Trans A. 2017;48:2363–74. https://doi.org/10.1007/s11661-017-4027-8.

Rahmani K, Torabian A. Influence of welding on low cycle fatigue properties of Co-based superalloy FSX-414. Trans Nonferrous Met Soc China. 2016;26:1326–35.

Sims C. A history of superalloy metallurgy for superalloy metallurgists. In: Proceedings of the fifth international symposium on superalloys sponsored by the high temperature alloys Committee of the Metallurgical Society of AIME. Seven Springs, Pennsylvania, USA. October 7–11, 1984

Tomaszewska A, Mikuszewski T, Moskal G, Migas D. Primary microstructure, microsegregation and precipitates characterization of an as-cast new type γ-γ’ Co-Al-Mo-Nb cobalt-based superalloy. J All Comp. 2018;750:741–9. https://doi.org/10.1016/j.jallcom.2018.03.397.

Shirpay M, Kazempour-Liacy H. Failure analysis of a repaired gas turbine nozzle. J Fail Anal Prev. 2013;13:243–8. https://doi.org/10.1007/s11668-013-9667-4.

Kuzucu V, Ceylan M, Celik H, Aksoy I. Microstructure and phase analyses of stellite 6 plus 6 wt.% Mo alloy. J Mater Proc Technol. 1997;69:257–63. https://doi.org/10.1016/S0924-0136(97)00027-7.

Naalchian M, Kasiri-Asgarani M, Shamanian M, Bakhtiari R, Bakhsheshi-Rad H. Comprehensive microstructural investigation during dissimilar transient liquid phase bonding cobalt-based superalloys by BNi-9 amorphous interlayer foil. J Mater Res Technol. 2021;13:2144–60. https://doi.org/10.1016/j.jmrt.2021.05.069.

Kuzucu V, Ceylan M, Celik H, Aksoy I. An investigation of stellite-6 alloy containing 5.0 wt% silicon. J Mater Proc Technol. 1998;79:47–51. https://doi.org/10.1016/S0924-0136(97)00452-4.

Szala J, Szczotok A, Richter J, Cwajna J, Maciejny A. Selection of methods for etching carbides in MAR-M509 cobalt-base superalloy and acquisition of their images. Mat Charact. 2006;56(4–5):325–35. https://doi.org/10.1016/j.matchar.2005.11.015.

Luna Ramirez A, Porcayo-Calderon J, Mazur Z, Salinas-Bravo V, Martinez-Gomez L. Microstructural changes during high temperature service of a cobalt-based superalloy first stage nozzle. Adv Mater Sci Eng. 2016;2016:1745839. https://doi.org/10.1155/2016/1745839.

Rakoczy Ł, Rutkowski B, Grudzień-Rakoczy M, Cygan R, Ratuszek W, Zielińska-Lipiec A. Analysis of γ’ precipitates, carbides and nano-borides in heat-treated Ni-based superalloy using SEM, STEM-EDX and HRSTEM. Materals. 2020;13(19):4452. https://doi.org/10.3390/ma13194452.

Kuzucu V, Ceylan M, Celik H, Aksoy I. Phase investigation of a cobalt base alloy containing Cr, Ni, W and C. J Mater Proc Technol. 1998;74:137–41. https://doi.org/10.1016/S0924-0136(97)00261-6.

Zhao Y, Zhang Y, Zhang Y, Luo Y, Tang D, Liu H, Fu H. Deformation behavior and creep properties oof Co–Al–W-based superalloys: a review. Prog Nat Sci Mater Int. 2021;31:641–8. https://doi.org/10.1016/j.pnsc.2021.09.009.

Coutsouradis D, Davin A, Lamberigts M. Cobalt-based superalloys for applications in gas turbines. Mater Sci Eng. 1987;88:11–9. https://doi.org/10.1016/0025-5416(87)90061-9.

Sato J, Omori T, Oikawa K, Ohnuma I, Kainuma R, Ishida K. Cobalt-base high-temperature alloys. Science. 2006;312:90–1. https://doi.org/10.1126/science.1121738.

Kamma R, Sakaguchi M, Okazaki M, Shimoda Y, Uchiyama T, Ochiai H, Watanabe M. Fatigue properties of alloy 718 overlay-coated with a Co-based X40 alloy by the micro spark coating. J Sol Mech Mater Eng. 2012;6(3):227–40. https://doi.org/10.1299/jmmp.6.227.

Schoonbaert S, Huang X. Brazing and wide gap repair of X-40 using Ni-base alloys. J Eng Gas Turb Power. 2008;130:032101. https://doi.org/10.1115/1.2836743.

Ghasemi A, Kolagar A, Pouranvari M. From as-cast to heat treated X-40 superalloy: effect of cooling rate after partial solution treatment on microstructural evolutions and mechanical properties. Mater Sci Eng. 2021;808:40891. https://doi.org/10.1016/j.msea.2021.140891.

Lukaszewicz M, Simms N, Dudziak T, Nicholls J. Effect of steam flow rate and sample orientation on steam oxidation of ferritic and austenitic steels at 650 and 700°C. Oxid Met. 2013;79(5–6):473–548. https://doi.org/10.1007/s11085-013-9358-2.

Dudziak T, Deodeshmukh V, Backert L, Sobczak N, Witkowska M, Ratuszek W, Chruściel K, Zielinski A, Sobczak J, Bruzda G. Phase investigations under steam oxidation process at 800°C for 1000 h of advanced steels and Ni-based alloys. Oxid Met. 2017;87:139–58. https://doi.org/10.1007/s11085-016-9662-8.

Dudziak T, Gajewski P, Śnieżyński B, Deodeshmukh V, Witkowska M, Ratuszek W, Chruściel K. Neural network modelling studies of steam oxidised kinetic behaviour of advanced steels and ni-based alloys at 800°C for 3000 hours. Corr Sci. 2018;133(1):94–111. https://doi.org/10.1016/j.corsci.2018.01.013.

Cao K, Yang W, Zhang J, Liu C, Qu P, Su H, Zhang J, Liu L. Solidification characteristics and as-cast microstructure of a Ru-containing nickel-based single crystal superalloy. J Mater Res Technol. 2021;11:474–86. https://doi.org/10.1016/j.jmrt.2021.01.043.

Wyckoff R. Crystal structures. New York: Interscience; 1963.

McClune F. New X-ray powder diffraction patterns from the JCPDS associateship. Powder Diffract. 1986;1:77–99.

Bowman A, Arnold G, Storms E, Nereson N. The crystal structure of Cr23C6. Acta Crystall B. 1972;28:3102–3. https://doi.org/10.1107/S0567740872007526.

Sims C, Stoloff N, Hagel W. Superalloys II. New York: Wiley--Interscience; 1987.

Matysiak H, Zagorska M, Balkowiec A, Adamczyk-Cieslak B, Dobkowski K, Koralnik M, Cygan R, Nawrocki J, Cwajna J, Kurzydlowski K. The influence of the melt-pouring temperature and inoculant content on the macro and microstructure of the IN713C Ni-based superalloy. JOM. 2016;68(1):185–97. https://doi.org/10.1007/s11837-015-1672-5.

Aigner K, Lengauer W, Rafaja D, Ettmayer P. Lattice parameters and thermal expansion of Ti(CxN1-x), Zr(CxN1-x), Hf(CxN1-x) and TiN1-x from 298 to 1473 K as investigated by high-temperature X-ray diffraction. J Alloys Compd. 1994;215:121–6. https://doi.org/10.1016/0925-8388(94)90828-1.

Momma K, Izumi F. VESTA 3 for three-dimensional visualization of crystal, volumetric and morphology data. J Appl Crystall. 2011;44:1272–6. https://doi.org/10.1107/S0021889811038970.

Guyard C, Barbangelo A, Allibert C, Driole J. Solidification path and phase equilibria in the liquid-solid range of cobalt-base alloy. J Mater Sci. 1981;16:604–12. https://doi.org/10.1007/BF02402776.

Hamar-Thibault S, Durrand-Charre M, Andries B. Carbide transformation during aging of wear-resistant cobalt alloys. Metall Mater Trans A. 1982;13:545–50. https://doi.org/10.1007/BF02644417.

Johansson T, Uhrenius B. Phase equilibria, isothermal reactions, and a thermodynamic study in the Co–W–C system at 1150°C. Met Sci. 1978;12(2):83–94. https://doi.org/10.1179/msc.1978.12.2.83.

Jiang W, Yao X, Guan H, Hu Z. Secondary carbide precipitation in a directionally solidified cobalt-base superalloy. Metall Mater Trans A. 1999;30A:513–20. https://doi.org/10.1007/s11661-999-0043-7.

Xie S, Wang T, Lu J, Yang H, Zhao G. Effects of Zr on microstructure and short-term strength in GH586. J Mater Sci Technol. 1999;15(5):415–8.

Wallace W, Holt R, Terada T. The nature of the sulfo-carbides observed in nickel-base superalloys. Metallography. 1973;6:511–26. https://doi.org/10.1016/0026-0800(73)90048-7.

Kudielka H, Rohde H. Structural investigation of the carbosulfides of titanium and zirconium. Zeitschrift für Kristallographie (Crystalline Materials). 1960;114:441–56.

Lobl K, Tuma G. Carbide precipitation and carbide equilibrium in the Co–Cr–C system. Metal Sci Heat Treat. 1973;15:21–3. https://doi.org/10.1007/BF00648453.

Fedoseeva A, Tkachev E, Dudko V, Dudova N, Kaibyshev R. Effect of alloying on interfacial energy of precipitation/matrix in high-chromium martensitic steeels. J Mater Sci. 2017;52:4197–209. https://doi.org/10.1007/s10853-016-0654-5.

Skupień P, Radwański K, Gazdowicz J, Arabasz S, Wiedermann J, Szala J. Microstructure of MAR M509 cobalt-based superalloy in as-cast conditions and after heat treatment. PIMŻ. 2010;62(1):259–64 (in polish).

Sklenička V, Kvapilová M, Král P, Dvořák J, Svoboda M, Podhorná B, Zýka J, Hrbáček K, Joch A. Degradation processes in high-temperature creep of cast cobalt-based superalloys. Mater Charact. 2018;144:479–89. https://doi.org/10.1016/j.matchar.2018.08.006.

Wagner H, Hall A. The physical metallurgy of cobalt-base superalloys. Defense metals informations center. Columbus: Battelle Memorial Institute; 1962.

Cacciamani G, Roncallo G, Wang Y, Vacchieri E, Costa A. Thermodynamic modelling of a six component (C–Co–Cr–Ni–Ta–W) system for the simulation of cobalt based alloys. J Alloys Compd. 2018;730:291–310. https://doi.org/10.1016/j.jallcom.2017.09.327.

Gui W, Zhang X, Zhang H, Sun X, Zheng Q. Melting of primary carbides in a cobalt-base superalloy. J Alloys Compd. 2019;787(30):152–7. https://doi.org/10.1016/j.jallcom.2019.02.041.

Gui W, Zhang H, Yang M, Jin T, Sun X, Zheng Q. The investigation of carbides evolution in a cobalt-base superalloy at elevated temperature. J Alloys Compd. 2017;695(25):1271–8. https://doi.org/10.1016/j.jallcom.2016.10.256.

Gui W, Zhang H, Yang M, Jin T, Sun X, Zheng Q. Influence of type and morphology of carbides on stress-rupture behavior of a cast cobalt-base superalloy. J Alloys Compd. 2017;728(25):145–51. https://doi.org/10.1016/j.jallcom.2017.08.287.

Wielgosz E, Kargul T. Differential scanning calorimetry study of peritectic steel grades. J Therm Anal Calorim. 2015;119:1547–53. https://doi.org/10.1007/s10973-014-4302-5.

Archana M, Jagadeeswara Rao C, Ningshen S, Philip J. High-temperature air and steam oxidation and oxide layer characteristics of alloy 617. J Mater Eng Perform. 2021;30:931–43. https://doi.org/10.1007/s11665-020-05367-8.

Dooley R. Program on technology innovation: oxide growth and exfoliation on alloys exposed to steam. California: Energy Power Research Institute EPRI; 2007.

Buscail H, Rolland R, Riffard F, Issartel C, Perrier S. Cobalt based alloy oxidation at high temperatures. HAL. 2017: 1–10. https://hal.archives-ouvertes.fr/hal-01628823

Yeh A, Wang S, Cheng C, Chang Y, Chang S. Oxidation behaviour of Si-bearing Co-based alloys. Oxid Met. 2016;86:99–112. https://doi.org/10.1007/s11085-016-9623-2.

Acknowledgements

The authors gratefully acknowledge the funding by National Centre for Research and Development, Poland, under grant POIR.01.01.01-00-0631/18. The oxidation resistance experiments were supported by the Polish National Science Centre (Preludium 14) under the grant for young scientists (M.G.R.) 2017/27/N/ST8/01801. M.G.R. thanks the European Virtual Institute on Knowledge-based Multifunctional Materials (KMM‐VIN) for the fellowship to spend a research period at the Institute of Materials Research, Slovak Academy of Sciences. O.M. was supported by the Scientific Grant Agency under contract VEGA project No. 2/0086/22.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: one sentence in section 3.4 was incomplete.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rakoczy, Ł., Grudzień-Rakoczy, M., Cygan, R. et al. Characterization of the as-cast microstructure and selected properties of the X-40 Co-based superalloy produced via lost-wax casting. Archiv.Civ.Mech.Eng 22, 143 (2022). https://doi.org/10.1007/s43452-022-00466-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-022-00466-w