Abstract

Demountable steel–concrete composite structures have attracted much attention from researchers because of its fast construction, demountability and environmental friendliness. Using ultra-high performance concrete (UHPC) in the hogging moment regions of demountable steel–concrete composite structures might improve their crack resistance and flexural performance. In this study, the cracking behavior, failure mode, stiffness, ultimate strength and relative slip of demountable steel-UHPC composite slabs with different stud spacings and longitudinal reinforcement ratios under hogging moment were experimentally investigated. A welded steel-UHPC composite slab was also tested to compare its behavior with the demountable slabs. The test results show the demountable steel-UHPC composite slabs have excellent crack control ability under hogging moment due to the slip of threaded headed stud and the strain hardening behavior of UHPC; the relative slip is directly associated with the stud spacing and controlled by the friction and shear force of threaded headed studs. As compared to the welded composite slab, the demountable composite slab can be easily separated after loading, the flexural capacity is slightly smaller, while the crack control ability is better and the ductility is higher. A constitutive model considering the reduction of tensile strength of UHPC after reinforcement was adoptedl the design formulas were developed to predict the elastic limit and the ultimate moment, and the bending stiffness of the demountable composite slabs under hogging moment. The test results verify the applicability of the proposed constitutive model of UHPC and design formulas.

Similar content being viewed by others

Abbreviations

- f Ute :

-

Elastic tensile strength of UHPC

- ε Ute :

-

Elastic tensile strain of UHPC

- E U :

-

Elastic modulus of UHPC

- f Utu :

-

Tensile strength of UHPC

- ε Utu :

-

Strain of UHPC when the tensile strength is reached

- f RUte :

-

Elastic tensile strength of UHPC after reinforcement

- ε RUte :

-

Elastic tensile strain of UHPC after reinforcement

- f RUtu :

-

Tensile strength of UHPC after reinforcement

- ε RUtu :

-

Strain of UHPC after reinforcement when the tensile strength is reached

- P e :

-

Load of composite slab when the elastic limit state is reached

- ε Ue :

-

Midspan strain of UHPC layer when the elastic limit state is reached

- ε se :

-

Midspan strain of steel plate when the elastic limit state is reached

- P u :

-

Ultimate load of composite slab

- P cr0.05 :

-

Load of composite slab when the maximum crack reached 0.05 mm

- P 0.3 :

-

Load of composite slab when the maximum crack reached 0.3 mm

- E 1 :

-

Stiffness of the composite slab in the stage I

- E 2 :

-

Stiffness of the composite slab in the stage II

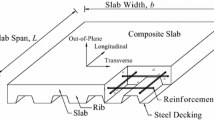

- b :

-

Width of the composite slab

- l :

-

Span of the composite slab

- a :

-

Distance between the support and the loading point

- h U :

-

Height of UHPC layer

- h s :

-

Height of steel plate

- e :

-

Distance between the center of steel rebar and the top surface of UHPC layer

- x :

-

Height of compression zone of composite slab

- f y :

-

Yield strength of steel rebar

- A s :

-

Area of steel rebar

- σ Uc :

-

Compressive stress on the top surface of UHPC layer when the elastic limit state of composite slab is reached

- ε sr :

-

Strain of steel rebar when the elastic limit state of composite slab is reached

- σ sr :

-

Stress of steel rebar when the elastic limit state of composite slab is reached

- ε pb :

-

Strain of steel plate on the bottom surface when the elastic limit state of composite slab is reached

- σ pb :

-

Stress of steel plate on the bottom surface when the elastic limit state of composite slab is reached

- ε pt :

-

Strain of steel plate on the top surface when the elastic limit state of composite slab is reached

- σ pt :

-

Stress of steel plate on the top surface when the elastic limit state of composite slab is reached

- E s :

-

Elastic modulus of steel rebar

- E p :

-

Elastic modulus of steel plate

- M e,t :

-

Moment test result of composite slab when elastic limit state is reached

- M e ,1 :

-

Moment of composite slab calculated according to lower limit of the elastic tensile strain of UHPC after reinforcement

- M e ,2 :

-

Moment of composite slab calculated according to upper limit of the elastic tensile strain of UHPC after reinforcement

- f p :

-

Yield strength of steel plate

- M u :

-

Ultimate moment test result of composite slab with full shear connection

- M up ,t :

-

Ultimate moment test result of composite slab

- M up :

-

Calculated value of ultimate moment of composite slab

- I eq :

-

Moment of inertia of the effective section of composite slab

- I U :

-

Moment of inertia of the UHPC layer

- I P :

-

Moment of inertia of the steel plate

- α E :

-

Elastic modulus ratio of steel to UHPC

- y 0 :

-

Distance between the neutral axis of the composite slab and the top of steel plate

- β U :

-

Reduction factor of UHPC layer height

- ζ:

-

Reduction factor of the bending stiffness considering the interface slip between the UHPC layer and the steel plate

- d c :

-

Distance between the neutral axis of the steel plate and the UHPC layer

References

Tong LW, Chen LH, Wen M, Xu C. Static behavior of stud shear connectors in high-strength-steel–UHPC composite beams. Eng Struct. 2020;218:1–15.

Nie JG, Li YX, Tao MX, Nie X. Uplift-restricted and slip-permitted T-shape connectors. J Bridge Eng. 2015;20(4):30–42.

Fei Y, Liu Y, Jiang Z, Xin HH. Shear performance of a novel demountable steel-concrete bolted connector under static push-out tests. Eng Struct. 2018;160:133–46.

Gheitasi A, Harris DK. Performance assessment of steel-concrete composite bridges with subsurface deck deterioration. Struct. 2015;2:8–20.

Suwaed ASH, Karavasilis TL. Demountable steel-concrete composite beam with full-interaction and low degree of shear connection. J Constr Steel Res. 2020;171: 106152.

Rehmann N, Lam D, Dai X, Ashour A. Experimental study on demountable shear connectors in composite slabs with profiled decking. J Constr Steel Res. 2016;122:178–89.

Moynihan MC, Allwood JM. Viability and performance of demountable composite connectors. J Constr Steel Res. 2014;99:47–56.

Kwon G, Engelhardt MD, Klingner RE. Behavior of post-installed shear connectors under static and fatigue loading. J Constr Steel Res. 2010;66:532–41.

Kwon G, Engelhardt MD, Klingner RE. Experimental behavior of bridge beams retrofitted with post-installed shear connectors. J Bridge Eng. 2011;16(4):536–45.

Lam D, Saveri E. Shear capacity of demountable shear connectors. Proc 10th International conference on advances in steel concrete composite and hybrid structures. Singapore. 2012;767–74. https://doi.org/10.3850/978-981-07-2615-7_110

Lin W, Yoda T, Taniguchi N, Kasano H, He J. Mechanical performance of steel concrete composite beams subjected to a hogging moment. J Struct Eng. 2014;140:1–11.

Lin W, Yoda T, Taniguchi N. Application of SFRC in steel–concrete composite beams subjected to hogging moment. J Constr Steel Res. 2014;101:175–83.

AFGC/SETRA. Ultra high performance fibre-reinforced concretes recommendations. Paris: AFGC/SETRA; 2013.

Chang W, Zheng WZ, Hao MJ. Compression behavior of ultra-high performance concrete (UHPC) confined with high-strength rectilinear ties. Arch Civ Mech Eng. 2021;22:27.

Kim JJ, Yoo DY. Spacing and bundling effects on rate-dependent pullout behavior of various steel fibers embedded in ultra-high-performance concrete. Arch Civ Mech Eng. 2020;20:46.

Wang JY, Guo JY. Damage investigation of ultra high performance concrete under direct tensile test using acoustic emission techniques. Cem Concr Compos. 2017;88:17–28.

Brühwiler E. Recommendation: ultra-high performance fibre reinforced cement-based composites (UHPFRC) construction material, dimensioning and application. Zurich: EPFL; 2016.

Dieng L, Marchand P, Gomes F, Tessier C, Toutlemonde F. Use of UHPFRC overlay to reduce stresses in orthotropic steel decks. J Constr Steel Res. 2013;89:30–41.

Zhang Y, Cai S, Zhu Y, Fan L, Shao XD. Flexural responses of steel-UHPC composite beams under hogging moment. Eng Struct. 2020;206:110–34.

Yan JB, Guan HN, Wang T. Steel-UHPC-steel sandwich composite beams with novel enhanced C-channel connectors: tests and analysis. J Constr Steel Res. 2020;170: 106077.

Wang JY, Guo JY, Jia LJ, Chen SM, Dong Y. Push-out tests of demountable headed stud shear connectors in steel-UHPC composite structures. Compos Struct. 2017;170:69–79.

Yang Y, Liu JB, Fan JS, Nie X. Experimental study on flexural capacity of steel plate-concrete composite slabs. J Build Struc. 2013;34(10):24–31.

Li WG, Shao XD, Fang H, Zhang Z. Experimental study on flexural behavior of steel-UHPC composite slabs (in Chinese). Chin Civil Eng J. 2015;48(11):93–102.

BS EN 12350–2–2009. Testing fresh concrete-Part 2: Slump-test. London: British Standard Institution. 2009.

BS EN 12350–3–2009. Testing hardened concrete-Part 3: Compressive strength of test specimens. London: British Standard Institution. 2009.

ASTM C469/C469M. Standard test method for static modulus of elasticity and Poisson’s ratio of concrete in compression. West Conshohocken, PA: ASTM International. 2014.

T/CECS10107–2020. Technical requirements for ultra high performance concrete. Beijing: China Association for Engineering Construction Standardization. 2020.

Bischoff PH. Tension stiffening and cracking of steel fiber-reinforced concrete. J Mater Civil Eng. 2003;15(2):174–82.

Bian C, Wang JY. Mechanical and damage mechanisms of reinforced ultra high performance concrete under tensile loading. Constr Build Mater. 2019;226:259–79.

Wille K, El-Tawil S, Naaman AE. Properties of strain hardening ultra high performance fiber reinforced concrete (UHP-FRC) under direct tensile loading. Cem Concr Compos. 2014;48:53–66.

Roy M, Hollmann C, Wille K. Influence of volume fraction and orientation of fibers on the pullout behavior of reinforcement bar embedded in ultra high performance concrete. Constr Build Mater. 2017;146:582–93.

Wang TM. Control of cracking in engineering structure (in Chinese). Beijing: China Architecture and Building Press; 1997.

Lin WW, Yoda T, Taniguchi N. Application of SFRC in steel–concrete composite beams subjected to hogging moment. J Constr Steel Res. 2020;101:175–83.

Park R. Evaluation of ductility of structures and structural assemblages from laboratory testing. Bull New Zeal Natl Soc Earthq Eng. 1989;22(3):155–66.

Wang KK, Zhao CH, Wu B, Deng KL, Cui B. Fully-scale test and analysis of fully dry-connected prefabricated steel-UHPC composite beam under hogging moments. Eng Struct. 2019;197: 109380.

Guo JY, Wang JY, Wu K. Effects of self-healing on tensile behavior and air permeability of high strain hardening UHPC. Constr Build Mater. 2019;204:342–56.

EN 1994-1-1. Eurocode 4: Design of composite steel and concrete structures, Part 1–1: General rules for buildings. Brussels: European committee for standardization; 2004.

Fan JS, Nie JG, Cai CS. Study on the continuous composite beam with partial shear connection (in Chinese). J Harbin Inst Technol. 2005;37:230–3.

Fehling E, Schmidt M, Walraven J, Leutbecher T, Fröhlich S. Ultra-high performance concrete UHPC: fundamentals, design, examples. Berlin: Ernst & Sohn; 2014.

Chen SM, Zhang R, Jia LJ, Wang JY. Flexural behaviour of rebar-reinforced ultra high performance concrete beams. Mag Concrete Res. 2018;70(19):997–1015.

PR China Minister of China. GB50017–2017: Code for design of steel structures. Beijing: China Planning Press. 2018.

AISC. Load and resistance factor design specification for structural steel buildings. Chicago: AISC; 2005.

Guo JY, Wang JY, Bian C. Cyclic tensile behavior of high strain hardening UHPC analyzed by acoustic emission techniques. Constr Build Mater. 2021;267: 121797.

Girhammar UA. A simplified analysis method for composite beams with interlayer slip. Int J Mech SCI. 2009;51(7):515–30.

Xu RQ, Chen DQ. Modified reduced stiffness method for calculation the deflection of composite beams (in Chinese). Eng Mech. 2013;30(2):285–91.

Maya LF, Zanuy C, Albajar L, Lopez C, Portabella J. Experimental assessment of connections for precast concrete frames using ultra high performance fibre reinforced concrete. Constr Build Mater. 2013;48:173–86.

Bournas DA, Negro P, Molina FJ. Pseudodynamic tests on a full-scale 3-storey precast concrete building: behavior of the mechanical connections and floor diaphragms. Eng Struct. 2013;57:609–27.

Vinutha D, Vidjeapriya R, Jaya KP. Seismic performance of precast slab to beam connection: an overview. Curr Sci India. 2021;121(1):61–76.

Acknowledgements

This work was supported by Ningbo major science and technology project [Grant Number 2020Z034], the China Postdoctoral Science Foundation [Grant Number 2020M671215] and the National Nature Science Foundation of China [Grant Number 52108239]. The financial support is greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Guo, JY., Wang, JY., Wang, YB. et al. Experimental study on demountable steel ultra-high performance concrete composite slabs under hogging moment. Archiv.Civ.Mech.Eng 22, 137 (2022). https://doi.org/10.1007/s43452-022-00458-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-022-00458-w