Abstract

One of the critical factors that govern the technology of concrete self-healing evaluation at laboratory scale is the crack induction pattern within the concrete sample. Within the various techniques of inducing artificial cracks, such as the flexural testing or splitting testing methods, there are limitations of inducing the microcracks homogenously throughout the entire volume of the concrete sample. In this study, an innovative technique is utilised to induce the microcracks at a controlled damage level to further study the self-healing phenomena in concrete at the laboratory scale. By placing a concrete sample into an ad-hoc fabricated steel mould and applying fractional compressive strength, the axial-circumferential pressure induces microcracks in the concrete sample, homogenously. A Finite Element Model was also built to investigate the hypothesis on the cracking pattern at various damage levels; jointly, experimental work was conducted with X-ray µCT images to reconstruct the three-dimensional sections at the various damage levels. Qualitative analyses in relation to the two test methods were conducted. Furthermore, quantitative analyses on the individual—artificially generated—cracks were conducted in terms of the crack size crack geometry variation and the orientation of the newly formed cracks. Results revealed that the proposed crack-inducing methodology is highly efficient to induce uniform cracks in the sample, assisting for the evaluation of concrete self-healing process. The novel method can be adapted to identify the optimised strategies for enhancing the structural performance of concrete, thus facilitating the safe operation of concrete infrastructure.

Graphic abstract

Similar content being viewed by others

References

Yan J, et al. Concrete crack detection and monitoring using a capacitive dense sensor array. Sensors. 2019;19(8):1843.

De Muynck W, De Belie N, Verstraete W. Microbial carbonate precipitation in construction materials: a review. Ecol Eng. 2010;36(2):118–36.

Ranjith PG, et al. A study of the effect of displacement rate and moisture content on the mechanical properties of concrete: use of acoustic emission. Mech Mater. 2008;40(6):453–69.

Sidiq A, Gravina R, Giustozzi F. Is concrete healing really efficient? A review. Constr Build Mater. 2019;205:257–73.

Qasim OA. A review paper on specimens size and shape effects on the concrete properties. Int J Recent Adv Sci Technol. 2018;5(3):13–25.

Wu M et al. Application of bacterial spores coated by a green inorganic cementitious material for the self-healing of concrete cracks 2020;113:103718

Snoeck D, Pel L, De Belie NJS Autogenous healing in cementitious materials with superabsorbent polymers quantified by means of NMR 2020;10(1):1–6

Sidiq A, et al. Self-repairing cement mortars with microcapsules: a microstructural evaluation approach. Constr Build Mater. 2020;232:117239.

Selvarajoo T et al. Characterisation of a vascular self-healing cementitious material system: flow and curing properties 2020;245:118332

Du W et al. Effect of temperatures on self-healing capabilities of concrete with different shell composition microcapsules containing toluene-di-isocyanate. 2020;247:118575

Maes M, Van Tittelboom K, De Belie N. The efficiency of self-healing cementitious materials by means of encapsulated polyurethane in chloride containing environments. Constr Build Mater. 2014;71:528–37.

Snoeck D, et al. Self-healing cementitious materials by the combination of microfibres and superabsorbent polymers. J Intell Mater Syst Struct. 2014;25(1):13–24.

Wang R, et al. Investigation of self-healing capability on surface and internal cracks of cement mortar with ion chelator. Constr Build Mater. 2020;236:117598.

Li W, et al. Preparation and properties of melamine urea-formaldehyde microcapsules for self-healing of cementitious materials. Materials. 2016;9(3):152.

Wang J, et al. Use of silica gel or polyurethane immobilized bacteria for self-healing concrete. Constr Build Mater. 2012;26(1):532–40.

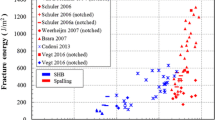

Tsangouri E, et al. Concrete fracture toughness increase by embedding self-healing capsules using an integrated experimental approach. Constr Build Mater. 2019;218:424–33.

Ferrara L, Krelani V, Carsana M. A “fracture testing” based approach to assess crack healing of concrete with and without crystalline admixtures. Constr Build Mater. 2014;68:535–51.

Hilloulin B, et al. Monitoring of autogenous crack healing in cementitious materials by the nonlinear modulation of ultrasonic coda waves, 3D microscopy and X-ray microtomography. Constr Build Mater. 2016;123:143–52.

Granger S et al. Mechanical characterization of the self-healing effect of cracks in Ultra High Performance Concrete (UHPC). In: Proceedings Third International Conference on Construction Materials, Performance, Innovations and Structural Implications, ConMat; 2005.

Xu J, et al. Application of ureolysis-based microbial CaCO3 precipitation in self-healing of concrete and inhibition of reinforcement corrosion. Constr Build Mater. 2020;265:120364.

Van Tittelboom K, et al. Comparison of different approaches for self-healing concrete in a large-scale lab test. Constr Build Mater. 2016;107:125–37.

Chen Q, Andrawes B. 3D Finite Element Modeling to Study the Behavior of Shape Memory Alloy Confined Concrete. In: Proceedings of the 15th World Conference on Earthquake Engineering, Lisbon, Portugal, September; 2012.

Labibzadeh M. The numerical simulations of the strengthened RC slabs with CFRPs using standard CDP material model of Abaqus code. Eur J Environ Civ Eng. 2015;19(10):1268–87.

Demir A, Ozturk H, Dok G. 3D numerical modeling of RC deep beam behavior by nonlinear finite element analysis. Disaster Sci Eng. 2016;2(1):13–8.

Djeddi F, et al. Strengthening in flexure–shear of RC beams with hybrid FRP systems: experiments and numerical modeling. J Reinf Plast Compos. 2016;35(22):1642–60.

Huang Z et al. Modelling of damage and its use in assessment of a prestressed bridge. 2016: Luleå tekniska universitet.

Othman H, Marzouk H. Applicability of damage plasticity constitutive model for ultra-high performance fibre-reinforced concrete under impact loads. Int J Impact Eng. 2018;114:20–31.

Nehdi ML, Ali MA. Experimental and numerical study of engineered cementitious composite with strain recovery under impact loading. Appl Sci. 2019;9(5):994.

Raza A, Ahmad A. Numerical investigation of load-carrying capacity of GFRP-reinforced rectangular concrete members using CDP model in ABAQUS. Advances in Civil Engineering; 2019.

Del Viso J, Carmona J, Ruiz G. Shape and size effects on the compressive strength of high-strength concrete. Cem Concr Res. 2008;38(3):386–95.

ASTM C42/C42M Standard Test Method for Obtaining and Testing Drilled Cores and Sawed Beams of Concrete. 2020.

BS 1881 - Part120 Testing concrete. Method for determination of the compressive strength of concrete cores. 1983. https://shop.bsigroup.com/ProductDetail/?pid=000000000000049250.

AS-1012.8.1:2014, Methods of testing concrete Method for making and curing concrete - Compression and indirect tensile test specimens, www.saiglobal.com 2018.

Burlion N, Pijaudier-Cabot G, Dahan N. Experimental analysis of compaction of concrete and mortar. Int J Numer Anal Meth Geomech. 2001;25(15):1467–86.

Kim J-K, Yi S-T. Application of size effect to compressive strength of concrete members. Sadhana. 2002;27(4):467.

AS-3972–2010, General purpose and blended cement; 2018.

Lubliner J et al. A plastic-damage model for concrete. Int. J. Solids and Structures; 1989

Lee J, Fenves GL. Plastic-damage model for cyclic loading of concrete structures. J Eng Mech. 1998;124(8):892–900.

Lubliner J et al. A plastic-damage model for concrete. 1989;25(3):299–326

Wimalasiri M, Robert D, C.-Q.J.J.o.M.i.C.E. Li, Permeability degradation of stressed concrete considering concrete plasticity. 2020; 32(9):04020265.

Attard MM, Setunge S. Stress-strain relationship of confined and unconfined concrete. Mater J. 1996;93(5):432–42.

Hsu L, Hsu C-T. Complete stress—strain behaviour of high-strength concrete under compression. Mag Concr Res. 1994;46(169):301–12.

Popovics S. A numerical approach to the complete stress-strain curve of concrete. Cem Concr Res. 1973;3(5):583–99.

Alfarah B, López-Almansa F, Oller S. New methodology for calculating damage variables evolution in Plastic Damage Model for RC structures. Eng Struct. 2017;132:70–86.

Carreira DJ, Chu K-H. Stress-strain relationship for plain concrete in compression. J Proc. 1985.

Müller H Constitutive modelling of high strength/high performance concrete-state of the art report. CEB FIP Bulletin. 2008; 42.

du Béton FI, fib (CEB-FIP) Model Code 2010: First complete draft. Bulletin. 55.

Liu BD, et al. Effect of moisture content on static compressive elasticity modulus of concrete. Constr Build Mater. 2014;69:133–42.

Akçaoğlu T, Tokyay M, Çelik T. Assessing the ITZ microcracking via scanning electron microscope and its effect on the failure behavior of concrete. Cem Concr Res. 2005;35(2):358–63.

Guggenbuhl P, et al. Texture analysis of X-ray radiographs of iliac bone is correlated with bone micro-CT. Osteoporos Int. 2006;17(3):447–54.

Alghamri R, Kanellopoulos A, Al-Tabbaa A. Impregnation and encapsulation of lightweight aggregates for self-healing concrete. Constr Build Mater. 2016;124:910–21.

Xu J, Wang X. Self-healing of concrete cracks by use of bacteria-containing low alkali cementitious material. Constr Build Mater. 2018;167:1–14.

Luo M, Qian C-X, Li R-Y. Factors affecting crack repairing capacity of bacteria-based self-healing concrete. Constr Build Mater. 2015;87:1–7.

Sidiq A, et al. Microstructural analysis of healing efficiency in highly durable concrete. Constr Build Mater. 2019;215:969–83.

Lorensen WE, Cline HE. Marching cubes: a high resolution 3D surface construction algorithm. ACM Siggraph Comput Graph. 1987;21(4):163–9.

Vegt I, Breugel V, Weerheijm J Failure mechanisms of concrete under impact loading. Fracture Mechanics of Concrete and Concrete Structures, FraMCoS-6, 2007;1:579–587.

Or D, Tuller M Cavitation during desaturation of porous media under tension. Water Resources Research, 2002;38(5): p. 19–1–19–14.

Hover K. Why is there air in concrete? Concrete Constr. 1993;38(1):11–5.

Wadell H. Volume, shape, and roundness of quartz particles. J Geol. 1935;43(3):250–80.

Bisbal F et al. Left atrial sphericity: a new method to assess atrial remodeling. Impact on the outcome of atrial fibrillation ablation. J Cardiovasc Electrophysiol. 2013;24(7):752–759.

Okeniyi JO, et al. Probability density fittings of corrosion test-data: implications on C 6 H 15 NO 3 effectiveness on concrete steel-rebar corrosion. Sadhana. 2014;39(3):731–64.

Hildebrand T, Rüegsegger P Quantification of bone microarchitecture with the structure model index. Comput Methods Biomech Bio MedEngineering, 1997;1(1):15–23.

Lorensen WE, Cline HE. Marching cubes: A high resolution 3D surface construction algorithm. In: ACM siggraph computer graphics. 1987; ACM.

Dawson AR, et al. Enhancing thermal properties of asphalt materials for heat storage and transfer applications. Road Mater Pavement Design. 2012;13(4):784–803.

Bažant ZP, Xiang Y. Size effect in compression fracture: splitting crack band propagation. J Eng Mech. 1997;123(2):162–72.

Acknowledgements

The authors acknowledge the technical assistance of RMMF (RMIT Microscopy and Microanalyses Facility) staff Dr. Chaitali Dekiwadia and of the Microscopy & Microanalysis Research Facility at RMIT University.

Funding

No funding was received for conducting this study.

Author information

Authors and Affiliations

Contributions

All authors: Conceptualization; All Authors: Data analysis; AS: Investigation and testing; All Authors: Methodology; AS: Writing—original draft; All Authors: Writing—review & editing; FG: Project administration and supervision.

Corresponding author

Ethics declarations

Human and animal rights statement

The authors confirm this article does not contain any studies with human participants or animals performed by any of the authors.

Conflict of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sidiq, A., Robert, D., Gravina, R. et al. Coupled FEM-microstructural X-ray examination of a controlled internal damage approach for concrete samples. Archiv.Civ.Mech.Eng 21, 62 (2021). https://doi.org/10.1007/s43452-021-00219-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-021-00219-1