Abstract

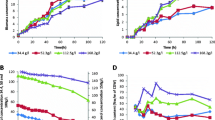

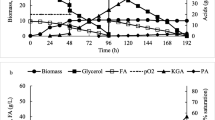

Purified glycerol obtained after acid treatment of crude glycerol solution was used as the carbon source for lipid and citric acid production using Y. lipolytica SKY7. Although purified glycerol was high in phosphorus, it was important to investigate the impact of fortification of trace elements in the medium on cell growth, lipid and citric acid (CA) production. When all the trace elements (including phosphates and sulfates) required for growth and lipid production were added to the purified glycerol medium, high biomass (51.67 g/L) and lipid concentration (19.47 g/L) were observed at 96 h of fed-batch fermentation with low CA concentration of 5.42 g/L. The purified glycerol medium without additional trace elements gave low biomass (27.67 g/L), lipid concentration (9.35 g/L) at 80 h of fed-batch fermentation, but gave high CA concentration (24.51 g/L). When purified glycerol was provided with only sulfates or all elements except KH2PO4, low biomass (32.59 g/L and 38.52 g/L) and citric acid concentration (1 g/L and 2.42 g/L) were obtained at 96 h.

Similar content being viewed by others

References

Bondioli P, Della Bella L. An alternative spectrophotometric method for the determination of free glycerol in biodiesel. Eur J Lipid Sci Technol. 2005;107(3):153–7.

Chen J, Yan S, Zhang X, Tyagi RD, Surampalli RY, Valéro J. Chemical and biological conversion of crude glycerol derived from waste cooking oil to biodiesel. Waste Manage. 2018;71:164–75.

Chen J, Zhang X, Yan S, Tyagi RD, Drogui P. Lipid production from fed-batch fermentation of crude glycerol directed by the kinetic study of batch fermentations. Fuel. 2017;209:1–9.

Concas A, Steriti A, Pisu M, Cao G. Comprehensive modeling and investigation of the effect of iron on the growth rate and lipid accumulation of Chlorella vulgaris cultured in batch photobioreactors. Biores Technol. 2014;153:340–50.

Evans CT, Scragg AH, Ratledge C. A comparative study of citrate efflux from mitochondria of oleaginous and non-oleaginous yeasts. FEBS J. 1983;130(1):195–204.

Fu G-Y, Lu Y, Chi Z, Liu G-L, Zhao S-F, Jiang H, Chi Z-M. Cloning and characterization of a pyruvate carboxylase gene from Penicillium rubens and overexpression of the genein the yeast Yarrowia lipolytica for enhanced citric acid production. Mar Biotechnol. 2016;18(1):1–14.

Gao Z, Ma Y, Wang Q, Zhang M, Wang J, Liu Y. Effect of crude glycerol impurities on lipid preparation by Rhodosporidium toruloides yeast 32489. Bioresour Technol. 2016;218:373–9.

Javani A, Hasheminejad M, Tahvildari K, Tabatabaei M. High quality potassium phosphate production through step-by-step glycerol purification: a strategy to economize biodiesel production. Biores Technol. 2012;104:788–90.

Kaur R, Roy D, Yellapu SK, Tyagi RD, Drogui P, Surampalli RY. Enhanced composting leachate treatment using extracellular polymeric substances as bioflocculant. J Environ Eng. 2019;145(11):04019075.

Kumar LR, Yellapu SK, Tyagi R, Zhang X. A review on variation in crude glycerol composition, bio-valorization of crude and purified glycerol as carbon source for lipid production. Biores Technol. 2019;293:122155.

Kuttiraja M, Dhouha A, Tyagi RD. Harnessing the effect of pH on lipid production in batch cultures of Yarrowia lipolytica SKY7. Appl Biochem Biotechnol. 2018;184(4):1332–466. https://doi.org/10.1007/s12010-017-2617-y.

Kuttiraja M, Krishna S, Dhouha A, Tyagi RD. A substrate-based approach for the selection of oil-bearing heterotrophs from nitrogen-deficient soil for lipid production. Appl Biochem Biotechnol. 2015;175(4):1926–37.

Liang Y, Cui Y, Trushenski J, Blackburn JW. Converting crude glycerol derived from yellow grease to lipids through yeast fermentation. Biores Technol. 2010;101(19):7581–6.

Liu X, Lv J, Xu J, Zhang T, Deng Y, He J. Citric acid production in Yarrowia lipolytica SWJ-1b yeast when grown on waste cooking oil. Appl Biochem Biotechnol. 2015;175(5):2347–56.

Ma Z, Chu C-H, Cheng D. A novel direct homogeneous assay for ATP citrate lyase. J Lipid Res. 2009;50(10):2131–5.

Marier J, Boulet M. Direct determination of citric acid in milk with an improved pyridine-acetic anhydride method. J Dairy Sci. 1958;41(12):1683–92.

Marjakangas JM, Lakaniemi A-M, Koskinen PE, Chang J-S, Puhakka JA. Lipid production by eukaryotic microorganisms isolated from palm oil mill effluent. Biochem Eng J. 2015;99:48–544.

Mathiazhakan K, Ayed D, Tyagi RD. Kinetics of lipid production at lab scale fermenters by a new isolate of Yarrowia lipolytica SKY7. Biores Technol. 2016;221:234–40.

Nanda M, Yuan Z, Qin W, Poirier M, Chunbao X. Purification of crude glycerol using acidification: effects of acid types and product characterization. Austin J Chem Eng. 2014;1(1):1–7.

Sabra W, Bommareddy RR, Maheshwari G, Papanikolaou S, Zeng A-P. Substrates and oxygen dependent citric acid production by Yarrowia lipolytica: insights through transcriptome and fluxome analyses. Microb Cell Fact. 2017;16(1):78.

Šajbidor J, Koželouhov’a D, Ĉert’ik M. Influence of some metal ions on the lipid content and arachidonic acid production by Mortierella sp. Folia Microbiol. 1992;37(6):404–6.

Shuib S, Wan Nawi WNN, Taha EM, Omar O, Abdul Kader AJ, Kalil MS, Abdul Hamid A. Strategic feeding of ammonium and metal ions for enhanced GLA-rich lipid accumulation in Cunninghamella bainieri 2A1. Sci World J. 2014;2014:173574. https://doi.org/10.1155/2014/173574.

Signori L, Ami D, Posteri R, Giuzzi A, Mereghetti P, Porro D, Branduardi P. Assessing an effective feeding strategy to optimize crude glycerol utilization as sustainable carbon source for lipid accumulation in oleaginous yeasts. Microb Cell Fact. 2016;15(1):75.

Tai M, Stephanopoulos G. Engineering the push and pull of lipid biosynthesis in oleaginous yeast Yarrowia lipolytica for biofuel production. Metab Eng. 2013;15:1–9.

Vuoristo KS, Mars AE, Sanders JP, Eggink G, Weusthuis RA. Metabolic engineering of TCA cycle for production of chemicals. Trends Biotechnol. 2016;34(3):191–7.

Wang Y, Gong Z, Yang X, Shen H, Wang Q, Wang J, Zhao ZK. Microbial lipid production from pectin-derived carbohydrates by oleaginous yeasts. Process Biochem. 2015;50(7):1097–102.

Yang X, Jin G, Gong Z, Shen H, Bai F, Zhao ZK. Recycling biodiesel-derived glycerol by the oleaginous yeast Rhodosporidium toruloides Y4 through the two-stage lipid production process. Biochem Eng J. 2014;91:86–91.

Yen H-W, Zhang Z. Effects of dissolved oxygen level on cell growth and total lipid accumulation in the cultivation of Rhodotorula glutinis. J Biosci Bioeng. 2011;112(1):71–4.

Yenush L. Potassium and sodium transport in yeast. Adv Exp Med Biol. 2016. https://doi.org/10.1007/978-3-319-25304-6_8.

Acknowledgements

The authors would like to acknowledge the Natural Sciences and Engineering Research Council of Canada (Grant A4984, Canada Research Chair) for financial support. We are grateful to the technical staff of INRS-ETE (Mr. Stephane Moise and Mr. Stefane Premont) for their timely help to analyze the samples on LC–MS and ICP.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Kumar, L.R., Yellapu, S.K., Tyagi, R.D. et al. Optimization of trace elements in purified glycerol for microbial lipid and citric acid production by Yarrowia lipolytica SKY7. Syst Microbiol and Biomanuf 1, 76–89 (2021). https://doi.org/10.1007/s43393-020-00006-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43393-020-00006-8