Abstract

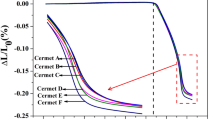

Ti(C,N)-HfN-WC-Ni-Mo cermets were fabricated, and effects of HfN and WC content and sintering temperature on their microstructural evolution and mechanical properties were investigated. These cermets were primarily comprised of Ti(C0.41,N0.5), HfN, WC, TiC, Mo and Ni. At an additive concentration of 30 mol.%, the cermet exhibited the most homogeneous microstructure. The grain size gradually increased with increasing sintering temperature. The defects in the cermet sintered at 1500 ℃ significantly reduced, and the fine grains were homogeneously distributed. The fracture mode in cermets was a combination of transgranular fracture and intergranular fracture. Vickers hardness increased, flexural strength and fracture toughness first increased and then decreased with an increase of HfN and WC content. The cermet sintered at 1500 ℃ exhibited better mechanical properties: Vickers hardness was 22.29 GPa, flexural strength was 1271.58 MPa, and fracture toughness was 7.33 MPa·m1/2. In addition, the toughening mechanism of the Ti(C,N)-HfN-WC cermets mainly involved crack deflection and bridging.

Graphical abstract

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the findings of this study are available within the article.

References

Q. Gou, J. Xiong, Z. Guo et al., Influence of NbC additions on microstructure and wear resistance of Ti(C, N)-based cermets bonded by CoCrFeNi high-entropy alloy. Int J Refract Met Hard Mater. 94, 105375–105385 (2021). https://doi.org/10.1016/j.ijrmhm.2020.105375

J. Song, Gao, R. Ahmad et al., Cutting performances of TiCN-HfC and TiCN-HfC-WC ceramic tools in dry turning hardened AISI H13. Adv. Appl. Ceram. 119, 380–386 (2020). https://doi.org/10.1080/17436753.2020.1765292

K. Xu, B. Zou, T. Wang et al., An experimental investigation of micro-machinability of aluminum alloy 2024 using Ti(C7N3)-based cermet micro end-mill tools. J Mater Process Tech. 235, 13–27 (2016). https://doi.org/10.1016/j.jmatprotec.2016.04.011

N. Liu, X. Chao, X. Huang et al., Effects of TiC/TiN addition on the microstructure and mechanical properties of ultra-fine grade Ti(C, N)-Ni cermets. J. Eur. Ceram. Soc. 26, 3861–3870 (2006). https://doi.org/10.1016/j.jeurceramsoc.2005.12.010

N. Lin, Z. Zheng, L. Zhao et al., Influences of ultrafine Ti(C, N) additions on microstructure and properties of micron Ti(C, N)-based cermets. Mater. Chem. Phys. 15, 197–206 (2019). https://doi.org/10.1016/j.matchemphys.2019.03.066

D. Xie, K. Shang, Z. Yi et al., Submicron Ti(C, N)-based cermets with improved microstructure using high-energy milled and subsequent heat-treated ultrafine Ti(C, N) powders. Ceram. Int. 49, 4064–4073 (2023). https://doi.org/10.1016/j.ceramint.2022.02.026

B. Zhan, N. Liu, W. Xu et al., Effect of ceramic powder size on microstructure and mechanical properties of Ti(C, N)-based cermets. Adv. Mater. Res. 335, 265–272 (2011). https://doi.org/10.4028/www.scientific.net/AMR.335-336.265

N. Liu, W.H. Yin, L.W. Zhu, Effect of TiC/TiN powder size on microstructure and properties of Ti(C, N)-based cermets. Mat. Sci. Eng. A. 445, 707–716 (2007). https://doi.org/10.1016/j.msea.2006.10.003

Z. Shi, D. Zhang, S. Cheng et al., Effect of nitrogen content on microstructures and mechanical properties of Ti(C, N)-based cermets. J. Alloy. Compd. 568, 68–72 (2013). https://doi.org/10.1016/j.jallcom.2013.03.138

Z. Shi, D. Yin, D. Zhang et al., Characterisation of Ti(C, N)-based cermets with various nitrogen contents studied by EBSD/SEM and TEM. J. Alloy. Compd. 695, 2857–2684 (2017). https://doi.org/10.1016/j.jallcom.2016.11.397

D. Zheng, High-Entropy-Alloy CoFeNiCr Bonded WC-Based Cemented Carbide Prepared by Spark Plasma Sintering. Metall. Mater. Trans. A 53, 2724–2729 (2022). https://doi.org/10.1007/s11661-022-06701-6

J. Song, L. Cao, J. Gao et al., Effects of HfN content and metallic additives on the microstructure and mechanical properties of TiC0.7N0.3-based ceramic tool materials. J. Alloy. Compd. 753, 85–92 (2018). https://doi.org/10.1016/j.jallcom.2018.04.213

A.-S. Namini, Z. Ahmadi, A. Bapaboor et al., Microstructure and thermomechanical characteristics of spark plasma sintered TiC ceramics doped with nano-sized WC. Ceram. Int. 45, 2153–2160 (2019). https://doi.org/10.1016/j.ceramint.2018.10.125

M. Chen, X. Zhang, X. Zhao et al., Effect of secondary carbides on the core-rim structure evolution of TiC-based cermets. Mater Res Express. 8, 76501–76508 (2021). https://doi.org/10.1088/2053-1591/ac0d92

S. Li, Q. Yang, W. Xiong et al., Magnetic and mechanical properties of TiC-xTiN-15MC-yNi (MC = Mo2C, WC) cermets. J. Alloy. Compd. 765, 1119–1126 (2018). https://doi.org/10.1016/j.jallcom.2018.06.257

L. Zhao, N. Lin, X. Han et al., Influence of microstructure evolution on mechanical properties, wear resistance and corrosion resistance of Ti(C, N)-Based cermet tools with various WC additions. Metals Mater. Int. 27, 2773–2781 (2021). https://doi.org/10.1007/s12540-020-00614-y

J. An, J. Song, G. Liang et al., Effects of HfB2 and HfN additions on the microstructures and mechanical properties of TiB2-based ceramic tool materials. Materials. 10, 461–472 (2017). https://doi.org/10.3390/ma10050461

X. Zhang, N. Liu, Microstructure, mechanical properties and thermal shock resistance of nano-TiN modified TiC-based cermets with different binders. Int. J. Refract. Metals Hard Mater. 26, 575–582 (2008). https://doi.org/10.1016/j.ijrmhm.2008.01.008

L. Xu, N. Lin, L. Zhao et al., Effect of Ni contents on mechanical properties and corrosion behavior of Ti(C, N)-WC-Mo2C-(Ni, Co) cermets. Mater. Chem. Phys. (2020). https://doi.org/10.1016/j.matchemphys.2020.123253

M. Chen, X. Zhang, X. Xiao et al., Effect of Co and Ni contents on the sintering behavior, microstructure evolution, and mechanical properties of (Ti, M)C-based cermets. JOM 73, 3403–3410 (2021). https://doi.org/10.1007/s11837-021-04842-4

Y. Li, N. Liu, X. Zhang et al., Effect of Mo addition on the microstructure and mechanical properties of ultra-fine grade TiC-TiN-WC-Mo2C-Co cermets. Int. J. Refract. Metals Hard Mater. 26, 190–196 (2008). https://doi.org/10.1016/j.ijrmhm.2007.05.005

R. Chaim, M. Levin, A. Shlayer et al., Sintering and densification of nanocrystalline ceramic oxide powders: a review. Br. Ceram. Trans. 107, 159–169 (2015). https://doi.org/10.1179/174367508X297812

Y. Fang, X. Zhao, M. Zhang et al., Properties of Ti(C, N)-based cermets reinforced with ZrO2 whiskers deposited via sulfate flux at high temperatures. Vacuum 191, 110336–110347 (2021). https://doi.org/10.1016/j.vacuum.2021.110336

X. Xu, Y. Zheng, H. Liang et al., Influence of sintering parameters on the grain growth and mechanical properties of Ti(C, N)-based cermets prepared via mechanical activation and in-situ carbothermal reduction. Mater. Today Commun. 33, 104667–104674 (2022). https://doi.org/10.1016/j.mtcomm.2022.104667

J. Gao, J. Song, M. Lv et al., Microstructure and mechanical properties of TiC0.7N0.3-HfC cermet tool materials. Ceram. Int. 44, 17895–17904 (2018). https://doi.org/10.1016/j.ceramint.2018.06.262

D. Wang, D. He, K. Li et al., Preparation and in-situ strengthening mechanisms of Mo composites with the addition of WC. Mat Sci Eng A. 848, 143478–143486 (2022). https://doi.org/10.1016/j.msea.2022.143478

Z. Cao, N. Jin, J. Ye et al., A first principles investigation on the solid solution behavior of transition metal elements (W, Mo, Ta, Cr) in Ti(C, N). Int. J. Refract. Metals Hard Mater. 99, 105605–105620 (2021). https://doi.org/10.1016/j.ijrmhm.2021.105605

D. Dong, W. Yang, H. Xiong et al., Ti(C, N)-based cermets with fine grains and uniformly dispersed binders: effect of the Ni-Co based binders. Ceram. Int. 46, 6300–6310 (2020). https://doi.org/10.1016/j.ceramint.2019.11.102

B.-Y. Kotur, Crystal chemistry of ternary intermetallic compounds of scandium with transition metals and carbon, silicon or germanium. J. Alloy. Compd. 219, 88–92 (1995). https://doi.org/10.1016/0925-8388(94)05013-9

H. Zhou, C. Huang, B. Zou et al., Effects of metal phases and carbides on the microstructure and mechanical properties of Ti(C, N)-based cermets cutting tool materials. Mat Sci Eng A. 17, 462–470 (2014). https://doi.org/10.1016/j.msea.2014.09.052

J. Li, H. Qiu, X. Zhang et al., Effects of (Ti, Mo)C particles on the abrasive wear-corrosion of low alloy martensitic steel. Wear 496, 204288–204298 (2022). https://doi.org/10.1016/j.wear.2022.204288

J. Lv, Y. Du, Y. Peng et al., Effect of C content on the surface gradient structure of (Ti, Mo)(C, N) and Ti(C, N)-based cermets. J. Mater. Res. Technol. 16, 544–554 (2022). https://doi.org/10.1016/j.jmrt.2021.12.021

J.-W. Kim, M.-S. Seo, S. Kang, Microstructure and mechanical properties of Ti-based solid-solution cermets. Mat Sci Eng A. 528, 2517–2521 (2011). https://doi.org/10.1016/j.msea.2010.11.076

A. Li, N. Lin, R. Li et al., Effects of hafnium content on microstructures and properties of newly developed (Ti, Hf)(C, N) ceramics. Ceram. Int. 49, 21471–21478 (2023). https://doi.org/10.1016/j.ceramint.2023.03.278

G. Zhao, L. Xin, L. Li et al., Cutting force model and damage formation mechanism in milling of 70 wt% Si/Al composite. Chin. J. Aeronaut. (2023). https://doi.org/10.1016/j.cja.2022.07.018

L. Chen, Y. Wang, Y. Li et al., Microstructural evolution, mechanical and thermal properties of TiC-ZrC-Cr3C2 composites. Int. J. Refract. Metals Hard Mater. 80, 188–194 (2019). https://doi.org/10.1016/j.ijrmhm.2019.01.008

A.-G. Evans, K.-T. Faber, Toughening of ceramics by circumferential microcracking. Am. Ceram. Soc. 64, 394–398 (2010). https://doi.org/10.1111/j.1151-2916.1981.tb09877.x

Z. Zhang, Y. Xu, M. Yi et al., Synthesis and characterization of extremely hard and strong (W, Ti, Ta)C cermet by spark plasma sintering. Int. J. Refract. Metals Hard Mater. 105, 105831–105839 (2022). https://doi.org/10.1016/j.ijrmhm.2022.105831

P. Sarker, T. Harrington, C. Toher et al., High-entropy high-hardness metal carbides discovered by entropy descriptors. Nat. Commun. 9, 4980–4989 (2018). https://doi.org/10.1038/s41467-018-07160-7

D. Bregiroux, J. Cedelle, Spark plasma sintering of nanostructured ZnS ceramics: grain growth control and improved hardness. Mat. Sci. Eng. A. 827, 142064–142068 (2021). https://doi.org/10.1016/j.msea.2021.142064

S. Liu, D. Liu, Effect of hard phase content on the mechanical properties of TiC-316 L stainless steel cermets. Int. J. Refract. Metals Hard Mater. 82, 273–278 (2019). https://doi.org/10.1016/j.ijrmhm.2019.04.020

Acknowledgements

This work was supported by National Natural Science Foundation of China (Grant Nos. 52205492 and 51875388), Fundamental Research Program of Shanxi Province, China (Grant no. 202103021223121).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, J., Song, J., Gao, J. et al. Fabrication, microstructure evolution, and mechanical properties of Ti(C,N)-HfN-WC-Ni-Mo cermets. J. Korean Ceram. Soc. (2024). https://doi.org/10.1007/s43207-024-00376-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43207-024-00376-y