Abstract

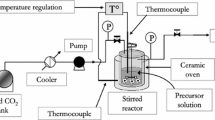

Mesoporous titanium dioxide particles (TiO2) were prepared by reactive precipitation in the supercritical anti-solvent (SAS) technique using carbon dioxide in an ambient saturated with water in the presence of the ionic liquid (IL) 1-methyl-3-octylimidazolium bis[trifluoromethylsulfonyl] imide, [C8mim][NTf2]. All experiments of reactive precipitation with SAS were conducted at 40 °C, with a pressure of 8.0 MPa, a CO2 liquid flow rate of 20 mL min–1, and a solution flow rate of 2 mL min–1. Additionally, the influence of the molar ratio of titanium(IV) isopropoxide/isopropanol and ionic liquid/titanium(IV) isopropoxide was investigated. The particles were characterized by X-ray powder diffraction, thermogravimetric analysis, N2 adsorption-desorption analysis (BET surface area), and field-emission gun scanning electron microscopy. Results indicate the formation of anatase and brookite crystalline phases after calcination at 450 °C for 2 h. Besides, the peaks related to the brookite phase were more intense on samples synthesized using the IL. The synthesized TiO2 particles have suitable structural properties, such as high surface area, controlled porosity, narrow pore size distribution (lower than 6 nm), and high thermal stability. Further, particles with spherical morphology are produced, while those synthesized with the IL present smooth surfaces. The use of the IL decreases the particle size from 1.12 ± 0.78 μm (TiO2 without IL) to particles in the range from 0.32 ± 0.13 to 0.66 ± 0.44 μm. Furthermore, the higher the precursor/alcohol ratio, the larger the particle size, thus demonstrating that the particle size also depends on the precursor/alcohol ratio.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the findings of this study are available within the article. Additionally, raw data are available on request from the corresponding author.

References

Aaymonier C et al (2006) Review of supercritical fluids in inorganic materials science. J Supercrit Fluids 38:242–251. https://doi.org/10.1016/j.supflu.2006.03.019

Adschiri T, Yoko A (2018) Supercritical fluids for nanotechnology. J Supercrit Fluids 134:167–175. https://doi.org/10.1016/j.supflu.2017.12.033

Agartan L et al (2015) Effect of initial water content and calcination temperature on photocatalytic properties of TiO2 nanopowders synthesized by the sol–gel process. Ceram Int 41:12788–12797. https://doi.org/10.1016/j.ceramint.2015.06.114

Ahmad MS, Pandey AK, Rahim NA (2017) Advancements in the development of TiO2 photoanodes and its fabrication methods for dye sensitized solar cell (DSSC) applications. A review. Renew Sustain Energy Rev 77:89–108. https://doi.org/10.1016/j.rser.2017.03.129

Alonso E et al (2007) Synthesis of titanium oxide particles in supercritical CO2: Effect of operational variables in the characteristics of the final product. J Supercrit Fluids 39:453–461. https://doi.org/10.1016/j.supflu.2006.03.006

Bianchi CL et al (2014) Photocatalytic degradation of acetone, acetaldehyde and toluene in gas-phase: comparison between nano and micro-sized TiO2. Appl Catal B-Environ 146:123–130. https://doi.org/10.1016/j.apcatb.2013.02.047

Blanchard LA et al (1999) Green processing using ionic liquids and CO2. Nature 399:28–29. https://doi.org/10.1038/19887

Blanchard LA et al (2001) High-pressure phase behavior of ionic liquid/CO2 systems. J Phys Chem B 105:2437–2444. https://doi.org/10.1021/jp003309d

Bu X, Zhang G, Zhang C (2012) Effect of nitrogen doping on anatase–rutile phase transformation of TiO2. Appl Surf Sci 258:7997–8001. https://doi.org/10.1016/j.apsusc.2012.04.154

Cansell F, Aymonier C (2009) Design of functional nanostructured materials using supercritical fluids. J Supercrit Fluids 47:508–516. https://doi.org/10.1016/j.supflu.2008.10.002

Chen Y, Mu TC (2021) Revisiting greenness of ionic liquids and deep eutectic solvents. Green Chem Eng 2:174–186. https://doi.org/10.1016/j.gce.2021.01.004

Chen PC, Chen CC, Chen SH (2017) A review on production, characterization, and Photocatalytic applications of TiO2 nanoparticles and nanotubes. Curr Nanosci 13:373–393. https://doi.org/10.2174/1573413713666170511163542

Choi H et al (2006) Thermally stable nanocrystalline TiO2 photocatalysts synthesized via sol–gel methods modified with ionic liquid and surfactant molecules. Chem Mater 18:5377–5384. https://doi.org/10.1021/cm0615626

Choi EH, Hong SI, Moon DJ (2008) Preparation of thermally stable mesostructured nano-sized TiO2 particles by modified sol–gel method using ionic liquid. Catal Lett 123:84–89. https://doi.org/10.1007/s10562-008-9398-4

Cui L et al (2012) Facile microwave-assisted hydrothermal synthesis of TiO2 nanotubes. Mater Lett 75:175–178. https://doi.org/10.1016/j.matlet.2012.02.004

Dahl M, Liu Y, Yin Y (2014) Composite Titanium Dioxide Nanomaterials. Chem Rev 114:9853–9889. https://doi.org/10.1021/cr400634p

Dong R et al (2014) TiO2 microspheres with variable morphology, size and density synthesized by a facile emulsion-mediated hydrothermal process. Mater Lett 123:135–137. https://doi.org/10.1016/j.matlet.2014.03.008

Franceschi E et al (2008) Phase behavior and process parameters effects on the characteristics of precipitated theophylline using carbon dioxide as antisolvent. J Supercrit Fluid 44:8–20. https://doi.org/10.1016/j.supflu.2007.09.031

Freire MG et al (2008) Mutual solubilities of water and the [Cnmim][Tf2N] hydrophobic ionic liquids. J Phys Chem B 112:1604–1610. https://doi.org/10.1021/jp7097203

Ghows N, Entezari MH (2010) Ultrasound with low intensity assisted the synthesis of nanocrystalline TiO2 without calcination. Ultrason Sonochem 17:878–883. https://doi.org/10.1016/j.ultsonch.2010.03.010

Gunti S, Kumar A, Ram MK (2018) Nanostructured photocatalysis in the visible spectrum for the decontamination of air and water. Int Mater Rev 63:257–282. https://doi.org/10.1080/09506608.2017.1379264

Hu S et al (2008) Synthesis of mesostructure anatase TiO2 particles in room-temperature ionic liquids. Mater Lett 62:2954–2956. https://doi.org/10.1016/j.matlet.2008.01.082

Huddleston JG et al (1998) Room temperature ionic liquids as novel media for clean liquid–liquid extraction. Chem Commun 16:1765–1766. https://doi.org/10.1039/a803999b

Humayun M et al (2018) Modification strategies of TiO2 for potential applications in photocatalysis: a critical review. Green Chem Lett Rev 11:86–102. https://doi.org/10.1080/17518253.2018.1440324

Katal R et al (2020) A review on the synthesis of the various types of anatase TiO2 facets and their applications for photocatalysis. Chem Eng J 384:123384. https://doi.org/10.1016/j.cej.2019.123384

Keskin et al (2007) A review of ionic liquids towards supercritical fluid applications. J Supercrit Fluids 43:150–180. https://doi.org/10.1016/j.supflu.2007.05.013

Larder RR et al (2021) Porous hollow TiO2 microparticles for photocatalysis: exploiting novel ABC triblock terpolymer templates synthesized in supercritical CO2. Polym Chem 12:2904–2913. https://doi.org/10.1039/D1PY00334H

Leyva-Porras C et al (2015) Low-temperature synthesis and characterization of anatase TiO2 nanoparticles by an acid assisted sol–gel method. J Alloys Compd 647:627–636. https://doi.org/10.1016/j.jallcom.2015.06.041

Liu H et al (2009) Hydrothermal synthesis of mesostructured nanocrystalline TiO2 in an ionic liquid–water mixture and its photocatalytic performance. Solid State Sci 11:1655–1660. https://doi.org/10.1016/j.solidstatesciences.2009.06.011

Mamaghani AH, Haghighat F, Lee CS (2019) Hydrothermal/solvothermal synthesis and treatment of TiO2 for photocatalytic degradation of air pollutants: Preparation, characterization, properties, and performance. Chemosphere 219:804–825. https://doi.org/10.1016/j.chemosphere.2018.12.029

Marin RP et al (2015) Supercritical antisolvent precipitation of TiO2 with tailored anatase/rutile composition for applications in redox catalysis and photocatalysis. Appl Catal A-Gen 504:62–73. https://doi.org/10.1016/j.apcata.2015.02.023

Miao S et al (2006) Synthesis of mesoporous TiO2 films in ionic liquid dissolving cellulose. Micropor Mesopor Mat 95:26–30. https://doi.org/10.1016/j.micromeso.2006.04.013

Paszkiewicz M et al (2016) The ILs-assisted solvothermal synthesis of TiO2 spheres: the effect of ionic liquids on morphology and photoactivity of TiO2. Appl Catal B-Environ 184:223–237. https://doi.org/10.1016/j.apcatb.2015.11.019

Shahi SK et al (2015) Green synthesis of photoactive nanocrystalline anatase TiO2 in recyclable and recoverable acidic ionic liquid [Bmim] HSO4. J Mater Sci 50:2443–2450. https://doi.org/10.1007/s10853-014-8799-6

Shahi SK, Kaur N, Singh V (2016) Fabrication of phase and morphology controlled pure rutile and rutile/anatase TiO2 nanostructures in functional ionic liquid/water. Appl Surf Sci 360:953–960. https://doi.org/10.1016/j.apsusc.2015.11.092

Shayegan Z, Lee CS, Haghighat F (2018) TiO2 photocatalyst for removal of volatile organic compounds in gas phase – A review. Chem Eng J 334:2408–2439. https://doi.org/10.1016/j.cej.2017.09.153

Shen W et al (2015) Preparation of titanium dioxide nanoparticle modified photocatalytic self-cleaning concrete. J Clean Prod 87:762–765. https://doi.org/10.1016/j.jclepro.2014.10.014

Silva EP et al (2014) scCO2-based synthesis of semi-crystalline TiO2 nanoparticles: a rapid and direct strategy. Mater Lett 136:133–137. https://doi.org/10.1016/j.matlet.2014.07.156

Silva EP et al (2019) Effect of phase composition on the photocatalytic activity of titanium dioxide obtained from supercritical antisolvent. J Colloid Interf Sci 535:245–254. https://doi.org/10.1016/j.jcis.2018.09.098

Sing KSW et al (1985) Reporting physisorption data for gas-solid systems. Pure Appl Chem 57:603–619. https://doi.org/10.1351/pac198254112201

Stallings WE, Lamb HH (2003) Synthesis of nanostructured titania powders via hydrolysis of titanium isopropoxide in supercritical carbon dioxide. Langmuir 19:2989–2994. https://doi.org/10.1021/la020760i

Sui R, Rizkalla A, Charpentier PA (2011) Experimental study on the morphology and porosity of TiO2 aerogels synthesized in supercritical carbon dioxide. Micropor Mesopor Mat 142:688–695. https://doi.org/10.1016/j.micromeso.2011.01.016

Tadros ME et al (1996) Synthesis of titanium dioxide particles in supercritical CO2. J Supercrit Fluids 9:172–176. https://doi.org/10.1016/S0896-8446(96)90029-7

Tang ZR et al (2006) Preparation of TiO2 using supercritical CO2 antisolvent precipitation (SAS): a support for high activity gold catalysts. Stud Surf Sci Catal 162:219–226. https://doi.org/10.1016/S0167-2991(06)80910-9

Verma YL, Singh MP, Singh RK (2012) Ionic liquid assisted synthesis of nano-porous TiO2 and studies on confined ionic liquid. Mater Lett 86:73–76. https://doi.org/10.1016/j.matlet.2012.07.025

Wu D et al (2015) Tunable synthesis of single-crystalline-like TiO2 mesocrystals and their application as effective scattering layer in dye-sensitized solar cells. J Colloid Interf Sci 456:125–131. https://doi.org/10.1016/j.jcis.2015.06.023

Yoo KS, Lee TG, Kim J (2005) Preparation and characterization of mesoporous TiO2 particles by modified sol–gel method using ionic liquids. Micropor Mesopor Mat 84:211–217. https://doi.org/10.1016/j.micromeso.2005.05.029

Zhang B et al (2015) Ionic liquid-assisted synthesis of morphology controlled TiO2 particles with efficient photocatalytic activity. RSC Adv 5:81108–81114. https://doi.org/10.1039/C5RA17213F

Zhao H, Xia S, Ma P (2005) Use of ionic liquids as ‘green’solvents for extractions. J Chem Technol Biotechnol: Int Res Process Environ Clean Technol 80(10):1089–1096. https://doi.org/10.1002/jctb.1333

Acknowledgements

The authors thank the National Council of Technological and Scientific Development–CNPq (grants 304419/2015-0, 305438/2018-2, 313453/2018-7), the Coordination for the Improvement of Higher Education Personnel–CAPES (Finance Code 001) and the Sergipe State Research and Technological Innovation Foundation (FAPITEC/SE) from Brazil for financial support and scholarships supply for this work. This research used facilities of the Multiuser Centre for Nanotechnology at UFS (CMNano-UFS).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Prado, L.R., Figueiredo, R.T., Silva, R.S. et al. Reactive precipitation of titanium dioxide particles in supercritical CO2 by SAS technique with an ionic liquid as adjuvant. Braz. J. Chem. Eng. 41, 287–298 (2024). https://doi.org/10.1007/s43153-023-00319-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43153-023-00319-w