Abstract

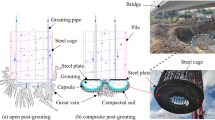

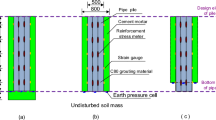

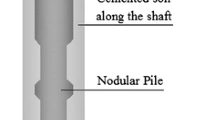

Compacted cement stabilized gravel pile can effectively control secondary disasters of subgrade, while the bearing mechanism of semi-rigid pile composite foundation is not clear. The load–settlement (Q–S) curves, pile mechanical features and pile–soil stress characteristics of the composite foundation were analyzed by field tests and numerical simulation. Moreover, the characteristic value and calculating equation of the bearing capacity were discussed. Results show that the axial force of the group pile in composite foundation increases first and then decreases with the depth, the negative friction resistance is in the upper part, the neutral point is located at one-fifth of the length below the top. The lateral friction of the lower part of the pile plays a role before the upper lateral friction, and more than 90% of the pile load is supported by lateral friction. The curve of pile–soil stress ratio is hump-shaped, the stress ratio of pile to adjacent pile center soil is 6.08–6.65, and the stress ratio of pile to diagonal pile center soil is 7.5–9.45. Q–S curve of the single pile is characterized as a sharp decline, the characteristic value of the bearing capacity can be obtained by the equation of rigid pile, and the reduction coefficient of the pile strength is 0.25. Q–S curve of the composite foundation performs a slow downward tendency, the characteristic value of the bearing capacity can be obtained by the equation of compacted cement–soil piles, it is suggested that the correction coefficient of the vertical compressive bearing capacity is 1.0, and the bearing capacity correction coefficient of soil between piles is 1.05–1.15.

Similar content being viewed by others

Data Availability

All data, models, and code generated or used during the study appear in the submitted article.

References

Choi, C. Y., & Jung, J. H. (2018). Study of the long-term behavior characteristics of roadbed on concrete track of high-speed railway. Journal of the Korea Academia-Industrial cooperation Society, 19(4), 8–16. https://doi.org/10.5762/KAIS.2018.19.4.8

Tan, Q. L., Li, L. J., & Wang, S. L. (2014). Measurement and analysis of high-speed railway subgrade settlement in China: A case study. Sensors & Transducers, 170(5), 184–191.

Cheng, X. S., Liu, G. N., Gong, L. J., Zhou, X. H., & Shi, B. Z. (2020). Mechanical characteristics+differential settlement of CFG pile and cement-soil compacted pile about composite foundation under train load. Geomechanics and Engineering, 20(2), 155.

Cheng, X. S., Zhang, W. L., Zha, W. X., Zhou, Y. C., & Gong, L. J. (2020). Mechanical characteristics of pile-net composite foundations in collapsible loess areas. Jordan Journal of Civil Engineering, 14(3), 443–449.

Gao, C. H., Du, G. Y., Liu, S. Y., Zhang, D. W., Zhang, K., & Zeng, B. (2020). Field study on the treatment of collapsible loess using vibratory probe compaction method. Engineering Geology, 37(4), 591–598. https://doi.org/10.1016/j.enggeo.2020.105715

Shi, B. Z., Cheng, X. S., Gong, L. J., & Liu, G. N. (2020). Selection design and parameter optimization of composite foundations in collapsible loess areas. Geotechnical and Geological Engineering, 38, 3175–3201. https://doi.org/10.1007/s10706-020-01216-6

Xiao, D., Jiang, G. L., Liao, D., Hu, Y. F., & Liu, X. F. (2018). Influence of cement-fly ash-gravel pile-supported approach embankment on abutment piles in soft ground. Journal of Rock Mechanics and Geotechnical Engineering, 10(5), 977–985. https://doi.org/10.1016/j.jrmge.2018.06.001

Xiao, H., Guo, X., & Huang, L. W. (2015). Analysis of the effect of groundwater exploitation on high-speed railway Pile-Slab structure subgrade. The Open Mechanical Engineering Journal, 9, 455–459. https://doi.org/10.2174/1874155X01509010455

Zhang, D. B., Zhang, Y., Kim, C. W., Meng, Y., Garg, A., Garg, A., & Fang, K. (2018). Effectiveness of CFG pile-slab structure on soft soil for supporting high-speed railway embankment. Soils and Foundations, 58(6), 1458–1475. https://doi.org/10.1016/j.sandf.2018.08.007

Zhou, S. H., Wang, B. L., & Shan, Y. (2020). Review of research on high-speed railway subgrade settlement in soft soil area. Railway Engineering Science, 28(2), 129–145. https://doi.org/10.1007/s40534-020-00214-x

Zhao, Y. X., Chen, X. J., Pan, L., & Duan, L. B. (2019). Walking omnidirectional rotary hydraulic pile drilling machine. China, 201922304247.3, 2019-12-20

Wu, Y. (2021). Application of dry mix cement gravel pile in roadbed reinforcement. Journal of Huaibei Vocational and Technical College, 21(3), 107–111. https://doi.org/10.16279/j.cnki.cn34-1214/z.2022.03.023

Zhang, J. B. (2021). Numerical simulation for weak subgrade strengthening cement gravel mixing trenchless pile. Highway, 66(4), 18–22.

Bi, D. (2013). Gravel pile of dry mixed cement trial research in reinforcing subgrade. China Engineering Consulting, 12(1), 58–61. https://doi.org/10.3969/j.issn.1006-9607.2013.12.001

Chen, W., & Li, Y. Z. (2014). Analysis on cement gravel pile application in soft foundation treatment construction of expressway. Transportation Science & Technology, 267(7), 66–69. https://doi.org/10.3963/j.issn.1671-7570.2014.06.021

Wang, S. W., Wang, Z. F., & Liu, H. D. (2009). Testing on dry mixed cement gravel pile in embankment of Xuchang-Luohe Section of Beijing-Zhuhai Expessway. Rock and Soil Mechanics, 30(5), 1421–1424. https://doi.org/10.1016/S1874-8651(10)60073-7

Yu, J. Y. (2015). Application of cement stabilizing sand-gravel pile with tamp filling in treatment technology of roadbed frost damage. Water Resources & Hydropower of Northeast, 367(2), 13–16. https://doi.org/10.3969/j.issn.1002-0624.2015.02.005

Tan, B. S., & Deng, C. (2019). Experimental study on road performance of retailing backwall new filling subgrade reinforced with cement-gravel pile. Journal of Water Resources Water Engineering, 30(2), 225–230. https://doi.org/10.11705/j.issn.1672-643X.2019.02.35 238.

Zhao, E. S. (2021). Experimental study on treatment of secondary diseases of loess foundation with cement graded crushed stone rammed pile. Lanzhou: Lanzhou Jiaotong University. https://doi.org/10.27205/d.cnki.gltec.2021.000648

Liu, S. T., Liu, S. J., Liu, T. L., Dai, J. G., & Cao, W. D. (2020). Design method for gradation of skeleton-density cement stabilized macadam. Journal of Huaqiao University (Natural Science), 41(5), 582–588. https://doi.org/10.11830/ISSN.1000-5013.201912039

Zhao, L. J., Jing, W. Z., Hou, J. R., Feng, Z. X., & Xue, S. Q. (2018). Influence of mixing method on performance of compressive strength for cement stabilized macadam mixture. China Journal of Highway and Transport, 31(1), 151–158. https://doi.org/10.19721/j.cnki.1001-7372.2018.01.018

JGJ 79-2012. (2012). Technical code for ground treatment of buildings. Beijing: China Building Industry Press. in Chinese.

TB 10106. (2010). Technical code for ground treatment of railway engineering. China Railway Publishing House (in Chinese)

Granitzer, A. N., & Tschuchnigg, F. (2021). Practice-oriented validation of embedded beam formulations in geotechnical engineering. Processes, 10(9), 1–27. https://doi.org/10.3390/pr9101739

Kaya, O., Zhang, Y., Ceylan, H., Kim, S., Yang, S., Taylor, P. C., & Gopalakrishnan, K. (2019). Numerical analysis of longitudinal cracking in widened jointed plain concrete pavement systems. International Journal of Pavement Research and Technology, 12(3), 277–287. https://doi.org/10.1007/s42947-019-0034-z

Wang, L. J., Hu, C. B., & Zeng, Y. X. (2017). Numerical analysis of early-age curing behavior of cement concrete pavement. Engineering Mechanics, 34(7), 146–155. https://doi.org/10.6052/j.issn.1000-4750.2016.02.0121

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest regarding the publication of this paper.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gao, F., Cheng, X., Zhao, Y. et al. Bearing Capacity Characteristics of Compacted Cement Stabilized Gravel Pile Composite Foundation. Int. J. Pavement Res. Technol. 17, 170–182 (2024). https://doi.org/10.1007/s42947-022-00226-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42947-022-00226-2