Abstract

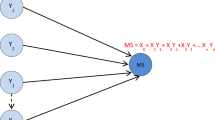

Pavement engineering has always relied on asphalt concrete as the primary material. As a result, increasing the quality of asphalt concrete for greater performance and longer durability has remained a focus of research. The present paper aims to assess the potential of soft computing-based models, such as Artificial neural networks, Support vector machines, Gaussian process, M5P tree, Random forest, and Random tree-based models, used for the prediction of Marshall Stability of carbon–fiber asphalt mix. Five different statistical indices are used to evaluate the performance of each model with different input variables, such as Bitumen content (BC), Carbon fiber (CF), Bitumen grade (VG), Fiber length (FL), and Fiber diameter (FD), Specific gravity coarse aggregate (SG(CA)), Water absorption coarse aggregate (WA(CA)) and Specific Gravity of bitumen (SG(B)), to get the Marshall Stability (MS) as an output. Five statistical indices were used to assess the effectiveness of the applied models i.e., Coefficient of correlation (CC), Mean absolute error (MAE), Root mean square error (RMSE), Relative absolute error (RAE) and Root relative squared error (RRSE). According to performance evaluation results, it has been found that the ANN-based model has outperformed all the applied models for predicting the Marshall Stability of asphalt concrete using carbon fiber with CC value as 0.9287 and 0.9126, R2 value as 0.8624 and 0.8328, MAE value as 1.7527 and 1.8702, RMSE value as 2.3305 and 2.4438, RAE value as 32.51 and 39.64% and RRSE values as 37.30 and 43.59% for both the training and testing stages respectively. Taylor's diagram suggests that the ANN model outperforms the other applied models. Sensitivity analysis shows that the bitumen content (BC) is the more sensitive parameter in the carbon–fiber asphalt mix. Furthermore, carbon fiber is comparable to the sensitivity of the bitumen content which shows the significance of the carbon fiber in the asphalt mix in predicting the Marshall Stability.

Similar content being viewed by others

Data availability

In the submitted manuscript, all data, models, and code developed or utilized during the study paper are included.

References

Liu, X., & Wu, S. (2011). Study on the graphite and carbon fiber modified asphalt concrete. Construction and Building Materials, 25(4), 1807–1811. https://doi.org/10.1016/j.conbuildmat.2010.11.082

Zulkati, A., Diew, W. Y., & Delai, D. S. (2012). Effects of fillers on properties of asphalt-concrete mixture. Journal of transportation engineering, 138(7), 902–910. https://doi.org/10.1061/(ASCE)TE.1943-5436.0000395

Kareem, T. A., Kijewski’t, T., & Tamurat, Y. (1999). Mitigation of motions of tall buildings with specific examples of recent applications. Wind and Structures, 2(3), 201–251.

Wu, S., Ye, Q., Li, N., & Yue, H. (2007). Effects of fibers on the dynamic properties of asphalt mixtures. Journal of Wuhan University of Technology-Materials Science Ed., 22(4), 733–736. https://doi.org/10.1007/s11595-006-4733-3

Ziari, H., Orouei, M., Divandari, H., & Yousefi, A. (2021). Mechanical characterization of warm mix asphalt mixtures made with RAP and Para-fiber additive. Construction and Building Materials, 12(279), 122456.

Yousefi, A., Behnood, A., Nowruzi, A., & Haghshenas, H. (2021). Performance evaluation of asphalt mixtures containing warm mix asphalt (WMA) additives and reclaimed asphalt pavement (RAP). Construction and Building Materials, 25(268), 121200.

Yousefi, A., Pirmohammad, S., & Sobhi, S. (2020). Fracture toughness of warm mix asphalts containing reclaimed asphalt pavement. Journal of Stress Analysis, 5(1), 85–98.

Upadhya, A., Thakur, M. S., Sharma, N., & Sihag, P. (2021). Assessment of soft computing-based techniques for the prediction of marshall stability of asphalt concrete reinforced with glass fiber. International Journal of Pavement Research and Technology. https://doi.org/10.1007/s42947-021-00094-2

Yousefi, A. A., Sobhi, S., Aliha, M. M., Pirmohammad, S., & Haghshenas, H. F. (2021). Cracking properties of warm mix asphalts containing reclaimed asphalt pavement and recycling agents under different loading modes. Construction and Building Materials, 20(300), 124130.

Mawat, H. Q., & Ismael, M. Q. (2020). Assessment of moisture susceptibility for asphalt mixtures modified by carbon fibers. Civil Engineering Journal, 6(2), 304–317. https://doi.org/10.28991/cej-2020-03091472

Shanbara, H. K. (2011). Effect of carbon fiber on the performance of reinforced asphalt concrete mixture. Muthanna Journal of Engineering and Technology (MJET), 1(1), 39–51.

Pirmohammad, S., Amani, B., & Shokorlou, Y. M. (2020). The effect of basalt fibres on fracture toughness of asphalt mixture. Fatigue & Fracture of Engineering Materials & Structures, 43(7), 1446–1460.

Alfalah, A., Offenbacker, D., Ali, A., Decarlo, C., Lein, W., Mehta, Y., & Elshaer, M. (2020). Assessment of the impact of fiber types on the performance of fiber-reinforced hot mix asphalt. Transportation Research Record, 2674(4), 337–347.

Chen, H., & Xu, Q. (2010). Experimental study of fibers in stabilizing and reinforcing asphalt binder. Fuel, 89(7), 1616–1622. https://doi.org/10.1016/j.fuel.2009.08.020

Wang, H., Yang, J., Liao, H., & Chen, X. (2016). Electrical and mechanical properties of asphalt concrete containing conductive fibers and fillers. Construction and Building Materials, 122, 184–190. https://doi.org/10.1016/j.conbuildmat.2016.06.063

Bilondi, M. P., Marandi, S. M., & Ghasemi, F. (2016). Effect of recycled glass powder on asphalt concrete modification. Structural Engineering and Mechanics, 59(02), 373–385. https://doi.org/10.12989/sem.2016.59.2.373

Pirmohammad, S., Shokorlou, Y. M., & Amani, B. (2020). Influence of natural fibers (kenaf and goat wool) on mixed mode I/II fracture strength of asphalt mixtures. Construction and Building Materials, 239, 117850.

Pirmohammad, S., & Mengharpey, M. H. (2020). Influence of natural fibers on fracture strength of WMA (warm mix asphalt) concretes using a new fracture test specimen. Construction and Building Materials, 251, 118927.

Jahromi, S. G., & Khodaii, A. (2008). Carbon fiber reinforced asphalt concrete. Arabian Journal for Science & Engineering, 33, 355–564.

Pirmohammad, S., Shokorlou, Y. M., & Amani, B. (2020). Corrigendum to “Laboratory investigations on fracture resistance of asphalt concretes reinforced with carbon and kenaf fibers at− 15° C” [Eng. Fract. Mech. 226 (2020) 106875]. Engineering Fracture Mechanics, 230, 106977.

Geckil, T., & Ahmedzade, P. (2020). Effects of carbon fibre on performance properties of asphalt mixtures. Baltic Journal of Road & Bridge Engineering (RTU Publishing House). https://doi.org/10.7250/bjrbe.2020-15.472

Yoo, D. Y., Kim, S., Kim, M. J., Kim, D., & Shin, H. O. (2019). Self-healing capability of asphalt concrete with carbon-based materials. Journal of Materials Research and Technology, 8(1), 827–839. https://doi.org/10.1016/j.jmrt.2018.07.001

Khabiri, M. M., & Alidadi, M. (2016). The experimental study of the effect of glass and carbon fiber on physical and micro-structure behavior of asphalt. International Journal of Integrated Engineering, 8(3), 1–8.

Alfalah, A., Offenbacker, D., Ali, A., Mehta, Y., Elshaer, M., & Decarlo, C. (2021). Evaluating the impact of fiber type and dosage rate on laboratory performance of fiber-reinforced asphalt mixtures. Construction and Building Materials, 310, 125217.

Vo, H. V., Park, D. W., Seo, W. J., & Yoo, B. S. (2017). Evaluation of asphalt mixture modified with graphite and carbon fibers for winter adaptation: Thermal conductivity improvement. Journal of Materials in Civil Engineering, 29(1), 04016176. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001675

Moghadas Nejad, F., Vadood, M., & Baeetabar, S. (2014). Investigating the mechanical properties of carbon fibre-reinforced asphalt concrete. Road Materials and Pavement Design, 15(2), 465–475. https://doi.org/10.1080/14680629.2013.876442

Liu, B., Wu, X., Shi, J., Wu, X., Jiang, J., & Qin, J. (2020). Effect of cement as mineral filler on the performance development of emulsified asphalt concrete. Advances in Concrete Construction, 10(6), 515–526. https://doi.org/10.12989/acc.2020.10.6.515

Zhao, S. Q. (2012). Study on short carbon fiber asphalt concrete Marshall. Advanced Materials Research, 529, 446–449.

Salehi, A.W., Baglat, P., Sharma, B.B., Gupta, G., & Upadhya, A. (2020) A CNN model: earlier diagnosis and classification of alzheimer disease using MRI. In 2020 International Conference on Smart Electronics and Communication (ICOSEC) (pp. 156–161). IEEE. https://doi.org/10.1109/ICOSEC49089.2020.9215402.

Upadhya, A., Thakur, M.S., Pandhian, S.M., & Tayal, S. (2021) Estimation of Marshall stability of asphalt concrete mix using neural network and M5P tree. In Computational technologies in materials science (pp. 223–236). CRC Press.

Sharma, N., Thakur, M., Upadhya, A., & Sihag, P. (2021). Evaluating flexural strength of concrete with steel fibre by using machine learning techniques. Composite Materials and Engineering, 3(3), 201–220. https://doi.org/10.12989/cme.2021.3.3.201

Sharma, N., Thakur, M., Upadhya, A., & Sihag, P. (2022). Comparison of machine learning algorithms to evaluate strength of concrete with marble powder. Advances in Materials Research. https://doi.org/10.12989/amr.2022.11.0.000

Upadhyay, S., Upadhya, A., Salehi, W., & Gupta, G. (2021). The medical aspects of EMI effect on patients implanted with pacemakers. Materials Today: Proceedings, 45, 5243–5248. https://doi.org/10.1016/j.matpr.2021.01.826

Sharma, N., Thakur, M. S., Vambol, V., & Vambol, S. (2021) Predicting compressive strength of concrete matrix using engineered cementitious composites: A comparative study between ANN and RF models. In Computational technologies in materials science (pp. 207–221). CRC Press.

Sihag, P., Singh, B., Sepah Vand, A., & Mehdipour, V. (2020). Modelling the infiltration process with soft computing techniques. ISH Journal of Hydraulic Engineering, 26(2), 138–152.

Saif, M. A., El-Bisy, M. S., & Alawi, M.H. (2013). Application of soft computing techniques to predict the stability of asphaltic concrete mixes. In Third international conference on soft computing technology in civil, structural and environmental engineering, Cagliari, Sardinia, Italy.

Simatupang, S.I., Suparma, L.B., & Aminullah, A. (2018). MATLAB graphical user interface (GUI) for prediction of optimum asphalt content that satisfies Marshall parameters of HRS-base hot mixture asphalt by using artificial neural networks.

Majidifard, H., Jahangiri, B., Rath, P., Contreras, L. U., Buttlar, W. G., & Alavi, A. H. (2021). Developing a prediction model for rutting depth of asphalt mixtures using gene expression programming. Construction and Building Materials, 267, 120543. https://doi.org/10.1016/j.conbuildmat.2020.120543

Li, Z., Cheng, C., Kwan, M. P., Tong, X., & Tian, S. (2019). Identifying asphalt pavement distress using UAV LiDAR point cloud data and random forest classification. ISPRS International Journal of Geo-Information, 8(1), 39. https://doi.org/10.3390/ijgi8010039

Morova, N., Sargin, Ş., Terzi, S., Saltan, M., & Serin, S. (2012). Modeling Marshall Stability of light asphalt concretes fabricated using expanded clay aggregate with Artificial Neural Networks. In 2012 International Symposium on Innovations in Intelligent Systems and Applications (pp. 1–4). IEEE. https://doi.org/10.1109/INISTA.2012.6246946.

Reddy, T. C. S. (2018). Predicting the strength properties of slurry infiltrated fibrous concrete using artificial neural network. Frontiers of Structural and Civil Engineering, 12(4), 490–503. https://doi.org/10.1007/s11709-017-0445-3

Mallick, R. B., MadankaraKottayi, N., Veeraragavan, R. K., Dave, E., DeCarlo, C., & Sias, J. E. (2019). Suitable tests and machine learning approach to predict moisture susceptibility of hot-mix asphalt. Journal of Transportation Engineering, Part B: Pavements, 145(3), 04019030.

Yan, C., Zhang, Y., & Bahia, H. U. (2022). Predicting rutting performance of asphalt mixture from binder properties and mixture design variables. Road Materials and Pavement Design, 23(1), 62–79.

Mirzaiyanrajeh, D., Dave, E. V., Sias, J. E., & Ramsey, P. (2022). Developing a prediction model for low-temperature fracture energy of asphalt mixtures using machine learning approach. International Journal of Pavement Engineering. https://doi.org/10.1080/10298436.2021.2024185

ASTM D6913-04, (2017). Standard test methods for particle size distribution of soils. Pennsylvania, PA: American Society for Testing of Materials.

ASTM C-128, (1992). Standard test method for specific gravity and absorption of fine aggregate. West Conshohocken, PA: Annual Book of ASTM Standards.

ASTM C-127, (1992). Test method for specific gravity and adsorption of coarse aggregate. West Conshohocken, PA: Annual Book of ASTM Standards.

ASTM C-131 (2003). Standard test method for resistance to degradation of small-size coarse aggregate. Annual Book of ASTM Standards, West Conshohocken, PA.

ASTM D4791 – 19 (2019). Standard test method for flat particles, elongated particles, or flat and elongated particles in coarse aggregate. Annual Book of ASTM Standards, West Conshohocken, PA.

ASTM D5 / D5M – 20 (2006). Standard test method for penetration of bituminous materials. Annual Book of ASTM Standards, West Conshohocken, PA.

ASTM D70 / D70M – 21 (2003). Standard test method for specific gravity and density of semi-solid asphalt binder (pycnometer method). Annual Book of ASTM Standards, West Conshohocken, PA.

ASTM D36 / D36M – 14 (2020). Standard test method for softening point of bitumen (ring-and-ball apparatus).

ASTM D92 – 18 (2005). Standard test method for flash and fire points by Cleveland Open Cup Tester. Annual Book of ASTM Standards, West Conshohocken, PA.

ASTM D 1559, (1989). Resistance to Plastic Flow of Bituminous Mixtures Using Marshall Apparatus.

Vahidi, E. K., Malekabadi, M. M., Rezaei, A., Roshani, M. M., & Roshani, G. H. (2017). Modelling of mechanical properties of roller compacted concrete containing RHA using ANFIS. Computers and Concrete, 19(4), 435–442. https://doi.org/10.12989/sem.2016.59.2.373

Nguyen, M. D., Pham, B. T., Ho, L. S., Ly, H.-B., Le, T.-T., Qi, C., Le, V. M., Le, L. M., Prakash, I., Son, L. H., & Bui, D. T. (2020). Soft-computing techniques for prediction of soils consolidation coefficient. CATENA, 195, 104802. https://doi.org/10.1016/j.catena.2020.104802

Vadood, M., Johari, M. S., & Rahai, A. (2015). Developing a hybrid artificial neural network-genetic algorithm model to predict resilient modulus of polypropylene/polyester fiber-reinforced asphalt concrete. The Journal of the Textile Institute, 106(11), 1239–1250. https://doi.org/10.1080/00405000.2014.985882

Yang, G., Yu, W., Li, Q. J., Wang, K., Peng, Y., & Zhang, A. (2019). Random Forest–based pavement surface friction prediction using high-resolution 3D image data. Journal of Testing and Evaluation, 49(2), 1141–1152. https://doi.org/10.1520/JTE20180937

Thakur, M. S., Pandhiani, S. M., Kashyap, V., Upadhya, A., & Sihag, P. (2021). Predicting bond strength of FRP bars in concrete using soft computing techniques. Arabian Journal for Science and Engineering, 46(5), 4951–4969. https://doi.org/10.1007/s13369-020-05314-8

Singh, B., Sihag, P., Tomar, A., & Sehgad, A. (2019). Estimation of compressive strength of high-strength concrete by random forest and M5p model tree approaches. Journal of Materials and Engineering Structures, 6, 583–592.

Hoang, N. D., Pham, A. D., Nguyen, Q. L., & Pham, Q. N. (2016). Estimating compressive strength of high performance concrete with Gaussian process regression model. Advances in Civil Engineering. https://doi.org/10.1155/2016/2861380

Zhang, X. Y., Zhao, Y. G., & Lu, Z. H. (2019). Unified Hermite polynomial model and its application in estimating non-Gaussian processes. Journal of Engineering Mechanics, 145(3), 04019001.

Cortes, C., & Vapnik, V. (1995). Support-vector networks. Machine Learning, 20(3), 273–297.

Park, J. Y., Yoon, Y. G., & Oh, T. K. (2019). Prediction of concrete strength with P-, S-, R-wave velocities by support vector machine (SVM) and artificial neural network (ANN). Applied Sciences, 9, 4053.

Quinlan, J. R. (1986). Induction of decision trees. Machine Learning, 1(1), 81–106.

Singh, B., Sihag, P., Tomarand, A., & Sehgal, A. (2019). Estimation of compressive strength of high-strength concrete by random forest and M5P model tree approaches. Journal of Materials and Engineering Structures, 6, 583–592.

Breiman, L. (2001). Random forests. Machine Learning, 45(1), 5–32.

Kalmegh, S. (2015). Analysis of weka data mining algorithm reptree, simple cart and randomtree for classification of Indian news. International Journal of Innovative Science, Engineering & Technology, 2(2), 438–446.

Farooq, F., Amin, N. M., Khan, K., Sadiq, R. M., Javed, F. M., Aslam, F., & Alyousef, R. (2020). A comparative study of random forest and genetic engineering programming for the prediction of compressive strength of high strength concrete (HSC). Applied Sciences, 10, 2–10. https://doi.org/10.3390/app10207330

Cutler, A., & Zhao, G. (2001). Pert-perfect random tree ensembles. Computing Science and Statistics, 33, 490–497.

Zarei, M., Akbarinia, F., Rahmani, Z., Zahedi, M., & Zarei, A. (2020). Economical and technical study on the effect of carbon fiber with high strength on hot mix asphalt (HMA). Electronic Journal of Structural Engineering, 20, 6–12.

Funding

No funding information has been done in this paper.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest by the authors with anyone whosoever is connected with this research.

Appendix

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Upadhya, A., Thakur, M.S. & Sihag, P. Predicting Marshall Stability of Carbon Fiber-Reinforced Asphalt Concrete Using Machine Learning Techniques. Int. J. Pavement Res. Technol. 17, 102–122 (2024). https://doi.org/10.1007/s42947-022-00223-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42947-022-00223-5