Abstract

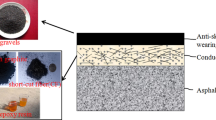

This paper focused on ice processing and snow melting on urban pavement during the winter time in South China under the emergent situation. A kind of electrothermal cushion with carbon fiber was developed to improve resistance to skidding of pavement in winter and help melt ices and snows on the surface of pavement to ensure driving safety. This special cushion is composed of multilayer materials and structures. Laboratory tests for the cushion were conducted to analyze its electrothermal performance, heating uniformity, effect of ice melting, skidding resistance and frictions. At the same time, the durability of the ice melting cushion was evaluated. The results indicate that the developed anti-skidding electrothermal ice melting cushion with carbon fiber is stable in heating ability, high in heating speed, and the surface and bottom temperature of the ice melting mat during operation is not more than 30 ℃ without burning pavements and wheel tires, and the melting rate can reach 78.7% for one hour. The cushion can achieve excellent skid resistance and interlayer friction performance. The cushion can completely meet the requirements such as repeated rolling compaction under vehicle load, abrasion, bursting, etc., and have good durability. Therefore, the cushion is recommended to directly be placed on the pavement surface without interrupting traffics to improve the anti-skidding performance and short-term ice and snow melting in winter. The cushion has lower heating and deicing cost and has a better deicing effect and better economic benefits. Moreover, the cushion only needs to be used in winter, which extends its service life and can be reused without adverse impact on road performance.

Similar content being viewed by others

References

Cheng, G. Z., Mo, X. Y., & Mao, C. Y. (2011). Urban road traffic safety evaluation method under the condition of Ice and snow pavement. Journal of Transportation Systems Engineering and Information Technology, 11(1), 130–134.

Peng, X. D., Meng, X. K., Dang, L. U., et al. (2003). Advances in study on traction behavior of automotive tires on icy and snowy highways. Tribology., 23(5), 451–456.

Quirion-Blais, O., Langevin, A., & Trépanier, M. (2017). A case study of combined winter road snow plowing and de-icer spreading. Canadian Journal of Civil Engineering, 44(12), 1005–1013.

Dan, H. C., Tan, J. W., Du, Y. F., et al. (2020). Simulation and optimization of road deicing salt usage based on Water-Ice-Salt Model. Cold Regions Science and Technology, 169, 102917.

Hu, H. W., Zha, X. D., Cen, Y. Q., et al. (2020). Research status and prospect of solar pavement. Journal of Chang’an University Nature of Science Edition, 40(1), 16–29.

Liu, Z., Yang, X., Wang, Y., et al. (2019). Engineering properties and microwave heating induced ice-melting performance of asphalt mixture with activated carbon powder filler. Construction and Building Materials, 197, 50–62.

Wang, K., Nelsen, D. E., & Nixon, W. A. (2006). Damaging effects of deicing chemicals on concrete materials. Cement and Concrete Composites, 28(2), 173–188.

Wei, J. G., Fu, G. W., & Fu, Q. L. (2014). Influence of chlorine salt snow-melting agent on road performance of asphalt binder. Journal of Traffic and Transportation Engineering, 9(1), 7–13.

Tan, Y. Q., Zhang, C., Xu, H. N., et al. (2019). Snow melting and deicing characteristics and pavement performance of active deicing and snow melting pavement. China Journal of Highway and Transport, 32(4), 1–17.

Zhang, C., Tan, Y. Q., Chen, F. C., et al. (2019). Long-term thermal analysis of an airfield-runway snow-melting system utilizing heat-pipe technology. Energy Conversion and Management, 186, 473–486.

Liu, K., Huang, S., Jin, C., et al. (2017). Prediction models of the thermal field on ice-snow melting pavement with electric heating pipes. Applied Thermal Engineering, 120, 269–276.

Mirzanamadi, R., Hagentoft, C., Johansson, P., & Johnsson, J. (2018). Anti-icing of road surfaces using hydronic heating pavement with low temperature. Cold Regions Science and Technology, 145, 106–118.

Wang, X., Zhu, Y., Zhu, M., et al. (2017). Thermal analysis and optimization of an ice and snow melting system using geothermy by super-long flexible heat pipes. Applied Thermal Engineering, 112, 1353–1363.

Liu, Q., Schlangen, E., Garcia, A., et al. (2010). Induction heating of electrically conductive porous asphalt concrete. Construction and Building Materials, 24(7), 1207–1213.

Wan, J., Wu, S., Xiao, Y., et al. (2019). Enhanced ice and snow melting efficiency of steel slag based ultra-thin friction courses with steel fiber. Journal of Cleaner Production, 236, 117613.

Yang, T., Yang, Z. J., Singla, M., et al. (2012). Experimental study on carbon fiber tape-based deicing technology. Journal of Cold Regions Engineering, 26(2), 55–70.

Zhou, X. M., Yang, Z. J., Chang, C., et al. (2012). Numerical assessment of electric roadway deicing system utilizing emerging carbon nanofiber paper. Journal of Cold Regions Engineering, 26(1), 1–15.

Wang, Z., Gao, J., Ai, T., et al. (2014). Laboratory investigation on microwave deicing function of micro surfacing asphalt mixtures reinforced by carbon fiber. Journal of Testing and Evaluation, 42(2), 498–507.

Zha, X. D., Chen, Y. Q., & Cheng, J. (2012). Experimental research on performances for conductive asphalt mixture with chopped PAN-based carbon fiber. Journal of Functional Materials, 43(7), 872–876.

Yan, Z., Liu, W., Chen, J., et al. (2021). Pavement conductive wearing surface with graphite heating film de-icing potential and performance experimental study. International Journal of Pavement Research and Technology, 14(6), 688–696.

Pan, P., Wu, S., Hu, X., et al. (2017). Effect of freezing-thawing and ageing on thermal characteristics and mechanical properties of conductive asphalt concrete. Construction and Building Materials, 140, 239–247.

Sun, Y., Wu, S., Liu, Q., et al. (2018). Snow and ice melting properties of self-healing asphalt mixtures with induction heating and microwave heating. Applied Thermal Engineering, 129, 871–883.

Liu, J. L., Xu, J. Y., Huang, H., et al. (2020). Microwave deicing efficiency and dielectric property of road concrete modified using different wave absorbing material. Cold Regions Science and Technology, 174, 103064.

Li, H., Zhang, Q., & Xiao, H. (2013). Self-deicing road system with a CNFP high-efficiency thermal source and MWCNT/cement-based high-thermal conductive composites. Cold Regions Science and Technology, 86, 22–35.

Xu, S. L., Yu, W. T., & Song, S. D. (2011). Numerical simulation and experimental study on electrothermal properties of carbon/glass fiber hybrid textile reinforced concrete. Sci. China Technol. Sci., 54(9), 2421–2428.

Zhu, D. J., Tuo, M. A., & Liu, W. H. (2016). Experimental study on electrical heating technology utilizing carbon fiber tape. Science China Technological Sciences, 43(5), 131–136.

Chen, Y. S., & Li, Z. X. (2013). Deicing mechanism for crumb rubber asphalt pavement. Journal of Central South University (Science and Technology), 44(5), 2073–2081.

Zhou, C. X., & Tan, Y. Q. (2009). Study of de-icing performance of crumb rubber granular asphalt mixture. Journal of Build Materials, 12(6), 672–675.

Chen, J., Ma, X., Wang, H., et al. (2018). Experimental study on anti-icing and deicing performance of polyurethane concrete as road surface layer. Construction and Building Materials, 161, 598–605.

Wright, M., Parry, T., & Airey, G. (2016). Chemical pavement modifications to reduce ice adhesion. Proceedings of the Institution of Civil Engineers-Transportation, 169(2), 76–87.

Yao, Y. S., Chen, T. J., Xiang, H., et al. (2013). Experiment of active deicing and snow melting pavement coating with environmental friendly and long-term action. Journal of Traffic Transport Engineering, 13(4), 8–15.

JTG D50–2017. (2017). Specifications for Design of Highway Asphalt Pavement. Beijing: Renmin Communication Press of China.

Acknowledgments

This work has been funded by the National Natural Science Foundation of China (Grant No. 51878077), Postgraduate Scientific Research Innovation Project of Hunan Province (Grant No. CX20190645).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zha, X., Hu, H., Zhang, C. et al. Development and Laboratory Simulation Tests of Anti-skidding Ice Melting Cushion with Carbon Fibers for Pavement. Int. J. Pavement Res. Technol. 15, 1251–1261 (2022). https://doi.org/10.1007/s42947-021-00086-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42947-021-00086-2