Abstract

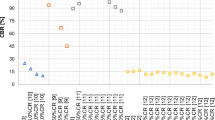

In a continuous effort to promote the environmental sustainability of the road construction sector while increasing the durability of road pavements, a growing number of studies have focused on recycled materials to be used as polymer modification for asphalt. Australia is also following the ‘sustainability’ trend by reusing end-of-life tyres (EOLTs) in the form of crumb rubber (CR) for road applications. Blending conditions are influential in determining the final properties of waste rubber-modified bitumen and are explored in this study to promote the recycling of EOLTs further. Two shear mixing rates (700 rpm and 3500 rpm) and three mixing durations (30, 60 and 90 min) were selected at 7.5% (low concentration), 15% (medium concentration), and 22.5% (high concentration) of CR. Blends were prepared by mixing CR in C320 bitumen while keeping the temperature constant at 177 ± 10 °C. Physio-chemical, thermal, and rheological tests were conducted to characterize the optimal blending conditions. Although the current CR bitumen specifications are predominantly based on viscosity and bitumen–rubber interaction time, the present study highlights the impact of blending conditions on blends to be adopted for different purposes (i.e., 7.5% low-content CR for local roads with less traffic vs. 22.5% CR for medium–high-trafficked roads). It has been observed that mixing duration and applied shear rate significantly influence the rheological properties and are closely correlated. A mixing duration of 60 min is effective to swell rubber particles, although further increasing the mixing time breaks the polymeric chains and deteriorates the rheological properties. Increasing the shear mixer speed to 3500 rpm reduces the total time required to fully swell the CR particles by approx. 30 min. The shear rate can produce a relatively stiffer blend at higher mixing speeds, which was observed through the increase in the complex shear modulus and fatigue parameter values; this was further assessed through Fourier Transform InfraRed analysis and aging indices.

Similar content being viewed by others

References

“Asphalt is the pavement of choice in Australia | Asphalt magazine.”. Retrieved April 04, 2020 from http://asphaltmagazine.com/asphalt-is-the-pavement-of-choice-in-australia/.

Australian Infrastructure Statistics-Yearbook 2018, Canberra, 2018.

Airey, G., & Brown, S. (1998). Rheological performance of aged polymer modified bitumens. Journal of the Association of Asphalt Paving Technologists, 67, 66–87

Zhang, Q., Chen, Y., & Li, X. (2009). Rutting in asphalt pavement under heavy load and high temperature. In GeoHunan international conference: Challenges and recent advances in pavement technologies and transportation geotechnics (pp. 39–48).

White, G. & Reid, G. (2018). Recycled waste plastic for extending and modifying asphalt binders. In 8th symposium on pavement surface characteristics: SURF 2018-Vehicle to Road Connectivity (pp. 1–13).

White, G. & Reid, G. (2019). Recycled waste plastic modification of bituminous binder. In: 7th international conference on bituminous mixtures and pavements (pp. 3–12).

White, G., Embleton, K., & Hogan, F. (2015). Next generation binder for airport asphalt. In 16th AAPA international flexible pavements conference (pp. 1–17).

Giustozzi, F., Crispino, M., Toraldo, E., & Mariani, E. (2019). Mix design of polymer-modified and fiber-reinforced warm-mix asphalts with high amount of reclaimed asphalt pavement: Achieving sustainable and high-performing pavements. Transportation Research Record, 2523(1), 3–10

González, V., Martínez-Boza, F. J., Navarro, F. J., Gallegos, C., Pérez-Lepe, A., & Páez, A. (2010). Thermomechanical properties of bitumen modified with crumb tire rubber and polymeric additives. Fuel Processing Technology, 91(9), 1033–1039

Petersen, D., Lu, X., & Isacsson, U. (1997). Characterization of styrene-butadiene-styrene polymer modified bitumens—Comparison of conventional methods and dynamic mechanical analyses. Journal of Testing and Evaluation, 25(4), 383

Joohari, I. B., & Giustozzi, F. (2020). Chemical and high-temperature rheological properties of recycled plastics-polymer modified hybrid bitumen. Journal of Cleaner Production, 276, 1–17

Nizamuddin, S., Jamal, M., Gravina, R., & Giustozzi, F. (2020). Recycled plastic as bitumen modifier: The role of recycled linear low- density polyethylene in the modification of physical, chemical and rheological properties of bitumen. Journal of Cleaner Production, 266, 121988

Al-Adham, K., & Wahhab, H.A.-A. (2018). Influence of temperature on Jnr values of polymer modified asphalt binders. International Journal of Pavement Research and Technology, 11(6), 603–610

González, V., Martínez-Boza, F. J., Gallegos, C., Pérez-Lepe, A., & Páez, A. (2012). A study into the processing of bitumen modified with tire crumb rubber and polymeric additives. Fuel Processing Technology, 95, 137–143

Bressi, S., Santos, J., Orešković, M., & Losa, M. (2019). A comparative environmental impact analysis of asphalt mixtures containing crumb rubber and reclaimed asphalt pavement using life cycle assessment. International Journal of Pavement Engineering, 22, 524–538

Singh, D., & Girimath, S. (2018). Toward utilization of ground tire rubber and reclaimed pavement materials with asphalt Binder: Performance evaluation using essential work of fracture. International Journal of Pavement Research and Technology, 11(6), 594–602

Genever, M. (2017). National market development strategy for used tyres 2017–2022 final strategy. No. June.

Pickin, J. & Donovan, S. (2020). Exports of Australian waste-derived products and wastes in January 2020.

TSA. (2019). TSA annual report 2018/2019.

Lo Presti, D. (2013). Recycled tyre rubber modified bitumens for road asphalt mixtures: A literature review. Construction and Building Materials, 49, 863–881

Wang, H., Liu, X., Apostolidis, P., Erkens, S., & Scarpas, T. (2019). Numerical investigation of rubber swelling in bitumen. Construction and Building Materials, 214(April), 506–515

Stroup-gardiner, M., Newcomb, D., & Tanquist, B. Asphalt-rubber interactions. In Transportation research record 1417 (pp. 99–108).

Polacco, G., Filippi, S., Merusi, F., & Stastna, G. (2015). A review of the fundamentals of polymer-modified asphalts: Asphalt/polymer interactions and principles of compatibility. Advances in Colloid and Interface Science, 224, 72–112

Navarro, F. J., Partal, P., Martínez-Boza, F. J., & Gallegos, C. (2007). Influence of processing conditions on the rheological behavior of crumb tire rubber-modified bitumen. Journal of Applied Polymer Science, 104(3), 1683–1691

Navarro, F. J., Partal, P., Martínez-Boza, F., & Gallegos, C. (2005). Influence of crumb rubber concentration on the rheological behavior of a crumb rubber modified bitumen. Energy and Fuels, 19(5), 1984–1990

Navarro, F. J., Partal, P., Martínez-Boza, F., Valencia, C., & Gallegos, C. (2002). Rheological characteristics of ground tire rubber-modified bitumens. Chemical Engineering Journal, 89(1–3), 53–61

Jamrah, A., Kutay, M. E., & Varma, S. (2015). Backcalculation of swollen crumb rubber modulus in asphalt rubber binder and its relation to performance. Transportation Research Record, 2505, 99–107

Aflaki, S., & Memarzadeh, M. (2011). Using two-way ANOVA and hypothesis test in evaluating crumb rubber modification (CRM) agitation effects on rheological properties of bitumen. Construction and Building Materials, 25(4), 2094–2106

Billiter, T. C., Chun, J. S., Davison, R. R., Glover, C. J., & Bullin, J. A. (1997). Investigation of the curing variables of asphalt-rubber binder. Petroleum Science and Technology, 15(5), 445–469

Li, H., Zao, H., & Liao, K. (2009). Study on the technological conditions of crumb tire rubber-modified bitumens. Petroleum Science and Technology, 27(14), 1521–1533

Kök, B. V., Yilmaz, M., Akpolat, M., & Sav, C. (2018). Effects of preparation conditions on the properties of crumb rubber modified binder. International Journal of Civil and Environmental Engineering, 12(3), 295–300

Tayh, S. A., & Yousif, R. A. (2018). Effect of blending speed and blade level on the properties of reclaimed rubber modified bitumen. ARPN Journal of Engineering and Applied Sciences, 13(21), 8386–8392

Celauroa, B., Celauroa, C., LoPresti, D., & Bevilacqua, A. (2012). Definition of a laboratory optimization protocol for road bitumen improved with recycled tire rubber. Construction and Building Materials, 37(11), 562–572

Mashaan, N. S., Ali, A. H., Karim, M. R., & Abdelaziz, M. (2011). Effect of blending time and crumb rubber content on properties of crumb rubber modified asphalt binder. International Journal of Physical Science, 6(9), 2189–2193

Picado-Santos, L. G., Capitão, S. D., & Neves, J. M. C. (2020). Crumb rubber asphalt mixtures: A literature review. Construction and Building Materials, 247, 118577

Lo Presti, D., Airey, G., & Partal, P. (2012). Manufacturing terminal and field bitumen-tyre rubber blends: The importance of processing conditions. Procedia Social and Behavioral Sciences, 53, 485–494

Thives, L. P., Pais, J. C., Pereira, P. A. A., Trichês, G., & Amorim, S. R. (2013). Assessment of the digestion time of asphalt rubber binder based on microscopy analysis. Construction and Building Materials, 47, 431–440

VicRoads. (2019). Section 422: Light Traffic Crumb Rubber Asphalt. In Standard specification sections for roadworks and bridgeworks (pp. 1–4).

Depaolini, A. R., et al. (2017). Physical and chemical characterization of representative samples of recycled rubber from end-of-life tires. Chemosphere, 184, 1320–1326

Chen, C., & Lee, M.-T. (2019). Application of crumb rubber in cement-matrix composite. Materials (Basel), 12(3), 529

Ghavibazoo, A., & Abdelrahman, M. (2013). Composition analysis of crumb rubber during interaction with asphalt and effect on properties of binder. International Journal of Pavement Engineering, 14(5), 517–530

Dong, R., & Zhao, M. (2018). Research on the pyrolysis process of crumb tire rubber in waste cooking oil. Renewable Energy, 125, 557–567

Yu, G. X., Li, Z. M., Zhou, X. L., & Li, C. L. (2011). Crumb rubber-modified asphalt: Microwave treatment effects. Petroleum Science and Technology, 29(4), 411–417

Artamendi, I., et al. (2006). Diffusion kinetics of bitumen into waste tyre rubber. Asphalt Paving Technology, 75(April), 133–164

Gawel, I., Stepkowski, R., & Czechowski, F. (2006). Molecular interactions between rubber and asphalt. Industrial and Engineering Chemistry Research, 45(9), 3044–3049

Wang, H., Liu, X., Apostolidis, P., & Erkens, S. (2020). Experimental investigation of rubber swelling in bitumen. Transportation Research Record: Journal of the Transportation Research Board, 2674(2), 203–212

Wang, H., Liu, X., Zhang, H., Apostolidis, P., Scarpas, T., & Erkens, S. (2018). Asphalt-rubber interaction and performance evaluation of rubberised asphalt binders containing non-foaming warm-mix additives. Road Materials and Pavement Design. https://doi.org/10.1080/14680629.2018.1561380

Jamal, M., & Giustozzi, F. (2020). Low-content crumb rubber modified bitumen for improving Australian local roads condition. Journal of Cleaner Production, 271, 1–13

Lo Presti, D., Memon, N. A., Airey, G. D. (2012). Influence of processing conditions on rheology of tyre rubber modified bitumens. In Asphalt rubber (pp. 1–16).

Kim, H. H., Mazumder, M., Lee, M.-S., & Lee, S.-J. (2018). Effect of blending time on viscosity of rubberized binders with wax additives. International Journal of Pavement Research and Technology, 11(6), 655–665

Al-Haddad, A. H. A. (2015). Construction of a complex shear modulus master curve for Iraqi asphalt binder using a modified sigmoidal fitting. International Journal of Science and Technology Research, 04(February), 682–690

Yusoff, N. I. M., Jakarni, F. M., Nguyen, V. H., Rosli, M. H., & Airey, G. D. (2013). Modelling the rheological properties of bituminous binders using mathematical equations. Construction and Building Materials, 40, 174–188

Yusoff, N. I. M., Airey, G. D., & Rosli, M. H. (2010). Predictability of complex modulus using rheological models. Asian Journal of Science Research, 3(1), 18–30

Wang, H., Liu, X., Apostolidis, P., & Scarpas, T. (2018). Non-Newtonian behaviors of crumb rubber-modified bituminous binders. Applied Science, 8(10), 1760

ADOT. (2008). Standard specifications.

AAPA. (2018). CRM-OGAGGA-Model_Specification-v1–12-June-2018.pdf.

Zhang, F., & Hu, C. (2015). The research for crumb rubber/waste plastic compound modified asphalt. Journal of Thermal Analysis and Calorimetry, 124, 729–741

Subhy, A., Pires, G. M., Lo Presti, D., & Airey, G. D. (2018). The effects of laboratory ageing on rheological and fracture characteristics of different rubberised bitumens. Construction and Building Materials, 180(August), 188–198

Ge, D., Chen, S., & You, Z. (2019). Correlation of DSR results and FTIR’s carbonyl and sulfoxide indexes: Effect of aging temperature on asphalt rheology. Journal of Materials in Civil Engineering, 31(7), 1–10

Dony, A., et al. (2016). MURE National Project: FTIR spectroscopy study to assess ageing of asphalt mixtures. In 6th Eurasphalt & Eurobitume Congress (pp. 1–11), no. June.

Porot, B. H. L., Cannone, A. F., Huber, L. P. L. (2018). FTIR spectral analysis of bituminous binders: Reproducibility and impact of ageing temperature.

Wang, H., Liu, X., Apostolidis, P., van de Ven, M., Erkens, S., & Skarpas, A. (2020). Effect of laboratory aging on chemistry and rheology of crumb rubber modified bitumen. Materials and Structures. https://doi.org/10.1617/s11527-020-1451-9

Airey, G. D. (2002). Use of black diagrams to identify inconsistencies in rheological data use of black diagrams to identify inconsistencies in rheological data. Road Materials and Pavement Design., 3(4), 403–424

Nivitha, M. R., Krishnan, J. M., & Rajagopal, K. R. (2018). Viscoelastic transitions exhibited by modified and unmodified bitumen. International Journal of Pavement Engineering, 21, 766–780

Petersen, J. C., et al. (1994). Binder characterization and evaluation. Volume 1. No SHRP-A-367.

Constantino, G. (2014). A program for the fitting of Debye, Cole-Cole, Cole-Davidson, and Havriliak-Negami dispersions to dielectric data. Journal of Colloid and Interface Science, 419, 102–106

Khamzin, A. A., Nigmatullin, R. R., & Popov, I. I. (2013). Log-periodic corrections to the Cole–Cole expression in dielectric relaxation. Physica A: Statistical Mechanics and its Applications, 392(1), 136–148

Mezger, T. G. (2014). The rheology handbook. (4th ed.). Vincentz Network GmbH Co. KG.

Perez, J., Cavaille, J. Y., Etienne, S., & Jourdan, C. (1988). Physical interpretation of the rheological behaviour of amorphous polymers through the glass transition. Revue de Physique Appliquée, 23(2), 125–135

Nati-Ali, K. L., et al. (2015). Chain branching detection by Cole-Cole modeling of rheological properties changes during PET mechanical recycling. Polymer Testing, 31, 500–504

Rolere, S., Cartault, M., Sainte-Beuve, J., & Bonfils, F. (2017). A rheological method exploiting Cole-Cole plot allows gel quantification in natural rubber. Polymer Testing, 61, 378–385

Bergeret, N., & Alberola, A. (1994). Physical modeling of the interphase in amorphous thermoplastic/glass bead composites. Polymer Composites, 15(6), 442–452

Funding

The authors would like to acknowledge the support given by Tyre Stewardship Australia under the scholarship “Crumb rubber asphalt binder characterization and specifications for road pavement applications”.

Author information

Authors and Affiliations

Contributions

MJ and FG: Conceptualization; MJ and FG: Methodology; MJ: Investigation and testing; MJ and FG: Data analysis; MJ: Writing—original draft; MJ, FG: Writing—review and editing, FG: Project administration, funding and supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare not to have any conflict of interest.

Rights and permissions

About this article

Cite this article

Jamal, M., Giustozzi, F. Chemo-rheological Investigation on Waste Rubber-Modified Bitumen Response to Various Blending Factors. Int. J. Pavement Res. Technol. 15, 395–414 (2022). https://doi.org/10.1007/s42947-021-00045-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42947-021-00045-x